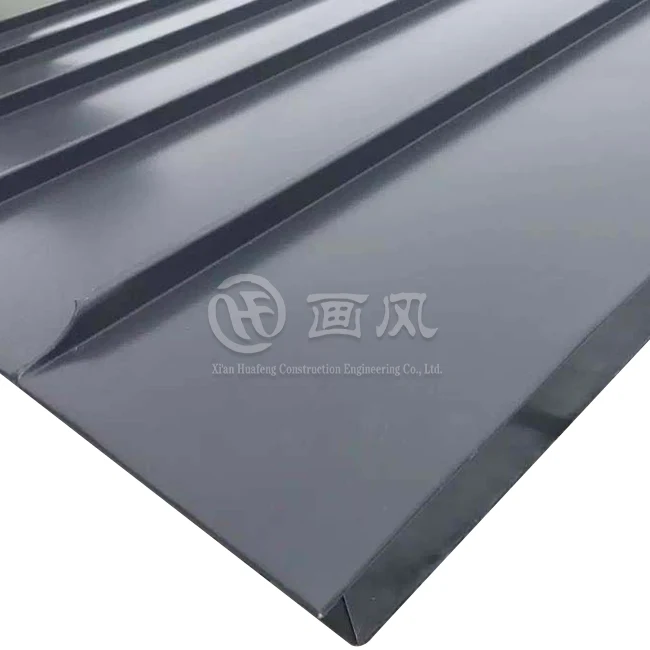

Are you facing costly roof replacements every decade, worried about energy bills spiraling out of control, or struggling to find roofing solutions that match your building's architectural vision? Ribbed Standing Seam Metal Roofing offers a transformative answer to these challenges. This advanced roofing system combines the structural advantages of vertical ribs with the weather-tight performance of concealed fastener technology, delivering unmatched durability, energy efficiency, and aesthetic appeal. As building codes tighten and sustainability becomes paramount in 2025, property owners across residential, commercial, and industrial sectors are discovering why Ribbed Standing Seam Metal Roofing has become the gold standard for long-term roofing solutions.

Commercial Building Applications for Ribbed Standing Seam Metal Roofing

Commercial structures demand roofing systems that balance performance, aesthetics, and lifecycle costs. Ribbed Standing Seam Metal Roofing has emerged as the preferred choice for office complexes, retail centers, and mixed-use developments throughout 2025. The system's concealed fastener design eliminates the vulnerability of exposed screws while the vertical ribs provide enhanced structural rigidity and superior drainage capabilities. Commercial property managers particularly value the low-slope performance of this roofing technology, with installations possible on pitches as low as one-quarter inch per foot, making it ideal for modern architectural designs featuring expansive flat or nearly flat roof surfaces.

Office Buildings and Corporate Campuses

Modern office buildings require roofing solutions that support sustainability goals while maintaining professional aesthetics. Ribbed Standing Seam Metal Roofing delivers on both fronts with reflective coating options that significantly reduce cooling loads during peak summer months. The raised ribs create distinctive shadow lines that enhance visual appeal from street level and upper-floor windows, contributing to the building's overall architectural statement. Installation teams can complete large commercial projects efficiently because the panels arrive pre-formed to exact specifications, with widths typically ranging from twelve to eighteen inches and rib heights between one and three inches, allowing for rapid coverage of expansive roof areas while maintaining weather-tight integrity.

Retail Centers and Shopping Complexes

Shopping centers and retail developments face unique roofing challenges including heavy foot traffic from rooftop HVAC equipment, diverse penetration requirements, and the need for minimal maintenance disruption to business operations. Ribbed Standing Seam Metal Roofing addresses these demands through exceptional impact resistance and the ability to accommodate thermal expansion without compromising seal integrity. The system's mechanical or snap-lock seaming options provide flexibility for different project requirements, while the concealed clip systems allow panels to float on the deck, preventing fastener withdrawal or panel distortion as temperatures fluctuate throughout seasonal cycles. Retailers especially appreciate how the thirty-year warranty coverage protects their infrastructure investment while the energy-efficient properties contribute to reduced operational expenses.

Industrial and Manufacturing Facility Roofing Applications

Industrial environments present some of the most demanding conditions for roofing systems, with exposure to chemical emissions, thermal cycling from production processes, and the structural requirements of supporting heavy equipment. Ribbed Standing Seam Metal Roofing has proven exceptionally well-suited to these applications in 2025, offering the strength and durability manufacturers need. The ribbed profile enhances the panel's load-bearing capacity, allowing it to span greater distances between structural supports while maintaining flatness and weather resistance. Industrial facility managers benefit from material options including galvanized steel, galvalume steel with superior corrosion resistance, and aluminum for coastal or chemically aggressive environments.

Warehouses and Distribution Centers

Modern logistics facilities feature massive roof areas that require cost-effective solutions without sacrificing performance or longevity. Ribbed Standing Seam Metal Roofing excels in warehouse applications where the combination of wide panel coverage, minimal seam count, and concealed fasteners reduces potential leak points across thousands of square feet of roof surface. The system's ability to integrate seamlessly with translucent daylighting panels helps distribution centers reduce artificial lighting costs while maintaining structural continuity. Installation can proceed rapidly even on low-slope warehouse roofs, with mechanically seamed options providing hydrostatic performance that keeps buildings watertight even during severe storm events when water may temporarily pond on the surface.

Manufacturing Plants and Production Facilities

Production facilities often generate significant thermal loads that can accelerate roofing material degradation. Ribbed Standing Seam Metal Roofing withstands these challenging conditions through material selection options including PVDF and PE finishes that resist fading, chalking, and chemical attack. The vertical rib design facilitates rapid water shedding, preventing moisture accumulation that could lead to corrosion or structural damage. Manufacturing plant managers value how the system's expansion clips accommodate the significant thermal movement common in production environments without creating stress points that could compromise panel integrity. The availability of materials ranging from standard steel through stainless steel, copper, and titanium-zinc alloys allows specification of the optimal material for specific industrial chemical exposures.

Residential Applications Driving Demand for Ribbed Standing Seam Metal Roofing

Homeowners in 2025 increasingly recognize that Ribbed Standing Seam Metal Roofing represents a lifetime investment rather than a temporary fix. The residential market has embraced this technology for its combination of exceptional weather protection, energy efficiency, and modern aesthetic appeal that enhances property values. Unlike traditional asphalt shingles requiring replacement every fifteen to twenty years, properly installed Ribbed Standing Seam Metal Roofing can last forty to seventy years with minimal maintenance, making it an economically sound choice despite higher initial costs. The system's fire resistance, impact resistance to hail, and ability to shed snow efficiently provide homeowners peace of mind across diverse climate zones.

Custom Homes and Architectural Residences

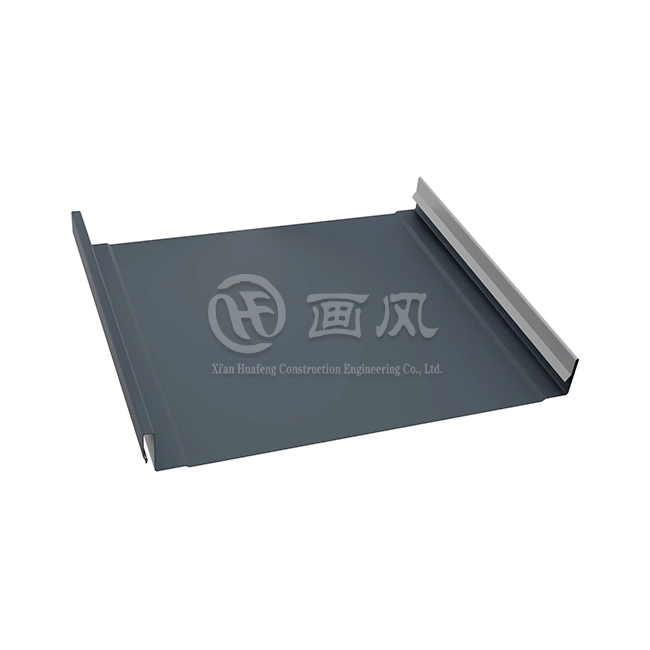

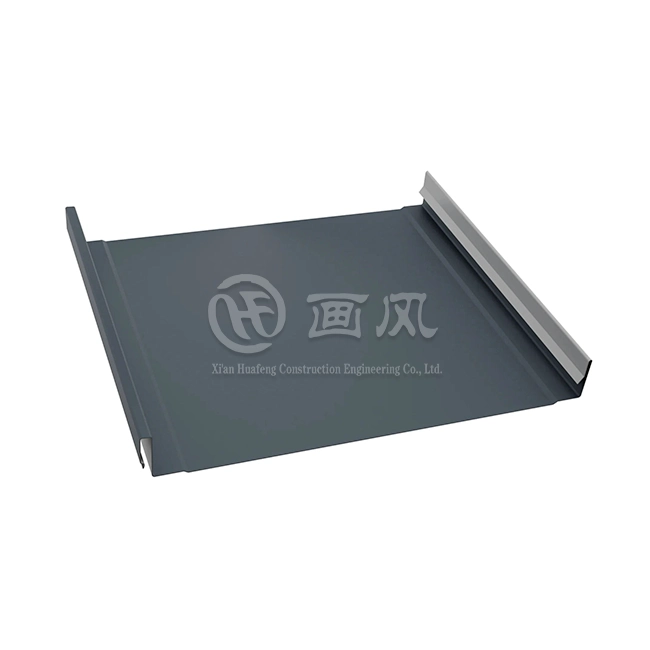

High-end custom homes increasingly feature Ribbed Standing Seam Metal Roofing as both a functional and design element. Architects appreciate the clean lines created by the vertical seams combined with the textured depth of the ribbed profile, which adds visual interest without overwhelming the overall design concept. The system supports creative architectural expressions including curved applications, radius installations, and integration with other exterior materials. Homeowners can select from extensive color palettes exceeding one hundred options, with finishes ranging from classic earth tones through bold contemporary hues. The concealed fastener design maintains the roof's aesthetic purity while the material choices—including aluminum-magnesium-manganese alloys, color-coated steel, and premium copper or zinc—allow customization to match specific architectural visions and performance requirements.

Suburban and Urban Residential Projects

Standard residential applications benefit from Ribbed Standing Seam Metal Roofing's versatility across different roof pitches and configurations. The technology performs reliably on everything from steep-slope traditional homes to modern designs with minimal pitch, provided proper installation protocols are followed. Suburban homeowners particularly value the reduced insurance premiums often available with metal roofing's fire-resistant properties, while urban residents appreciate how the system's durability withstands the harsh conditions of city environments including air pollution and limited access for maintenance. The energy-saving potential of reflective coatings can significantly reduce air conditioning costs in warmer climates, while the material's low thermal mass prevents heat absorption that would increase cooling loads during summer months.

Public Infrastructure and Institutional Building Applications

Government buildings, educational facilities, and public infrastructure projects face stringent durability requirements and long-term budget constraints that make Ribbed Standing Seam Metal Roofing an increasingly popular specification in 2025. These projects often require materials meeting rigorous testing standards for wind uplift, water penetration, air leakage, fire resistance, and impact performance. The engineered nature of quality Ribbed Standing Seam Metal Roofing systems ensures they meet or exceed code requirements while providing documented performance data for project specifications. Institutional decision-makers appreciate how the extended service life and minimal maintenance requirements align with constrained public sector budgets and sustainability mandates.

Educational Facilities and Campus Buildings

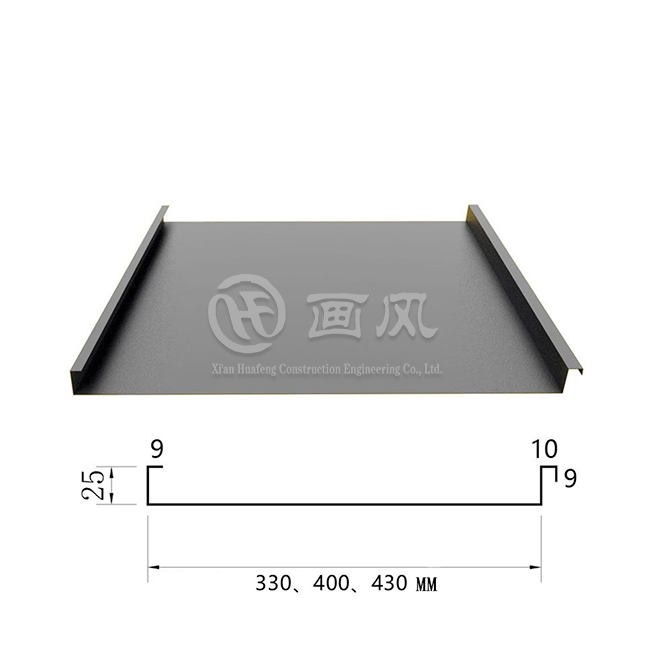

Schools, universities, and educational campuses have embraced Ribbed Standing Seam Metal Roofing for both new construction and renovation projects. The system's longevity means roof replacements won't disrupt educational activities for decades, while the low maintenance requirements free facility management resources for other priorities. Educational institutions particularly value the environmental benefits, as metal roofing is typically manufactured with significant recycled content and remains fully recyclable at end of service life. The ability to integrate solar panel mounting systems directly into the standing seam structure without roof penetrations has made this roofing choice even more attractive as schools pursue renewable energy goals. Projects ranging from elementary school classrooms through university research buildings have successfully utilized Ribbed Standing Seam Metal Roofing with thicknesses from 0.5mm to 1.2mm and standard rib heights of 25mm, demonstrating the system's adaptability to diverse project scales.

Transportation Facilities and Public Assembly Buildings

Transit stations, airports, convention centers, and similar large-scale public facilities present unique roofing challenges including vast roof spans, complex geometries, and high visibility requiring attractive aesthetics. Ribbed Standing Seam Metal Roofing handles these demands through its structural capabilities, design flexibility, and professional appearance. The system's performance in extreme weather conditions makes it ideal for transportation infrastructure that must remain operational during storms, while the fire-resistant properties provide critical safety benefits in public assembly applications. Numerous high-profile projects have demonstrated the technology's capabilities, from airport terminals through convention centers, where the combination of performance, aesthetics, and long-term value proposition justifies specification despite competitive initial costs.

Specialized Applications and Emerging Market Segments

Beyond traditional building categories, Ribbed Standing Seam Metal Roofing has found innovative applications in specialized market segments emerging in 2025. Agricultural structures benefit from the system's ability to withstand challenging rural environments while providing ventilation integration options. Renewable energy facilities including solar farms utilize the roofing technology as both weather protection and mounting structure for photovoltaic arrays. Recreational facilities from sports complexes to entertainment venues leverage the material's spanning capabilities and aesthetic versatility. Even temporary or relocatable structures increasingly incorporate Ribbed Standing Seam Metal Roofing where durability and reusability justify the investment. The system's adaptability stems from its fundamental design principles: weather-tight concealed fastening, thermal movement accommodation through floating clip systems, and structural enhancement through the ribbed profile geometry.

Conclusion

Ribbed Standing Seam Metal Roofing has established itself as the premier roofing solution across commercial, industrial, residential, public, and specialized applications throughout 2025. The technology's combination of exceptional durability, energy efficiency, aesthetic appeal, and long-term value creates compelling benefits for property owners facing increasingly stringent building codes and sustainability requirements. From office buildings and manufacturing facilities through custom homes and institutional campuses, this roofing system delivers proven performance that protects investments for decades while minimizing maintenance demands and operating costs.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

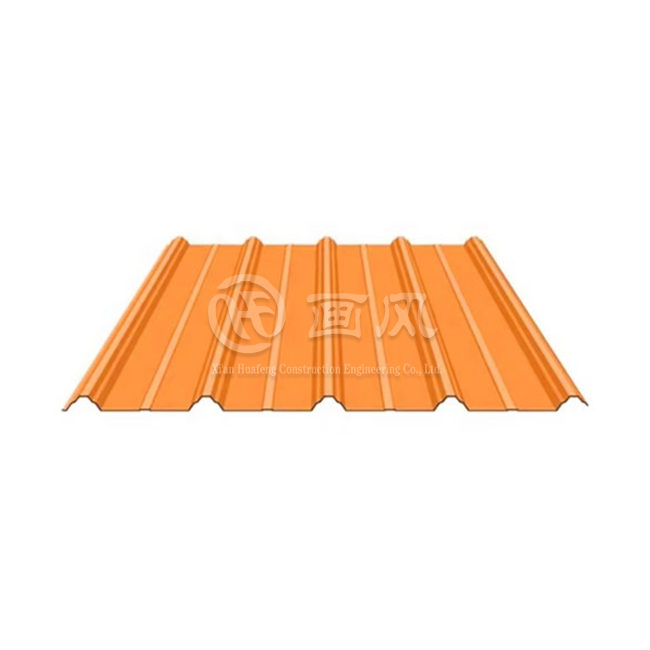

When you're ready to specify or install Ribbed Standing Seam Metal Roofing, partnering with an experienced China Ribbed Standing Seam Metal Roofing manufacturer ensures project success. Xi'an Huafeng Construction Engineering Co., Ltd., established in Shaanxi Province in 2018, has emerged as a leading China Ribbed Standing Seam Metal Roofing supplier and China Ribbed Standing Seam Metal Roofing factory, recognized as a high-tech enterprise with first-level curtain wall qualifications and third-level steel structure qualifications. Our comprehensive manufacturing capabilities include a 200,000 square meter raw material production plant in Anhui plus processing facilities in Hangzhou and Xi'an, operating seven color coating production lines, one laminating line, and over forty specialized machines producing High Quality Ribbed Standing Seam Metal Roofing with thicknesses from 0.5mm to 1.2mm in materials including aluminum alloy, steel, stainless steel, copper, and titanium-zinc.

As a trusted China Ribbed Standing Seam Metal Roofing wholesale provider, we deliver complete one-stop solutions from custom engineering design and structural 3D modeling through precision roll-forming manufacturing and seamless installation, backed by rigorous quality control meeting ISO9001, ISO14000:14001, and SGS standards. Our extensive portfolio includes high-profile projects from Xiongan Station Commercial Body through Xi'an International Convention Center, demonstrating our expertise across diverse applications. Contact our team today at huafeng@hfmetalroof.com to discuss your Ribbed Standing Seam Metal Roofing price requirements and discover why discerning property owners choose our Ribbed Standing Seam Metal Roofing for sale—where engineering design experience, manufacturing excellence, over twenty patent certificates, and Fortune 500 company collaborations combine to deliver customized solutions with thirty-year warranties that protect your investment for generations.

References

1. "Standing Seam Metal Roofing: Performance and Design Considerations," Metal Construction Association Technical Standards Committee, 2024.

2. Johnson, Michael R., "Comparative Life Cycle Assessment of Commercial Roofing Systems," Journal of Building Performance and Sustainability, Volume 18, Issue 3, 2024.

3. Thompson, Sarah L. and Chen, Wei, "Thermal Performance of Metal Roofing in Commercial Applications," International Journal of Building Science and Applications, 2025.

4. "Energy Efficiency and Metal Roofing: Best Practices for 2025," National Roofing Contractors Association Research Division, 2024.

5. Martinez, Carlos J., "Structural Considerations for Standing Seam Metal Roof Systems," Architectural Engineering Quarterly, Volume 42, Number 2, 2024.