Picture this scenario that haunts experienced roofing contractors daily: a meticulously installed standing seam metal roof begins showing water infiltration at the perimeter edges within months of completion, not because the panels failed, but because improper Standing Seam Trims were specified or installed incorrectly. This nightmare situation underscores a critical reality in metal roofing systems where trim components are not merely aesthetic finishing touches but essential weatherproofing elements that determine project success or costly callbacks. Understanding what questions to ask about Standing Seam Trims before material procurement and installation can mean the difference between a watertight, long-lasting roof system and a liability that damages both your reputation and bottom line.

Understanding Standing Seam Trims Material Specifications and Performance Requirements

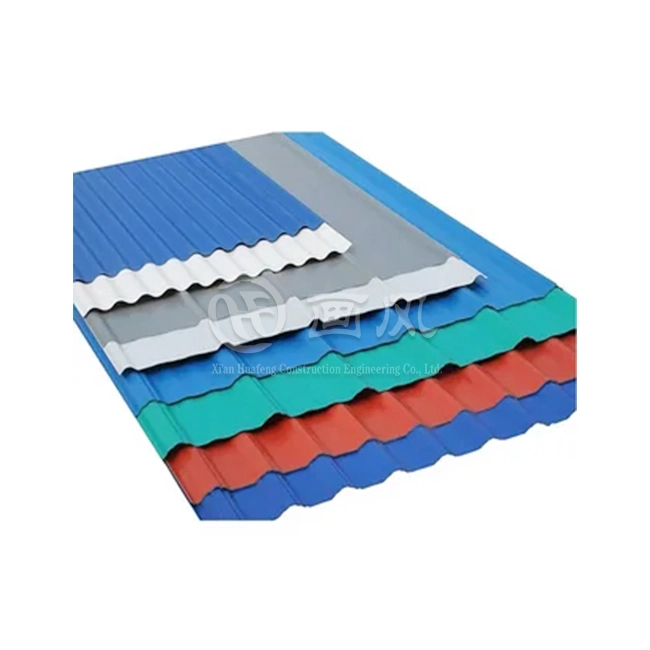

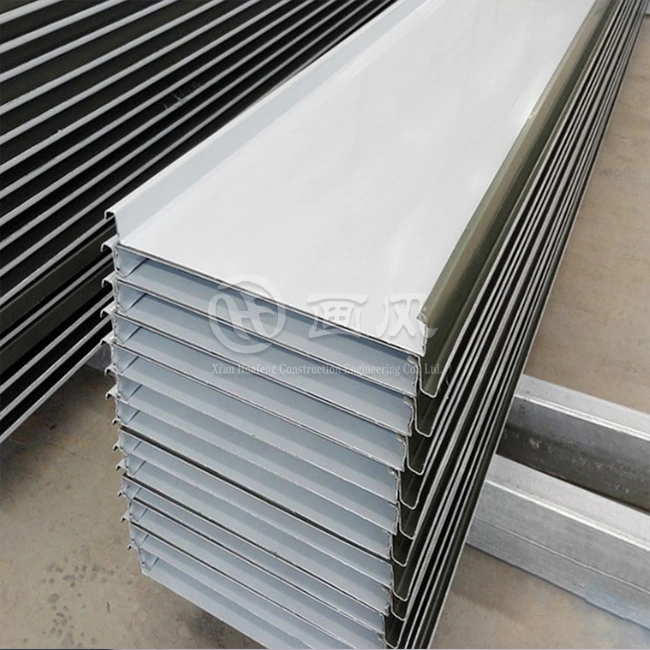

The foundation of any successful standing seam metal roofing project begins with comprehensive knowledge of trim material specifications, as these components must withstand the same environmental stresses as primary roofing panels while providing critical transitional weatherproofing. When evaluating Standing Seam Trims for your projects, contractors must first investigate the material composition options available, including aluminum alloy, color steel, and galvanized steel, each offering distinct advantages for specific applications and environmental conditions. Aluminum alloy trims provide exceptional corrosion resistance and lightweight handling characteristics, making them ideal for coastal environments or projects where roof load considerations are paramount, though contractors should verify the specific alloy grade such as 3003, 3004, or 5052 to ensure adequate strength properties for the intended application. Color steel Standing Seam Trims offer cost-effectiveness combined with adequate performance for most commercial and industrial applications, particularly when protected by high-quality coating systems that resist UV degradation, chalking, and color fading over extended service periods. Galvanized steel trims represent the traditional choice for many contractors, providing robust structural properties and proven long-term performance, though proper coating and finishing treatments become essential to prevent premature corrosion in aggressive environments. Beyond base material selection, contractors must question manufacturers about coating systems, film thickness specifications, adhesion test results, and weather resistance data, as these factors directly impact the service life and maintenance requirements of Standing Seam Trims throughout the building's operational lifespan.

-

Critical Performance Standards for Standing Seam Trims

Performance verification represents another essential area where contractors must ask detailed questions before committing to specific Standing Seam Trims products or suppliers. Professional contractors should request comprehensive testing documentation including salt spray resistance results, which indicate how trims will perform in corrosive environments, adhesion test data showing coating bond strength under thermal cycling conditions, and impact resistance specifications that confirm trims can withstand installation handling and environmental hazards without compromising their protective coatings. Weather resistance testing becomes particularly critical for Standing Seam Trims, as these components occupy exposed positions along roof perimeters where they face maximum UV exposure, temperature extremes, and moisture intrusion potential, making accelerated weathering test results essential for predicting long-term performance and avoiding premature failure scenarios. Contractors working on projects with specific code requirements or performance specifications should also inquire about third-party certification compliance, including ISO9001 quality management verification, ISO14001 environmental management standards, and SGS testing validation, all of which provide independent verification that Standing Seam Trims meet stated performance claims. Dimensional stability under thermal cycling represents another critical performance parameter, as trims that warp, distort, or pull away from fastening points due to thermal expansion create water infiltration pathways and compromise the entire roofing system's integrity. Fire resistance ratings, wind uplift resistance values, and structural load capacity specifications should also be thoroughly reviewed and documented, particularly for commercial projects where building codes mandate specific performance thresholds for all roofing components including Standing Seam Trims.

Application-Specific Standing Seam Trims Selection and Compatibility Considerations

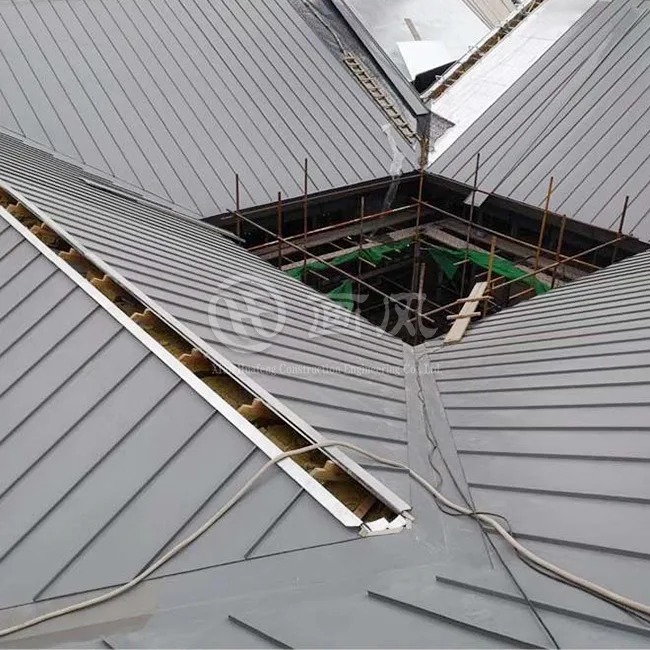

Matching Standing Seam Trims to specific roofing applications requires contractors to ask targeted questions about compatibility with various roof details and transitions where these components serve critical weatherproofing functions. Ridge applications demand Standing Seam Trims that can accommodate thermal movement while maintaining weather-tight seals at the roof's highest and most exposed location, requiring contractors to verify that proposed trim profiles provide adequate coverage width, proper drainage channels, and compatible fastening systems that won't create leak pathways over time. Eave trims represent the first line of defense against water infiltration and must incorporate drip edges, proper pitch angles, and secure attachment methods that resist wind uplift forces while channeling water away from fascia boards and building walls, making it essential for contractors to question suppliers about tested wind resistance ratings and installation specifications. Gable Standing Seam Trims face unique challenges as they must seal vertical roof edges against wind-driven rain while accommodating panel expansion and contraction movements perpendicular to their installation axis, requiring contractors to verify that trim designs include appropriate flexibility, secure fastening details, and adequate overlap dimensions to maintain weatherproofing integrity throughout seasonal temperature variations. Inner corner applications where roof planes intersect create complex water management challenges, demanding Standing Seam Trims with specialized profiles that can form watertight transitions without creating water dams or debris accumulation zones, making it critical for contractors to request detailed installation drawings and proven application examples before specifying these components. Flashing panel trims serve as transitional elements between roofing systems and various penetrations or wall intersections, requiring contractors to confirm that proposed Standing Seam Trims include proper hem configurations, adequate stiffness to resist oil-canning or buckling, and compatible finishing details that integrate seamlessly with adjacent building components.

-

Ensuring System Compatibility and Integration

System compatibility extends beyond simple dimensional matching to encompass thermal expansion coefficients, coating system compatibility, and fastening method coordination between Standing Seam Trims and primary roofing panels. Contractors must ask manufacturers about thermal expansion rates for proposed trim materials and verify that these match or accommodate the expansion characteristics of primary roofing panels to prevent buckling, separation, or fastener failure at critical connection points. Coating compatibility becomes essential when mixing material types, as dissimilar metals in direct contact can create galvanic corrosion cells that rapidly degrade both Standing Seam Trims and adjacent panels, making it imperative that contractors question suppliers about approved material combinations and required isolation methods for any dissimilar metal interfaces. Fastening system coordination represents another critical inquiry area, as Standing Seam Trims must connect securely to roof substrates while accommodating the same thermal movement as primary panels without creating rigid constraints that cause buckling or material fatigue. Contractors should request detailed fastening specifications including recommended fastener types, spacing requirements, substrate penetration depths, and any required sealant or closure strip applications that ensure weathertight installations. Color matching considerations also require careful contractor attention, as Standing Seam Trims must coordinate aesthetically with primary roofing panels while accounting for potential color variation between different material types and coating processes, making it advisable to request physical samples of all proposed materials before final specification to verify acceptable color coordination under actual daylight conditions.

Quality Control, Manufacturing Standards, and Supply Chain Verification

Professional contractors recognize that Standing Seam Trims quality and consistency directly impact installation efficiency and long-term project performance, making it essential to ask detailed questions about manufacturing processes, quality control systems, and supply chain reliability before committing to specific suppliers. Manufacturing facility capabilities represent a critical inquiry area, as contractors should verify that prospective suppliers operate modern production equipment capable of maintaining tight dimensional tolerances, consistent coating application, and repeatable profile configurations across production runs. Questions about production line technology should include specifics about roll-forming systems, coating application methods, quality monitoring equipment, and in-process inspection protocols that ensure every Standing Seam Trims component meets specification requirements before shipment. Quality management system certification provides independent verification of manufacturing consistency, with contractors advised to confirm that Standing Seam Trims suppliers maintain current ISO9001 certification demonstrating documented quality procedures, continuous improvement processes, and systematic defect prevention methods. Environmental management certification such as ISO14001 indicates supplier commitment to sustainable manufacturing practices and proper handling of coating materials and waste streams, which can be important for projects with environmental performance requirements or green building certification goals. Third-party testing validation through organizations like SGS provides additional assurance that Standing Seam Trims performance claims are supported by independent laboratory testing rather than unverified manufacturer assertions.

-

Raw Material Sourcing and Traceability Requirements

Raw material quality fundamentally determines Standing Seam Trims performance, making it essential for contractors to question suppliers about their material sourcing practices and quality verification procedures. Professional manufacturers maintain approved supplier lists with documented performance histories and require material certification documentation and third-party test reports for all incoming raw materials, whether aluminum, steel, or specialized coating materials. Contractors should ask potential Standing Seam Trims suppliers about their incoming material inspection processes, including sampling procedures, testing parameters, acceptance criteria, and rejection protocols that ensure only specification-compliant materials enter production. Traceability systems allow manufacturers and contractors to track Standing Seam Trims components from raw material receipt through production, quality inspection, packaging, and delivery to job sites, providing essential documentation for quality verification and warranty administration. Contractors should inquire about lot numbering systems, production record retention periods, and material certification availability to ensure adequate traceability for their specific project requirements. Brand specification represents another important consideration, with leading manufacturers utilizing recognized material suppliers such as Alucosuper, YATAI, and LIDAO for aluminum products, BAOSTEEL, GUANZHOU, and XINYU for steel materials, and specialized suppliers like NedZink for titanium zinc applications, all of which provide documented quality assurance and consistent performance characteristics.

Installation Support, Technical Documentation, and Project Success Resources

Comprehensive installation support and technical documentation separate professional Standing Seam Trims suppliers from commodity material vendors, making it essential for contractors to evaluate the depth and quality of technical resources available before material selection. Detailed installation drawings represent the foundation of successful Standing Seam Trims applications, with contractors advised to request complete detail drawings for all standard and custom trim applications including fastening specifications, overlap dimensions, sealant requirements, and closure strip placements that ensure watertight installations. Project-specific drawing customization capabilities allow suppliers to provide tailored installation details that address unique architectural conditions, unusual roof geometries, or special performance requirements, giving contractors confidence that proposed Standing Seam Trims solutions will function properly in their specific applications. On-site installation support services distinguish premier Standing Seam Trims manufacturers from basic material suppliers, with leading companies providing experienced technical representatives who can review site conditions, verify proper material storage and handling, observe initial installations to confirm proper technique, and address field questions that arise during construction. Contractors should inquire about the availability and cost of such services, as professional installation guidance during critical project phases can prevent costly errors and ensure optimal long-term performance. Technical training programs offered by advanced Standing Seam Trims manufacturers provide contractor crews with detailed product knowledge, proper handling techniques, installation best practices, and troubleshooting guidance that translates directly into improved installation quality and reduced callback risk.

-

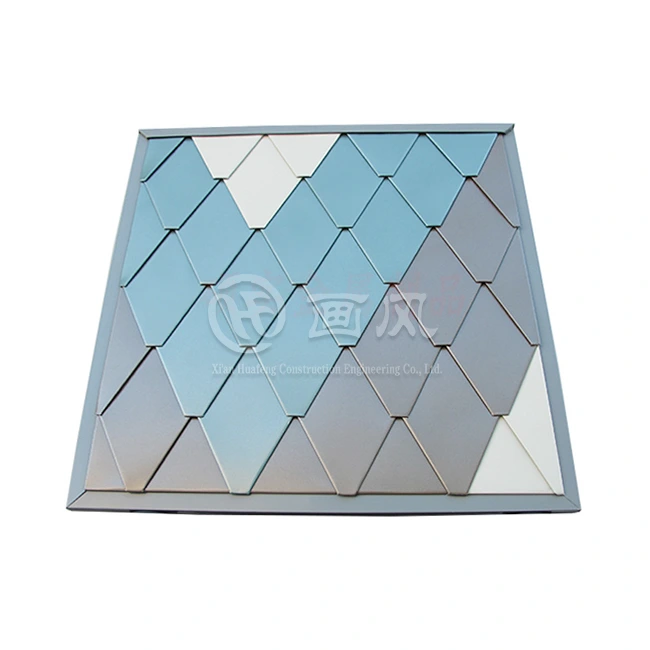

Customization Capabilities and Project-Specific Solutions

Custom Standing Seam Trims fabrication capabilities enable contractors to address unique architectural details and special project requirements that standard catalog products cannot accommodate. Professional manufacturers maintain design engineering staff who can review project drawings, identify special trim requirements, develop custom profile solutions, and provide fabrication drawings for contractor approval before production begins. Contractors should question potential suppliers about their custom fabrication capabilities including minimum order quantities, lead time requirements, tooling costs if any, and design support availability to determine whether customization services align with project needs and schedules. Sample production and approval processes provide contractors with physical verification that proposed Standing Seam Trims meet project requirements before full production and delivery, representing essential risk management for projects with special performance requirements or unique aesthetic specifications. Contractors should request detailed information about sample production procedures including turnaround time, approval documentation requirements, and sample retention policies that ensure production materials match approved samples. Sequential numbering systems employed by sophisticated Standing Seam Trims manufacturers simplify installation coordination by marking each component with location identifiers that correspond to roof section drawings, dramatically reducing installation errors and improving crew productivity on complex projects with numerous custom trim pieces.

Packaging, Delivery Logistics, and Project Site Coordination

Proper Standing Seam Trims packaging and delivery coordination directly impact installation efficiency and material condition upon arrival, making these operational factors essential contractor inquiry areas. Professional packaging systems protect Standing Seam Trims components during transportation and site storage while facilitating efficient unloading and installation sequencing that minimizes material handling and reduces damage risk. Contractors should ask suppliers about their packaging methodologies including protective wrapping materials, bundling configurations, labeling systems, and palletization standards that ensure materials arrive in installation-ready condition. Section-based packaging organization allows Standing Seam Trims to be bundled according to roof sections or installation sequences, with package identification cards including section plans and component number lists that enable installers to quickly locate required pieces without extensive searching through multiple bundles. This organizational approach particularly benefits large or complex projects where efficient material flow directly impacts installation productivity and schedule adherence. Contractors should verify that prospective Standing Seam Trims suppliers can provide this level of packaging sophistication and confirm that package marking systems align with project drawing conventions and installation sequencing plans.

-

Transportation and Delivery Coordination Requirements

Transportation method flexibility enables contractors to select delivery approaches that best match project site conditions, material volume requirements, and construction schedule constraints. Professional Standing Seam Trims suppliers offer multiple transportation options including direct delivery to job sites, delivery to contractor warehouses for consolidation with other materials, or phased deliveries that match installation sequences and minimize on-site storage requirements. Contractors should discuss transportation options during supplier evaluation to ensure proposed delivery methods align with site access limitations, storage space availability, and construction phasing requirements that characterize their specific projects. Delivery scheduling coordination becomes critical for projects with limited staging areas or just-in-time delivery requirements where Standing Seam Trims must arrive in specific sequences that match installation progress without creating material congestion or extended exposure to weather conditions. Contractors should question suppliers about their scheduling flexibility, advance notice requirements, delivery time windows, and procedures for adjusting delivery dates if project conditions change, all of which impact the supplier's ability to support smooth project execution. Secure packaging that withstands transportation vibration, stacking loads, and environmental exposure during transit and temporary storage protects Standing Seam Trims from damage that could compromise their appearance or performance, making packaging robustness an essential evaluation criterion for contractor supplier selection.

Conclusion

Successful standing seam metal roofing projects depend fundamentally on contractors asking comprehensive questions about Standing Seam Trims materials, performance specifications, manufacturing quality, installation support, and delivery logistics before material procurement decisions. Professional contractors who thoroughly evaluate these critical factors position themselves to deliver superior project outcomes with minimal callbacks and maximum client satisfaction.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as your premier China Standing Seam Trims manufacturer and China Standing Seam Trims supplier, offering unmatched expertise since our establishment in 2018. As a recognized high-tech enterprise with first-level building curtain wall qualifications and third-level building steel structure qualifications, we operate a 200,000 square meter raw material production facility in Anhui complemented by processing plants in Hangzhou and Xi'an, featuring seven color coating production lines and over forty precision manufacturing machines. Our comprehensive one-stop solution encompasses custom engineering design with 3D modeling, precision roll-forming manufacturing with real-time quality control, and seamless on-site installation management, all supported by ISO9001, ISO14001, and SGS certifications plus over twenty registered patents. Whether you need High Quality Standing Seam Trims, competitive Standing Seam Trims price quotations, or Standing Seam Trims for sale with complete technical support, our expert engineering team delivers customized solutions backed by extensive project experience including landmark installations at Xi'an International Convention Center and Inner Mongolia Tongliao Art Museum. Contact us today as your trusted China Standing Seam Trims factory and China Standing Seam Trims wholesale partner at huafeng@hfmetalroof.com to discuss your next project requirements and discover how our commitment to precision, quality, and client satisfaction translates into lasting value for your roofing investments.

References

1. Baker, M.C. & Thompson, R.J. (2023). Metal Roofing Systems: Engineering Design and Installation Standards. Journal of Building Envelope Design, 18(4), 245-267.

2. National Roofing Contractors Association. (2024). NRCA Metal Panel and SPF Roof Systems Manual. NRCA Publications Division.

3. Sheffield, D.K., Martinez, L.P. & Wong, H.S. (2022). Performance Evaluation of Standing Seam Metal Roofing Components Under Accelerated Weathering Conditions. Construction and Building Materials, 156, 892-904.

4. Williams, P.G. (2023). Architectural Metal Roofing: Material Selection, Design Integration, and Installation Best Practices. McGraw-Hill Professional Engineering.