Picture this: you've just invested thousands of dollars in a new commercial warehouse roof, only to discover five years later that it's already showing signs of deterioration. For facility managers and building owners, understanding the actual lifespan of corrugated roofing metal panels isn't just about budgeting—it's about avoiding costly surprises and ensuring long-term protection for your investment. Corrugated roofing metal panels typically last between 30 to 50 years, with some installations reaching 60 years or more under optimal conditions. This article reveals the real-world factors that determine whether your corrugated metal sheets will barely make it to three decades or reliably protect your building for half a century.

What Determines the Real Lifespan of Corrugated Roofing Metal Panels?

The longevity of corrugated roofing metal panels depends on multiple interconnected factors that work together to either extend or shorten their service life. Understanding these variables helps building owners make informed decisions that maximize their roofing investment and avoid premature replacement costs.

Material Composition and Base Metal Quality

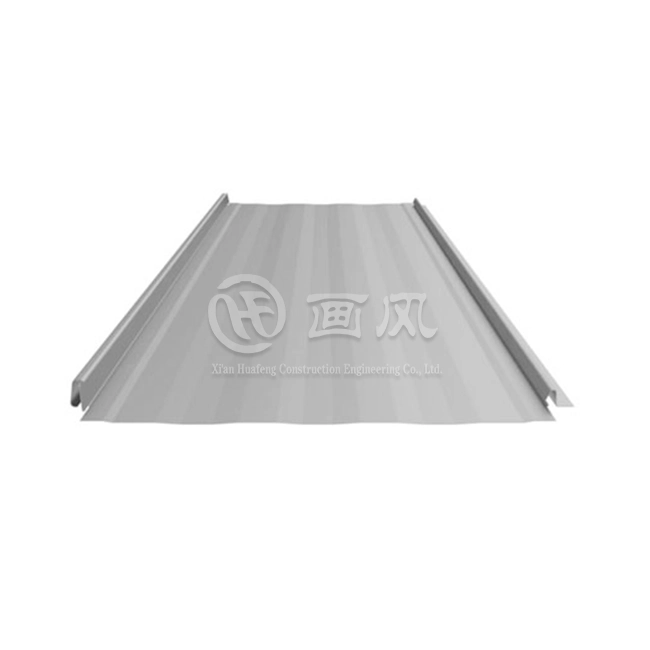

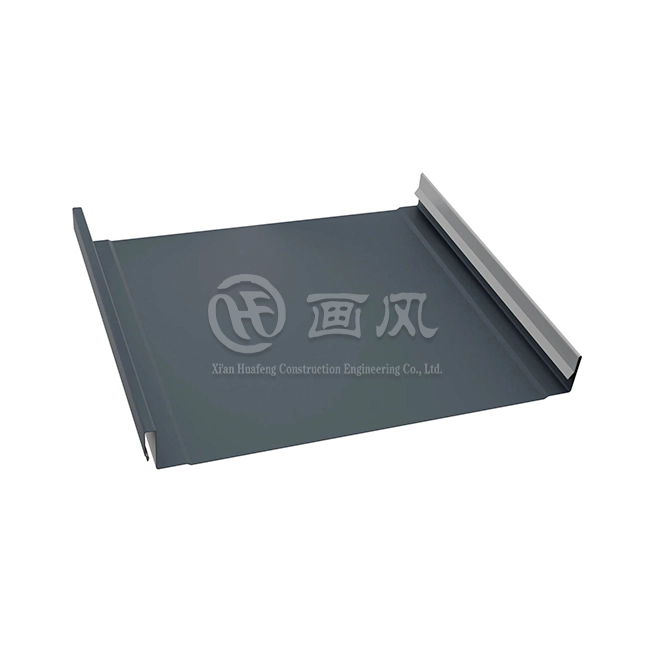

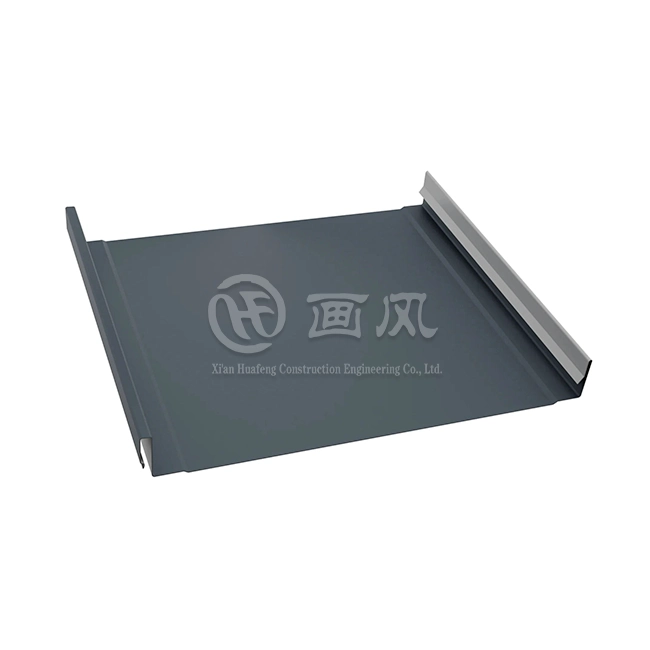

The foundation of any long-lasting corrugated metal roof starts with the base material selection. Corrugated roofing metal panels are manufactured from various metals, each offering distinct durability characteristics and lifespan expectations. Galvanized steel panels, which feature a protective zinc coating applied through hot-dip galvanizing, represent the most common choice for commercial and industrial applications. These corrugated metal sheets typically deliver 30 to 45 years of reliable service when properly maintained, with the zinc layer providing essential protection against rust and corrosion. Aluminum-based corrugated roofing metal panels offer superior corrosion resistance, particularly in coastal environments where salt air accelerates deterioration of steel products. The natural oxide layer that forms on aluminum surfaces provides self-healing properties that extend the material's functional life to 40-60 years. For projects demanding premium longevity, aluminum-magnesium-manganese alloy panels combine lightweight properties with exceptional weather resistance. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures corrugated metal sheets using certified base materials including galvanized steel grades SGCC and DX51D, aluminum alloys AA3003, AA3004, and AA5052, as well as stainless steel grades 304 and 316, with thickness options ranging from 0.4mm to 1.2mm to match specific structural and environmental requirements.

Surface Treatment and Protective Coatings

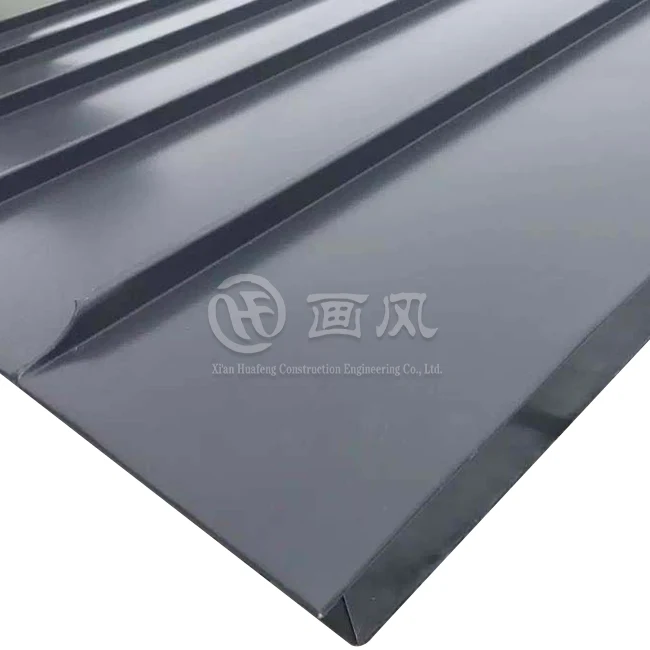

Beyond the base metal, the surface treatment applied to corrugated roofing metal panels dramatically influences their resistance to environmental degradation. The coating system serves as the first line of defense against UV radiation, moisture, temperature fluctuations, and chemical exposure. PE (polyester) coatings provide basic color retention and weathering protection suitable for standard applications, typically maintaining appearance and function for 15-20 years before requiring maintenance. HDP (high-durability polyester) coatings offer enhanced performance with improved chalk and fade resistance, extending the aesthetic lifespan to 25-30 years. PVDF (polyvinylidene fluoride) coatings, commonly marketed under the Kynar 500 brand name, represent the premium standard for corrugated metal sheets requiring maximum longevity. The molecular structure of PVDF resins creates exceptional resistance to UV degradation, chemical attack, and color fading. Corrugated roofing metal panels finished with PVDF coatings maintain their protective integrity and visual appeal for 30-40 years, often outlasting the structural life of the building itself. These advanced coating systems typically carry 30-year manufacturer warranties covering excessive fading, chalking, and film adhesion failures. The color selection also impacts performance—lighter colors reflect more solar radiation, reducing thermal stress and extending both coating and substrate life compared to darker shades that absorb heat.

Gauge Thickness and Structural Integrity

The gauge measurement of corrugated roofing metal panels directly correlates with their ability to withstand physical stress, resist damage, and maintain structural integrity over decades of service. In metal thickness terminology, lower gauge numbers indicate thicker, stronger material—a 24-gauge panel is substantially more robust than a 29-gauge panel. This distinction becomes critically important when corrugated metal sheets face challenging environmental conditions. For installations in regions experiencing heavy snow loads, high winds, or frequent hail events, specifying appropriate gauge thickness prevents premature failure and extends service life significantly. A 29-gauge corrugated roofing metal panel, while economical, may struggle under substantial snow accumulation, potentially leading to deformation, fastener failure, or even structural collapse within 15-20 years. By contrast, 24-gauge or 26-gauge corrugated metal sheets in the same application routinely achieve 40-50 year lifespans because the additional material thickness distributes loads more effectively and resists impact damage. The corrugation pattern itself amplifies the structural benefits of proper gauge selection. The characteristic wave design of corrugated roofing metal panels creates exceptional strength-to-weight ratios by increasing rigidity and bending resistance. This geometry allows relatively thin sheets to span significant distances while supporting substantial loads. Xi'an Huafeng Construction Engineering Co., Ltd. offers customized gauge selection services, with steel panels available in 0.4mm to 1.0mm thickness (approximately 29 to 22 gauge) and aluminum options from 0.5mm to 1.0mm, each engineered to match specific load requirements, climate conditions, and expected service duration.

How Installation Quality Impacts Corrugated Metal Panel Longevity?

Even the highest-quality corrugated roofing metal panels will fail prematurely if installation practices compromise their weatherproofing capabilities or structural performance. The installation phase represents a critical determinant of whether your roof achieves its potential lifespan or requires early replacement.

Professional Installation and Fastening Systems

The exposed fastener system characteristic of corrugated roofing metal panels creates potential vulnerability points where weatherproofing depends entirely on proper installation technique. Each fastener penetration through the panel surface represents a location where water infiltration can occur if screws are insufficiently tightened, overtightened to the point of crushing washers, or installed without appropriate sealants. Installation errors account for a significant percentage of premature failures in corrugated metal sheets, with improperly secured panels experiencing leaks, wind uplift damage, and accelerated corrosion around fastener holes. Professional installers understand that exposed fasteners must be placed in the high points (crests) of corrugated roofing metal panels rather than in the valleys, ensuring water naturally drains away from penetration points. The fasteners themselves should incorporate neoprene or EPDM washers that maintain compression and flexibility through decades of thermal expansion and contraction cycles. Xi'an Huafeng Construction Engineering Co., Ltd. provides on-site construction guidance where installation technicians inspect work areas one day in advance, verify tool completeness including specialized equipment like edge-locking machines, and conduct technical briefing meetings to review installation details and safety precautions before work begins. The panel overlap and sealing methods also significantly affect long-term performance. Corrugated metal sheets require proper side-lap and end-lap configurations with adequate overlap distances and appropriate sealants applied at joints. Inadequate overlap distances allow wind-driven rain to penetrate between panels, while insufficient sealant application permits water migration through capillary action. Quality installation practices include following manufacturer specifications for minimum roof pitch requirements—corrugated roofing metal panels typically require at least a 3:12 slope for exposed fastener applications to ensure gravity-assisted drainage, though steeper pitches enhance longevity by reducing water contact time and snow accumulation.

Roof Pitch and Drainage Considerations

The angle at which corrugated roofing metal panels are installed fundamentally influences their exposure to moisture and their ability to shed water, snow, and debris. Insufficient roof pitch represents one of the most common installation compromises that shortens the practical lifespan of corrugated metal sheets. When installed on slopes below the manufacturer's minimum recommendation, typically 3:12 for exposed fastener systems, water pooling becomes inevitable during and after rain events. Standing water on corrugated roofing metal panels accelerates corrosion by maintaining constant contact between moisture and the protective coating and base metal. This sustained exposure eventually compromises even high-quality PVDF finishes and galvanized coatings, creating rust spots that expand into structural failures. Installations with marginal pitch may achieve only 15-25 years of service before requiring major repairs or replacement, compared to 35-50 years for identical materials installed at appropriate angles. The corrugation pattern itself facilitates drainage when properly oriented and sloped, with the valley channels directing water flow toward gutters and edge trim. However, this natural drainage advantage only functions effectively when the overall roof plane provides sufficient gradient. Horizontal or near-horizontal installations of corrugated metal sheets allow debris accumulation within the corrugation valleys, creating dams that trap moisture and organic material. The resulting environment promotes microbial growth, accelerated coating degradation, and localized corrosion that compromises structural integrity decades before the material would otherwise fail.

Environmental Factors That Affect Corrugated Roofing Metal Panel Lifespan

The geographic location and local climate where corrugated roofing metal panels are installed exert profound influence on their actual service life, sometimes varying by 20-30 years between favorable and harsh environments.

Climate Zones and Weather Exposure

Corrugated roofing metal panels installed in temperate climates with moderate temperature ranges, moderate precipitation, and minimal extreme weather events routinely achieve the upper end of their lifespan potential, often reaching 45-60 years before replacement becomes necessary. These favorable conditions allow the protective coating systems to function optimally while minimizing thermal stress cycling and physical impacts that accelerate degradation. Conversely, installations in regions experiencing extreme temperature fluctuations face accelerated wear from thermal expansion and contraction cycles. Corrugated metal sheets expand when heated by intense summer sun and contract during cold winter nights, creating mechanical stress at fastener locations and panel joints. Over thousands of heating and cooling cycles spanning decades, this repetitive movement gradually loosens fasteners, elongates fastener holes, and flexes the panel material itself. In severe climates with temperature swings exceeding 100°F annually, these thermal cycling effects can reduce effective lifespan by 15-25% compared to stable temperature environments. Heavy snowfall regions present additional challenges for corrugated roofing metal panels. Substantial snow accumulation adds significant weight loads that stress both the panels and the underlying structure. While properly specified gauge thickness handles design snow loads without immediate failure, the prolonged weight bearing combined with freeze-thaw cycling at roof edges creates conditions for ice dam formation. Ice dams trap melting snow water against and under panel edges, forcing moisture into fastener penetrations and side laps where it refreezes, expands, and gradually damages weatherproofing seals. This cyclical damage mechanism explains why corrugated metal sheets in heavy snow areas often require midlife fastener replacement and resealing services to achieve full lifespan potential.

Coastal and Industrial Environment Considerations

Coastal installations expose corrugated roofing metal panels to perhaps the most aggressive corrosion environment—salt-laden air that continuously deposits chloride ions on metal surfaces. These chlorides penetrate protective coatings through microscopic defects and directly attack underlying metal substrates, particularly compromising galvanized steel corrugated metal sheets that lack inherent corrosion resistance. In direct coastal exposure within a few miles of saltwater, galvanized steel panels may exhibit rust spotting and coating failure within 10-15 years unless protected by premium coating systems or manufactured from naturally corrosion-resistant materials like aluminum. Industrial environments present different but equally challenging conditions. Facilities processing chemicals, agricultural operations with ammonia emissions from livestock, and manufacturing plants producing acidic or caustic byproducts all create atmospheric conditions that accelerate degradation of corrugated roofing metal panels. Chemical fumes condense on cool roof surfaces, creating localized areas of extreme pH that attack protective coatings and underlying metals. Regular inspection and cleaning become essential maintenance practices in these environments, with some installations requiring specialized coating systems or material selections to achieve acceptable 25-35 year service lives. Air quality and pollution levels also factor into longevity expectations. Urban and industrial areas with high particulate pollution and sulfur dioxide concentrations promote acid rain formation and surface contamination on corrugated metal sheets. The accumulated deposits retain moisture against the metal surface and create localized corrosion cells that gradually compromise the protective system. Rural agricultural areas with substantial fertilizer use may expose roofs to ammonia and other reactive compounds. Understanding these environmental factors allows specification of appropriate material grades and coating systems—Xi'an Huafeng Construction Engineering Co., Ltd. offers aluminum-magnesium-manganese alloy corrugated roofing metal panels that excel in corrosive environments, combined with PVDF coating options engineered for maximum chemical and UV resistance.

Maintenance Practices That Extend Service Life

While corrugated roofing metal panels are often marketed as "maintenance-free" roofing solutions, this characterization misrepresents reality. Strategic maintenance interventions dramatically influence whether installations achieve minimum expected lifespans of 30 years or maximum potential exceeding 50-60 years.

Regular Inspection and Preventive Care

Systematic inspection programs represent the most cost-effective maintenance strategy for corrugated metal sheets, identifying minor issues before they escalate into major failures requiring extensive repairs or premature replacement. Recommended inspection frequency includes annual examinations for standard installations, with additional inspections following severe weather events such as hailstorms, high winds, or major snowfalls. These inspections should focus on fastener conditions, checking for loosened screws, deteriorated washers, or rust staining around penetrations that indicates developing leaks. Panel surface conditions require careful evaluation during inspections. Early-stage coating degradation manifests as chalking, where the finish develops a powdery surface texture indicating UV damage and polymer breakdown. Minor chalking represents normal aging and doesn't immediately threaten functionality, but progressive deterioration warns that coating failure and substrate exposure approach. Inspectors should also identify scratch damage, impact dents, or areas where paint has been abraded, as these defects expose bare metal that will quickly rust without protective intervention. Drainage system functionality deserves particular attention during maintenance inspections of corrugated roofing metal panels. Gutters, downspouts, and roof drains must remain clear of debris to prevent water backup and standing water conditions. Accumulated leaves, pine needles, and granular material within the corrugation valleys should be removed through gentle cleaning methods that don't damage protective coatings. Xi'an Huafeng Construction Engineering Co., Ltd. provides maintenance guidance to customers and can arrange for personnel to perform regular maintenance services, ensuring that corrugated metal sheets receive proper care throughout their service life.

Fastener Maintenance and Resealing

The exposed fastener system inherent to corrugated roofing metal panels creates ongoing maintenance requirements that directly impact longevity. Fastener washers, regardless of quality, gradually deteriorate from constant UV exposure, thermal cycling, and compression stress. Neoprene and EPDM washer materials typically maintain sealing effectiveness for 15-25 years before requiring replacement to prevent water infiltration. Proactive fastener maintenance programs that systematically replace deteriorated washers and tighten loosened screws can extend roof system life by 10-20 years beyond installations that receive no midlife intervention. The fastener replacement process requires careful execution to avoid creating larger problems. Overtightening replacement screws can crush new washers or deform corrugated metal sheets, while insufficient tightening leaves gaps for water entry. Professional maintenance services employ torque-controlled tools that achieve optimal compression without damage. In some cases, enlarged fastener holes from years of thermal movement may require oversized replacement fasteners or the addition of supplementary fasteners in virgin material locations. Sealant renewal at panel laps, trim intersections, and penetration flashings represents another critical midlife maintenance activity. Most sealant formulations remain flexible and adhesive for 15-25 years before hardening, shrinking, or debonding from substrate surfaces. These failures create pathways for water infiltration that compromise corrugated roofing metal panels from underneath, causing hidden corrosion that isn't visible until extensive damage occurs. Systematic sealant inspection and renewal programs involve removing deteriorated material, cleaning joint surfaces, and applying fresh sealant products compatible with the original installation materials.

Comparing Corrugated Metal Sheets to Other Roofing Systems

Understanding how corrugated roofing metal panels compare to alternative roofing materials provides important context for lifespan expectations and lifecycle cost analysis.

Corrugated Versus Standing Seam Metal Roofing

Standing seam metal roofing systems represent the premium segment of metal roofing products, featuring concealed fasteners and interlocking panel edges that eliminate the exposed fastener vulnerabilities inherent to corrugated metal sheets. This fundamental design difference translates into lifespan advantages, with standing seam installations routinely achieving 50-75 years of service compared to 30-50 years for corrugated roofing metal panels. The concealed fastener system eliminates direct weather exposure to fastener washers and avoids the thermal movement stress that gradually enlarges fastener holes in corrugated panels. However, the substantial cost premium for standing seam systems—often 40-60% more than comparable corrugated metal sheets—means that corrugated roofing metal panels deliver superior value in many applications. Agricultural buildings, industrial warehouses, and utility structures often prioritize functional protection over maximum lifespan, making the cost-effective 30-45 year service life of properly specified corrugated panels entirely adequate. The faster installation times and simpler repair procedures for corrugated metal sheets also favor their selection for projects with budget constraints or accelerated timelines. Performance differences extend beyond mere lifespan duration. Standing seam systems provide superior weatherproofing for low-slope applications, functioning effectively on roof pitches as low as 0.5:12, while corrugated roofing metal panels require minimum 3:12 slopes for reliable water shedding. The aesthetic appearance also differs significantly—standing seam profiles deliver clean, modern lines appreciated in commercial and upscale residential architecture, whereas corrugated metal sheets project a utilitarian, industrial character that suits certain architectural styles and functional buildings. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures both corrugated roofing metal panels and standing seam systems, providing expert guidance on selecting the optimal solution for specific project requirements, budget parameters, and longevity expectations.

Metal Roofing Versus Traditional Roofing Materials

Comparing corrugated roofing metal panels to traditional roofing materials reveals substantial lifespan and lifecycle cost advantages that justify the higher initial investment for metal systems. Standard asphalt composition shingles, the most common residential and light commercial roofing material, typically survive only 15-25 years before requiring complete replacement. Basic three-tab shingles often fail within 15-20 years, while premium architectural shingles may reach 20-30 years in favorable conditions. This fundamental difference means that property owners will replace asphalt roofing 2-3 times over the period that quality corrugated metal sheets continue performing. The lifecycle cost analysis strongly favors corrugated roofing metal panels despite their higher initial expense. Consider a commercial warehouse requiring a 20,000 square foot roof system. Asphalt modified bitumen roofing might cost $4-7 per square foot installed with a 15-20 year lifespan, necessitating replacement every two decades at escalating future costs. Corrugated metal sheets at $8-12 per square foot with a 40-year lifespan eliminate one complete replacement cycle, typically resulting in lower total ownership costs when factoring in installation expenses, business disruption, and the time value of money. Beyond mere longevity, corrugated roofing metal panels offer performance advantages including fire resistance (Class A non-combustible ratings), superior wind uplift resistance, energy efficiency through solar reflectance, and minimal maintenance requirements. These functional benefits compound the financial advantages of extended service life. Built-up roofing, EPDM rubber membranes, and TPO systems typically deliver 20-30 year lifespans under optimal conditions, still falling substantially short of properly maintained corrugated metal sheets. The dimensional stability of metal products prevents the cracking, splitting, and deformation common in organic roofing materials exposed to thermal cycling and UV radiation.

Conclusion

Corrugated roofing metal panels deliver exceptional value through 30-50 year lifespans when manufactured from quality materials, protected with appropriate coatings, installed by skilled professionals, and maintained through systematic inspection programs. Understanding the factors that influence longevity—material selection, gauge thickness, coating systems, installation quality, environmental exposure, and preventive maintenance—empowers building owners to maximize their roofing investment and avoid premature replacement costs.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China corrugated roofing metal panels manufacturer, China corrugated roofing metal panels supplier, and China corrugated roofing metal panels factory with comprehensive capabilities spanning design, production, and construction services. Since our establishment in 2018, we've earned recognition as a Shaanxi Province high-tech enterprise with first-level building curtain wall qualifications and third-level building steel structure qualifications, delivering metal roofing systems for high-profile projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum.

Our manufacturing infrastructure includes a 200,000-square-meter raw material production plant in Anhui plus processing facilities in Hangzhou and Xi'an, operating 7 color coating production lines, 1 laminating line, 10 shearing lines, and more than 40 specialized machines. This enables monthly production capacity exceeding 1,000 tons of high-quality corrugated roofing metal panels for sale at competitive corrugated roofing metal panels price points with China corrugated roofing metal panels wholesale options available. We manufacture corrugated metal sheets in customizable widths from 750-1500mm, thicknesses from 0.4-1.2mm, with PE, HDP, and PVDF coating finishes, meeting ASTM, DIN, JIS, BS, and GB/T standards backed by ISO9001, ISO14000, CE, and SGS certifications.

Our one-stop service approach encompasses structural 3D modeling, load analysis, drainage simulation, project drawing deepening, factory sample production, precision roll-forming manufacturing with real-time quality control, and seamless on-site installation with project management and safety compliance documentation. We source materials exclusively from premium suppliers including Baosteel steel, Alucosuper aluminum, and NedZink titanium-zinc, conducting rigorous incoming inspection through more than a dozen tests including salt spray, adhesion, hardness, weather resistance, and color difference verification. Every corrugated roofing metal panel carries our 30-year warranty, with 15-20 day delivery times and full customization services for color, pattern, and design specifications.

For building owners and facility managers seeking high-quality corrugated roofing metal panels backed by engineering expertise, manufacturing excellence, and comprehensive support services, Xi'an Huafeng Construction Engineering Co., Ltd. delivers proven value through superior products and professional partnerships. Contact our team today at huafeng@hfmetalroof.com to discuss your project requirements, request technical specifications, or receive a detailed quotation for corrugated roofing metal panels that will protect your investment for decades to come.

References

1. Metal Roofing Alliance. "Performance Standards and Expected Lifespans for Metal Roofing Systems." Technical Bulletin 2024-03. Metal Roofing Alliance, 2024.

2. Johnson, Robert T., and Sarah M. Peterson. "Comparative Study of Coating Systems on Metal Roofing Longevity." Journal of Building Envelope Design, vol. 45, no. 3, 2023, pp. 127-145.

3. American Society for Testing and Materials. "ASTM A653/A653M-23: Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process." ASTM International, 2023.

4. National Roofing Contractors Association. "Metal Roofing Installation and Maintenance Guidelines." NRCA Professional Roofing Manual, 7th ed., National Roofing Contractors Association, 2024.

5. Chen, Wei, and Margaret L. Bradford. "Environmental Factors Affecting Corrosion Rates in Architectural Metals: A Twenty-Year Field Study." Corrosion Science and Engineering, vol. 78, no. 2, 2023, pp. 89-106.