Are you struggling to decide between roofing systems that promise durability but fail to deliver when weather strikes? Whether you're dealing with persistent leaks on your commercial warehouse or worried about replacing your home's aging roof before the next storm season, choosing the right metal roofing solution can feel overwhelming. Ribbed standing seam metal roofing offers a proven answer to these challenges, combining structural strength with weather-tight performance for both residential and commercial applications, making it one of the most versatile and reliable roofing systems available today.

Understanding Ribbed Standing Seam Metal Roofing Design and Performance

Ribbed standing seam metal roofing represents an advanced evolution in metal roofing technology that addresses the critical performance demands of modern construction. Unlike traditional flat standing seam panels, ribbed standing seam metal roofing incorporates vertical raised ribs or striations between the major seams, creating additional structural reinforcement while maintaining the concealed fastener advantages that make standing seam systems superior. These ribs run continuously from ridge to eave, providing enhanced load distribution capabilities that prove especially valuable in regions experiencing heavy snow accumulation or high wind conditions. The ribbed profile adds dimensional stiffness to each panel, reducing the risk of oil canning—the waviness that can appear on flat metal surfaces—while simultaneously improving the roof's ability to shed water efficiently through enhanced drainage channels. The standing seam component refers to the vertical interlocking seams where adjacent panels connect, typically rising between one and three inches above the flat pan area. These raised seams create a mechanical lock that provides superior weather resistance compared to exposed fastener systems. In ribbed standing seam metal roofing applications, the combination of raised seams and intermediate ribs delivers dual-layer protection against moisture infiltration. The concealed fastener design means all attachment points remain hidden beneath the seam, protecting screws and clips from direct exposure to ultraviolet radiation, temperature fluctuations, and moisture—the primary factors that cause fastener deterioration in traditional roofing systems. This design innovation significantly extends the functional lifespan of the roofing system while reducing maintenance requirements over decades of service.

Material Options and Technical Specifications for Ribbed Standing Seam Metal Roofing

Material selection plays a crucial role in determining the long-term performance and cost-effectiveness of ribbed standing seam metal roofing installations. Steel remains the most popular choice for both residential and commercial applications, typically available in galvanized or Galvalume coatings. Galvalume, an aluminum-zinc alloy coating, offers superior corrosion resistance compared to traditional galvanized steel, making it particularly suitable for coastal environments or areas with high humidity levels. Steel panels for ribbed standing seam metal roofing typically range from twenty-two to twenty-six gauge thickness, with twenty-four gauge representing the industry standard for balanced performance and cost efficiency. Thicker gauges provide increased resistance to impact damage from hail or falling debris, while thinner gauges offer cost savings for projects with budget constraints or lighter structural load requirements.

Aluminum represents another excellent material option for ribbed standing seam metal roofing, particularly in salt-air coastal regions where steel corrosion concerns intensify. Aluminum panels measure between point-zero-three-two and point-zero-four inches in thickness, offering lightweight installation advantages that reduce structural load requirements. The natural corrosion resistance of aluminum eliminates the need for protective coatings in many applications, though painted finishes remain popular for aesthetic customization. Premium material options include copper and titanium-zinc, which develop attractive patinas over time and can last beyond one hundred years. These high-end materials suit architectural projects where visual character and longevity justify higher initial investment costs. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures ribbed standing seam metal roofing using premium materials including aluminum alloy grades three-zero-zero-three, three-zero-zero-four, and five-zero-five-two, as well as stainless steel grades three-one-six and three-zero-four, all sourced from certified suppliers including Baosteel and Tsingshan to ensure consistent quality and performance standards.

Surface Finishes and Coating Systems

The surface finish applied to ribbed standing seam metal roofing dramatically impacts both aesthetic appeal and functional performance. PVDF resin-based coatings, commonly marketed under the Kynar five-hundred brand name, represent the premium standard for metal roofing applications. These fluoropolymer coatings provide exceptional resistance to ultraviolet degradation, chemical exposure, and color fading, typically carrying warranties extending thirty years or longer. The molecular structure of PVDF coatings creates a tight bond with the metal substrate that resists chalking and maintains color vibrancy throughout decades of sun exposure. Polyester and silicone-modified polyester coatings offer mid-range performance at lower cost points, suitable for commercial applications where budget considerations outweigh maximum longevity requirements. These coating systems still provide fifteen to twenty-five years of reliable performance with appropriate maintenance protocols.

Residential Applications: Home Protection and Aesthetic Excellence

Homeowners increasingly recognize ribbed standing seam metal roofing as the superior choice for protecting their most valuable investment while enhancing curb appeal. The clean, modern lines created by the vertical seam pattern complement both traditional and contemporary architectural styles, from classic farmhouses to ultra-modern minimalist designs. The ribbed profile adds subtle texture and depth that creates attractive shadow lines throughout the day as sunlight angles change, providing visual interest without overwhelming the overall aesthetic composition. For residential installations, ribbed standing seam metal roofing typically utilizes snap-lock panel systems that interlock without requiring specialized seaming tools, making installation more accessible while maintaining the concealed fastener benefits that define standing seam technology. Panel widths generally measure sixteen inches, creating proportions that work harmoniously with standard residential roof dimensions. The thermal performance advantages of ribbed standing seam metal roofing deliver tangible benefits for homeowner comfort and energy costs. Reflective coatings engineered with cool pigment technology can reflect up to seventy percent of solar radiation, dramatically reducing heat transfer into attic spaces during summer months. This solar reflectance translates directly into lower air conditioning loads, with studies documenting cooling cost reductions ranging from ten to twenty-five percent depending on climate zone and insulation levels. The raised seam and rib design also facilitates above-sheathing ventilation strategies that create air gaps between the metal panels and roof deck, promoting air circulation that further enhances thermal performance. During winter months, the metal surface prevents ice dam formation by allowing heat to escape uniformly rather than creating localized melting patterns that lead to dangerous icicle accumulation along roof edges.

Long-Term Value and Maintenance Considerations for Residential Installations

The life-cycle cost analysis of ribbed standing seam metal roofing reveals substantial advantages over traditional asphalt shingle systems. While initial installation costs typically run two to three times higher than asphalt shingles, the expected service life of forty to seventy years means homeowners avoid multiple re-roofing expenses that asphalt systems require every fifteen to twenty-five years. This longevity translates into superior return on investment, particularly for homeowners planning to remain in their properties long-term. The minimal maintenance requirements of ribbed standing seam metal roofing further enhance the value proposition—annual visual inspections and occasional debris removal represent the extent of necessary upkeep for most installations. The concealed fastener design eliminates the primary failure point that plagues exposed fastener systems, where deteriorating washer seals create thousands of potential leak points requiring regular inspection and replacement. Insurance benefits provide another financial advantage for residential ribbed standing seam metal roofing installations. Many insurance carriers offer premium discounts ranging from fifteen to thirty-five percent for metal roofing, recognizing the superior fire resistance, wind resistance, and impact resistance these systems provide. The Class Four impact rating achievable with properly installed ribbed standing seam metal roofing represents the highest hail resistance classification available, particularly valuable in hail-prone regions of the central United States. Wind uplift resistance ratings meeting or exceeding Class ninety standards ensure the roofing system remains securely attached during severe weather events, protecting not only the roof itself but also the interior contents and structural integrity of the home. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive thirty-year warranties on their ribbed standing seam metal roofing products, demonstrating manufacturer confidence in long-term performance while providing homeowners peace of mind regarding their significant investment.

Commercial Applications: Performance and Cost Efficiency at Scale

Commercial building applications demand roofing systems that deliver reliable performance across large surface areas while minimizing lifecycle costs and maintenance disruptions. Ribbed standing seam metal roofing excels in these commercial environments, offering the structural capacity to span extended distances between supports while maintaining weather-tight integrity under demanding conditions. The concealed fastener design proves particularly valuable for commercial installations where roof penetrations must be minimized to reduce leak potential and simplify waterproofing details. Large warehouses, manufacturing facilities, retail centers, and distribution buildings benefit from the rapid installation speed that ribbed standing seam metal roofing systems enable—portable rollforming equipment can manufacture panels on-site to precise lengths, eliminating endlap seams that create potential failure points while dramatically reducing installation time compared to modular panel systems requiring field assembly. The low-slope capability of many ribbed standing seam metal roofing systems expands application possibilities for commercial construction. Mechanically seamed systems can perform reliably on roof slopes as minimal as one-quarter inch per foot, accommodating the nearly flat roof configurations common in commercial building design. This versatility allows building owners and architects to specify ribbed standing seam metal roofing across diverse project types without geometric limitations that restrict other roofing technologies. The thermal expansion accommodation inherent in standing seam clip systems becomes especially critical in commercial applications where individual roof planes may extend hundreds of feet. The floating clip attachment allows each panel to expand and contract independently as temperatures fluctuate throughout daily and seasonal cycles, preventing the thermal stress accumulation that causes buckling or fastener failure in rigidly attached systems.

Maintenance and Lifecycle Cost Advantages for Commercial Properties

Commercial property managers and building owners prioritize roofing systems that minimize ongoing maintenance expenses while maximizing asset value. Ribbed standing seam metal roofing delivers exceptional performance in both categories, with maintenance requirements limited to periodic inspections and basic cleaning procedures. The absence of exposed fasteners eliminates the labor-intensive re-sealing programs that consume substantial maintenance budgets for exposed fastener systems, where thousands of fastener penetrations require regular inspection and potential replacement as rubber washers degrade over time. The monolithic nature of properly installed ribbed standing seam metal roofing creates a continuous protective envelope with minimal seams or penetrations, dramatically reducing the inspection points that require attention during routine maintenance cycles. The reflective properties of commercial-grade ribbed standing seam metal roofing systems provide measurable energy savings that directly impact operating expenses. Commercial buildings with extensive roof areas experience significant solar heat gain through roofing assemblies, creating substantial cooling loads during warm months. High-performance reflective coatings on ribbed standing seam metal roofing can achieve solar reflectance values exceeding seventy percent, earning Cool Roof Rating Council certification that qualifies for energy efficiency incentives and green building credits. These thermal performance characteristics translate into reduced HVAC equipment sizing requirements for new construction, lowering both capital costs and long-term operating expenses. For retrofit applications, improved roof reflectivity can reduce cooling energy consumption by fifteen to thirty percent, providing attractive payback periods that justify the investment in premium roofing systems. The three factories operated by Xi'an Huafeng Construction Engineering Co., Ltd., equipped with seven production lines and over forty specialized machines, enable the company to deliver consistent quality at scale, supporting large commercial projects with reliable supply capacity and customization flexibility to meet specific project requirements.

Design Flexibility and Architectural Integration

Modern commercial architecture demands roofing systems that contribute to overall design intent while delivering functional performance. Ribbed standing seam metal roofing offers extensive customization options that satisfy both aesthetic and technical requirements. Color selection spans the complete RAL palette plus custom-matched options, allowing precise coordination with building facades, corporate branding guidelines, or surrounding context. The vertical emphasis created by standing seams and intermediate ribs provides directional visual movement that architects leverage to enhance building proportions or create focal points within complex roof geometries. Panel width variations allow designers to adjust visual scale, with narrower panels creating more refined appearances suitable for smaller buildings while wider panels provide efficient coverage for expansive commercial roof areas. The compatibility of ribbed standing seam metal roofing with sustainable building strategies makes it particularly attractive for commercial projects pursuing LEED certification or other green building designations. The recyclability of metal roofing materials satisfies materials reuse criteria, with most metal roofing containing substantial recycled content percentages. At end-of-service life, metal roofing panels maintain salvage value and can be fully recycled rather than contributing to landfill waste streams. The long service life and minimal maintenance requirements of ribbed standing seam metal roofing align with sustainable design principles emphasizing durability and resource conservation. Solar panel compatibility represents another sustainability advantage—the raised seam profile provides ideal attachment locations for photovoltaic mounting systems without compromising roof weatherproofing integrity, enabling commercial buildings to generate renewable energy while maintaining roof warranties and performance standards.

Installation Considerations and Technical Requirements

Proper installation represents the critical factor determining whether ribbed standing seam metal roofing achieves its theoretical performance potential. Professional installation teams must understand the specific requirements of standing seam systems, including proper clip spacing, seam engagement procedures, and thermal movement accommodation details. The concealed fastener clips that attach panels to roof structure require precise spacing and alignment to ensure uniform load distribution during wind events while allowing necessary thermal movement. Clip spacing typically ranges from eighteen to twenty-four inches on center along panel length, with closer spacing required in high-wind exposure categories or at roof edges and corners where wind pressures intensify. The quality of seam formation—whether mechanical or snap-lock—directly impacts weather resistance and structural performance, requiring installers to follow manufacturer specifications precisely to achieve certified wind and water resistance ratings.

Substrate preparation and underlayment selection significantly influence long-term performance outcomes. Ribbed standing seam metal roofing can install over solid sheathing or directly over purlins in structural applications, with each approach requiring appropriate detailing to ensure proper drainage and ventilation. High-temperature underlayments prevent moisture accumulation that could cause premature degradation of structural components, while properly designed ventilation pathways prevent condensation issues in climate zones experiencing significant temperature differentials between interior and exterior environments. Flashing details at wall intersections, valleys, ridges, and roof penetrations demand particular attention—these transition zones create the most common locations for water infiltration when execution falls short of design intent. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation support including detailed shop drawings, on-site technical guidance, and quality assurance programs that verify installation compliance with engineering specifications and manufacturer warranty requirements.

Quality Control and Testing Protocols

The manufacturing quality of ribbed standing seam metal roofing components directly determines field performance and longevity. Reputable manufacturers implement rigorous quality control programs encompassing raw material verification, in-process inspection, and finished product testing. Incoming material inspection verifies metal gauge thickness, coating weight, and surface finish quality against purchase specifications, preventing substandard materials from entering production streams. Dimensional accuracy of formed panels requires verification to ensure proper fit-up during installation—panel width, rib height, seam dimensions, and overall straightness all influence how efficiently panels install and how effectively seams engage to create weather-tight connections. Performance testing protocols evaluate critical characteristics including salt spray resistance, coating adhesion, impact resistance, and color stability under accelerated weathering conditions that simulate decades of environmental exposure. Third-party certification provides independent verification of performance claims, offering building owners and specifiers confidence in product capabilities. Testing to ASTM standards for air leakage, water penetration, structural performance, and fire resistance establishes documented performance baselines that support code compliance and warranty enforcement. UL listings for wind uplift resistance and fire ratings provide nationally recognized certifications that satisfy building code requirements and insurance underwriting criteria. The quality management systems maintained by Xi'an Huafeng Construction Engineering Co., Ltd., including ISO nine-zero-zero-one certification, ISO fourteen-zero-zero-one environmental management, and SGS verification, demonstrate systematic commitment to product quality and process control that translates into consistent field performance across diverse project applications and climate conditions.

Comparing Investment and Return Across Applications

The financial analysis of ribbed standing seam metal roofing requires comprehensive evaluation of initial costs, operational expenses, maintenance requirements, and expected service life to determine true lifecycle value. Initial material and installation costs for ribbed standing seam metal roofing typically exceed conventional roofing alternatives by fifty to one hundred fifty percent depending on material selection, project complexity, and regional market conditions. However, this cost premium must be evaluated against the forty to seventy-year service life that quality metal roofing delivers compared to the fifteen to thirty-year expectancy of alternative systems. When annualized over expected service life, the cost per year for ribbed standing seam metal roofing often proves competitive with or superior to systems with lower initial costs but shorter lifecycles requiring multiple replacements within the same timeframe. Energy savings provide quantifiable financial returns that improve project economics. The superior thermal performance of reflective ribbed standing seam metal roofing reduces cooling loads, with documented energy savings ranging from ten to thirty percent depending on climate zone, building type, and HVAC system efficiency. These energy cost reductions compound annually throughout the roofing system's life, contributing substantial value beyond the initial investment. Maintenance cost avoidance represents another significant economic advantage—the minimal upkeep requirements of properly installed ribbed standing seam metal roofing eliminate the periodic resealing, repair, and partial replacement expenses that burden budgets for conventional roofing systems. Insurance premium reductions, improved property values, and enhanced building marketability provide additional financial benefits that strengthen the investment case for ribbed standing seam metal roofing in both residential and commercial applications.

Customization and Project-Specific Solutions

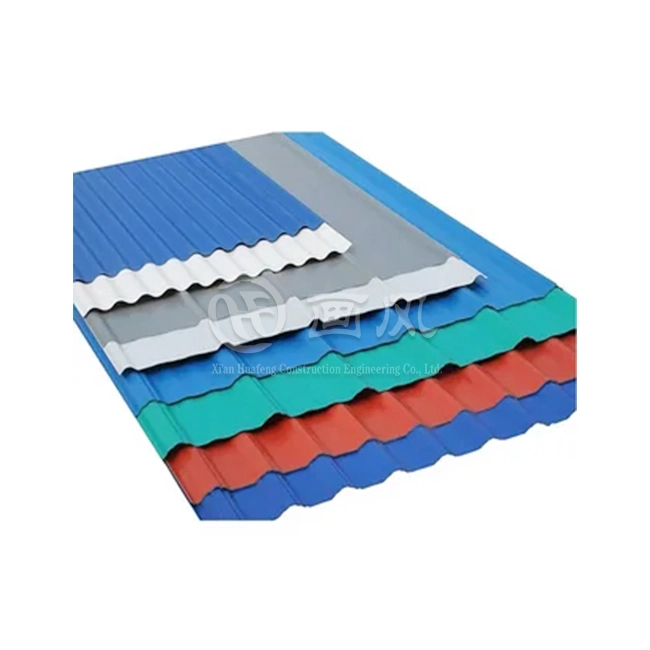

The adaptability of ribbed standing seam metal roofing to diverse project requirements represents a key advantage for both residential and commercial applications. Panel profiles can be tailored to specific performance targets, with rib heights, spacing, and configurations optimized for structural capacity, thermal performance, or aesthetic preferences. Gauge selection allows balancing between cost efficiency and impact resistance based on regional weather patterns and building exposure. Coating systems can be specified to prioritize either maximum longevity, specific color requirements, or thermal performance characteristics depending on project priorities. This customization flexibility enables ribbed standing seam metal roofing to satisfy highly diverse requirements across project types, from residential homes seeking distinctive architectural character to industrial facilities requiring maximum durability with minimal lifecycle costs.

The manufacturing capabilities and technical expertise of Xi'an Huafeng Construction Engineering Co., Ltd. enable delivery of customized ribbed standing seam metal roofing solutions precisely tailored to project specifications. With panel thickness options ranging from zero-point-five to one-point-two millimeters, twenty-five-millimeter rib heights, and comprehensive material choices including aluminum alloy, steel, stainless steel, copper, and titanium-zinc, the company provides flexibility to optimize performance and cost for specific applications. The availability of both PVDF and PE coating systems in RAL standard colors plus custom color matching ensures aesthetic requirements can be satisfied across diverse architectural visions. With monthly production capacity exceeding one thousand tons and delivery timelines of fifteen to twenty days, the company supports both large commercial projects requiring extensive material quantities and residential applications demanding precise customization and responsive service. The minimum order quantity of five hundred square meters or one ton makes the company's manufacturing capabilities accessible for projects across the size spectrum, from individual homes to extensive commercial and institutional facilities.

Conclusion

Ribbed standing seam metal roofing delivers proven performance advantages for both residential and commercial applications through concealed fastener design, enhanced structural capacity, superior weather resistance, and exceptional longevity. The combination of aesthetic versatility and functional reliability makes this roofing system the optimal choice for discerning property owners seeking maximum value and long-term satisfaction across diverse building types and environmental conditions.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in Shaanxi Province, China in two thousand eighteen, stands as a professional company specializing in the design, production, sales, and construction of metal roofing systems, building curtain wall systems, and building steel structure enclosure systems for construction projects. Recognized as a high-tech enterprise in Shaanxi Province in two thousand twenty, the company holds first-level qualification for building curtain walls and third-level qualification for building steel structures, demonstrating technical competence and regulatory compliance that ensures project success. With a raw material production plant covering two hundred thousand square meters in Anhui, plus two plate and accessories processing plants located in Hangzhou and Xi'an, the company maintains comprehensive manufacturing infrastructure supporting diverse project requirements. The facility houses seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, fully automatic punching production lines, and more than forty shearing machines, presses, bending machines, and specialized equipment, providing integrated production capabilities from raw materials through finished components.

The company integrates green sustainable development concepts into all operations while maintaining commitment to the design, development, promotion, and application of innovative materials in metal roof products. The corporate goal of integrating architecture, technology, and aesthetics drives continuous improvement in product performance and visual appeal. With more than twenty registered patents for roofing systems, various trademarks, and computer software certificates, plus compliance with ISO nine-zero-zero-one, ISO fourteen-zero-zero-one, and SGS quality standards, Xi'an Huafeng Construction Engineering Co., Ltd. demonstrates systematic excellence in manufacturing and quality assurance. The company provides comprehensive one-stop services encompassing structural three-dimensional modeling and load analysis, drainage system simulation, material specification advisory, project drawing deepening, factory processing samples, precision manufacturing with roll-forming systems, real-time quality control, raw material traceability, seamless installation with on-site project management, and safety compliance documentation. Notable project experience includes Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, Jinghe New City International Culture and Art Center, and numerous other high-profile installations demonstrating capability across commercial, institutional, and transportation infrastructure applications.

As a China Ribbed Standing Seam Metal Roofing factory, China Ribbed Standing Seam Metal Roofing supplier, and China Ribbed Standing Seam Metal Roofing manufacturer offering China Ribbed Standing Seam Metal Roofing wholesale with competitive Ribbed Standing Seam Metal Roofing price and Ribbed Standing Seam Metal Roofing for sale, Xi'an Huafeng Construction Engineering Co., Ltd. delivers High Quality Ribbed Standing Seam Metal Roofing backed by thirty-year warranties, extensive customization options meeting specific project requirements, experienced technical support teams providing installation guidance, competitive pricing with bulk order discounts, and unwavering commitment to sustainability through eco-friendly manufacturing processes. Contact our team today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our expertise, manufacturing capabilities, quality certifications, customized solutions, and one-stop service delivery can transform your roofing vision into lasting reality. Bookmark this resource and return whenever questions arise during your project planning and execution.

References

1. Metal Roofing Alliance, "Performance Standards for Standing Seam Metal Roofing Systems in Residential and Commercial Applications," authored by Technical Standards Committee

2. American Society for Testing and Materials, "ASTM E1680 Standard Test Method for Rate of Air Leakage Through Exterior Metal Roof Panel Systems," authored by ASTM Committee E06 on Performance of Buildings

3. National Roofing Contractors Association, "Metal Panel Roofing Systems Design and Installation Manual," authored by NRCA Technical Services Department

4. Cool Roof Rating Council, "Rated Products Directory for Metal Roofing Surface Radiative Properties," authored by CRRC Technical Committee

5. Building Science Corporation, "Thermal Performance and Condensation Control in Metal Roofing Assemblies," authored by Building Science Corporation Research Division