Picture this: you've invested in a beautiful commercial building, only to face leaking roofs, corroded panels, and costly repairs within a few years. Traditional roofing materials often fail to withstand harsh weather conditions, leading to maintenance nightmares and unexpected expenses. Aluminum Standing Seam Roofing Panels offer a revolutionary solution that combines exceptional durability with contemporary aesthetics, eliminating these common pain points while delivering a premium architectural statement that lasts for decades.

Understanding Aluminum Standing Seam Roofing Technology

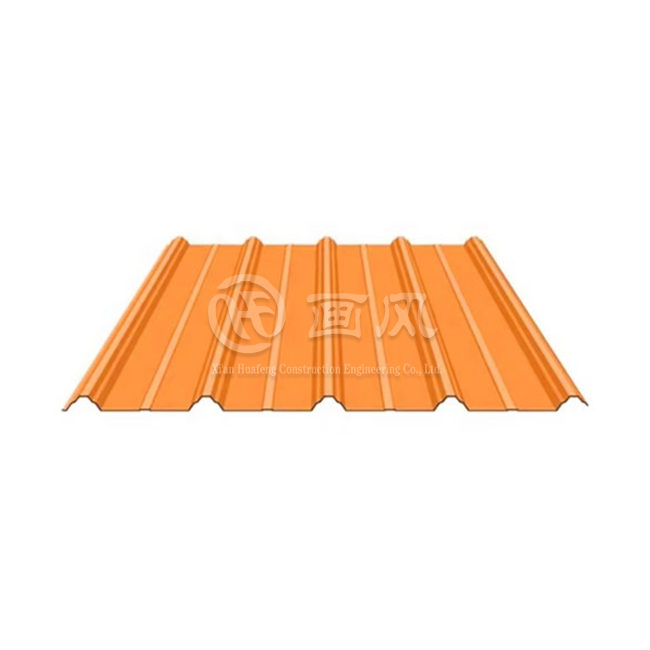

Aluminum Standing Seam Roofing Panels represent a sophisticated engineering approach to modern construction challenges. This high-performance roofing system utilizes aluminum alloy panels connected through mechanical locking technology, known as the standing seam method, which creates a continuous and completely waterproof roof structure. Unlike traditional roofing materials that rely on overlapping shingles or exposed fasteners, aluminum standing seam systems feature concealed clips that allow the panels to expand and contract naturally with temperature fluctuations without compromising the roof's integrity. The panels are manufactured from premium aluminum alloys including AA3003, AA3004, and AA5052, each selected for specific performance characteristics that ensure optimal corrosion resistance and structural stability.

-

Material Composition and Performance Characteristics

The aluminum alloys used in standing seam roofing panels are specifically engineered to deliver superior performance across multiple parameters. AA3003 aluminum alloy provides excellent formability and corrosion resistance, making it ideal for complex architectural designs. AA3004 offers enhanced strength while maintaining the lightweight properties that make aluminum so advantageous for roofing applications. AA5052 alloy delivers the highest corrosion resistance, particularly valuable in coastal environments or industrial areas where exposure to salt spray or chemical emissions poses significant challenges. These Aluminum Standing Seam Roofing Panels undergo rigorous surface treatment processes, including PVDF coating or anodizing, which further enhance their durability and aesthetic appeal. The PVDF coating creates an ultra-durable finish that resists fading, chalking, and chemical degradation for decades, while anodized finishes provide a distinctive metallic appearance with exceptional scratch resistance.

-

Mechanical Locking Systems and Waterproofing Excellence

The standing seam connection method represents a fundamental advantage over traditional roofing systems. This mechanical locking technique creates raised seams that stand vertically above the roof surface, typically ranging from 25mm to 65mm in height. These elevated seams serve multiple critical functions: they provide positive drainage by channeling water away from vulnerable areas, accommodate thermal movement without creating stress points, and eliminate the need for exposed fasteners that could compromise waterproofing. The double standing seam configuration offers maximum security for high-wind environments, while single snap-lock systems provide efficient installation for projects requiring accelerated schedules. Each panel interlocks with adjacent panels through precision-engineered profiles that create weathertight barriers capable of withstanding extreme conditions. This design philosophy ensures that Aluminum Standing Seam Roofing Panels deliver zero-leak performance even under severe weather events including heavy rainfall, snow accumulation, and hurricane-force winds.

Advantages of Aluminum Over Traditional Roofing Materials

When comparing roofing material options, aluminum standing seam systems demonstrate compelling advantages that translate directly into lifecycle value. The fundamental properties of aluminum create benefits that address the most common roofing challenges faced by building owners and facility managers. Weight considerations alone make aluminum an exceptional choice, as aluminum panels weigh approximately one-third as much as comparable steel panels. This reduced weight minimizes structural loading requirements, potentially reducing foundation and framing costs while expanding design possibilities for retrofit applications where existing structures have limited load-bearing capacity.

-

Corrosion Resistance and Longevity

Aluminum's natural corrosion resistance stems from its ability to form a protective oxide layer immediately upon exposure to air. This self-healing characteristic means that even if the surface coating is scratched or damaged, the underlying aluminum automatically generates a new protective barrier that prevents further deterioration. Unlike steel-based roofing materials that require galvanization or constant maintenance to prevent rust, Aluminum Standing Seam Roofing Panels maintain their structural integrity for 50 years or more without the degradation that plagues ferrous materials. In coastal environments where salt spray rapidly corrodes steel components, aluminum systems continue performing without any special protective measures beyond standard PVDF coatings. Industrial facilities dealing with acidic emissions or chemical exposure benefit tremendously from aluminum's inherent chemical resistance, which prevents the premature failure common with other roofing materials in challenging atmospheric conditions.

-

Sustainability and Environmental Responsibility

Modern construction increasingly prioritizes sustainable materials that minimize environmental impact throughout their lifecycle. Aluminum stands as one of the most environmentally responsible roofing materials available today, with 100% recyclability that retains full material value through unlimited recycling cycles. The energy required to produce recycled aluminum represents only 5% of the energy needed for primary aluminum production, creating substantial carbon footprint reductions when recycled content is utilized. Many aluminum standing seam roofing products incorporate significant recycled content without any compromise in performance specifications. Beyond recyclability, aluminum's exceptional solar reflectivity reduces cooling loads in warm climates, contributing to improved building energy efficiency and reduced operational costs. The lightweight nature of Aluminum Standing Seam Roofing Panels also reduces transportation fuel consumption and installation equipment requirements, further minimizing the environmental impact of roofing projects.

Design Flexibility and Architectural Applications

Contemporary architecture demands materials that accommodate creative vision while delivering uncompromising performance. Aluminum standing seam roofing systems excel in both realms, offering designers unprecedented freedom to realize innovative concepts without sacrificing practical functionality. The malleability of aluminum allows these panels to be formed into complex curves and geometric patterns that would be impossible or prohibitively expensive with rigid roofing materials. Commercial buildings, industrial facilities, educational institutions, transportation terminals, and high-end residential projects all benefit from the aesthetic versatility that aluminum standing seam systems provide.

-

Color Options and Surface Finishes

Design professionals appreciate the extensive color palette available for Aluminum Standing Seam Roofing Panels, with RAL and Pantone color-matching capabilities ensuring perfect coordination with overall architectural schemes. PVDF coating technology delivers vibrant, long-lasting colors that resist fading even under intense UV exposure, maintaining the building's aesthetic appeal for decades without repainting or refinishing. Metallic finishes create distinctive contemporary appearances that complement modern architectural styles, while traditional colors provide appropriate context for historic renovation projects. Custom color formulations accommodate specific branding requirements or unique design visions, with factory-applied finishes ensuring consistent quality and coverage that field-applied paints cannot achieve. The smooth, clean lines of standing seam profiles contribute to minimalist aesthetic principles increasingly popular in contemporary design, creating visual sophistication that elevates any project.

-

Installation Efficiency and Project Benefits

Beyond aesthetic considerations, aluminum standing seam roofing systems deliver substantial practical advantages during installation and throughout the building's operational life. The lightweight panels reduce handling requirements and allow smaller crews to complete installations more quickly than comparable steel systems would permit. Prefabrication capabilities mean that panels arrive on-site custom-cut to exact specifications, minimizing field labor and virtually eliminating material waste. The mechanical seaming process requires specialized equipment but proceeds rapidly once crews are properly trained, with experienced installers completing thousands of square feet daily. This installation efficiency translates directly into reduced labor costs and accelerated project schedules, allowing buildings to become operational sooner and reducing financing costs during construction. The concealed fastener design eliminates the tedious and time-consuming process of installing and sealing thousands of exposed screws, while simultaneously eliminating future maintenance issues associated with fastener deterioration and sealant failure.

Technical Specifications and Performance Standards

Professional specifications for Aluminum Standing Seam Roofing Panels encompass numerous parameters that ensure optimal performance across diverse applications and environmental conditions. Panel thickness typically ranges from 0.7mm to 1.2mm, with thicker gauges specified for high-wind zones or projects requiring enhanced puncture resistance. The effective coverage width varies from 300mm to 600mm depending on panel profile and project requirements, with wider panels offering faster installation while narrower profiles accommodate tighter radius curves. Rib height selection influences both aesthetic appearance and functional performance, with taller ribs providing enhanced water channeling capacity and superior structural strength for longer panel runs.

-

Quality Assurance and Manufacturing Standards

Manufacturing excellence distinguishes professional-grade aluminum roofing systems from commodity products. Advanced production facilities equipped with precision roll-forming equipment ensure consistent panel dimensions and profile accuracy across entire project quantities. Quality control protocols verify coating thickness, adhesion properties, and color consistency through rigorous testing regimens that exceed industry standards. Xi'an Huafeng Construction Engineering Co., Ltd. operates three dedicated facilities with seven color coating production lines and over forty specialized machines that manufacture aluminum standing seam panels meeting ASTM, DIN, JIS, BS, and GB/T standards. Raw material traceability systems document the origin and composition of every coil processed, ensuring that specified aluminum alloys and coating systems are consistently delivered. Incoming material inspection procedures verify that supplier-provided materials meet stringent quality requirements before entering production, while finished product inspection confirms that completed panels satisfy dimensional tolerances and appearance standards before shipment.

-

Performance Testing and Certification

Comprehensive performance testing validates that Aluminum Standing Seam Roofing Panels deliver the durability and weather resistance that building owners require. Salt spray testing simulates decades of coastal exposure in accelerated timeframes, confirming that coating systems and substrate materials resist corrosion under extreme conditions. Adhesion testing ensures that coating layers bond permanently to the aluminum substrate without delamination risk. Hardness testing verifies surface durability against impact and abrasion. Weather resistance testing exposes samples to accelerated UV radiation, temperature cycling, and moisture exposure that simulate years of natural weathering. These rigorous evaluation protocols provide the technical foundation for 30-year warranties that give building owners confidence in their roofing investment. ISO9001 quality management certification, ISO14001 environmental management certification, and SGS third-party verification demonstrate commitment to manufacturing excellence and product reliability.

Real-World Applications and Project Success Stories

The versatility and performance of aluminum standing seam roofing systems become evident through examination of completed projects across diverse building types and geographic locations. Transportation facilities including Xiongan Station Commercial Body have utilized aluminum-magnesium-manganese metal roofing to create distinctive architectural statements while delivering maintenance-free performance in high-traffic environments. Convention centers such as the Xi'an International Convention and Exhibition Center showcase the ability of Aluminum Standing Seam Roofing Panels to cover large spans with minimal structural support while creating visually striking roof profiles. Cultural institutions including the Inner Mongolia Tongliao Art Museum demonstrate how metal roofing systems contribute to contemporary architectural expression while providing the weather protection and longevity that public buildings require.

-

Commercial and Industrial Installations

Industrial facilities face particularly demanding roofing challenges due to operational requirements, environmental exposures, and lifecycle cost considerations. Manufacturing plants require roof systems that withstand chemical emissions, accommodate rooftop equipment, and provide long-term reliability without production disruptions for maintenance. Logistics centers and warehouses need cost-effective solutions that cover massive square footage while meeting stringent leak-prevention requirements to protect inventory. Office buildings and commercial developments seek architectural sophistication combined with energy efficiency and minimal maintenance obligations. Aluminum standing seam roofing addresses all these requirements through a single integrated system that delivers performance, aesthetics, and value. The Weihua Cadre College Teaching Building and Office Building project exemplifies how educational institutions benefit from the quiet operation, fire resistance, and longevity that aluminum roofing provides. Infrastructure projects like the Hangzhou Sanpu Drainage Pump Station utilize aluminum's corrosion resistance to protect critical equipment from water damage while withstanding the corrosive atmospheres common in wastewater treatment environments.

Conclusion

Aluminum Standing Seam Roofing Panels represent the optimal convergence of durability, aesthetic appeal, and lifecycle value for contemporary construction projects. Their superior corrosion resistance, lightweight construction, environmental sustainability, and architectural flexibility position them as the premium roofing solution for discerning building owners who refuse to compromise on performance or appearance.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Aluminum Standing Seam Roofing Panels manufacturer and China Aluminum Standing Seam Roofing Panels supplier, offering comprehensive solutions from initial design through final installation. Recognized as a high-tech enterprise in Shaanxi Province with first-level building curtain wall qualifications and third-level building steel structure qualifications, our company delivers unmatched expertise in metal roofing systems. Our three manufacturing facilities span over 200,000 square meters in Anhui, with additional processing plants in Hangzhou and Xi'an, equipped with seven color coating production lines and more than forty specialized machines ensuring precision manufacturing and rapid delivery within 15-20 days.

As a trusted China Aluminum Standing Seam Roofing Panels factory offering competitive Aluminum Standing Seam Roofing Panels price and High Quality Aluminum Standing Seam Roofing Panels, we provide one-stop solutions encompassing structural 3D modeling, load analysis, drainage system simulation, custom fabrication, and professional installation services. Our engineering team conducts thorough project drawing development, factory sample production, and precision manufacturing with real-time quality control. We maintain extensive material selection partnerships with premium brands including Alucosuper, YATAI, and LIDAO for aluminum alloys, ensuring every project utilizes certified materials meeting international standards. With more than 20 registered patents, ISO9001, ISO14001, CE, and SGS certifications, plus successful collaborations with Fortune 500 companies worldwide, we deliver aluminum roofing solutions that exceed expectations.

Whether you're planning a commercial development, industrial facility, or architectural landmark, our China Aluminum Standing Seam Roofing Panels wholesale capabilities and customized production services ensure your project receives optimal solutions. We offer comprehensive support including design optimization, raw material quality testing, multiple packaging options, and flexible transportation methods. Our Aluminum Standing Seam Roofing Panels for sale come with 30-year warranties backed by rigorous quality assurance protocols and decades of proven performance. Contact us today at huafeng@hfmetalroof.com to discuss your roofing requirements and discover how our expertise transforms architectural visions into lasting reality. Bookmark this resource and reach out whenever questions arise about your next metal roofing project.

References

1. "Metal Roofing Systems: Design and Installation Guidelines" - National Roofing Contractors Association Technical Manual, 2023

2. "Aluminum in Building: Properties, Applications, and Sustainability" - Aluminum Association Technical Report, 2024

3. "Standing Seam Metal Roof Systems: Performance Evaluation and Best Practices" - ASTM International Standards Committee, 2023

4. "Sustainable Building Materials: Life Cycle Assessment of Roofing Systems" - International Journal of Construction Engineering and Management, Dr. Michael Chen and Dr. Sarah Rodriguez, 2024

_1757558889992.webp)