Coastal property owners face a critical challenge that keeps them up at night: will their roof withstand relentless salt spray, hurricane-force winds, and intense UV exposure? The answer lies in choosing the right roofing system. Yes, Snap Clad Standing Seam Roof Panel can effectively handle coastal environments when properly specified with aluminum materials, stainless steel clips, and premium PVDF coatings designed specifically for marine applications. This advanced roofing solution combines concealed fastener technology with corrosion-resistant materials to provide decades of reliable performance even in the harshest oceanfront conditions.

Understanding Coastal Roofing Challenges and Snap Clad Standing Seam Solutions

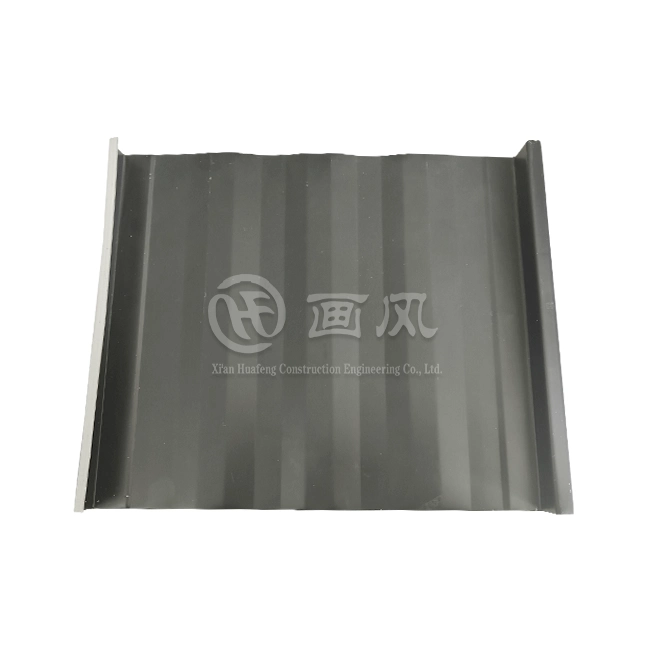

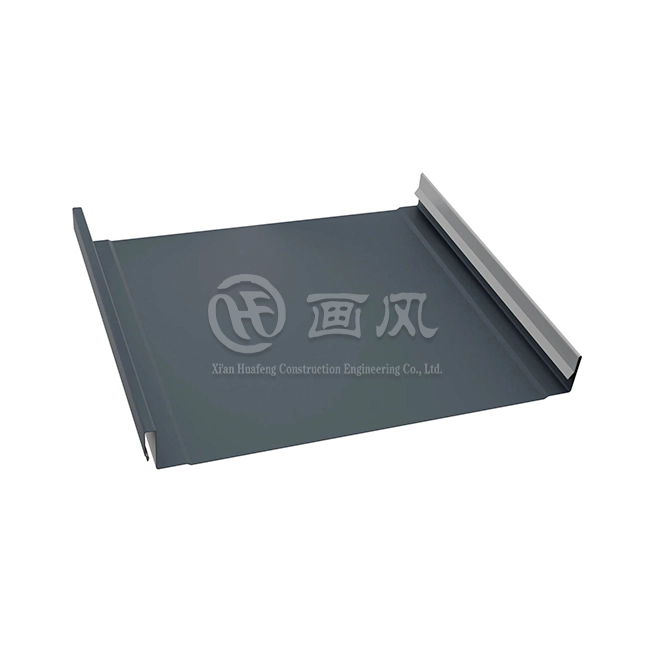

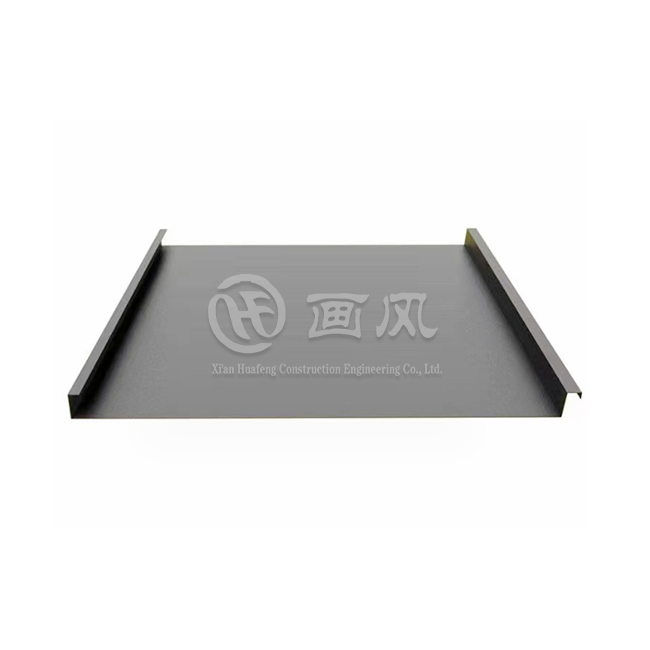

Coastal environments present unique and severe challenges for building materials. Salt-laden air carried by ocean breezes deposits corrosive particles on roofing surfaces, initiating microscopic damage that accelerates over time. High humidity levels create persistent moisture exposure, while intense UV radiation degrades protective coatings. Hurricane-prone regions add the threat of extreme wind uplift forces that can tear inadequately secured roofs from their mountings. These combined environmental stressors demand roofing systems specifically engineered for marine applications. Snap Clad Standing Seam Roof Panel addresses these challenges through intelligent design features that set it apart from conventional roofing systems. The concealed fastener system eliminates exposed screws vulnerable to salt spray corrosion, while the snap-together interlock design creates a continuous weather barrier without penetrations. The standing seam profile with heights ranging from 45mm to 50mm provides structural rigidity and exceptional wind resistance. Most critically, the system accommodates thermal expansion through floating clip technology, preventing stress-induced failures common in rigid attachment methods.

Material Selection for Marine Environments

The foundation of coastal performance begins with proper material selection. For Snap Clad Standing Seam Roof Panel installations near saltwater, aluminum alloy represents the optimal choice due to its natural corrosion resistance. Unlike steel substrates that develop iron oxide rust when exposed to salt spray, aluminum forms a self-healing oxide layer that protects the underlying metal. Industry standards recommend aluminum panels paired with 300-series stainless steel clips for all installations within 3,000 feet of breaking surf. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Snap Clad Standing Seam Roof Panel using premium aluminum alloys including 3003, 3004, and 5052 grades sourced from certified suppliers like Alucosuper, YATAI, and LIDAO. These alloys provide the ideal balance of formability, strength, and marine-grade corrosion resistance. Panel thickness options from 0.5mm to 1.2mm allow engineers to specify appropriate gauges based on span requirements and wind load calculations. The material selection extends beyond panels to include all system components, ensuring galvanic compatibility that prevents electrochemical corrosion at connection points.

Advanced Coating Systems for Salt Spray Protection

Premium coatings serve as the first line of defense against coastal corrosion. PVDF (Polyvinylidene Fluoride) coating systems feature carbon-fluorine molecular bonds that provide exceptional resistance to salt spray, UV degradation, and color fade. Two-coat PVDF applications deliver superior protection compared to single-coat polyester finishes, with topcoats that resist chalking even under continuous salt exposure. These high-performance finishes maintain their appearance and protective properties for decades in marine environments. Xi'an Huafeng applies both PVDF and PE (Polyester) finishes through advanced coil coating processes at their seven production lines. The PVDF option delivers 30-year warranty protection with proven field performance in coastal installations worldwide. Chrome-based pretreatments and high-build primers enhance adhesion while providing additional corrosion barriers beneath the topcoat. The company offers standard RAL colors plus custom color matching to meet specific architectural requirements, with coating application on both sides of panels for comprehensive protection including cut edges and concealed surfaces.

Installation Best Practices for Coastal Snap Clad Standing Seam Applications

Proper installation techniques prove just as critical as material selection for coastal longevity. The concealed clip system requires precise placement and fastening to achieve both weather-tightness and thermal movement accommodation. Stainless steel clips must be installed at maximum 18-inch centers on roof applications, with closer spacing in high-wind zones. Each clip attaches to the roof deck or purlins using corrosion-resistant fasteners, then the Snap Clad Standing Seam Roof Panel male leg snaps into the clip while the female leg receives the next panel's male edge. Seam engagement requires careful attention to ensure proper interlock without over-stressing the connection. The snap-lock design provides tactile and audible confirmation of correct assembly, eliminating guesswork during installation. Factory-applied sealant beads within the seam provide secondary moisture protection, though the primary weather barrier comes from proper panel overlap and clip positioning. All penetrations for vents, equipment, and accessories require specialized flashing details with continuous sealant application and stainless steel components.

Critical Details for Marine Exposure

Coastal installations demand heightened attention to edge conditions and transitions. Eave details should incorporate factory-notched panels that eliminate field cutting and exposed raw edges vulnerable to corrosion initiation. Ridge caps, hip conditions, and valley assemblies require custom fabrication using matching aluminum materials with welded or soldered joints rather than mechanical seams. Trim pieces including fascia, rake edges, and copings should receive the same premium coating treatment as field panels. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation support through their technical team. Site surveys conducted prior to fabrication identify specific exposure conditions, prevailing wind directions, and potential saltwater concentration levels. The company's design department creates detailed shop drawings showing every transition condition with appropriate material specifications. On-site installation guidance ensures proper clip placement, seam engagement, and flashing integration. Post-installation water testing verifies system integrity before project acceptance, providing documented proof of watertight performance.

Wind Resistance and Structural Performance

Coastal regions face extreme wind events that subject roofing systems to enormous uplift forces. Hurricane winds create negative pressure zones that attempt to peel roofs from buildings, with pressures exceeding 150 pounds per square foot in severe storms. Snap Clad Standing Seam Roof Panel provides superior wind resistance through its continuous interlock system and engineered clip connections. The 1.75-inch to 2-inch seam height creates structural rigidity that distributes loads across the entire roof plane rather than concentrating stress at individual fastener points. Independent testing validates the wind performance of properly installed standing seam systems. UL 90-rated assemblies demonstrate resistance to hurricane-force winds when specified with appropriate clip spacing and high-performance attachment hardware. The floating clip design allows panels to expand and contract with temperature changes while maintaining secure attachment during wind events. This movement accommodation prevents fatigue failures that compromise fixed-attachment systems over time. For critical applications in extreme wind zones, engineers can specify enhanced clip configurations with reduced spacing to achieve even higher uplift resistance ratings.

Long-Term Performance and Maintenance in Salt Environments

Coastal Snap Clad Standing Seam Roof Panel installations require minimal but strategic maintenance to maximize service life. The concealed fastener design eliminates the most common failure point in coastal roofing—corroded exposed screws that create leak paths and red rust staining. However, salt accumulation on panel surfaces can accelerate coating degradation if allowed to persist. Quarterly rinsing with fresh water removes salt deposits before they concentrate to damaging levels, a simple procedure that significantly extends coating life. Annual professional inspections identify early signs of potential issues including sealant degradation at penetrations, clip movement, or coating damage from debris impact. Prompt repairs of any scratches or coating breaches prevent corrosion initiation at vulnerable points. Touch-up paint pens in matching colors allow immediate field repair of minor damage. Every five to seven years, roof cleaning and optional clear sealant application refreshes the protective coating system, maintaining both appearance and corrosion resistance.

Warranty Considerations for Marine Applications

Manufacturers typically modify standard warranties for coastal installations due to increased environmental severity. Aluminum Snap Clad Standing Seam Roof Panel systems generally maintain full warranty coverage in marine locations when installed according to specified requirements including stainless steel clips and proper material grades. Steel substrate systems, by contrast, often carry warranty exclusions for installations within specified distances of breaking surf—commonly one-quarter mile—due to accelerated corrosion risk. Xi'an Huafeng Construction Engineering Co., Ltd. provides 30-year service life warranties on properly specified coastal installations of their Snap Clad Standing Seam Roof Panel systems. This warranty commitment reflects confidence in the marine-grade materials and engineering that underpin their coastal product specifications. The company maintains detailed project documentation including material certifications, coating test reports, and installation records that support warranty claims. Their ISO9001 and ISO14001 certifications ensure consistent quality control throughout the manufacturing process, from raw material selection through final product packaging.

Cost-Benefit Analysis of Snap Clad Standing Seam in Coastal Markets

Initial investment in premium coastal roofing systems exceeds the cost of standard installations, with aluminum Snap Clad Standing Seam Roof Panel typically commanding prices two to three times higher than basic steel panel systems. However, lifecycle cost analysis reveals substantial long-term savings through extended service life, reduced maintenance requirements, and avoided premature replacement expenses. A properly specified coastal standing seam roof can provide 40 to 60 years of service, compared to 15 to 25 years for less corrosion-resistant alternatives. The avoidance of corrosion-related failures delivers significant value beyond material longevity. Coastal property owners avoid the disruption and interior damage associated with roof leaks, which often cause far greater expense than the roofing system itself. Insurance carriers increasingly recognize superior wind resistance and durability of standing seam systems through reduced premiums for hurricane-prone coastal properties. Energy efficiency benefits from reflective coatings reduce cooling costs in hot coastal climates, providing ongoing operational savings throughout the roof's service life.

Return on Investment Factors

Several factors influence the financial return from investing in quality Snap Clad Standing Seam Roof Panel systems for coastal applications. Property type and use determine the cost of roofing failures—commercial facilities with expensive inventory or sensitive equipment face higher risk exposure than residential applications. Roof complexity affects both initial installation costs and ongoing maintenance requirements, with simple gable roofs delivering better cost-effectiveness than complex designs with multiple penetrations and transitions. Local labor rates and material availability impact project economics significantly. Xi'an Huafeng Construction Engineering Co., Ltd. optimizes project costs through their integrated manufacturing and installation approach. Their three factories with seven production lines and over 40 machines provide economies of scale that reduce material costs. Direct shipping from manufacturing facilities to project sites eliminates distributor markups. Technical support from design through installation reduces costly field modifications and ensures first-time quality. With minimum order quantities of only 500 square meters or one ton and delivery timeframes of 15 to 20 days, the company provides responsive service that keeps projects on schedule and budget.

Conclusion

Snap Clad Standing Seam Roof Panel systems excel in coastal environments when properly engineered with aluminum materials, stainless steel components, and premium PVDF coatings that resist salt spray corrosion, withstand hurricane-force winds, and maintain appearance for decades in harsh marine conditions.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 in Shaanxi Province, China, stands as a high-tech enterprise specializing in metal roofing systems, building curtain walls, and steel structure enclosure solutions. Recognized as a Shaanxi Province high-tech enterprise in 2020, the company holds first-level qualifications for building curtain walls and third-level qualifications for building steel structures, demonstrating technical competence validated by government authorities. The company operates three advanced manufacturing facilities: a 200,000-square-meter raw material production plant in Anhui, plus plate and accessories processing plants in Hangzhou and Xi'an. This manufacturing infrastructure includes seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, fully automatic punching systems, and more than 40 specialized machines including shearing equipment, presses, and bending machines. This production capacity enables monthly output exceeding 1,000 tons while maintaining strict quality control standards certified under ISO9001 and ISO14000:14001 guidelines.

Product offerings include standing seam metal roofing panels, aluminum-magnesium-manganese plates, titanium-zinc plates, corrugated sheets, flat lock panels, and comprehensive roofing accessories. The company sources premium materials from certified suppliers including Alucosuper, YATAI, and LIDAO for aluminum; BAOSTEEL, GUANZHOU, and XINYU for steel; and Baosteel and Tsingshan for stainless steel. This material traceability ensures consistent quality and performance characteristics essential for demanding coastal applications. Xi'an Huafeng delivers comprehensive one-stop solutions from initial design through final installation. The engineering team provides structural 3D modeling, load analysis, drainage system simulation, and material specification advisory services. Design departments deepen architectural drawings to construction-ready shop drawings with detailed node specifications. Factory sample production allows customers to verify materials, colors, and finishes before full production commitment. Quality assurance includes incoming material inspection, in-process monitoring, finished product verification, and systematic packaging organized by installation sequence to simplify field work.

Successful project implementations demonstrate the company's capabilities across diverse applications. Notable installations include the Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, Jinghe New City International Culture and Art Center, multiple educational and cultural facilities, and critical infrastructure projects. These reference projects span commercial, institutional, transportation, and cultural building types, showcasing versatility and technical execution across varying scales and complexity levels. The company maintains over 20 registered patents for roofing systems along with numerous trademarks and software certifications, reflecting ongoing innovation and intellectual property development. This commitment to technical advancement aligns with the company's green sustainable development philosophy and mission to integrate architecture, technology, and aesthetics. The focus on new material development and application addresses contemporary challenges including renewable energy integration, building envelope performance optimization, and lifecycle environmental impact reduction.

As a trusted China Snap Clad Standing Seam Roof Panel factory, China Snap Clad Standing Seam Roof Panel supplier, and China Snap Clad Standing Seam Roof Panel manufacturer, Xi'an Huafeng offers competitive China Snap Clad Standing Seam Roof Panel wholesale pricing with High Quality Snap Clad Standing Seam Roof Panel products featuring premium specifications. The company's Snap Clad Standing Seam Roof Panel for sale includes customized thickness, height, material, and color options with transparent Snap Clad Standing Seam Roof Panel price structures that reflect engineering requirements and project scale. Contact huafeng@hfmetalroof.com today to discuss your coastal roofing project requirements and receive expert technical guidance from our experienced engineering team.

References

1. "Metal Roofing for Coastal Applications: Material Selection and Performance Criteria" - American Society of Civil Engineers, Structural Engineering Institute

2. "Corrosion Protection of Metal Building Components in Marine Environments" - ASTM International Committee on Materials for Construction

3 ."Wind Resistance Design for Metal Roofing Systems in Hurricane-Prone Regions" - Metal Construction Association Technical Standards Committee

4. "Long-Term Performance of PVDF Coatings in Salt Spray Environments" - Journal of Protective Coatings and Linings Research Foundation

5. "Standing Seam Metal Roof Systems: Installation Standards for Coastal Zones" - National Roofing Contractors Association Technical Operations Division

(1)_1763110678300.webp)