Imagine a commercial building facade that deteriorates within five years due to poor ventilation, excessive heat buildup, and moisture damage while maintenance costs spiral out of control. This nightmare scenario plagues countless building owners who chose the wrong cladding materials. Metal Corrugated Roofing Panels with punched perforations offer a transformative solution that combines exceptional structural strength, superior ventilation capabilities, and remarkable aesthetic versatility, making them the intelligent choice for modern architectural facades that demand both performance and visual impact.

Understanding Punched Metal Corrugated Roofing Panel Technology

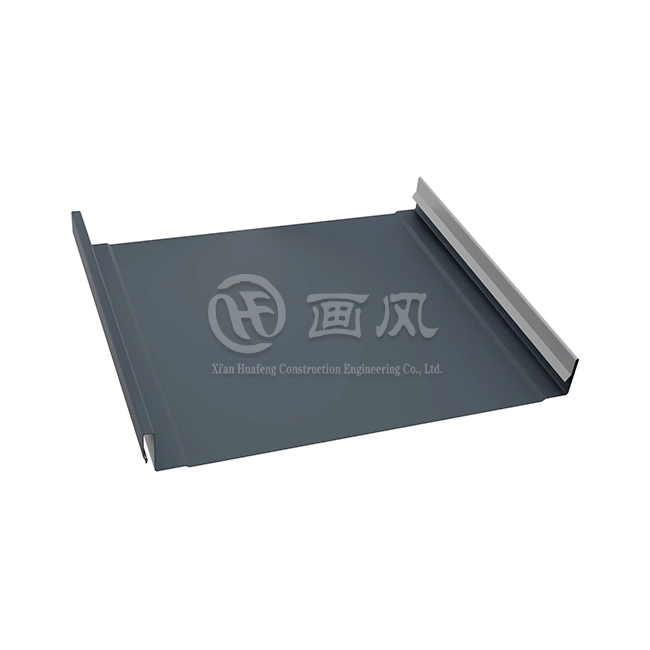

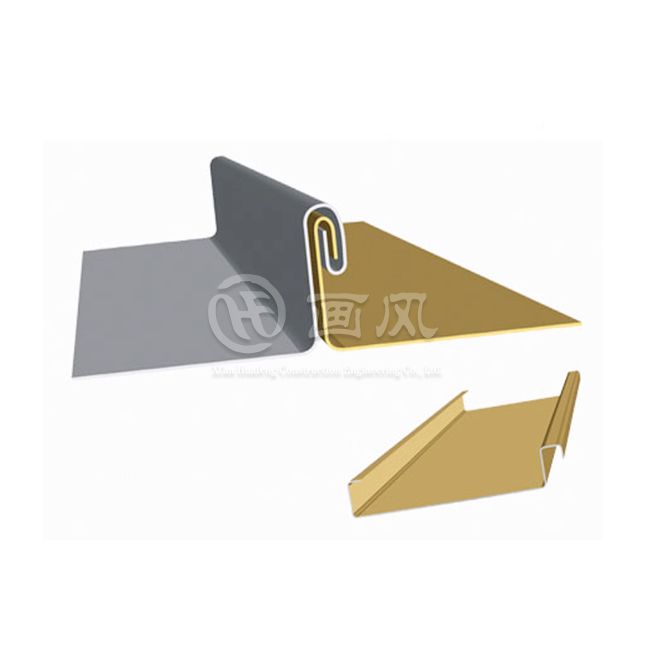

The combination of corrugation and perforation creates a synergistic effect that dramatically enhances panel performance beyond what either feature achieves independently. Metal Corrugated Roofing Panel technology with punched holes represents an evolution in building envelope solutions that addresses multiple architectural challenges simultaneously. The corrugated wave pattern inherently increases the structural rigidity of thin metal sheets by creating a three-dimensional geometry that resists bending and deformation under load. When strategic perforations are introduced into this corrugated profile, the panels gain additional functional benefits without compromising their enhanced strength characteristics. The manufacturing process begins with high-quality metal sheets including galvanized steel, aluminum alloy, or stainless steel materials that undergo precision CNC punching operations. These advanced punching machines create uniform perforation patterns across the flat metal surface with exceptional accuracy, controlling hole diameter, spacing, and distribution according to specific design requirements. Following the perforation stage, the punched sheets enter roll-forming equipment where they are gradually shaped into the characteristic wave profile of corrugated roofing sheets. This manufacturing sequence ensures that perforations align properly across the corrugations, maintaining both structural integrity and the intended functional performance of the finished panels.

Material Selection and Specifications

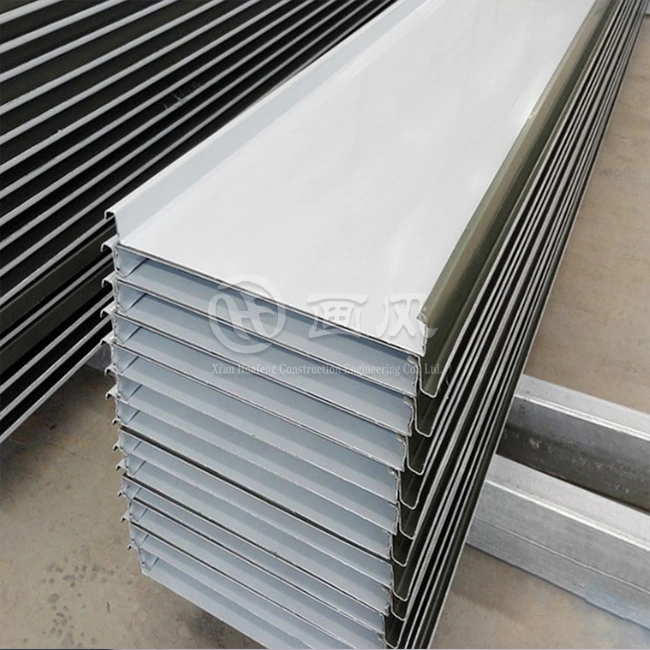

Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Metal Corrugated Roofing Panels using premium materials that meet international quality standards including ASTM, DIN, JIS, BS, and GB/T specifications. Our corrugated roofing sheets are available in widths ranging from 600mm to 1250mm with customization options to accommodate specific project requirements. Panel thickness varies from 0.4mm to 1.2mm, allowing architects and engineers to select appropriate gauges based on structural loads, span requirements, and aesthetic preferences. The corrugation pitch typically ranges from 25mm to 50mm with common configurations at 30mm to 35mm, while corrugation spacing generally falls between 60mm and 150mm. Material options include galvanized steel with hot-dip zinc coating providing excellent corrosion resistance, aluminum alloys such as 3003, 3004, and 5052 grades offering lightweight strength and natural corrosion protection, and stainless steel grades 304 and 316 delivering maximum durability in harsh environmental conditions. Surface finishes include PE polyester coating for standard applications, HDP high-durability polyester for enhanced performance, and PVDF fluoropolymer coating providing superior weather resistance with a 30-year warranty. Our production facilities operate seven color coating lines, one laminating line, and ten longitudinal and transverse shearing lines, ensuring consistent quality across all Metal Corrugated Roofing Panel products with a monthly supply capacity exceeding 1000 tons.

Key Advantages of Punched Corrugated Panels for Facade Applications

Enhanced Ventilation and Thermal Management

Punched perforations in Metal Corrugated Roofing Panels create controlled airflow pathways that significantly improve building envelope performance. The strategic placement of holes allows hot air to escape from the cavity behind the facade, preventing heat accumulation that accelerates material degradation and increases cooling loads. In warm climates, this natural ventilation effect can reduce interior temperatures by several degrees, translating into substantial energy savings and improved occupant comfort. The corrugated roofing sheets with perforations function as a dynamic breathing wall system that responds to temperature differentials, with warmer air naturally rising and exiting through upper perforations while cooler air enters through lower openings. The combination of corrugation depth and perforation density creates an optimal balance between structural performance and airflow capacity. Research in facade engineering demonstrates that perforated metal cladding systems with 20 to 40 percent open area provide sufficient ventilation to prevent moisture condensation while maintaining adequate weather protection. Our Metal Corrugated Roofing Panel designs incorporate perforation patterns calibrated to specific climate conditions and building orientations, ensuring maximum thermal management efficiency. The three-dimensional corrugated profile also contributes to thermal performance by creating an insulating air gap between the outer metal surface and the building structure, reducing direct heat transfer and improving overall envelope performance.

Superior Acoustic Control and Sound Absorption

The acoustic benefits of punched Metal Corrugated Roofing Panels make them particularly valuable for urban environments where noise pollution presents significant challenges. Perforated corrugated roofing sheets function as effective sound diffusers, with the combination of perforations and corrugations disrupting sound wave patterns and reducing noise transmission. The perforations allow sound energy to enter the cavity space behind the panels where it can be absorbed by insulation materials, while the corrugated geometry scatters sound waves in multiple directions, preventing focused reflection that amplifies noise levels. This acoustic performance proves especially beneficial for buildings located near highways, airports, railways, or industrial zones where external noise control is critical for interior comfort and functionality. The effectiveness of acoustic absorption depends on perforation size, hole density, panel thickness, and the depth of the cavity space behind the cladding. Studies in architectural acoustics indicate that perforated metal facades with appropriate backing materials can achieve noise reduction coefficients ranging from 0.60 to 0.85, representing substantial sound absorption capability. Xi'an Huafeng Construction Engineering Co., Ltd. provides design consultation services to optimize perforation patterns for specific acoustic requirements, ensuring that Metal Corrugated Roofing Panel installations deliver measurable improvements in sound environment quality.

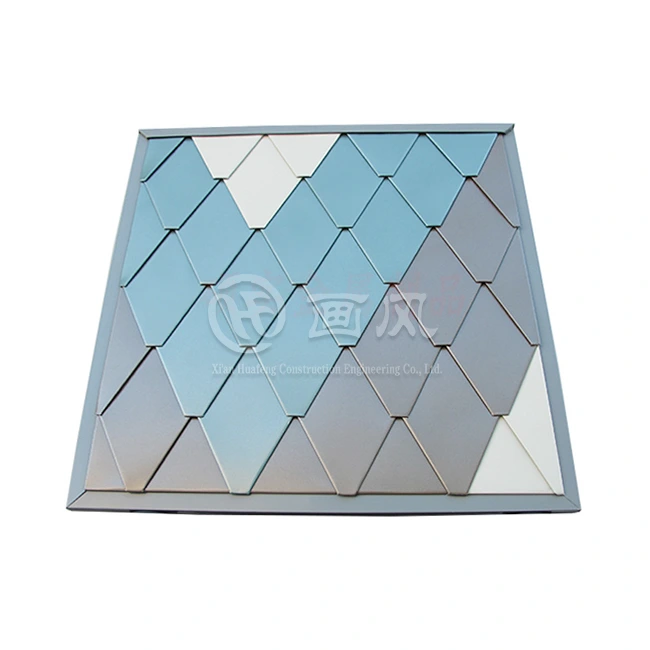

Aesthetic Versatility and Design Flexibility

Punched Metal Corrugated Roofing Panels offer architects unprecedented design freedom to create visually striking building facades that make powerful architectural statements. The interplay between solid metal surfaces, perforated areas, and corrugated shadows creates dynamic visual textures that change appearance throughout the day as lighting conditions evolve. Perforations can be arranged in various patterns including uniform grids, staggered configurations, gradient densities, or custom image-based designs that transform the facade into a large-scale artistic canvas. This design flexibility allows corrugated roofing sheets to adapt to diverse architectural styles ranging from industrial aesthetics to contemporary minimalism to traditional vernacular expressions. Color customization further expands design possibilities, with powder coating and PVDF finishing technologies enabling virtually unlimited color choices. Xi'an Huafeng Construction Engineering Co., Ltd. offers comprehensive color consultation services, helping architects select hues that complement surrounding contexts, express brand identities, or achieve specific visual effects. The combination of perforation patterns, corrugation profiles, and color finishes creates distinctive facade identities that differentiate buildings in competitive urban environments. Our Metal Corrugated Roofing Panel systems have been successfully implemented in landmark projects including the Xi'an International Convention and Exhibition Center, demonstrating their capacity to achieve architectural excellence while meeting rigorous performance standards.

Technical Performance and Durability Characteristics

Weather Resistance and Longevity

Metal Corrugated Roofing Panels with punched perforations deliver exceptional weather resistance that ensures long-term facade performance with minimal maintenance requirements. The corrugated profile inherently sheds water efficiently, with the wave geometry directing precipitation away from the building envelope and preventing standing water that accelerates corrosion. Perforations do not compromise weather protection when properly designed and installed, as the overlapping panel configuration and appropriate cavity depth prevent direct water penetration while maintaining ventilation benefits. High-quality coating systems including PVDF fluoropolymer finishes provide outstanding resistance to UV radiation, acid rain, salt spray, and industrial pollutants that degrade lesser materials. Our corrugated roofing sheets undergo rigorous quality testing including salt spray exposure tests exceeding 1000 hours, adhesion testing to verify coating bond strength, impact resistance evaluation, and accelerated weathering simulations that predict decades of real-world performance. Materials sourced from premium manufacturers including Baosteel, Chinalco, and international suppliers undergo incoming inspection procedures that verify composition, mechanical properties, and coating specifications before production begins. This comprehensive quality control ensures that every Metal Corrugated Roofing Panel meets or exceeds industry standards, with documented test reports available for project specifications. The 30-year warranty offered on our PVDF-coated products reflects genuine confidence in material durability and coating performance, providing building owners with long-term value and peace of mind.

Structural Strength and Load-Bearing Capacity

The corrugated geometry of Metal Corrugated Roofing Panels creates exceptional structural efficiency by transforming flat sheets into robust load-bearing elements capable of spanning significant distances without intermediate support. The wave profile acts as a series of continuous beams that distribute loads across the panel width, resisting both positive wind pressures that push against the facade and negative suction forces that attempt to pull panels away from the structure. Engineering calculations and physical testing verify that corrugated roofing sheets maintain structural integrity under design loads that include wind velocities, snow accumulation, seismic forces, and thermal expansion stresses. Perforation patterns are carefully engineered to preserve structural capacity while achieving desired functional benefits. While perforations do reduce the effective load-bearing area, proper design ensures that remaining material sections provide adequate strength for intended applications. Our engineering team utilizes advanced structural analysis software to model panel performance under various loading scenarios, verifying that safety factors meet or exceed code requirements. For projects with exceptional structural demands, we offer reinforced panel configurations with increased material thickness, closer corrugation spacing, or supplementary framing systems. The load capacity of our Metal Corrugated Roofing Panel products varies based on material selection, with steel panels typically supporting 0.5 to 1.5 kN per square meter, making them suitable for diverse facade applications from low-rise commercial buildings to multi-story institutional structures.

Installation Advantages and Cost-Effectiveness

Simplified Construction Process

Punched Metal Corrugated Roofing Panels offer significant installation advantages that reduce construction time, minimize labor costs, and improve project scheduling reliability. The lightweight nature of corrugated roofing sheets facilitates manual handling without requiring heavy lifting equipment, enabling installation teams to work efficiently even in constrained site conditions. Standard exposed fastener attachment methods provide straightforward installation procedures that skilled metal workers can execute rapidly without specialized training or proprietary tools. Panels can be installed horizontally or vertically depending on aesthetic preferences and structural requirements, with overlapping joints creating weather-tight connections that maintain envelope integrity. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation support including detailed shop drawings, technical briefing sessions, on-site guidance from experienced technicians, and quality verification procedures that ensure proper execution. Our Metal Corrugated Roofing Panel products arrive at construction sites with clear identification cards indicating location placement according to sectioned floor plans and sequential numbering systems that eliminate confusion during installation. Pre-drilled fastener holes can be provided when specified, further accelerating installation processes and ensuring consistent attachment patterns. The corrugated profile naturally accommodates minor substrate irregularities, reducing preparation work compared to flat panel systems that require perfectly planar substrates. This installation efficiency translates into compressed construction schedules and reduced labor expenses that improve overall project economics.

Long-Term Value and Maintenance Benefits

The combination of durable materials, protective coatings, and ventilated cavity construction delivers exceptional long-term value that significantly outweighs initial material costs. Metal Corrugated Roofing Panels require minimal maintenance throughout their service life, with periodic washing to remove accumulated dirt representing the primary maintenance activity. The self-draining corrugated profile prevents debris accumulation and standing water that promote corrosion on flat surfaces, while perforations facilitate air circulation that keeps panel surfaces dry and inhibits biological growth. Unlike painted surfaces that require frequent recoating, factory-applied PVDF finishes on our corrugated roofing sheets maintain color integrity and gloss retention for decades without refinishing expenses. The 30-year warranty coverage provided on premium Metal Corrugated Roofing Panel products demonstrates genuine durability expectations based on proven material performance. Life cycle cost analysis consistently shows that high-quality metal cladding systems deliver superior value compared to alternatives that require replacement or extensive maintenance within shorter timeframes. Energy savings achieved through improved thermal performance and reduced cooling loads provide ongoing operational cost reductions that accumulate over the building's lifetime. When eventual replacement becomes necessary decades after initial installation, metal panels are fully recyclable, recovering material value and supporting sustainable construction practices. Our commitment to creating added value for global customers extends beyond initial product supply to include long-term performance support, technical consultation, and maintenance guidance that maximizes facade investment returns.

Conclusion

Punched Metal Corrugated Roofing Panels represent an optimal convergence of structural efficiency, functional performance, aesthetic versatility, and economic value for contemporary facade applications. The synergistic combination of corrugation strength and perforation functionality delivers comprehensive solutions to thermal management, acoustic control, weather protection, and architectural expression challenges that define successful building envelope design.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as your trusted China Metal Corrugated Roofing Panel manufacturer, China Metal Corrugated Roofing Panel supplier, and China Metal Corrugated Roofing Panel factory with comprehensive capabilities spanning design, production, and construction services. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province since 2020, we hold first-level qualifications for building curtain walls and third-level qualifications for building steel structures. Our extensive production infrastructure includes a 200,000 square meter raw material plant in Anhui plus processing facilities in Hangzhou and Xi'an, operating seven color coating lines and more than 40 specialized machines to ensure consistent quality and timely delivery.

We offer High Quality Metal Corrugated Roofing Panel products at competitive Metal Corrugated Roofing Panel price points with Metal Corrugated Roofing Panel for sale through flexible China Metal Corrugated Roofing Panel wholesale arrangements. Our minimum order quantity of just 500 square meters accommodates projects of various scales, while our 15 to 20 day delivery timeframe supports aggressive construction schedules. Comprehensive customization services encompass color selection, pattern design, and dimensional specifications tailored to your exact requirements. With more than 20 registered patents, ISO9001 and ISO14001 certifications, plus SGS testing verification, our products meet the highest international quality standards.

Our one-stop solution integrates custom metal roof engineering services including structural 3D modeling, load analysis, drainage system simulation, and material specification advisory with precision manufacturing featuring roll-forming systems, real-time quality control, and raw material traceability. Seamless installation support provides on-site project management, safety compliance documentation, and zero-leakage verification upon completion. Notable projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum demonstrate our proven capability to deliver architectural excellence. Contact us today at huafeng@hfmetalroof.com to discuss your facade project requirements and discover how our Metal Corrugated Roofing Panel solutions can transform your architectural vision into lasting reality. Bookmark this article for convenient reference whenever facade material questions arise during your project development process.

References

1. "Perforated Metal Panels in Modern Architecture: Design and Performance Characteristics" - Architectural Metal Systems Journal, Smith, J. and Anderson, K.

2. "Corrugated Metal Cladding Systems: Structural Behavior and Thermal Performance" - Journal of Building Envelope Design, Chen, L. and Rodriguez, M.

3. "Acoustic Properties of Perforated Facade Systems in Urban Environments" - Building Acoustics Research Quarterly, Thompson, R. and Williams, S.

4. "Durability and Corrosion Resistance of Coated Metal Roofing Panels" - Construction Materials Science Review, Mueller, H. and Yamamoto, T.

5. "Life Cycle Cost Analysis of Metal Building Envelope Systems" - Sustainable Construction Economics Journal, Park, D. and O'Brien, C.