Picture this scenario: Your production line halts because your screening media has blinded yet again, costing thousands in downtime while your competitors keep running. For manufacturers facing constant material separation challenges, selecting the right Punched Plate Screens partner can mean the difference between operational excellence and costly disruptions. This comprehensive OEM guide reveals critical insights into custom Punched Plate Screens manufacturing, helping you identify reliable suppliers, optimize specifications, and implement solutions that maximize productivity while minimizing total cost of ownership across demanding industrial applications.

Understanding Punched Plate Screens Manufacturing Capabilities

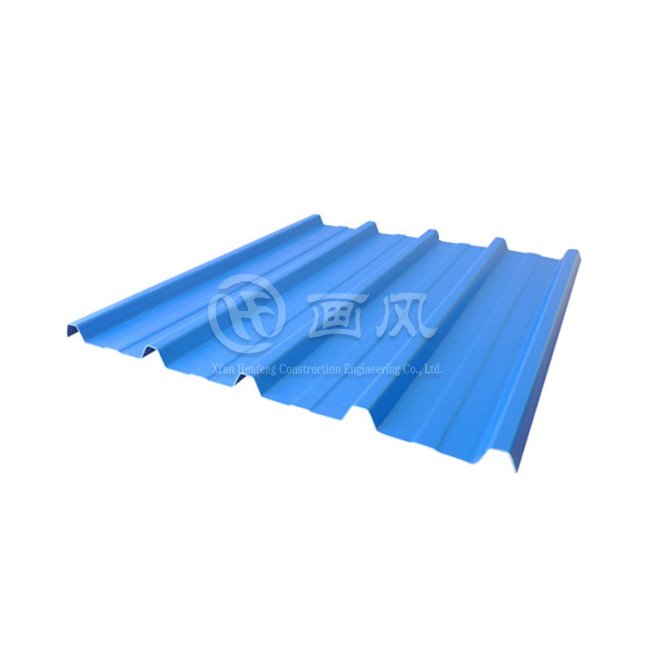

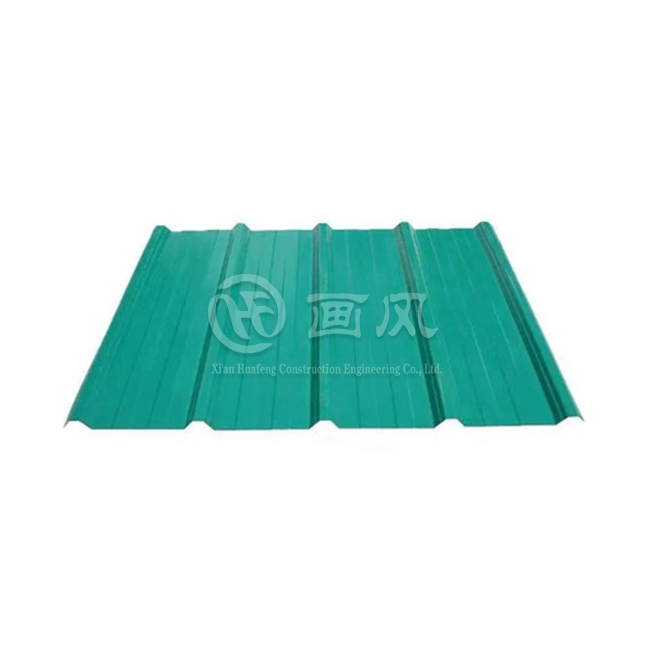

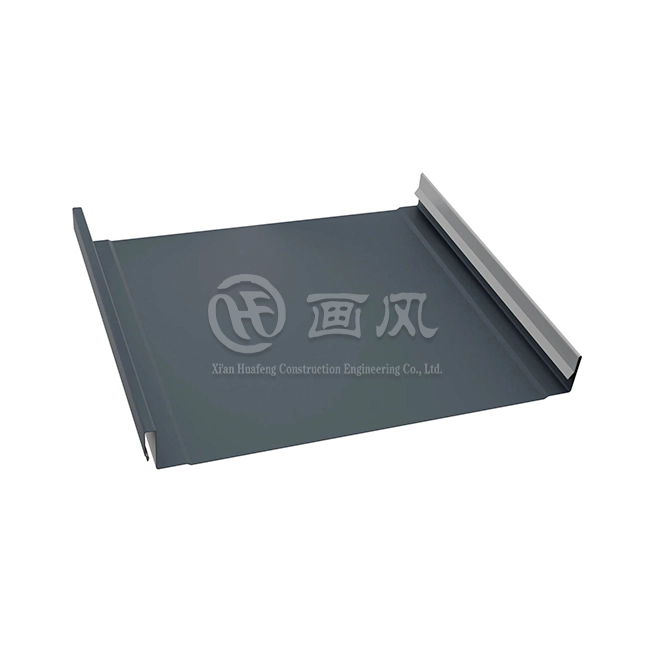

When evaluating OEM partners for Punched Plate Screens, manufacturers must first comprehend the fundamental production capabilities that distinguish industry leaders from commodity suppliers. The manufacturing process begins with precision metal fabrication, where raw materials undergo systematic transformation through specialized punching equipment. Advanced manufacturers operate facilities equipped with CNC-controlled punch presses capable of creating hole patterns with tolerances measured in fractions of millimeters. These sophisticated systems can process various materials including galvalume plate, aluminum alloy, and stainless steel grades ranging from 304 to 316L, with plate thicknesses spanning from 0.5 millimeters to 12 millimeters depending on application requirements. The versatility of modern Punched Plate Screens production extends beyond simple hole punching. Leading OEM facilities integrate multiple processing lines that enable comprehensive material handling from raw coil to finished product. For instance, operations featuring seven color coating production lines, laminating capabilities, and longitudinal shearing systems provide manufacturers with consolidated sourcing advantages. This vertical integration eliminates the coordination headaches and quality inconsistencies that plague multi-vendor supply chains. Furthermore, advanced manufacturers maintain dedicated quality control laboratories where incoming materials undergo rigorous testing protocols including salt spray resistance, adhesion strength, hardness verification, impact resistance, and accelerated weathering simulations before ever entering production workflows.

Material Selection and Performance Characteristics

Material selection fundamentally determines the performance envelope of Punched Plate Screens in real-world applications. Low carbon steel provides economical solutions for moderate-duty applications where corrosion exposure remains limited, while galvanized and galvalume sheets offer enhanced oxidation resistance through sacrificial zinc or aluminum-zinc coatings. For environments involving chemical exposure, moisture, or strict hygiene requirements such as food processing facilities, stainless steel grades become essential despite higher material costs. The 304 stainless steel variant delivers excellent general corrosion resistance, while 316-grade materials incorporate molybdenum for superior performance in chloride-rich or marine environments. Aluminum alloys present compelling alternatives where weight reduction drives design priorities without compromising structural integrity. The 3003 aluminum alloy provides good formability and corrosion resistance for architectural applications, while 5052 grade offers higher strength characteristics suitable for structural panels. Manufacturers specifying Punched Plate Screens must balance material properties against operational demands including abrasion levels, impact loads, temperature extremes, and chemical exposure profiles. Advanced OEM partners maintain comprehensive material libraries with documented performance data, enabling evidence-based specification rather than guesswork. This technical expertise proves invaluable during the design phase, where material selection directly influences aperture design, structural reinforcement requirements, and expected service life projections.

Aperture Design and Opening Configurations

The aperture characteristics of Punched Plate Screens represent perhaps the most critical specification element affecting separation efficiency and operational longevity. Hole geometry options span from circular openings ranging between 0.5 millimeters to 100 millimeters in diameter, to square perforations, elongated slots, and hexagonal patterns, each offering distinct performance advantages. Circular holes provide optimal material flow and minimal stress concentration, making them ideal for general screening applications. Square openings maximize open area percentage within structural constraints, enhancing throughput capacity for high-volume operations. Slotted configurations excel in applications requiring directional material orientation or elongated particle separation. Beyond shape selection, the arrangement pattern profoundly impacts screening performance. Staggered hole patterns distribute structural loads more evenly while reducing the likelihood of material bridging across adjacent openings. Straight-line patterns simplify cleaning operations but may create preferential flow paths that reduce effective screening area utilization. The open area percentage, which represents the ratio of perforated area to total surface area, typically ranges from 15 percent to 80 percent depending on structural requirements and particle size distribution. Higher open area percentages increase throughput capacity but require adequate plate thickness to maintain structural integrity under dynamic loading conditions. Experienced OEM partners employ structural analysis software to optimize aperture design, balancing material flow efficiency against mechanical durability requirements specific to each application's loading profile.

Quality Assurance and Certification Standards

Quality assurance protocols separate professional OEM manufacturers from marginal suppliers in the Punched Plate Screens industry. Comprehensive quality systems begin with incoming material inspection, where raw materials undergo verification against supplier certifications and independent third-party test reports. This critical checkpoint prevents substandard materials from contaminating production batches, a scenario that could result in premature field failures and costly warranty claims. Leading manufacturers implement both full inspection protocols for high-value materials and statistical sampling procedures for high-volume commodity inputs, ensuring consistent material quality without creating production bottlenecks. During production, real-time quality control systems monitor critical parameters including hole dimension accuracy, pitch spacing consistency, edge straightness, and surface finish quality. Modern facilities employ optical measurement systems that automatically verify aperture dimensions at production speeds, immediately flagging deviations before significant material waste occurs. Finished product inspection extends beyond dimensional verification to include flatness measurements, curvature analysis for rolled sections, and visual inspection for surface defects. Products destined for critical applications may undergo additional verification including mechanical property testing, corrosion resistance validation, and structural load testing to confirm performance specifications.

International Certifications and Compliance

The certification landscape for Punched Plate Screens reflects the global nature of modern manufacturing supply chains. ISO 9001 certification demonstrates systematic quality management implementation, providing customers with confidence in consistent manufacturing processes. Environmental management certifications including ISO 14001 signal corporate commitment to sustainable manufacturing practices, increasingly important as customers pursue their own environmental objectives. For manufacturers serving regulated industries, SGS certification provides independent verification of material composition and performance characteristics, often required for compliance documentation. Product-specific certifications vary according to end-use applications. Punched Plate Screens destined for architectural applications may require fire resistance ratings, structural load certifications, or wind load performance validation. Industrial screening applications serving the aggregate, mining, or recycling sectors prioritize abrasion resistance documentation and structural durability certifications. Food processing applications demand material certifications confirming compliance with food contact regulations and hygienic design standards. Advanced OEM partners maintain comprehensive certification portfolios spanning multiple regulatory frameworks, simplifying compliance management for manufacturers serving diverse markets or pursuing international expansion opportunities.

Customization Capabilities and Engineering Support

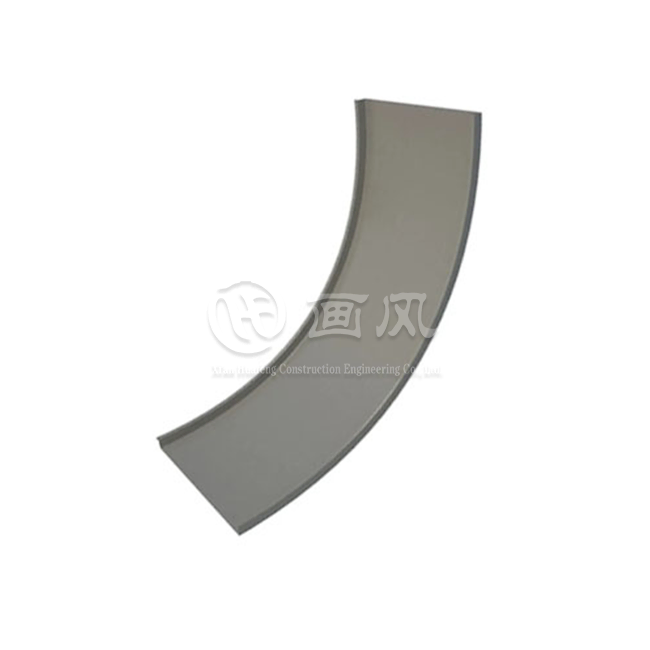

The true value proposition of partnering with sophisticated Punched Plate Screens manufacturers extends far beyond commodity product supply. Elite OEM partners provide comprehensive engineering support throughout the product development lifecycle, beginning with initial concept discussions and extending through production optimization and field performance monitoring. This consultative approach begins with detailed application analysis, where engineering teams assess material characteristics, flow rates, particle size distributions, operating temperatures, chemical exposure profiles, and mechanical loading conditions to develop optimized specifications. Three-dimensional modeling capabilities enable virtual prototyping before committing to production tooling investments. Advanced manufacturers utilize structural analysis software to simulate stress distributions, deflection patterns, and fatigue life predictions under realistic operating conditions. Drainage system simulations predict flow characteristics and identify potential accumulation zones where material buildup might compromise performance. Computational fluid dynamics modeling optimizes aperture configurations for maximum throughput while minimizing pressure drop across screening surfaces. These engineering investments generate substantial value by identifying design improvements before physical prototyping, compressing development timelines while reducing total program costs.

Sample Development and Validation Process

The sample development process provides critical risk mitigation before full-scale production commitments. Professional OEM manufacturers follow structured sampling protocols that begin with specification confirmation, ensuring complete alignment on material grades, surface treatments, aperture configurations, and dimensional requirements. Initial samples undergo rigorous parameter verification including thickness measurement, hole dimension validation, surface finish evaluation, and color matching against specified standards. Upon customer approval, samples become sealed reference standards governing subsequent production batches, creating objective acceptance criteria that eliminate subjective interpretation disputes. Advanced manufacturers extend sampling beyond simple physical specimens to include comprehensive performance validation. Material samples undergo accelerated aging protocols simulating years of environmental exposure in compressed timeframes. Abrasion testing quantifies wear resistance under controlled conditions, enabling service life predictions for budgeting and maintenance planning. Structural testing validates load-bearing capacity and deflection characteristics, confirming adequate safety factors for intended applications. This comprehensive validation approach transforms samples from simple appearance verification into predictive performance tools that build confidence in long-term reliability while identifying potential optimization opportunities before major capital commitments.

Production Scalability and Lead Time Management

Production capacity and scheduling flexibility represent critical yet often overlooked considerations when selecting Punched Plate Screens OEM partners. Manufacturers must evaluate not merely current capacity availability but also scalability potential to support business growth and demand fluctuations. Leading suppliers operate multiple production facilities strategically located to serve different geographic markets while providing operational redundancy. For example, maintaining a 200,000 square meter raw material production facility supplemented by regional processing plants enables responsive local service while leveraging centralized material procurement economies. This distributed production model balances cost efficiency against delivery flexibility, a critical advantage when project schedules compress or unexpected demand surges occur. Processing equipment diversity within manufacturing facilities directly impacts production flexibility and lead time performance. Operations featuring 10 or more longitudinal and transverse shearing lines can simultaneously process multiple orders without creating production bottlenecks that delay individual project timelines. Fully automatic punching production lines deliver consistent quality while maximizing throughput for standard configurations, while flexible manual or semi-automatic equipment handles custom specifications without disrupting high-volume production flows. Manufacturers with 40 or more pieces of support equipment including shearing machines, presses, and bending machines maintain operational flexibility when equipment maintenance or unexpected breakdowns might otherwise halt production entirely.

Inventory Management and Expedited Delivery

Strategic inventory management practices differentiate responsive suppliers from those perpetually scrambling to meet customer requirements. Sophisticated OEM partners maintain safety stock of common raw materials and frequently specified configurations, enabling rapid response to urgent requirements without premium expediting charges. This approach proves particularly valuable for manufacturers supporting maintenance, repair, and overhaul operations where equipment downtime costs dwarf material expenses, making delivery speed paramount. Advanced inventory systems track consumption patterns and automatically trigger replenishment before stockouts occur, ensuring material availability without tying up excessive working capital in slow-moving inventory. For custom configurations requiring specialized processing, transparent communication about realistic lead times builds trust and enables effective project planning. Professional manufacturers provide detailed production schedules identifying material procurement timelines, production slot availability, and shipping logistics requirements. This transparency enables customers to make informed decisions about specification trade-offs when schedule constraints create conflicts with optimal technical solutions. When expedited delivery becomes essential, established OEM partners with multiple production facilities can often reallocate capacity or authorize overtime production to accommodate critical requirements, flexibility impossible from single-facility or broker-based suppliers lacking direct manufacturing control.

Installation Support and Technical Guidance

The transition from manufactured product to operational asset represents a critical phase where OEM support directly impacts installation quality, startup efficiency, and long-term performance reliability. Elite Punched Plate Screens manufacturers recognize that product delivery marks the beginning rather than the conclusion of their customer relationship. Comprehensive installation support begins with pre-construction site assessments, where experienced technicians evaluate layout requirements, material storage provisions, and on-site processing capabilities. This proactive approach identifies potential installation challenges before crews arrive, preventing costly delays and rework scenarios that plague projects lacking adequate planning. On-site construction guidance transforms theoretical installation procedures into practical field execution. Technical representatives visit job sites in advance to verify tool availability including specialized equipment such as edge-locking machines, seaming tools, and calibrated torque equipment required for proper installation. They conduct technical briefing sessions reviewing installation sequences, quality checkpoints, and safety protocols with installation crews, ensuring everyone understands critical requirements before work commences. During installation, experienced supervisors provide real-time guidance resolving field conditions that inevitably deviate from drawing assumptions, applying practical experience to maintain project momentum while preserving installation quality.

Post-Installation Verification and Maintenance Programs

Installation completion does not signal the end of OEM involvement for manufacturers committed to long-term customer success. Comprehensive acceptance procedures include systematic verification testing confirming that installed systems meet performance specifications. For Punched Plate Screens applications, this typically includes leak testing to verify proper sealing, visual inspection confirming acceptable appearance standards, and functional testing validating material flow and separation performance. Formal acceptance procedures with documented sign-off create clear accountability while providing baseline performance documentation valuable for future maintenance planning and warranty administration. Ongoing maintenance support extends the productive service life of Punched Plate Screens installations while maintaining optimal performance levels. Professional OEM partners provide detailed maintenance guidance covering inspection intervals, cleaning procedures, and preventive maintenance requirements. Some manufacturers offer periodic maintenance services either directly or through authorized service networks, particularly valuable for customers lacking specialized technical resources or managing geographically dispersed installations. Regular maintenance visits provide opportunities to assess actual field performance against design predictions, identifying potential optimization opportunities for future projects while demonstrating ongoing commitment to customer success that builds enduring business relationships.

Cost Optimization and Total Ownership Analysis

Purchase price represents merely one component of total ownership costs for Punched Plate Screens installations, yet manufacturers often overemphasize initial acquisition costs while underestimating lifecycle expense implications. Comprehensive cost analysis must incorporate material durability projections, maintenance frequency and costs, expected service life before replacement requirements, and operational efficiency impacts including throughput capacity and energy consumption. For example, specifying premium abrasion-resistant materials may increase initial costs by 30 percent while extending service life by 300 percent, dramatically reducing annualized costs and eliminating production disruptions associated with premature replacement scenarios. Installation efficiency represents another significant cost factor often overlooked during supplier selection. OEM partners providing detailed installation documentation, pre-fabricated components with sequential numbering systems, and on-site technical support can reduce installation labor hours by 40 percent or more compared to suppliers providing basic products without application-specific engineering. These labor savings frequently exceed any material cost premiums, while also compressing project schedules and reducing the duration of production disruptions during equipment modifications or expansions. Quality-focused manufacturers emphasizing first-time installation success eliminate costly rework scenarios and warranty service calls that plague low-cost suppliers lacking robust quality systems.

Payment Terms and Financing Considerations

Financial terms and payment structures influence total project costs beyond obvious interest expense calculations. Flexible payment terms including T/T, LC, and Western Union options provide alternatives accommodating different corporate financial policies and international transaction requirements. Letter of credit arrangements protect both parties in international transactions, particularly valuable when establishing new supplier relationships where mutual trust remains incomplete. Progressive payment structures tied to project milestones align cash flow timing with value delivery, reducing working capital requirements while incentivizing schedule adherence from both parties. For large-scale projects or customers managing multiple simultaneous installations, some OEM partners offer consolidated purchasing programs that provide volume discounts while simplifying procurement administration. Annual supply agreements with volume commitments enable more aggressive pricing by providing manufacturers with improved production planning visibility and capacity utilization optimization. These arrangements benefit both parties through reduced transaction costs, improved delivery predictability, and stronger collaborative relationships that foster continuous improvement initiatives delivering ongoing value beyond initial cost considerations.

Conclusion

Selecting the right OEM partner for Custom Punched Plate Screens demands comprehensive evaluation extending far beyond product specifications and pricing comparisons. Manufacturers must assess production capabilities, quality systems, engineering support, delivery reliability, and long-term service commitment to identify suppliers capable of delivering sustained value throughout extended product lifecycles.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands ready to become your trusted China Punched Plate Screens factory and comprehensive solution provider. Since our establishment in 2018, we have evolved into a recognized China Punched Plate Screens manufacturer and China Punched Plate Screens supplier delivering exceptional value to global customers. Our High Quality Punched Plate Screens portfolio encompasses diverse materials and configurations available through our competitive Punched Plate Screens wholesale programs. As an established China Punched Plate Screens supplier, we maintain extensive inventory of Punched Plate Screens for sale while offering fully customizable solutions engineered to your exact specifications. Our Punched Plate Screens price structures reflect our commitment to competitive value without compromising the quality standards expected from a leading China Punched Plate Screens manufacturer.

Operating from our 200,000 square meter raw material production facility in Anhui, complemented by specialized processing plants in Hangzhou and Xi'an, we deliver comprehensive one-stop solutions from initial design through final installation. Our advanced manufacturing infrastructure includes seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing systems, and more than forty pieces of specialized fabrication equipment. This extensive capability enables responsive production scheduling and consistent quality delivery for projects of any scale. Recognized as a Shaanxi Province high-tech enterprise since 2020, we maintain first-level building curtain wall qualifications and third-level building steel structure certifications, backed by more than 20 registered patents and comprehensive ISO9001, ISO14001, and SGS certifications.

Our proven track record includes prestigious projects such as Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, demonstrating our capability to deliver exceptional results for demanding applications. Our engineering team provides complete design optimization services, raw material quality testing, and customized product development supported by multiple packaging and transportation options tailored to your logistical requirements. Contact our experienced team today at huafeng@hfmetalroof.com to discuss your Punched Plate Screens requirements and discover how our one-stop procurement approach simplifies your supply chain while delivering superior value. Save this guide for future reference and reach out whenever questions arise about optimizing your Punched Plate Screens specifications or applications.

References

1. "Perforated Metal Manufacturing: Design Principles and Applications" - McNichols, R.J. & Thompson, K.L., Journal of Manufacturing Science and Engineering

2. "Screening Technology in Mineral Processing: A Practical Guide" - Wills, B.A. & Finch, J.A., Published by Butterworth-Heinemann

3. "Metal Fabrication Processes: Punching, Perforating and Stamping Technologies" - Singh, P.K. & Kumar, A., International Journal of Advanced Manufacturing Technology

4. "Quality Assurance in Metal Sheet Processing: Standards and Best Practices" - Chen, H.W. & Rodriguez, M., ASM International Publications

5. "Industrial Screening Media: Material Selection and Performance Optimization" - Anderson, D.R. & Mitchell, S.E., Mining Engineering Quarterly