Are you frustrated with constant roof repairs, water leaks during storms, and mounting maintenance costs? Traditional roofing systems with exposed fasteners leave building owners vulnerable to weather damage, frequent screw replacements, and shortened roof lifespans. The Snap Clad Standing Seam Roof Panel offers a revolutionary alternative, delivering concealed fastener technology, superior weather resistance, and a 30-year warranty that eliminates these persistent problems while providing exceptional durability and aesthetic appeal.

Understanding Snap Clad Standing Seam Roof Panel Technology

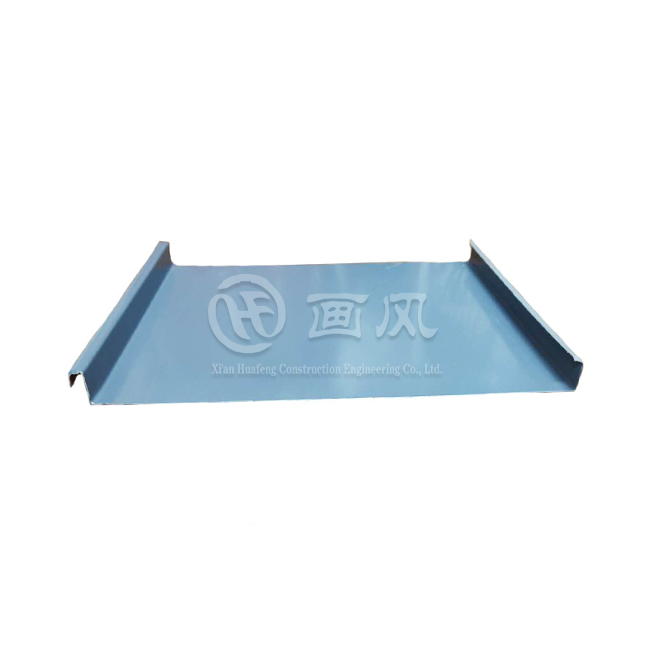

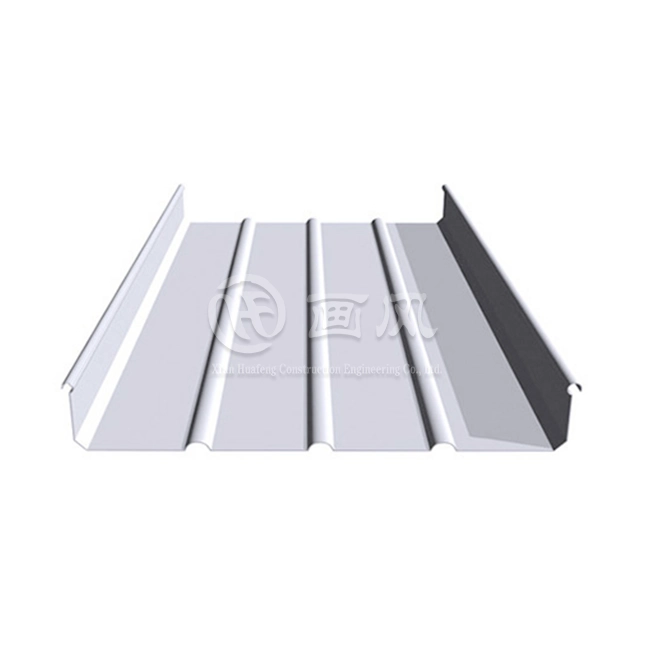

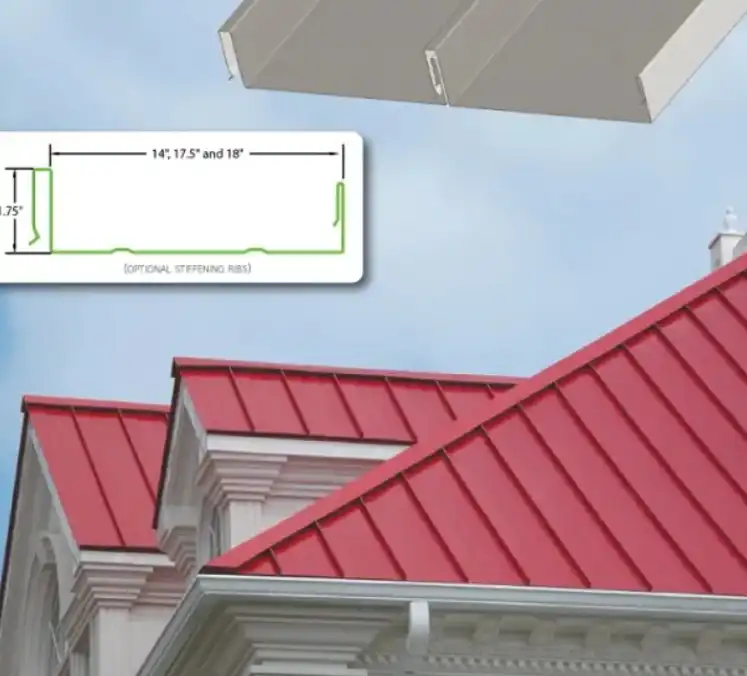

The Snap Clad Standing Seam Roof Panel represents a significant advancement in modern roofing engineering. Unlike conventional roofing systems that rely on exposed fasteners penetrating the weatherproof surface, this innovative system utilizes a concealed clip mechanism that attaches panels securely to the roof deck while keeping all fasteners hidden beneath the metal surface. This fundamental design difference addresses the primary weakness of traditional roofing, where each exposed screw creates a potential entry point for moisture infiltration. The snap-lock technology features precisely engineered male and female edges that interlock seamlessly, creating continuous weather barriers along every seam. Manufacturing facilities produce these panels through advanced roll-forming processes that ensure dimensional accuracy and consistent quality across every linear foot. The system accommodates thermal expansion and contraction through floating clip assemblies, allowing the metal to move naturally with temperature fluctuations without compromising the roof's integrity or creating stress points that could lead to failure.

Key Performance Features of Snap Clad Standing Seam Roof Panel Systems

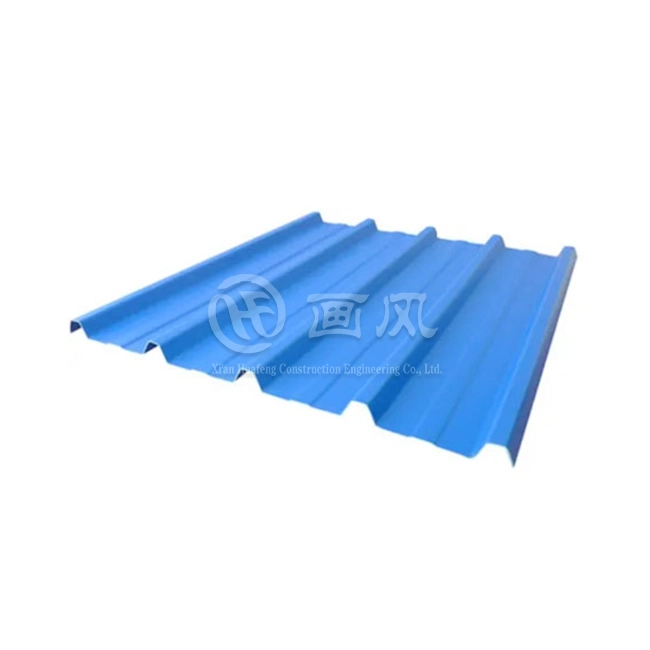

Modern Snap Clad Standing Seam Roof Panel installations deliver exceptional performance characteristics that traditional roofing simply cannot match. The concealed fastener design eliminates the weathertightness vulnerabilities inherent in screw-down systems, where rubber washers deteriorate over time and create leak pathways. Panel profiles typically feature seam heights ranging from 45-50mm, providing robust structural performance and excellent wind uplift resistance that meets stringent commercial building codes. Material options include aluminum alloy, Galvalume steel, stainless steel, copper, and titanium zinc, with thickness specifications from 0.5-1.2mm to accommodate various load requirements and environmental conditions. Premium PVDF and PE coating systems protect against UV degradation, acid rain, salt spray, and industrial pollutants, maintaining color integrity and surface quality for decades. The snap-together installation methodology reduces labor requirements significantly compared to mechanically seamed alternatives, while still delivering commercial-grade weatherproofing performance. Engineering certifications validate wind resistance ratings, fire classifications, and structural load capacities, ensuring compliance with international standards including ASTM, DIN, JIS, BS, and GB/T specifications.

Installation Advantages and Efficiency Benefits

Installation efficiency represents one of the most compelling advantages of Snap Clad Standing Seam Roof Panel systems compared to traditional roofing approaches. Contractors can complete installations faster because the snap-lock mechanism eliminates the need for specialized seaming equipment that mechanical lock systems require. Each panel simply snaps into place over pre-positioned clips, creating secure connections without hand-forming operations or mechanical crimping processes. This streamlined installation methodology reduces on-site labor hours by approximately thirty to forty percent compared to double-lock mechanical seam installations, translating directly into lower project costs and faster building occupancy schedules. The system's design accommodates roof pitches as low as 2:12 in most applications, expanding the range of structures suitable for standing seam technology. Pre-engineered panel systems arrive at jobsites with factory-applied finishes and precisely cut lengths, minimizing field modifications and reducing waste generation. Quality control processes implemented during manufacturing ensure dimensional consistency that facilitates smooth installation workflows, while the absence of specialized equipment requirements makes the system accessible to a broader range of qualified roofing contractors.

Snap Clad Standing Seam Roof Panel vs Traditional Metal Roofing Systems

The performance gap between Snap Clad Standing Seam Roof Panel installations and traditional exposed fastener metal roofing becomes increasingly apparent over the lifecycle of the building. Traditional screw-down metal roofs attach corrugated or ribbed panels directly to structural purlins using self-tapping screws with neoprene or EPDM washers. These rubber seals constitute the primary waterproofing barrier, yet they face constant exposure to ultraviolet radiation, temperature cycling, and environmental contaminants that accelerate degradation. Within five to ten years, washer deterioration typically begins, allowing moisture penetration that leads to substrate damage and interior leaks. Maintenance requirements intensify as building owners face recurring expenses for screw replacement programs, typically recommended every decade to prevent widespread failure. The thermal cycling inherent in metal roofing causes continuous expansion and contraction that stresses fastener holes, gradually enlarging them and further compromising weathertightness. In contrast, Snap Clad Standing Seam Roof Panel systems isolate all fastening components beneath the weather surface, protecting them from environmental exposure while allowing unrestricted thermal movement through floating clip assemblies.

Weatherproofing Performance Comparison

Weatherproofing capabilities distinguish Snap Clad Standing Seam Roof Panel technology from conventional roofing alternatives in fundamental ways. Traditional exposed fastener systems create hundreds or thousands of penetration points across the roof surface, each representing a potential leak location that requires vigilant maintenance monitoring. Water testing protocols consistently demonstrate superior performance for concealed fastener systems, particularly in wind-driven rain conditions where uplift forces and lateral water movement challenge conventional weatherproofing barriers. The continuous vertical seams of Snap Clad Standing Seam Roof Panel installations create natural drainage pathways that efficiently channel water off the roof surface without creating horizontal barriers where moisture can accumulate. Capillary break designs within the panel interlocks prevent water from migrating upward through the seams, even under pressure differential conditions. This multi-layer weatherproofing approach provides reliable protection across diverse climate zones, from tropical regions with heavy rainfall to northern environments experiencing freeze-thaw cycling. Field performance data spanning decades validates the longevity advantage, with properly installed standing seam systems routinely exceeding fifty years of service life while maintaining their original weathertight integrity.

Long-Term Cost Analysis and Value Proposition

Comprehensive lifecycle cost analysis reveals the economic advantages of Snap Clad Standing Seam Roof Panel systems despite higher initial installation expenses compared to traditional roofing options. While conventional exposed fastener metal roofs might cost forty to sixty percent less initially, the accumulated maintenance expenditures over thirty years typically exceed the incremental investment required for standing seam technology. Building owners face recurring screw replacement programs averaging eight thousand to fifteen thousand dollars per cycle for commercial structures, alongside periodic repairs addressing localized failures and water damage remediation. Energy performance differentials further amplify the cost equation, as the thermal responsiveness of standing seam systems without hundreds of thermal bridges through fastener penetrations contributes to measurably lower cooling and heating loads. Insurance carriers increasingly recognize the superior wind resistance and hail impact performance of standing seam roofing, offering premium reductions that provide ongoing operational savings. The extended service life eliminates at least one complete roof replacement cycle within a typical building's operational timeline, avoiding the substantial expenses and operational disruptions associated with major re-roofing projects.

Material Selection and Specification Considerations for Snap Clad Standing Seam Roof Panel Projects

Specifying appropriate materials for Snap Clad Standing Seam Roof Panel applications requires careful evaluation of environmental conditions, structural requirements, aesthetic objectives, and budget parameters. Aluminum alloy options, particularly 3003 and 3004 grades, deliver excellent corrosion resistance for coastal environments while minimizing structural dead load on the building frame. The material's natural durability extends to industrial settings where chemical exposure might compromise other metals, making it ideal for manufacturing facilities, processing plants, and similar applications. Galvalume steel substrates provide optimal strength-to-weight ratios and cost-effectiveness for general commercial and industrial installations, with the aluminum-zinc coating offering superior corrosion protection compared to traditional galvanized finishes. Stainless steel grades 304 and 316 serve specialized applications demanding exceptional durability and zero maintenance requirements, justifying their premium cost for landmark structures and institutional buildings with extended design life expectations. Copper installations deliver unmatched aesthetic appeal while developing natural patina finishes that protect the underlying material indefinitely, creating distinctive architectural statements for high-visibility projects.

Coating Systems and Surface Protection Technologies

Surface coating technologies applied to Snap Clad Standing Seam Roof Panel substrates critically influence long-term appearance retention and environmental durability. Premium PVDF resin-based coatings containing seventy percent polyvinylidene fluoride deliver exceptional resistance to ultraviolet degradation, chemical exposure, and color fading, backed by warranties extending thirty years or more for finish performance. These coating systems undergo rigorous accelerated weathering testing protocols that simulate decades of natural exposure, validating their ability to maintain gloss retention and color stability across diverse climate zones. Polyester enamel coatings offer economical alternatives for applications where extreme longevity requirements do not justify premium coating investments, though their reduced resistance to chalking and fading limits warranty coverage to fifteen to twenty years typically. Specialty matte finishes have gained popularity for architectural applications seeking subdued appearances that minimize reflectivity while maintaining excellent durability characteristics. The coating application process utilizes continuous coil coating lines that apply precisely controlled film thicknesses and cure the finishes under optimized temperature profiles, ensuring uniform coverage and maximum adhesion to the metallic substrate.

Thickness Selection and Structural Performance

Panel thickness specifications for Snap Clad Standing Seam Roof Panel systems balance structural adequacy, weight considerations, and cost optimization across the project scope. Standard commercial installations typically employ steel panels ranging from twenty-four to twenty-two gauge (0.6-0.8mm), providing robust resistance to foot traffic damage during maintenance operations while maintaining reasonable material costs. Heavier twenty-gauge (0.9mm) specifications serve applications with concentrated load requirements or extended spanning conditions where enhanced stiffness prevents oil canning appearance issues. Aluminum panels generally range from 0.032 to 0.063 inches (0.8-1.6mm) thickness, with the material's lower density requiring increased thickness to achieve structural performance equivalent to steel installations. The relationship between panel thickness, spanning capability, and deflection control requires engineering analysis considering tributary load areas, wind exposure categories, and seismic design parameters specific to each project location. Thicker panels resist denting from hail impact and incidental contact, extending the roof's aesthetic lifespan even in challenging service environments.

Snap Clad Standing Seam Roof Panel Applications Across Building Types

Commercial building applications constitute the primary market segment for Snap Clad Standing Seam Roof Panel systems, where the combination of performance, longevity, and architectural versatility aligns perfectly with owner objectives. Warehouse and distribution facilities benefit from the system's ability to span long distances between structural supports while maintaining weather integrity across expansive roof areas. Office complexes and corporate campuses utilize standing seam technology to achieve contemporary architectural expressions that reinforce brand identity and demonstrate environmental responsibility through durable, recyclable building materials. Retail developments increasingly specify these systems for their low maintenance requirements and exceptional appearance retention, ensuring that facilities maintain their intended visual impact throughout extended lease terms. The compatibility with solar panel mounting systems makes Snap Clad Standing Seam Roof Panel installations ideal for buildings pursuing net-zero energy goals, as specialized clamps attach photovoltaic arrays directly to the standing seams without penetrating the weatherproof membrane.

Institutional and Residential Applications

Educational facilities, healthcare complexes, and government buildings represent significant application opportunities where the lifecycle value proposition of Snap Clad Standing Seam Roof Panel systems aligns with institutional procurement priorities. School districts facing budget constraints appreciate the reduced maintenance burden and extended service life that free capital resources for educational programming rather than building repairs. Hospital administrators recognize the infection control advantages of roofing systems that eliminate moisture infiltration and the associated mold growth risks that compromise indoor air quality. Government facilities benefit from domestic content provisions and sustainability credentials that support procurement policy objectives while delivering measurable taxpayer value through reduced ownership costs. Residential applications have expanded dramatically as homeowners discover the aesthetic sophistication and practical advantages of standing seam technology. Luxury custom homes showcase the material's architectural versatility through creative color combinations, diverse profile options, and integration with complementary building envelope systems. Even modest residential projects increasingly specify standing seam roofing as awareness grows regarding the lifecycle cost advantages and superior performance compared to conventional asphalt shingles that require replacement every fifteen to twenty years.

Industrial and Agricultural Structures

Manufacturing facilities and industrial complexes rely on Snap Clad Standing Seam Roof Panel installations to protect valuable equipment and inventory while maintaining productive work environments. The systems' exceptional weather resistance prevents production interruptions caused by roof leaks that might damage sensitive machinery or contaminate products. Chemical processing plants appreciate the corrosion resistance available through appropriate material selection, ensuring roof integrity despite aggressive atmospheric conditions that accelerate deterioration of conventional roofing materials. Agricultural applications have embraced standing seam technology for barn structures, equipment storage buildings, and livestock facilities where the combination of affordability, longevity, and minimal maintenance requirements addresses the economic realities of farming operations. The bright interior illumination provided by light-colored metal roofing reduces electrical consumption for agricultural buildings that operate year-round, contributing to overall farm profitability.

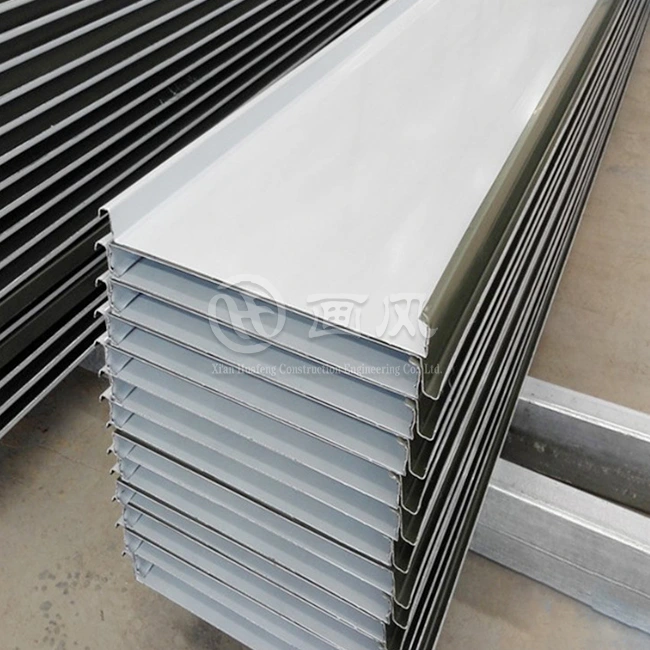

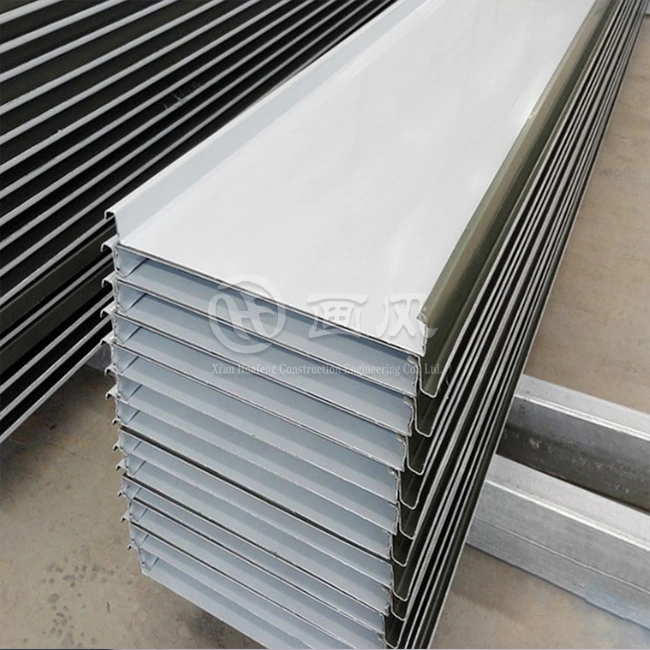

Manufacturing Excellence and Quality Assurance in Snap Clad Standing Seam Roof Panel Production

Manufacturing capabilities directly influence the quality, consistency, and performance reliability of Snap Clad Standing Seam Roof Panel systems delivered to project sites. Advanced production facilities integrate precision roll-forming equipment, computerized control systems, and comprehensive quality verification protocols to ensure every panel meets exacting dimensional tolerances and material specifications. Raw material procurement from certified suppliers guarantees substrate quality, with incoming inspection procedures verifying composition, mechanical properties, and coating characteristics before materials enter production workflows. Seven dedicated color coating production lines apply protective finishes under controlled environmental conditions, maintaining precise film thickness uniformity and cure schedules that optimize coating adhesion and durability. Longitudinal and transverse shearing equipment precisely cuts coil stock to specified dimensions, while automated punching systems create fastener holes and accessory mounting points with micron-level accuracy. More than forty specialized machines including shearing equipment, press brakes, and bending machines enable comprehensive in-house fabrication of trim components, flashing details, and custom accessories that ensure complete system integration.

Quality Control Processes and Testing Protocols

Rigorous quality control protocols embedded throughout the manufacturing process verify that Snap Clad Standing Seam Roof Panel products consistently meet performance specifications and customer expectations. Incoming material inspection encompasses visual examination for surface defects, dimensional verification using calibrated measuring instruments, and mechanical testing to confirm material properties align with mill certifications. Salt spray exposure testing evaluates coating adhesion and corrosion resistance under accelerated conditions simulating years of service exposure. Hardness testing and impact resistance verification ensure coating systems withstand the rigors of transportation, installation handling, and in-service conditions without premature failure. Film thickness measurements using electronic gauges confirm adequate coating application across panel surfaces, while color consistency evaluation using spectrophotometric analysis prevents batch-to-batch variations that might create visible differences in installed roofing. Finished product inspection examines dimensional accuracy, surface quality, and profile consistency before protective packaging prepares panels for shipment. This comprehensive quality assurance framework, combined with ISO9001 certification and adherence to ISO14001 environmental management standards, provides documented evidence of manufacturing excellence that supports performance warranties and customer confidence.

Production Capacity and Delivery Capabilities

Production capacity exceeding one thousand tons monthly positions manufacturing operations to serve both large-scale commercial projects and smaller residential applications with consistent reliability. Three strategically located manufacturing facilities spanning two hundred thousand square meters of production space in Anhui, plus processing plants in Hangzhou and Xi'an, enable efficient distribution across regional markets while maintaining responsive customer service. This geographic diversity reduces transportation costs and delivery timeframes, supporting project schedules that demand just-in-time material delivery coordinated with installation workflows. Advanced production planning systems optimize manufacturing sequences, minimizing changeover times between different panel specifications and maximizing throughput efficiency. Standard delivery timeframes of fifteen to twenty days for most orders accommodate typical project procurement schedules, while expedited processing capabilities address urgent requirements or unexpected schedule changes. Minimum order quantities of five hundred square meters or one ton ensure economical production runs while remaining accessible for modest project scales. The combination of substantial production capacity, geographic reach, and flexible manufacturing capabilities positions the organization to serve diverse market segments effectively.

Installation Best Practices and Technical Support for Snap Clad Standing Seam Roof Panel Projects

Successful Snap Clad Standing Seam Roof Panel installations depend on proper substrate preparation, precise panel alignment, and adherence to manufacturer installation guidelines throughout the construction process. Substrate conditions critically influence long-term system performance, requiring solid decking or adequately spaced structural purlins that provide continuous support along panel edges and prevent deflection under load. Waterproof underlayment membranes installed over solid substrates create secondary weather barriers that provide additional protection during installation and throughout the roof's service life. Installation begins with careful layout and clip placement, establishing consistent spacing patterns that maintain specified fastener density while accommodating panel thermal movement requirements. Panel installation progresses systematically across the roof surface, with each panel snapping securely onto pre-positioned clips before the adjacent panel installation commences. Quality installers verify proper engagement at every connection point, ensuring the male and female edges fully interlock without gaps or incomplete seating that might compromise weather resistance.

Technical Support and Engineering Services

Comprehensive technical support services guide Snap Clad Standing Seam Roof Panel projects from initial concept through final installation acceptance. Design teams provide structural three-dimensional modeling and load analysis that optimize panel specifications for project-specific requirements, considering wind exposure, snow loads, seismic forces, and deflection limitations. Drainage system simulation identifies optimal roof slopes, scupper locations, and overflow provisions that ensure reliable water removal under design storm intensities. Material specification advisory services help building owners and architects navigate the complex array of substrate options, coating systems, and accessory components to identify solutions that balance performance objectives with budget constraints. Project drawing deepening services transform architectural concepts into detailed installation drawings, coordinating roof panel layouts with structural framing, penetration locations, and adjacent building envelope components. Factory sample production enables stakeholders to evaluate actual panel appearances, verify color selections, and confirm material specifications before full production commitments. Processing drawing development breaks complex roof geometries into sequenced installation packages, with numbered panels and accessories that streamline jobsite logistics and prevent installation errors.

On-Site Support and Quality Verification

Installation guidance services deploy experienced technicians to project sites, providing hands-on training for installation crews and troubleshooting technical challenges that arise during construction. Pre-installation meetings review project drawings, clarify construction sequencing, and address safety protocols that protect workers and building occupants throughout the roofing operation. On-site inspections verify proper installation techniques, confirm adherence to manufacturer specifications, and identify corrective actions needed to address any deviations from approved methodologies. Post-installation testing programs validate weather resistance through water testing procedures that simulate design rainfall intensities, documenting the roof's ability to shed water without leakage or ponding. Final acceptance inspections examine completed installations systematically, verifying workmanship quality, aesthetic appearance, and functional performance before releasing project closeout documentation. Maintenance guidance educates building operators regarding proper roof care, inspection schedules, and minor repair procedures that preserve warranty coverage and maximize system longevity.

Conclusion

Snap Clad Standing Seam Roof Panel technology delivers demonstrable advantages over traditional roofing systems through concealed fastener design, superior weather resistance, reduced maintenance requirements, and extended service life exceeding fifty years. The combination of advanced manufacturing capabilities, comprehensive technical support, and proven field performance establishes standing seam technology as the optimal choice for building owners seeking lifecycle value, architectural excellence, and reliable weather protection.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, specializes in metal roofing systems, building curtain walls, and steel structure enclosure solutions with first-level curtain wall qualifications and third-level steel structure certifications. Our manufacturing infrastructure encompasses a two hundred thousand square meter raw material production plant in Anhui plus processing facilities in Hangzhou and Xi'an, operating seven color coating production lines, one laminating line, ten shearing production lines, and over forty specialized machines. We deliver complete one-stop solutions from custom engineering design and precision manufacturing through seamless on-site installation, supported by more than twenty registered patents, ISO9001 and ISO14001 certifications, and successful completion of prestigious projects including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum.

Partner with a China Snap Clad Standing Seam Roof Panel factory that combines engineering design experience with construction expertise. As a leading China Snap Clad Standing Seam Roof Panel supplier and China Snap Clad Standing Seam Roof Panel manufacturer, we offer China Snap Clad Standing Seam Roof Panel wholesale pricing with customized production capabilities and Snap Clad Standing Seam Roof Panel for sale across material options from 0.5-1.2mm thickness. Our High Quality Snap Clad Standing Seam Roof Panel systems feature competitive Snap Clad Standing Seam Roof Panel price structures backed by thirty-year warranties, design optimization services, raw material quality testing, multiple packaging options, and diverse transportation methods. Contact our team at huafeng@hfmetalroof.com to discuss your project requirements and discover how our one-stop procurement approach from raw materials to accessories delivers exceptional value for commercial, industrial, and institutional applications worldwide.

References

1. Metal Roofing Alliance. "Standing Seam Metal Roofing: Design and Installation Guidelines." National Roofing Contractors Association Technical Manual.

2. American Society for Testing and Materials. "Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process." ASTM A653/A653M.

3. Sheet Metal and Air Conditioning Contractors' National Association. "Architectural Sheet Metal Manual." 7th Edition.

4. National Coil Coating Association. "Technical Brief: PVDF Resin-Based Coatings for Metal Building Products." Technical Publication Series.

5. Metal Construction Association. "Technical Bulletin: Thermal Movement in Metal Building Components." MCA Engineering Guidelines.