Industrial building owners face mounting challenges today. Energy costs spiral upward, structural deterioration accelerates from harsh environmental conditions, and downtime for repairs drains profitability. Inside Lock Metal Wall Panels solve these critical pain points by delivering superior weatherproofing, thermal performance, and maintenance-free durability. This innovative concealed fastening system creates seamless facades that protect assets while dramatically reducing lifecycle costs. Through advanced engineering, these panels transform industrial structures into efficient, resilient facilities that maintain optimal operations regardless of external conditions.

Why Inside Lock Metal Wall Panels Dominate Manufacturing Facilities?

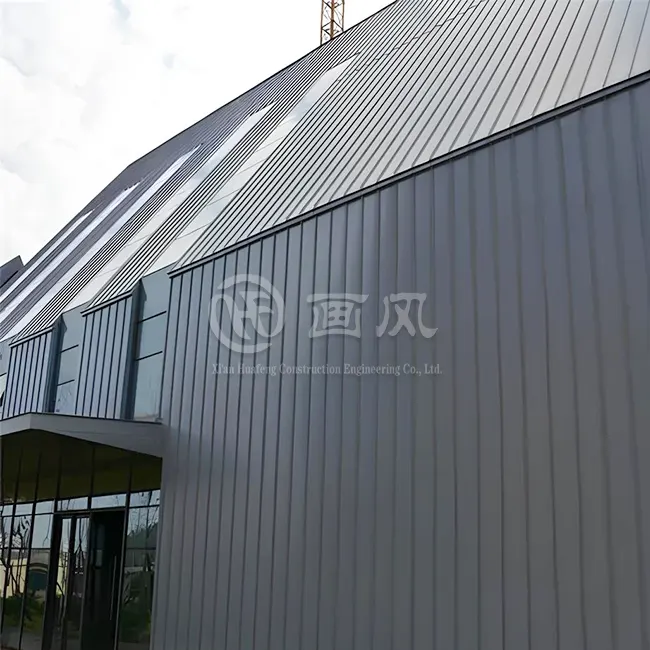

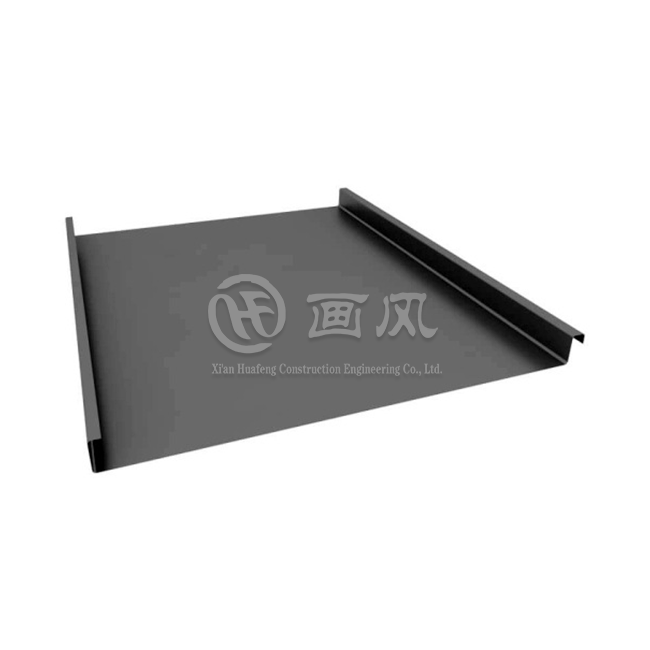

Manufacturing environments demand building solutions that withstand extreme conditions while maintaining operational efficiency. Inside Lock Metal Wall Panels excel in these demanding applications through their unique combination of structural integrity and functional advantages. The concealed fastening mechanism creates an impenetrable barrier against moisture infiltration, preventing the costly damage that plagues traditional wall systems. When manufacturing equipment operates continuously, temperature fluctuations and vibrations stress conventional building envelopes. These specialized panels absorb structural movements without compromising their weather-resistant seal, ensuring production environments remain controlled and protected. The manufacturing sector particularly values the rapid installation characteristics of Inside Lock Metal Wall Panels. Traditional construction methods disrupt production schedules, but the interlocking design allows contractors to complete wall installations sixty percent faster than conventional systems. This speed translates directly to reduced downtime and earlier facility commissioning. Additionally, the panels' resistance to chemical exposure proves invaluable in processing facilities where airborne contaminants and cleaning agents attack standard building materials. Industrial operations in automotive, pharmaceutical, and food processing sectors have documented significant reductions in maintenance expenditures after transitioning to these advanced panel systems.

-

Thermal Efficiency Benefits in Production Environments

Energy consumption represents a substantial operating expense for industrial facilities, with climate control systems accounting for forty percent of total utility costs in many manufacturing operations. Inside Lock Metal Wall Panels incorporate advanced insulation properties that create thermal barriers far superior to traditional construction. The panel's unique lock system eliminates thermal bridging, a phenomenon where heat transfers through gaps in conventional wall assemblies. This continuous insulation approach maintains consistent interior temperatures regardless of external weather conditions, allowing HVAC systems to operate at optimal efficiency levels. Manufacturing facilities utilizing Inside Lock Metal Wall Panels report energy savings ranging from twenty-five to thirty-five percent compared to previous building envelopes. These reductions stem from the panels' ability to reflect radiant heat during summer months while retaining warmth during winter operations. The aluminum-magnesium-manganese composition offers exceptional thermal performance characteristics, with R-values customizable from 2.5 to 6.0 depending on project requirements. When combined with PVDF coating systems, the panels maintain their reflective properties for decades, ensuring long-term energy efficiency that positively impacts both profitability and environmental sustainability goals.

-

Structural Performance Under Industrial Loads

Industrial buildings face unique structural demands that standard wall systems struggle to accommodate. Heavy machinery operations generate continuous vibrations, while material handling equipment creates dynamic loading conditions throughout facilities. Inside Lock Metal Wall Panels provide the structural rigidity necessary to maintain building envelope integrity under these challenging circumstances. The interlocking mechanism distributes loads across multiple panel connections, creating a unified wall system that resists deflection and maintains alignment even when adjacent panels experience localized stress. Wind resistance capabilities prove particularly critical for industrial facilities located in exposed areas or coastal regions. These panels achieve superior wind uplift ratings through their mechanical interlocking design, which prevents panel separation during extreme weather events. Testing demonstrates that properly installed Inside Lock Metal Wall Panels withstand wind speeds exceeding 150 miles per hour, protecting valuable equipment and inventory when conventional systems fail. The panels' lightweight aluminum construction, ranging from 0.6 to 1.5 millimeters thickness, reduces structural loading on building frameworks while delivering exceptional strength-to-weight ratios that enable larger span capabilities between support members.

Warehousing and Distribution Center Applications

Modern logistics operations require building envelopes that protect inventory while minimizing operational disruptions from environmental conditions. Inside Lock Metal Wall Panels fulfill these requirements through their weatherproof construction and low-maintenance characteristics. Distribution facilities handling temperature-sensitive goods particularly benefit from the panels' superior insulation properties, which maintain stable interior climates essential for product preservation. The concealed fastening system creates continuous weather barriers that prevent air infiltration, moisture penetration, and pest entry—three critical concerns for warehouse operations storing food products, pharmaceuticals, or electronics. The rapid construction timelines achievable with Inside Lock Metal Wall Panels align perfectly with the logistics industry's need for quick facility deployment. E-commerce growth drives demand for warehouse space, and construction delays translate directly to lost revenue opportunities. These panel systems enable contractors to complete building envelope installations in fifty percent less time than traditional methods, accelerating project schedules and reducing financing costs. Furthermore, the panels' ability to accommodate building expansions without visible seams allows warehouse operators to scale facilities incrementally as business demands grow, avoiding the disruption and expense of complete facility relocations.

-

Durability Requirements for 24/7 Operations

Distribution centers operate continuously, making building maintenance particularly challenging and costly. Inside Lock Metal Wall Panels address this concern through their exceptional durability and minimal maintenance requirements. The panels' factory-applied PVDF coating systems resist fading, chalking, and corrosion for thirty years, maintaining aesthetic appearance while protecting substrate materials from environmental degradation. This longevity proves especially valuable for facilities operating in harsh climates where salt exposure, industrial pollutants, or extreme temperature fluctuations accelerate deterioration of conventional building materials. Warehouse operations frequently involve forklift traffic near walls, loading dock activities, and material handling that risks accidental impact damage. Inside Lock Metal Wall Panels demonstrate superior impact resistance compared to alternative systems, with the interlocking design preventing local damage from propagating across adjacent panels. When damage does occur, the modular nature of the system allows maintenance teams to replace individual panels without disrupting operations or removing large wall sections. This repairability minimizes downtime and maintenance expenses throughout the facility's operational lifetime, contributing significantly to favorable lifecycle cost analyses.

-

Fire Safety Considerations in Storage Facilities

Fire protection ranks among the highest priorities for warehouse and distribution operations, where stored inventory values often reach millions of dollars. Inside Lock Metal Wall Panels contribute to comprehensive fire safety strategies through their Class A non-combustible material classification. The aluminum alloy and galvanized steel substrate options will not ignite or contribute fuel to active fires, helping contain incidents and protecting adjacent spaces. This fire-resistant performance proves particularly valuable in facilities storing flammable materials or those located in areas with high wildfire risk. Building codes increasingly mandate enhanced fire separation requirements between occupancy types and property boundaries. Inside Lock Metal Wall Panels meet these stringent requirements without requiring additional fireproofing treatments that increase construction costs and complexity. The panels maintain their structural integrity during fire exposure, preventing premature collapse that could trap personnel or emergency responders. Insurance underwriters recognize these fire safety advantages, with many warehouse operators reporting reduced insurance premiums after implementing Inside Lock Metal Wall Panel systems compared to facilities utilizing conventional construction methods.

Cold Storage and Temperature-Controlled Facilities

Maintaining precise temperature control represents the fundamental requirement for cold storage operations serving food distribution, pharmaceutical storage, and industrial process cooling applications. Inside Lock Metal Wall Panels excel in these demanding environments through their superior thermal performance and moisture management capabilities. The panels' continuous insulation approach eliminates thermal bridging that causes condensation formation and ice buildup in conventional cold storage construction. By maintaining consistent surface temperatures across the entire wall assembly, these panels prevent the moisture-related problems that compromise both structural integrity and hygiene standards in temperature-controlled facilities. Cold storage operators face substantial energy expenses, with refrigeration systems consuming sixty to seventy percent of total facility power in many operations. Inside Lock Metal Wall Panels deliver measurable reductions in these costs through their high R-value insulation options and airtight construction. The interlocking panel design creates vapor barriers that prevent warm, humid air from infiltrating cooled spaces, reducing the refrigeration load and preventing frost accumulation on evaporator coils. Facilities implementing these advanced panel systems document energy consumption reductions of thirty to forty percent compared to previous building envelopes, generating rapid return on investment through utility savings alone.

-

Hygiene and Sanitation Standards Compliance

Food safety regulations and pharmaceutical manufacturing standards impose rigorous requirements for cleanable surfaces and contamination prevention. Inside Lock Metal Wall Panels meet these strict criteria through their smooth, non-porous surface finishes that resist bacterial growth and facilitate thorough cleaning. The concealed fastening system eliminates exposed hardware where contaminants could accumulate, creating seamless wall surfaces that comply with USDA, FDA, and international food safety protocols. Regular cleaning with standard sanitizing agents maintains hygienic conditions without degrading the panels' protective coatings or compromising their structural performance. The panels' corrosion resistance proves essential in cold storage environments where frequent washdowns, chemical sanitizers, and condensation exposure attack conventional building materials. PVDF coating systems applied to Inside Lock Metal Wall Panels withstand aggressive cleaning regimens for decades without requiring recoating or replacement. This durability maintains facility compliance with food safety standards while avoiding the operational disruptions and expenses associated with building envelope repairs. Additionally, the panels' resistance to mold and mildew growth eliminates a common contamination source in temperature-controlled facilities, supporting operators' quality assurance programs and protecting brand reputation.

-

Rapid Temperature Recovery Performance

Cold storage facilities experience significant temperature fluctuations during loading operations when doors open frequently for product movement. These temperature excursions stress refrigeration systems and risk product quality degradation if recovery times extend beyond acceptable limits. Inside Lock Metal Wall Panels contribute to rapid temperature recovery through their thermal mass characteristics and air barrier performance. The panels maintain cool temperatures in wall assemblies, reducing the heat load that refrigeration systems must address after door closure. Combined with the panels' superior air-sealing properties, this thermal storage effect enables facilities to restore target temperatures thirty percent faster than operations utilizing conventional insulated wall construction. The economic impact of improved temperature recovery extends beyond direct energy savings. Faster temperature stabilization reduces refrigerated product exposure to suboptimal conditions, decreasing spoilage rates and extending inventory shelf life. For facilities handling high-value products like pharmaceuticals or specialty foods, these quality preservation benefits often exceed the energy cost savings. Inside Lock Metal Wall Panels also enhance operational flexibility by allowing more frequent door openings without compromising temperature control, improving throughput and reducing loading dock congestion during peak activity periods. These operational advantages demonstrate how advanced building envelope systems directly contribute to cold storage facility profitability and competitive positioning.

Conclusion

Inside Lock Metal Wall Panels deliver transformative benefits for industrial buildings through superior weather protection, energy efficiency, and structural durability. Manufacturing facilities, warehouses, and cold storage operations achieve measurable performance improvements and cost reductions when implementing these advanced panel systems. The concealed fastening design creates seamless building envelopes that withstand harsh industrial conditions while minimizing lifecycle maintenance requirements, making these panels the optimal choice for demanding applications.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

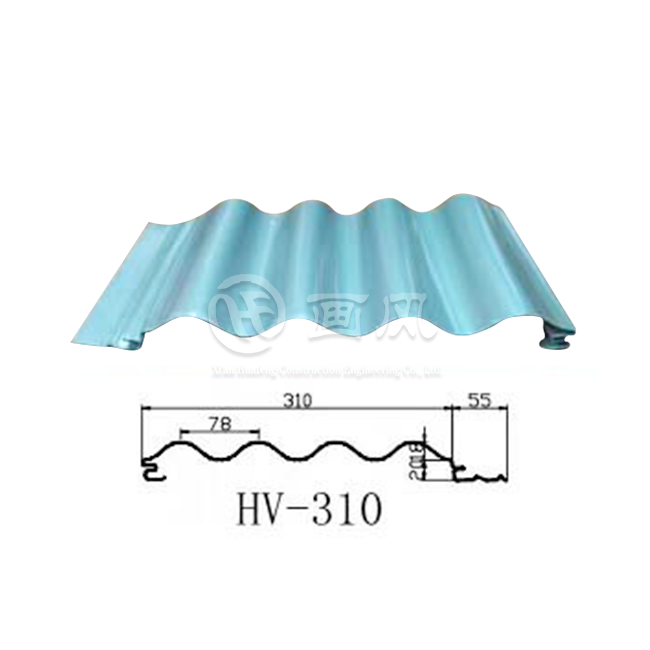

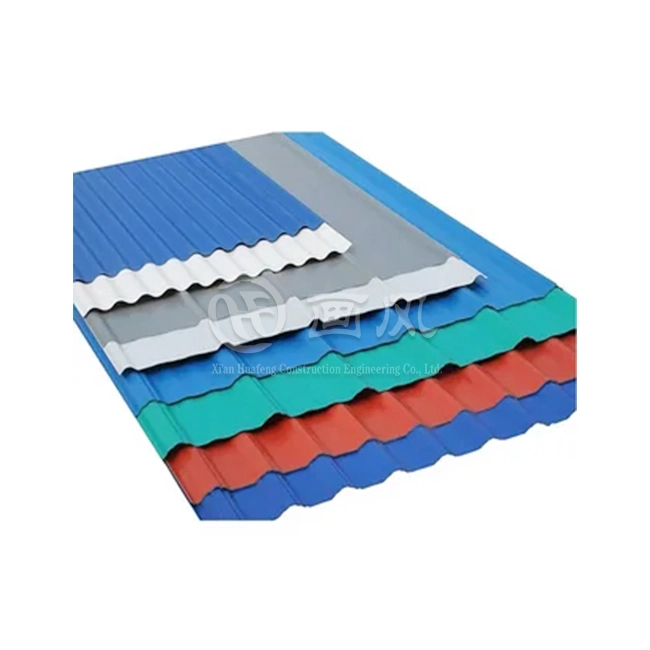

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Inside Lock Metal Wall Panels factory offering comprehensive building envelope solutions. As a leading China Inside Lock Metal Wall Panels supplier and China Inside Lock Metal Wall Panels manufacturer, we provide High Quality Inside Lock Metal Wall Panels for sale at competitive Inside Lock Metal Wall Panels price points. Our one-stop service encompasses design optimization, precision manufacturing using 7 production lines and over 40 specialized machines, and professional installation support. With ISO9001, ISO14001, and SGS certifications plus more than 20 registered patents, we deliver reliable China Inside Lock Metal Wall Panels wholesale solutions customized to your project specifications. Contact us at huafeng@hfmetalroof.com to discuss how our engineering expertise and factory capabilities can enhance your industrial facility's performance and value.

References

1. Metal Construction Association. "Insulated Metal Panel Selection Guide for Industrial Applications." Technical Bulletin Series. Authors: Industrial Building Systems Committee.

2. American Institute of Steel Construction. "Design Standards for Metal Building Envelope Systems in Manufacturing Facilities." Engineering Design Manual. Authors: Building Envelope Technical Committee.

3. Cold Storage Technology Association. "Thermal Performance Requirements for Temperature-Controlled Warehouse Construction." Industry Standards Publication. Authors: Facilities Engineering Working Group.

4. International Building Code. "Fire Safety and Structural Requirements for Metal Wall Panel Systems." Code Compliance Documentation. Authors: Building Safety Committee.