When you're facing roof leaks, costly repairs every few years, and escalating maintenance expenses, choosing the right roofing solution becomes critical. Whether you're a building owner evaluating long-term durability or a contractor weighing performance versus installation complexity, understanding 1 inch standing seam metal roofing can save you time, money, and future headaches. This comprehensive guide answers your most pressing questions about whether 1 inch standing seam metal roofing is the right choice for your commercial, industrial, or residential project.

What Makes 1 Inch Standing Seam Metal Roofing Unique?

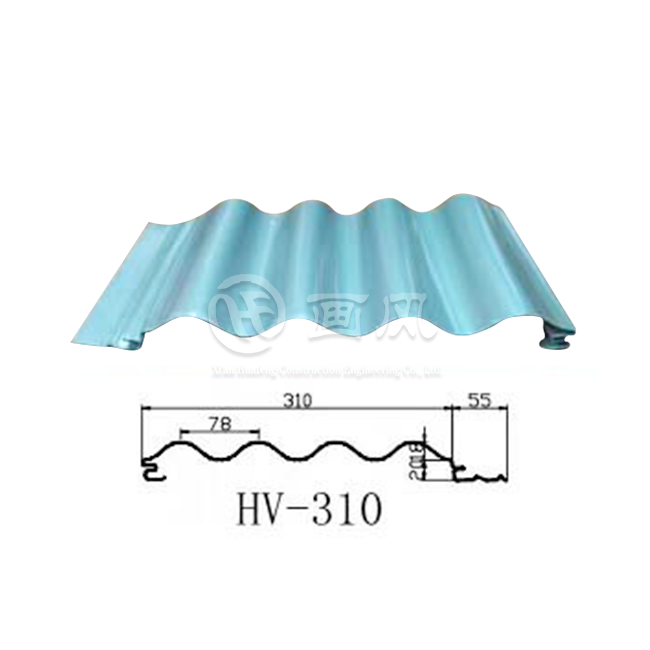

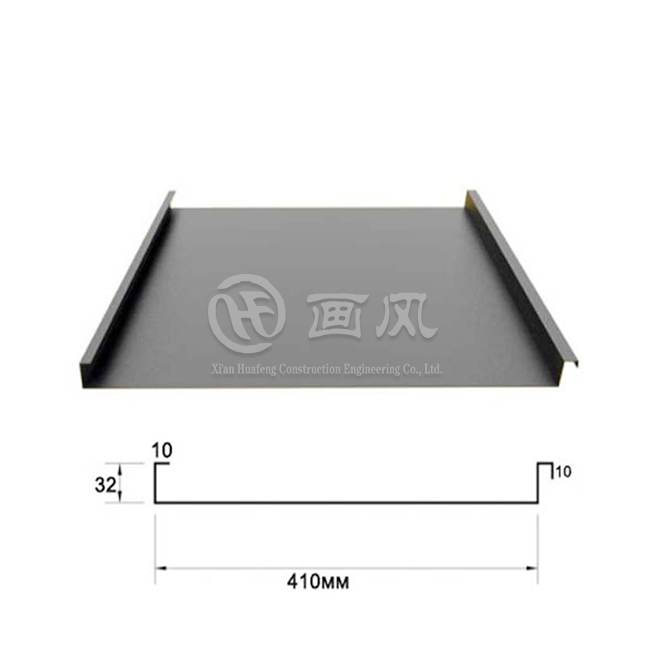

1 inch standing seam metal roofing represents a specialized category of concealed fastener roofing systems that strikes a balance between aesthetic appeal, structural performance, and installation efficiency. The defining characteristic is the one-inch vertical rib height, which refers to the raised seam that runs vertically along the roof panels from eave to ridge. This measurement is crucial because it directly impacts water drainage capacity, structural strength, and the overall weather-tightness of the roofing system. The 1 inch standing seam metal roofing system employs panels that interlock through either snap-lock or mechanically seamed connections. In most configurations, this system utilizes concealed fasteners, meaning screws and clips are hidden beneath the seams rather than exposed to weather elements. This concealed fastener approach dramatically reduces the risk of water infiltration at penetration points, which is one of the primary failure modes in traditional exposed fastener roofing systems. The panels typically measure between twelve and eighteen inches in width, with sixteen inches being most common for residential and light commercial applications.

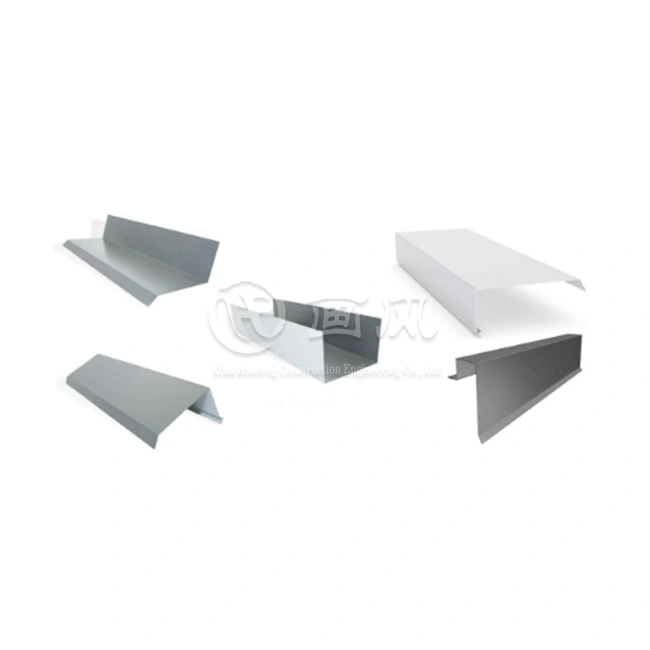

Material composition varies based on project requirements and environmental conditions. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures 1 inch standing seam metal roofing in aluminum-magnesium-manganese alloys, galvanized steel, galvalume steel, stainless steel, and titanium-zinc alloys. Thickness options range from 0.5mm to 1.2mm, with common aluminum panels measuring 0.7-0.8mm and steel panels typically at 0.6mm. These specifications allow customization based on structural load requirements, expected weather conditions, and budget considerations. The surface treatment significantly affects longevity and appearance. Premium coating options include PVDF (polyvinylidene fluoride) and PE (polyester) finishes, with PVDF offering superior UV resistance and color retention over decades of exposure. These coatings are available in extensive color ranges following RAL and other international color systems, allowing architectural flexibility while maintaining protective performance. This combination of structural design, material quality, and protective coatings enables 1 inch standing seam metal roofing to achieve service life expectations of thirty years or more with proper installation and minimal maintenance.

Installation Approaches for 1 Inch Standing Seam Systems

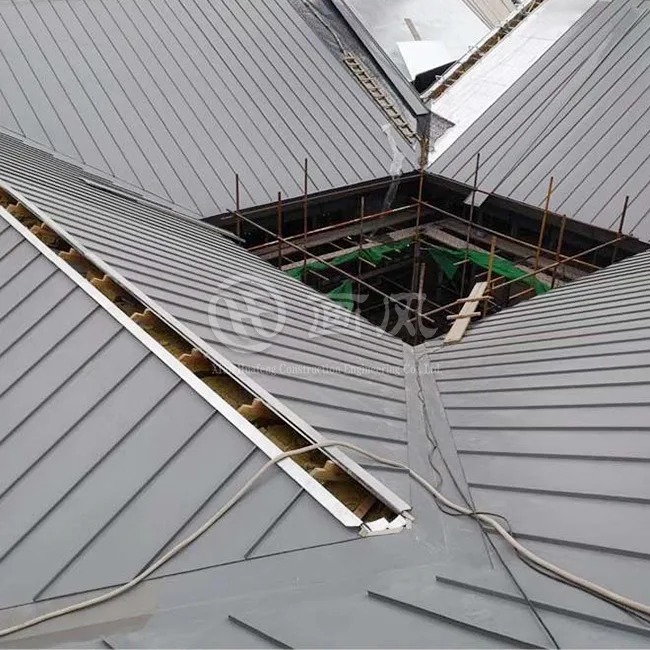

Installation methodology for 1 inch standing seam metal roofing varies depending on whether the system employs snap-lock technology or requires field seaming. Snap-lock systems offer faster installation because panels simply click together over concealed clips that are pre-fastened to the roof deck. Installation technicians can complete snap-lock installations more efficiently, reducing labor costs while maintaining weather-tight performance. However, the thermal movement capacity of snap-lock systems may be somewhat limited compared to mechanically seamed alternatives. Mechanically seamed 1 inch standing seam metal roofing requires specialized equipment to crimp or fold the panel seams together, creating an extremely robust connection that accommodates significant thermal expansion and contraction. This installation method demands greater skill and time investment but delivers superior performance in extreme temperature environments or on very low-slope applications. Professional contractors typically recommend mechanical seaming for commercial projects exceeding certain square footage thresholds or where wind uplift ratings must meet stringent building code requirements.

Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation support through its one-stop solution approach. Before installation begins, the engineering team conducts detailed project drawing deepening, analyzing floor plans, elevations, and node diagrams to identify optimal panel configurations. The design department creates 1:1 scale drawings of critical connection details, ensuring that transitions, penetrations, and terminations are properly detailed before manufacturing begins. This pre-construction planning eliminates field improvisation that often leads to performance problems or aesthetic inconsistencies. On-site installation follows rigorous protocols. Installation technicians arrive one day before work commences to inspect substrate conditions, verify tool availability including edge-locking machines and specialized fasteners, and confirm that auxiliary materials such as structural adhesive, rivets, and closure accessories are complete. Daily technical briefings review work sequences and safety precautions. Upon completion, comprehensive testing ensures zero leakage, followed by formal customer acceptance procedures. This systematic approach to 1 inch standing seam metal roofing installation minimizes callbacks and ensures warranty compliance.

Is 1 Inch Standing Seam Metal Roofing Suitable for Your Project Type?

Determining whether 1 inch standing seam metal roofing fits your specific application requires evaluating multiple project parameters including building type, roof slope, environmental exposure, aesthetic requirements, and budget constraints. Residential applications increasingly favor one-inch seam heights because the lower profile creates a more subtle, refined appearance compared to taller commercial profiles. The streamlined aesthetic complements contemporary architectural styles while still providing the durability and longevity advantages that make metal roofing attractive to homeowners seeking permanent roofing solutions. Commercial and industrial buildings present different considerations. While 1 inch standing seam metal roofing performs admirably in many commercial contexts, projects with extremely low roof slopes below 2:12 pitch may benefit from taller seam heights that provide additional water management capacity. Buildings in regions experiencing heavy snow accumulation or intense rainfall might also warrant consideration of taller seam profiles. However, for standard commercial applications with moderate slopes and typical weather exposure, the one-inch seam height delivers excellent performance at a competitive price point.

Agricultural buildings, warehouses, and other utility structures represent ideal applications for 1 inch standing seam metal roofing. These projects prioritize long-term durability and minimal maintenance over premium aesthetics, making metal roofing's superior lifespan particularly valuable. The concealed fastener design eliminates the gradual degradation of exposed fastener washers that plague lower-cost panel systems. Agricultural environments often involve corrosive conditions from livestock operations or chemical storage, making the protective coatings on quality standing seam panels essential for achieving multi-decade service life. Retrofit and re-roofing projects deserve special attention. The 1 inch standing seam metal roofing system can frequently be installed over existing roof assemblies without tear-off, providing both economic advantages and reduced project disruption. This approach requires careful evaluation of structural capacity since metal roofing adds weight to the building, though considerably less than traditional materials like concrete tile or slate. Xi'an Huafeng's engineering team analyzes structural drawings and existing conditions to determine retrofit feasibility, ensuring code compliance while maximizing cost efficiency through the avoidance of disposal expenses and shortened installation timelines.

Performance Considerations Across Climate Zones

Climate conditions dramatically influence whether 1 inch standing seam metal roofing represents the optimal choice. In coastal environments subject to salt spray and high humidity, material selection becomes paramount. Aluminum-magnesium-manganese alloys naturally resist corrosion in marine atmospheres, while steel-based panels require premium galvanization or specialized coating systems. The 1 inch standing seam metal roofing manufactured by Xi'an Huafeng utilizes materials from certified suppliers including Alucosuper, YATAI, and LIDAO for aluminum components, and Baosteel, Guanzhou, and Xinyu for steel substrates, ensuring base material quality that supports long-term coastal performance. Temperature extremes create thermal movement that roofing systems must accommodate without failure. Metal naturally expands when heated and contracts during cooling, generating forces that can stress fastener connections and panel seams. The clip-based attachment systems used with 1 inch standing seam metal roofing allow panels to float over the structural deck, accommodating this thermal movement without creating buckling, fastener pull-through, or seam separation. Proper clip spacing and type selection based on panel length and expected temperature range ensures thermal performance throughout the building's service life.

Wind uplift resistance depends on multiple factors including seam type, clip specification, fastener pattern, and deck attachment. Buildings in hurricane-prone regions or open terrain with high wind exposure require engineered systems with tested and certified uplift ratings. While 1 inch standing seam metal roofing can achieve substantial uplift capacity, taller seam profiles sometimes offer advantages in extreme wind zones. Professional engineering analysis considers local wind speed requirements, building height and exposure category, and roof geometry to specify appropriate system components. Xi'an Huafeng provides comprehensive engineering support backed by testing certifications conforming to ASTM, DIN, JIS, BS, and GB/T standards. Snow load management relates directly to seam height and panel coating. The smooth metal surface combined with premium coatings facilitates snow shedding on sloped roofs, reducing accumulated loads and associated structural demands. However, in regions with exceptional snow depths, snow retention systems may be required to prevent dangerous avalanche conditions at eaves and building entrances. The 1 inch standing seam metal roofing profile readily accepts clamp-on snow retention devices without penetrating the waterproof membrane, maintaining system integrity while addressing life safety requirements.

How Does 1 Inch Standing Seam Compare to Alternative Roofing Solutions?

When evaluating 1 inch standing seam metal roofing against competitive roofing systems, multiple performance dimensions merit comparison including initial cost, lifecycle cost, maintenance requirements, durability expectations, and aesthetic characteristics. Traditional asphalt shingle roofing represents the most common residential alternative, offering substantially lower initial installation cost but significantly shorter service life, typically fifteen to twenty years compared to thirty-plus years for quality metal roofing systems. The cost differential narrows considerably when analyzing total cost of ownership across multiple replacement cycles. Exposed fastener metal panels provide another comparison point. These systems use visible screws penetrating through the panel surface directly into structural purlins or deck substrates. Initial costs run lower than standing seam alternatives because installation proceeds faster and clip systems are eliminated. However, exposed fasteners create potential leak points that require maintenance vigilance, as fastener washers degrade from UV exposure and thermal cycling. Building owners frequently find themselves tightening screws or replacing failed fasteners within the first decade. The 1 inch standing seam metal roofing system eliminates this maintenance burden through its concealed fastener design.

Architectural metal roofing systems with taller seam profiles offer enhanced performance capabilities but at increased material and installation costs. Two-inch and three-inch seam heights provide greater structural rigidity, superior water management on low slopes, and more dramatic visual impact. For projects requiring these performance characteristics, the additional investment proves justified. However, many residential and light commercial applications find the one-inch seam height delivers adequate performance at a more accessible price point, making metal roofing feasible for budget-conscious projects that still prioritize long-term quality. Built-up roofing, modified bitumen, TPO, and EPDM membrane systems dominate low-slope commercial roofing markets. These systems perform reliably when properly installed and maintained, but typically require replacement or major restoration after twenty to twenty-five years. The 1 inch standing seam metal roofing alternative offers comparable or superior longevity with dramatically reduced maintenance requirements. Metal systems eliminate concerns about membrane punctures from foot traffic, equipment installation, or debris. The reflective properties of light-colored metal panels also provide energy efficiency advantages in cooling-dominated climates, potentially qualifying for utility rebates or green building certifications.

Economic Analysis: Initial Investment Versus Lifecycle Value

The financial decision to specify 1 inch standing seam metal roofing requires understanding both immediate budget impacts and long-term economic implications. Material costs for standing seam systems typically run two to three times higher than conventional asphalt shingles, while installation labor costs may also exceed traditional alternatives due to specialized skill requirements. For a residential project, this cost premium might represent an additional investment of several thousand dollars compared to standard shingle replacement. However, this analysis must consider the extended service life that quality metal roofing provides. When building owners amortize the installation investment across the expected service life, the cost per year often compares favorably to conventional alternatives. A properly installed 1 inch standing seam metal roofing system with premium PVDF coating can reasonably be expected to perform for thirty-five to forty-five years, while typical architectural shingles require replacement after eighteen to twenty-two years. Over a forty-five year ownership period, the metal roof requires one installation while shingle roofing demands two or possibly three replacement cycles, each disrupting building operations and generating disposal costs.

Maintenance expenses present another economic consideration. Standing seam metal roofing requires minimal ongoing maintenance beyond periodic inspections and clearing of debris from gutters and valleys. Asphalt shingles gradually lose granules, may require algae treatment in humid climates, and frequently need individual shingle replacement after storm events. These incremental maintenance costs accumulate substantially over decades. The concealed fastener design of 1 inch standing seam metal roofing eliminates the most common maintenance issue facing exposed fastener metal panels, creating a truly low-maintenance roofing solution. Energy efficiency impacts operating costs throughout the building's life. Reflective metal roofing surfaces, particularly when finished with cool-roof certified coatings, substantially reduce solar heat gain compared to dark asphalt shingles. This thermal performance translates to measurably lower air conditioning costs in warm climates. Xi'an Huafeng offers color options specifically designed to maximize solar reflectance while maintaining aesthetic appeal. Some utility companies and governmental agencies provide rebates or incentives for cool-roof installations, effectively reducing the net investment required. When factoring energy savings into lifecycle cost calculations, the economic advantage of 1 inch standing seam metal roofing becomes even more compelling.

What Quality Factors Should You Evaluate When Selecting 1 Inch Standing Seam Metal Roofing?

Material quality represents the foundation of long-term roofing performance, making supplier selection critical to project success. The base metal substrate must meet or exceed industry standards for thickness, coating weight, and material properties. For steel-based panels, the zinc coating weight on galvanized products or the aluminum-zinc alloy coating on galvalume steel directly correlates to corrosion resistance. Xi'an Huafeng Construction Engineering Co., Ltd. maintains a qualified supplier list including industry-leading manufacturers such as Baosteel, ensuring that raw materials arrive with proper certification and third-party testing documentation. Coating system selection deserves careful attention because the organic finish determines color retention, chalking resistance, and overall weather durability. Polyester coatings offer good performance at moderate cost for projects with standard exposure conditions. PVDF coatings provide superior performance characteristics including exceptional UV stability, chemical resistance, and color retention across decades of service. The investment premium for PVDF-coated 1 inch standing seam metal roofing typically proves justified for projects requiring maximum longevity or located in harsh environmental conditions. Coating thickness, measured in mils or microns, also influences performance, with heavier coating builds generally delivering enhanced protection.

Manufacturing quality control processes ensure consistent panel dimensions, proper seam formation, and coating integrity. Xi'an Huafeng operates seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing lines across three factory locations in Anhui, Hangzhou, and Xi'an. This production infrastructure incorporates real-time quality control with comprehensive incoming material inspection protocols. Each material lot undergoes verification testing including appearance inspection, dimensional accuracy, salt spray resistance, adhesion testing, hardness measurement, impact resistance, film thickness confirmation, acid resistance, weather resistance evaluation, and color difference assessment. This rigorous quality management system ensures that 1 inch standing seam metal roofing panels leaving the factory meet specification requirements. Engineering support and technical expertise distinguish quality suppliers from commodity vendors. Complex building geometries, challenging connection details, and performance requirements demand manufacturer involvement beyond simple product supply. Xi'an Huafeng provides comprehensive design services including structural 3D modeling, load analysis, and drainage system simulation. The design department works collaboratively with project teams to develop detailed shop drawings showing every panel, trim piece, and accessory component. This drawing deepening process identifies potential constructability issues before manufacturing begins, avoiding costly field modifications. Installation support, including on-site technical guidance and quality verification testing, ensures that the engineered system performs as intended.

Certification and Testing Documentation

Third-party certification provides independent verification that roofing products meet stated performance criteria. Quality manufacturers submit their systems to rigorous testing protocols established by organizations including ASTM International, FM Global, Underwriters Laboratories, and Miami-Dade Building Code Compliance. These tests evaluate wind uplift resistance, fire performance, impact resistance from hail or flying debris, water penetration resistance, and structural adequacy under design loads. Xi'an Huafeng maintains certifications including ISO9001 quality management, ISO14000 environmental management, and SGS product verification, demonstrating commitment to systematic quality assurance. Panel testing addresses specific performance parameters critical to long-term durability. Accelerated weathering tests subject coated panels to concentrated UV exposure, humidity cycling, and temperature extremes equivalent to decades of natural exposure. Salt spray testing evaluates corrosion resistance in coastal environments. Adhesion testing ensures coating systems remain bonded to the substrate under stress. These laboratory evaluations provide quantitative performance data that allows informed material selection based on project-specific environmental conditions. Reputable suppliers willingly provide test reports and certification documentation to support specification decisions for 1 inch standing seam metal roofing installations.

Wind uplift testing deserves particular attention for projects in high-wind regions. Testing protocols simulate extreme negative pressures that roof systems experience during severe weather events. Test assemblies duplicate field installation details including panel configuration, clip type and spacing, fastener specifications, and deck attachment. Successful testing results in published uplift ratings that engineers use for code compliance documentation. The clips, fasteners, and installation patterns used in tested assemblies must be followed precisely in the field to maintain the certified performance level. Xi'an Huafeng provides detailed installation instructions referencing applicable test reports to ensure that installed systems achieve their intended performance capabilities. Fire resistance ratings affect insurance costs and may be mandated by building codes for certain occupancies. Metal roofing inherently offers advantages in fire performance because the material is non-combustible. Testing evaluates the complete assembly including substrate, insulation if present, and any combustible components. Class A fire ratings represent the highest performance level, providing maximum resistance to external fire exposure. Quality 1 inch standing seam metal roofing systems readily achieve Class A ratings, offering building owners reduced insurance premiums and enhanced life safety protection compared to combustible roofing alternatives.

Conclusion

Selecting 1 inch standing seam metal roofing requires balancing performance requirements, aesthetic preferences, budget realities, and long-term value expectations. This versatile roofing system delivers exceptional durability, minimal maintenance demands, and superior weather resistance across diverse applications. When sourced from quality manufacturers utilizing premium materials, robust coating systems, and comprehensive engineering support, 1 inch standing seam metal roofing provides building owners with decades of reliable service and sustained curb appeal.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China 1 Inch Standing Seam Metal Roofing manufacturer offering unparalleled expertise in metal roofing systems since 2018. Recognized as a high-tech enterprise in Shaanxi Province with first-level building curtain wall qualifications and third-level steel structure qualifications, we provide comprehensive solutions from design through installation. Our three state-of-the-art factories spanning 200,000 square meters in Anhui, Hangzhou, and Xi'an house seven production lines and more than forty specialized machines producing High Quality 1 Inch Standing Seam Metal Roofing with 30-year warranties. As a trusted China 1 Inch Standing Seam Metal Roofing supplier and China 1 Inch Standing Seam Metal Roofing wholesale partner to Fortune 500 companies, we deliver competitive 1 Inch Standing Seam Metal Roofing price structures with minimum 500-square-meter orders and 15-20 day delivery timelines. Our ISO9001, ISO14000, and SGS certifications alongside twenty registered patents demonstrate commitment to quality excellence. Contact our China 1 Inch Standing Seam Metal Roofing factory team at huafeng@hfmetalroof.com to discuss your project requirements and discover why leading contractors choose our 1 Inch Standing Seam Metal Roofing for sale for commercial, industrial, and residential applications worldwide.

References

1. Standing Seam Metal Roofing Installation Guide - Metal Construction Association Technical Standards Committee

2. Architectural Metal Roofing: Design and Performance - Journal of Building Enclosure Design, Thompson Research Group

3. Life Cycle Cost Analysis of Commercial Roofing Systems - National Roofing Contractors Association Research Division

4. Thermal Performance of Metal Roofing in Various Climate Zones - American Society of Heating, Refrigerating and Air-Conditioning Engineers

5. Wind Resistance Testing Protocols for Standing Seam Metal Roof Systems - FM Global Property Loss Prevention Data Sheets