Imagine discovering water stains spreading across your ceiling after a heavy rainstorm, only to find out your metal roof was installed on too shallow a pitch. This frustrating scenario happens more often than you'd think when building owners don't understand how roof slope and weather conditions directly impact the performance of Aluminum Standing Seam Metal Roof Panels. Understanding the relationship between roof pitch requirements and weather resistance capabilities is crucial for ensuring your investment delivers decades of leak-free protection. This comprehensive guide reveals the critical pitch specifications, weather performance factors, and installation considerations that determine whether your aluminum standing seam roof system will excel or fail in your specific climate conditions.

Understanding Minimum Pitch Requirements for Aluminum Standing Seam Metal Roof Panels

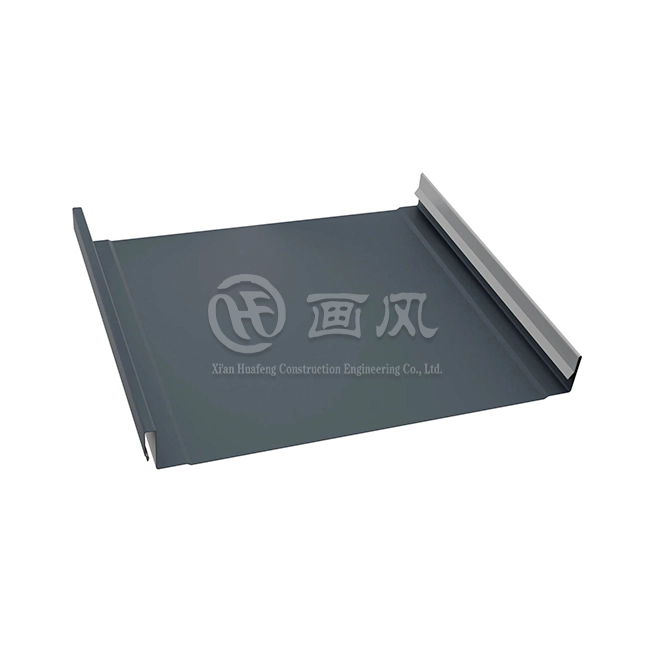

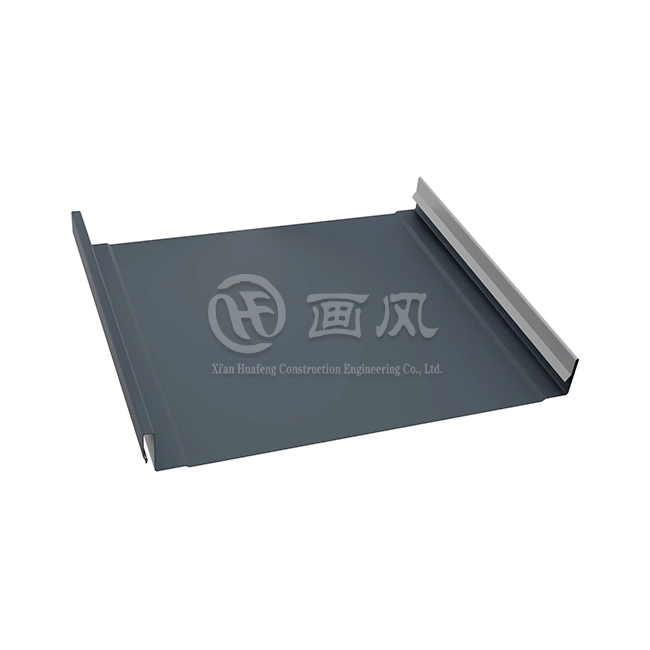

The roof pitch or slope fundamentally determines which type of metal roofing system will perform reliably on your structure. For Aluminum Standing Seam Metal Roof Panels, pitch requirements vary significantly based on the seaming method and local weather conditions. The construction industry measures roof pitch as a ratio of vertical rise to horizontal run, typically expressed as a fraction over twelve inches. Understanding these measurements is essential before selecting your roofing system. Mechanically seamed aluminum standing seam systems represent the most weather-resistant option available for low-slope applications. These systems utilize either single-lock or double-lock seaming methods, where the panel edges are mechanically crimped together using specialized equipment. Double-lock systems fold the seam twice, creating an exceptionally tight seal that can perform reliably on slopes as low as 0.5:12 when properly installed with in-seam sealant. This makes them ideal for nearly flat commercial roofs, industrial facilities, and modern architectural designs where traditional steep-slope roofing isn't feasible. The HF brand Aluminum Standing Seam Metal Roof Panels with PVDF finishes and heights ranging from 25mm to 65mm are specifically engineered to accommodate these challenging low-slope installations while maintaining superior weathertightness.

Weather Performance Across Different Pitch Categories

Low-slope roofs classified as having pitches below 3:12 face unique weather challenges that demand specialized roofing solutions. These roofs shed water more slowly than steep-slope systems, making them more vulnerable to wind-driven rain, ponding water, and ice dam formation during freeze-thaw cycles. Aluminum Standing Seam Metal Roof Panels excel in these conditions because their raised seams create effective channels that guide water off the roof surface even when drainage is slower. The concealed fastener design eliminates screw penetrations on the exposed surface, removing potential entry points where water could infiltrate during extreme weather events. The relationship between roof pitch and weather resistance becomes especially critical in regions experiencing heavy snowfall, intense rainfall, or coastal environments with wind-driven precipitation. Aluminum's natural corrosion resistance combined with PVDF coating technology provides exceptional protection against salt spray in marine environments and acid rain in industrial areas. Panels manufactured with AA3003, AA3004, or AA5052 aluminum alloys offer the optimal balance of strength and corrosion resistance needed for long-term weather exposure. When installed with thicknesses between 0.7mm and 1.2mm, these Aluminum Standing Seam Metal Roof Panels maintain structural integrity while accommodating thermal expansion and contraction across seasonal temperature variations.

Selecting the Right Seaming System for Your Climate Conditions

The choice between snap-lock and mechanically seamed Aluminum Standing Seam Metal Roof Panels significantly impacts both installation costs and long-term weather performance. Snap-lock systems offer faster installation and lower labor costs because panels simply snap together over concealed clips without requiring specialized seaming equipment. However, these systems generally require minimum roof pitches of 3:12 or greater and may not provide adequate weather protection in climates experiencing extreme wind-driven rain or heavy snow loads. The snap-together connection, while secure, doesn't create the same level of weathertightness as mechanically seamed profiles. Mechanically seamed systems require more installation labor but deliver superior weather resistance that justifies the additional investment in challenging climates. These systems utilize standing seam clips that attach to the roof deck, allowing the metal panels to float freely and accommodate thermal movement without stress. A mechanical or hand seamer then crimps the panel edges together, creating either a 90-degree single-lock or 180-degree double-lock seam. The double-lock configuration provides maximum protection against water infiltration, making it the preferred choice for roofs with pitches between 0.5:12 and 2:12 where water drainage occurs more slowly and weather exposure is more severe.

Aluminum Advantages in Extreme Weather Environments

Aluminum Standing Seam Metal Roof Panels demonstrate remarkable performance advantages over steel alternatives in several specific weather scenarios. The lightweight nature of aluminum, approximately one-third the density of steel, reduces structural loading while maintaining excellent strength-to-weight ratios. This characteristic proves especially valuable in seismic zones, retrofit applications over existing structures, and designs requiring minimal dead load on the building frame. The reduced weight doesn't compromise wind resistance when properly installed with engineered attachment systems rated for local wind loads. Coastal properties and buildings near industrial facilities benefit tremendously from aluminum's superior corrosion resistance compared to galvanized or galvalume steel products. While steel roofing relies on protective zinc coatings that eventually sacrifice themselves to protect the base metal, aluminum develops a natural protective oxide layer that continuously regenerates if scratched or damaged. This self-healing characteristic extends service life significantly in harsh environments where salt spray, industrial emissions, or acid rain would rapidly degrade steel systems. PVDF fluorocarbon coatings applied to Aluminum Standing Seam Metal Roof Panels provide an additional protective barrier that maintains color integrity for twenty-plus years while reflecting solar heat to reduce cooling costs in hot climates.

Critical Installation Considerations for Low-Slope Applications

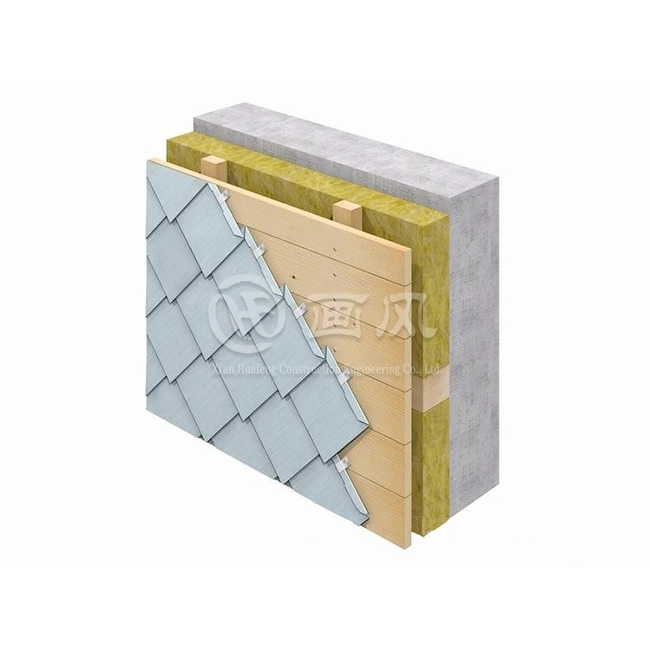

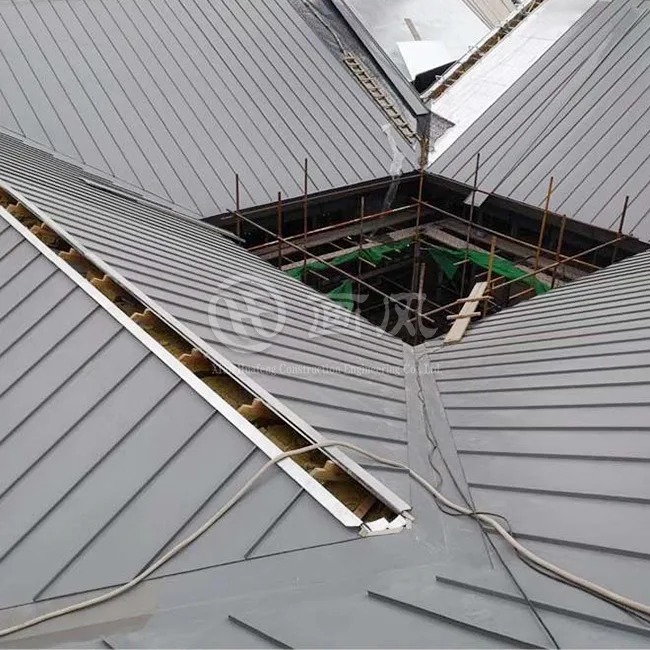

Proper installation techniques become exponentially more important as roof pitch decreases because margin for error diminishes significantly on low-slope applications. The foundation of any successful low-slope metal roof begins with selecting appropriate underlayment materials that provide secondary water protection if moisture somehow bypasses the metal panels. Self-adhering ice and water shield synthetic underlayment represents the industry best practice for roofs with pitches below 2:12, creating a fully adhered waterproof membrane that won't allow water migration beneath the panels. This contrasts with mechanically attached felt paper or synthetic underlayments that can allow water to travel laterally if the metal panel system is compromised. Proper panel alignment and clip spacing follow precise specifications that vary based on wind uplift ratings, roof pitch, and panel profile. Aluminum Standing Seam Metal Roof Panels must maintain consistent seam alignment across the entire roof surface to ensure mechanical seaming equipment can effectively lock the panels together. Clip placement typically occurs at sixteen to twenty-four inch intervals along the panel length, with closer spacing required in high wind regions or on steeper slopes where gravity forces increase panel movement tendencies. Each clip must attach securely to structural supports, using appropriate fasteners for the decking material whether plywood sheathing, metal purlins, or structural concrete.

Sealant Application and Quality Control Measures

In-seam sealant application becomes mandatory for mechanically seamed Aluminum Standing Seam Metal Roof Panels installed on slopes below 2:12 in most geographic regions. This sealant provides additional weatherproofing beyond the mechanical interlock, creating a capillary break that prevents water from wicking between the locked panel edges during wind-driven rain events. Quality control during sealant application ensures continuous coverage along the entire seam length without gaps that could compromise weather protection. Installers must follow manufacturer specifications regarding sealant type, application temperature ranges, and curing requirements to achieve warranted performance. The interaction between panel rib height and roof pitch also influences water-shedding capability. Higher profile panels with rib heights of 50mm to 65mm provide greater capacity for managing water flow on lower slopes compared to shorter 25mm to 40mm profiles. The raised seams create more pronounced drainage channels that direct water toward eaves and gutters even when the roof pitch provides minimal gravitational assistance. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Aluminum Standing Seam Metal Roof Panels with customizable rib heights specifically engineered to match your project's pitch and weather exposure requirements, ensuring optimal performance across diverse applications from industrial warehouses to architectural showcase buildings.

Maintenance and Long-Term Weather Performance

One significant advantage of Aluminum Standing Seam Metal Roof Panels involves their minimal maintenance requirements compared to traditional roofing systems. The combination of aluminum's corrosion resistance and PVDF coating durability means these roofs typically require only periodic inspections and cleaning to maintain peak performance throughout their service life. Recommended maintenance schedules generally call for annual visual inspections to identify any debris accumulation in valleys or around penetrations, with particular attention to ensuring gutters and downspouts remain clear to facilitate proper drainage. The factory-applied PVDF finishes on quality Aluminum Standing Seam Metal Roof Panels resist chalking and fading far better than conventional polyester coatings, maintaining architectural appearance for decades with minimal color degradation. These fluoropolymer coatings also resist dirt accumulation and biological growth, meaning roofs in humid climates or shaded areas remain cleaner naturally compared to asphalt shingles or other porous roofing materials. When cleaning becomes necessary, simple low-pressure washing with mild detergent typically restores the roof's appearance without damaging the coating or compromising weather protection.

Thermal Performance and Energy Efficiency Benefits

Aluminum Standing Seam Metal Roof Panels deliver exceptional thermal performance that translates directly into energy cost savings across various climate zones. The reflective properties of PVDF-coated aluminum surfaces bounce solar radiation back into the atmosphere rather than absorbing heat into the building structure. This cool roof effect can reduce attic temperatures by twenty to thirty degrees Fahrenheit compared to dark asphalt shingles, substantially decreasing air conditioning loads during summer months. The benefits prove especially pronounced in hot, sunny climates where cooling costs represent the largest portion of annual energy expenses. The standing seam design's raised profile creates a natural air gap between the metal panels and underlying roof deck, promoting ventilation that further enhances thermal performance. This ventilation channel allows hot air to escape from beneath the roofing system rather than conducting heat into the occupied space below. When combined with proper attic insulation and ventilation strategies, Aluminum Standing Seam Metal Roof Panels contribute to comprehensive building envelope performance that meets or exceeds modern energy code requirements. The lightweight nature of aluminum panels also simplifies the addition of supplementary rigid insulation layers in retrofit applications where improving thermal performance is desired without exceeding structural load capacities.

Conclusion

Successfully specifying and installing Aluminum Standing Seam Metal Roof Panels requires understanding the critical relationships between roof pitch, seaming systems, and local weather conditions to ensure decades of reliable leak-free performance.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Aluminum Standing Seam Metal Roof Panels manufacturer, factory, and supplier, delivering high-quality Aluminum Standing Seam Metal Roof Panels for sale at competitive prices. Since our establishment in 2018, we've specialized as a professional company focusing on metal roofing systems, building curtain wall systems, and building steel structure enclosure solutions. Recognized as a high-tech enterprise in Shaanxi Province with first-level curtain wall qualifications and third-level steel structure qualifications, we operate three strategically located facilities including a 200,000-square-meter raw material production plant in Anhui and two plate processing plants in Hangzhou and Xi'an.

Our comprehensive manufacturing capabilities include seven color coating production lines, one laminating line, ten longitudinal and transverse shearing lines, and more than forty specialized machines ensuring precision fabrication of High Quality Aluminum Standing Seam Metal Roof Panels. With over twenty patented roofing technologies and international certifications including ISO9001, ISO14000:14001, and SGS compliance, we deliver one-stop solutions from custom engineering design and 3D structural modeling through precision manufacturing and seamless on-site installation. Our China Aluminum Standing Seam Metal Roof Panels wholesale offerings include AA3003, AA3004, and AA5052 alloys with PVDF finishes, thicknesses from 0.7mm to 1.2mm, customizable RAL colors, and thirty-year warranties backed by rigorous quality control. Contact our team today at huafeng@hfmetalroof.com to discuss your project requirements and receive expert guidance on selecting the optimal roofing solution for your specific pitch and weather conditions.

References

1. International Code Council. "International Residential Code for One- and Two-Family Dwellings: Section R905.10.2 - Metal Roof Panels." 2021 edition.

2. ASTM International. "ASTM E2140 - Standard Test Method for Water Penetration of Metal Roof Panel Systems by Static Water Pressure Head." ASTM Committee E06 on Performance of Buildings.

3. Sheffield Metals. "Standing Seam Metal Roofing Technical Guide: Installation Requirements and Performance Standards." Sheffield Metals Technical Documentation.

4. Metal Construction Association. "Technical Bulletin: Low-Slope Metal Roof Systems - Design, Installation and Performance Guidelines." MCA Engineering Committee Publication.

5. American Architectural Manufacturers Association. "AAMA 620 - Standard Practice for Metal Curtain Walls: Including Material Selection and Weather Performance Requirements." AAMA Standards and Specifications.