Picture this: Your production line grinds to a halt because the Punched Plate Screens you ordered arrived with inconsistent apertures, wrong material specifications, or worse—they failed quality inspection entirely. You're now facing costly delays, frustrated stakeholders, and the daunting task of finding a reliable supplier who won't let you down again. If you've experienced this nightmare scenario, you're not alone. Finding a trustworthy OEM supplier for Punched Plate Screens demands more than a quick online search—it requires a comprehensive evaluation strategy that protects your investment and ensures operational continuity.

Understanding Punched Plate Screens and Their Critical Applications

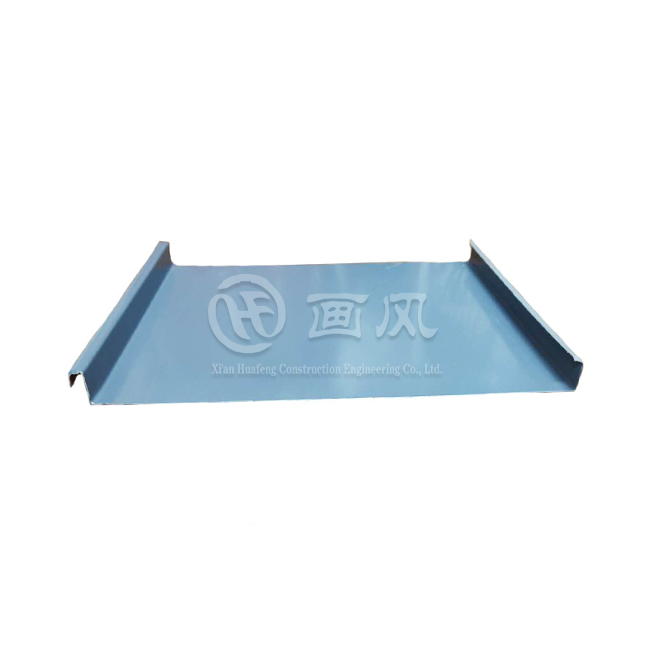

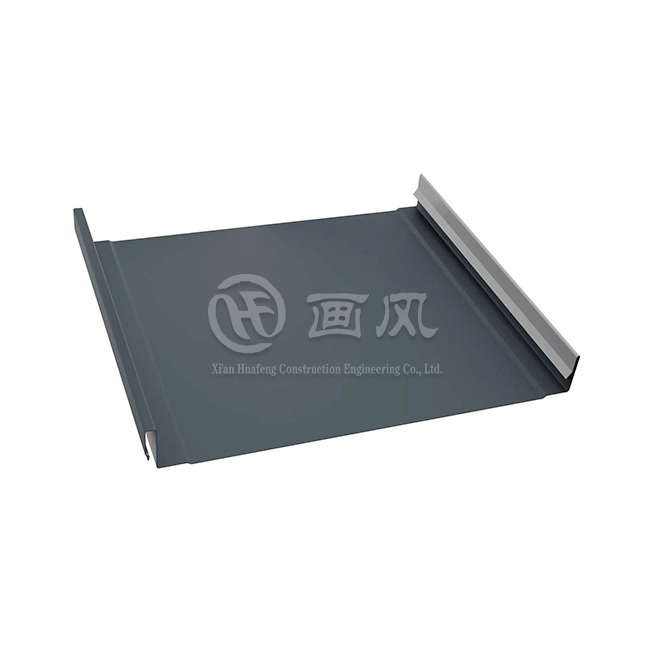

Punched Plate Screens represent a specialized category of perforated metal products that serve essential functions across multiple industries. These precision-engineered components consist of metal sheets—typically manufactured from galvalume plate, aluminum alloy, or stainless steel—that have been mechanically stamped or punched to create specific patterns of holes, slots, or geometric shapes. The strategic arrangement of these apertures determines the screen's performance characteristics, including filtration efficiency, material separation capabilities, and structural integrity under operational stress. The versatility of Punched Plate Screens makes them indispensable in industrial environments where robust material handling solutions are required. In mining operations, these screens withstand the abrasive impact of crushed rock and ore, providing reliable primary screening that protects downstream equipment. Construction projects utilize them for aggregate separation, ensuring consistent material grading that meets specification requirements. Agricultural applications benefit from their ability to sort and classify various products while resisting the corrosive effects of fertilizers and organic materials. Manufacturing facilities employ them in filtration systems, ventilation applications, and as protective barriers that balance security with visibility. The architectural sector has increasingly adopted Punched Plate Screens for both functional and aesthetic purposes, integrating them into building facades, decorative panels, and acoustic treatments that enhance modern design while providing practical performance benefits.

Essential Supplier Evaluation Criteria for OEM Punched Plate Screens

When sourcing OEM Punched Plate Screens, your supplier selection process should prioritize manufacturing capabilities that directly impact product quality and delivery reliability. The most critical factor is production facility infrastructure—suppliers operating advanced manufacturing plants with multiple production lines demonstrate the capacity to handle large-scale orders while maintaining consistent quality standards. Xi'an Huafeng Construction Engineering Co., Ltd., for instance, operates a raw material production plant covering 200,000 square meters in Anhui, supported by two specialized plate and accessories processing facilities in Hangzhou and Xi'an. This distributed manufacturing network enables responsive service across different regions while providing redundancy that protects against production disruptions. Material selection capabilities separate professional manufacturers from basic fabricators. High-quality China Punched Plate Screens suppliers maintain established relationships with premium material brands, ensuring raw material consistency that translates to predictable product performance. Look for suppliers who provide transparent material traceability, offering documentation from recognized steel producers like BAOSTEEL for steel products, Alucosuper and YATAI for aluminum applications, and Baosteel or Tsingshan for stainless steel requirements. The ability to work with diverse materials—including cold rolled sheet, galvanized sheet, galvalume sheet, color coated sheet, and specialized alloys—indicates technical versatility that accommodates evolving project specifications. Production equipment sophistication directly correlates with manufacturing precision and efficiency. Comprehensive China Punched Plate Screens manufacturers should operate multiple production technologies, including color coating lines, laminating systems, longitudinal and transverse shearing equipment, and fully automatic punching production lines. The presence of numerous specialized machines—such as shearing machines, presses, and bending machines—enables complex customization without outsourcing critical processes. This integrated approach reduces lead times, maintains quality control throughout fabrication, and provides cost advantages through operational efficiency.

Quality Assurance and Certification Requirements

Quality verification systems form the foundation of reliable OEM Punched Plate Screens procurement. Reputable China Punched Plate Screens factories implement multi-stage inspection protocols that begin with incoming material verification and extend through finished product validation. The most rigorous suppliers conduct comprehensive incoming material inspections that include appearance assessment, dimensional verification, salt spray testing, adhesion evaluation, hardness measurement, impact resistance testing, film thickness analysis, acid resistance validation, weather resistance examination, and color difference assessment. This thorough approach ensures that only materials meeting specifications enter the production process, eliminating the costly discovery of defects during final assembly or installation. International certification compliance provides objective evidence of manufacturing excellence and process maturity. When evaluating potential suppliers, prioritize those holding ISO9001 certification for quality management systems, demonstrating structured approaches to process control, continuous improvement, and customer satisfaction. Environmental responsibility, verified through ISO14001:14001 certification, indicates commitment to sustainable manufacturing practices that reduce environmental impact while maintaining operational efficiency. SGS verification offers third-party validation of product specifications and manufacturing capabilities, providing additional assurance for critical applications. CE certification demonstrates compliance with European safety, health, and environmental protection standards, essential for projects serving international markets or requiring adherence to global regulatory frameworks.

Patent portfolios and proprietary technologies distinguish innovative China Punched Plate Screens manufacturers from commodity suppliers. Companies investing in research and development typically secure multiple patent protections covering unique production processes, specialized product designs, or innovative application methodologies. These intellectual property assets indicate technical leadership and ongoing commitment to product advancement. Suppliers with 20 or more registered patents demonstrate sustained innovation that translates to competitive advantages in performance, durability, or installation efficiency. Additionally, computer software certificates for design and engineering tools suggest digital capabilities that streamline project collaboration and accelerate customization processes.

Customization Capabilities and Technical Support Services

The ability to deliver fully customized Punched Plate Screens separates strategic manufacturing partners from basic suppliers. Comprehensive customization begins with design consultation services that analyze project requirements and recommend optimal specifications. Professional China Punched Plate Screens suppliers employ engineering teams capable of conducting structural 3D modeling, load analysis, and drainage system simulation, ensuring that proposed solutions integrate seamlessly with broader project objectives. Material specification advisory services help clients navigate the trade-offs between different alloy options, surface treatments, and thickness selections, optimizing performance characteristics for specific operational environments. Project drawing deepening represents a critical service that transforms conceptual designs into manufacturable specifications. This process involves analyzing architectural engineering drawings, identifying feasible alternatives, and developing detailed fabrication drawings that capture every dimensional requirement and assembly detail. Experienced suppliers conduct 1:1 scale drawing development for critical nodes and connection points, eliminating ambiguity that could result in fabrication errors or installation complications. The collaborative refinement process, involving multiple communication cycles and formal drawing confirmations, ensures alignment between customer expectations and manufacturing execution before production begins.

Factory processing samples provide tangible validation of final product specifications before committing to full-scale production. High-quality Punched Plate Screens manufacturers produce physical samples based on confirmed parameters including board type, material grade, thickness specifications, surface treatment methods, and color selections. The sample approval process allows customers to verify dimensional accuracy, assess material properties, evaluate color matching, and confirm overall acceptability. Once approved, the sealed sample becomes the reference standard for production processing, quality assurance inspection, and final acceptance procedures. This disciplined approach minimizes the risk of specification drift during manufacturing and provides clear success criteria for delivery acceptance.

Logistics, Pricing Structure, and Payment Flexibility

Transparent pricing structures and flexible payment options facilitate smooth procurement processes for Punched Plate Screens for sale. Reputable suppliers provide detailed quotations that itemize material costs, fabrication expenses, surface treatment charges, and packaging fees, enabling accurate budget development and cost comparison. The availability of multiple payment methods—including T/T (Telegraphic Transfer), LC (Letter of Credit), and Western Union—accommodates different organizational preferences and international transaction requirements. Letter of Credit options provide particular value for large orders or new supplier relationships, offering financial protection through banking intermediation that ensures payment upon delivery of conforming products. Shipping flexibility from any port in China demonstrates logistical sophistication that optimizes transportation costs and delivery timelines. Suppliers with this capability can route shipments through the most efficient ports based on destination location, current shipping capacity, and seasonal rate fluctuations. This adaptability becomes particularly valuable for projects with tight delivery schedules or those located in regions better served by specific maritime routes. Standard export packaging protects products during international transportation, while the option for customized packaging at the buyer's requirement accommodates special handling needs, climate-specific protection, or integration with automated unloading systems.

Delivery coordination and installation support services add significant value beyond product supply. Professional Punched Plate Screens manufacturers provide on-site construction guidance or direct installation services that ensure proper implementation of their products. Pre-installation site visits allow technicians to assess working conditions, verify tool availability, and confirm that auxiliary materials—including rivets, structural adhesive, screws, and accessories—are complete and compatible. Technical briefing meetings review installation procedures, safety protocols, and quality checkpoints, reducing the risk of installation errors that could compromise performance or safety. Post-installation testing, particularly for roofing applications where zero leakage is critical, provides verification that products perform as specified under actual operating conditions.

Conclusion

Selecting the right OEM supplier for Punched Plate Screens requires systematic evaluation of manufacturing capabilities, quality systems, customization services, and commercial terms that collectively ensure project success and long-term value.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Punched Plate Screens factory, China Punched Plate Screens supplier, and China Punched Plate Screens manufacturer offering comprehensive China Punched Plate Screens wholesale solutions. Our extensive engineering experience spans design, production, and construction of premium Punched Plate Screens for sale, supported by 7 color coating production lines, 1 laminating line, 10 longitudinal and transverse shearing production lines, and over 40 specialized processing machines. With more than 20 patent certificates, CE certification, ISO certification, and SGS certification, we deliver High Quality Punched Plate Screens with competitive Punched Plate Screens price structures. Our collaboration with Fortune 500 companies validates our capabilities in customized production and one-stop procurement from raw materials to accessories. From design optimization and raw material quality testing to customized products with multiple packaging and transportation options, we provide complete solutions backed by multiple quality certifications. Contact us today at huafeng@hfmetalroof.com to discuss your Punched Plate Screens requirements and discover how our integrated manufacturing capabilities can support your project objectives.

References

1. "Perforated Metal Manufacturing: Standards and Specifications" - American Society for Testing and Materials (ASTM) Committee E05

2. "Industrial Screening Technology: Design and Application Guidelines" - Mining Equipment Manufacturers Association

3. "Quality Management in Metal Fabrication" - International Organization for Standardization Technical Committee

4. "Architectural Metal Systems: Performance and Specification" - Construction Specifications Institute

5. "Materials Selection for Industrial Applications" - American Institute of Steel Construction Engineering Standards Division