Imagine investing thousands in a premium commercial metal roof only to have water seeping through poorly fitted edges during the first storm season. Standing seam trims are the unsung heroes that transform a functional metal roof into a watertight, architecturally refined system. These precision-engineered components provide the critical finishing touches that seal vulnerable roof edges, ridges, and transitions while delivering the clean, professional aesthetic that defines high-quality commercial roofing installations. Understanding how standing seam trims contribute to both performance and appearance can help you make informed decisions that protect your investment and elevate your building's visual appeal.

What Makes Standing Seam Trims Essential for Commercial Roofing Systems?

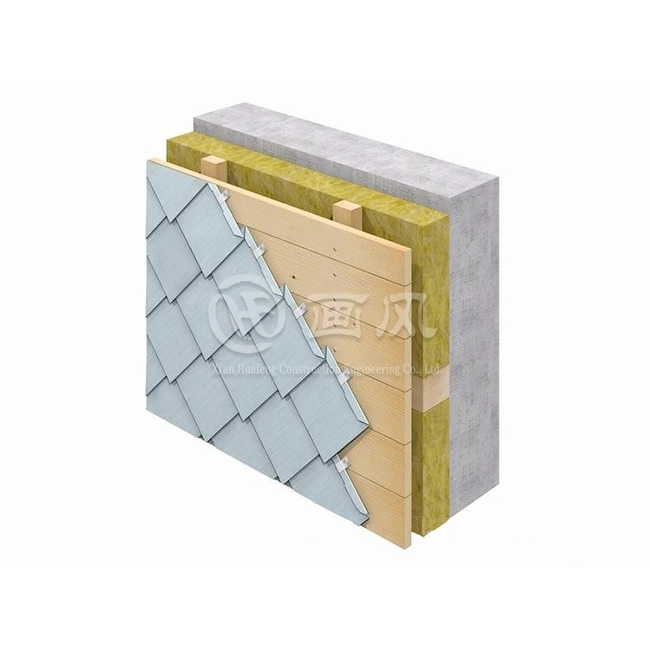

Standing seam trims represent far more than decorative accessories in modern commercial roofing applications. These specialized components serve as the crucial interface between roofing panels and building edges, managing water diversion, thermal expansion, and structural transitions with engineering precision. In commercial environments where building envelopes face continuous exposure to harsh weather conditions, properly designed and installed standing seam trims become the primary defense against moisture infiltration at the most vulnerable points of the roofing system. The engineering behind quality standing seam trims addresses multiple performance requirements simultaneously. Each trim piece must accommodate the natural expansion and contraction of metal roofing materials, which can experience significant dimensional changes with temperature fluctuations throughout daily and seasonal cycles. Commercial buildings with large roof expanses can see metal panels expand by several inches across their length, and trims must allow this movement without compromising watertight seals or creating stress points that could lead to material fatigue or failure over time. Material selection for standing seam trims directly impacts long-term performance and aesthetic consistency. High-quality manufacturers utilize aluminum alloy, galvanized steel, or color-coated steel that matches the thermal expansion characteristics of the primary roofing panels. This material compatibility ensures that trims and panels move together as a unified system rather than creating differential movement that could open gaps or create unsealed transitions. Advanced surface treatments including PVDF coatings provide exceptional resistance to UV degradation, chalking, and color fade, maintaining the premium appearance that distinguishes commercial installations.

-

The Critical Functions of Precision-Engineered Standing Seam Metal Trims

Beyond basic weather protection, standing seam trims perform multiple technical functions that contribute to overall system performance. Eave trims manage water discharge at roof edges, directing moisture away from fascia boards and building walls while providing starter profiles that establish proper panel alignment from the beginning of installation. Ridge trims cap the highest point of roof slopes, creating weather-resistant transitions that prevent wind-driven moisture penetration while accommodating ventilation requirements that regulate attic temperatures and prevent moisture accumulation in roof assemblies. Gable trims seal the rake edges where roofing panels terminate at the sides of sloped roofs, creating clean visual lines while protecting panel edges from wind uplift forces that could compromise panel attachment or create noise issues during high-wind events. Inner corner trims and flashing panel trims navigate complex roof geometries including valleys, dormers, and wall intersections where water concentration demands enhanced protection. Each trim type incorporates specific geometric features including hemmed edges, interlocking profiles, and strategic drainage channels that work together to create comprehensive weather protection. The installation precision of standing seam trims significantly influences final system performance. Professional installation requires careful attention to overlap sequences, fastener spacing, and sealant application at critical junctions. Manufacturers provide detailed installation specifications that address substrate preparation, fastener types and placement, expansion joint locations, and quality control verification procedures. Following these specifications ensures that trim components perform as engineered throughout the expected service life of the roofing system.

How Standing Seam Trim Materials and Manufacturing Quality Impact Long-Term Performance?

Material quality represents the foundation of trim performance and longevity in commercial roofing applications. Premium standing seam trims manufactured from first-run aluminum alloys in grades such as 3003, 3004, or 5052 deliver superior corrosion resistance, formability, and strength characteristics essential for complex trim profiles. These alloys maintain structural integrity through decades of thermal cycling while resisting the galvanic corrosion that can occur at material interfaces when dissimilar metals contact each other in the presence of moisture. Steel-based standing seam trims offer different performance characteristics suited to specific applications and budget requirements. Hot-dip galvanized steel provides economical corrosion protection through a zinc coating that sacrificially protects the underlying steel substrate. Galvalume steel combines aluminum and zinc coatings for enhanced corrosion resistance, particularly in industrial environments or coastal locations where atmospheric contaminants accelerate material degradation. Color-coated steel trims feature factory-applied paint systems that provide both aesthetic appeal and additional protective barriers against environmental exposure. Manufacturing processes significantly influence trim quality and consistency. Advanced roll-forming equipment produces trims with precise dimensional tolerances, consistent bend radii, and uniform edge treatments that ensure proper fit during installation. Quality manufacturers maintain strict process controls including material certification verification, dimensional inspection protocols, and surface finish quality assessments throughout production. These quality control measures prevent the dimensional variations and surface defects that can compromise installation efficiency and final appearance.

-

Surface Treatment Technologies That Protect Standing Seam Trims

Surface treatment selection dramatically affects both appearance retention and protective performance over decades of service. PVDF resin-based coating systems including formulations marketed under names such as Kynar 500 and Hylar 5000 represent the premium standard for commercial metal roofing applications. These fluoropolymer coatings form exceptionally durable surfaces that resist chalking, fading, and chemical attack while maintaining color stability under continuous UV exposure. Independent testing demonstrates that properly applied PVDF coatings retain color and gloss characteristics for thirty years or more in typical commercial environments. The coating application process influences final performance as significantly as the coating chemistry itself. Premium manufacturers apply coatings under controlled factory conditions using coil coating lines that ensure uniform thickness, complete coverage, and proper curing. Multiple coating layers including primers, color coats, and topcoats build comprehensive protection systems with total thicknesses measured in mils. Rigorous quality testing including adhesion tests, impact resistance evaluation, salt spray exposure, and accelerated weathering protocols verify that coatings meet stringent industry standards before products leave manufacturing facilities. Proper material selection requires matching trim specifications to specific environmental conditions and performance requirements. Coastal installations demand enhanced corrosion protection through upgraded alloys or coating systems specifically formulated for salt-laden atmospheres. Industrial environments with atmospheric contaminants require coatings resistant to chemical attack. High-temperature applications such as southern exposures or dark-colored roofs benefit from heat-reflective coating formulations that reduce surface temperatures and extend coating life. Working with experienced manufacturers ensures appropriate material specifications for each unique application.

Professional Installation Practices That Ensure Standing Seam Trim Effectiveness

Installation quality determines whether premium trim materials deliver their engineered performance potential. Professional installation begins with thorough substrate preparation including verification that roof decking provides adequate attachment strength, surfaces are clean and dry, and appropriate underlayment materials create secondary water barriers. Trim installation typically proceeds from eaves upward, establishing proper alignment and lap sequences that direct water flow away from vulnerable transitions. Fastener selection and placement represent critical installation details that directly affect wind uplift resistance and long-term attachment security. Quality installations utilize corrosion-resistant fasteners matched to substrate materials, with spacing and edge distances specified by manufacturers based on engineering analysis and testing. Over-driving fasteners can dimple trim surfaces and compromise appearance, while under-driven fasteners may not provide adequate holding power. Installation crews working with premium trim systems understand these requirements and implement quality control procedures to verify proper execution. Sealant application at trim junctions demands careful attention to material compatibility, surface preparation, and application techniques. High-performance sealants formulated specifically for metal roofing applications provide lasting flexibility, adhesion, and weather resistance. Proper surface cleaning removes contaminants that could interfere with adhesion, while correct bead sizing ensures adequate material volume without excessive squeeze-out that creates maintenance issues. Following manufacturer specifications for sealant types and application methods prevents premature failures that could compromise weather protection.

-

Quality Control Verification During Standing Seam Trim Installation

Comprehensive quality control during installation prevents defects that might not become apparent until after project completion. Visual inspections verify proper alignment, consistent lap dimensions, and absence of surface damage including scratches, dents, or coating imperfections. Fastener inspections confirm correct types, proper spacing, and adequate seating without over-tightening. Dimensional checks ensure that trim profiles maintain specified reveal dimensions and alignment tolerances throughout installation. Water testing represents the ultimate verification of installation quality. Professional installations include controlled water testing using calibrated spray equipment or hose testing following industry-standard protocols. Testing focuses on critical transitions including eave-to-wall intersections, valley configurations, and penetration flashings where water concentration creates the most demanding conditions. Identifying and correcting deficiencies during construction prevents costly remediation after building occupancy. Documentation of installation procedures and quality control results provides valuable records for warranty administration and future maintenance planning. Detailed photographs capturing key installation sequences, material identification labels showing product specifications, and signed inspection reports create comprehensive project documentation. This documentation proves particularly valuable when addressing warranty claims or planning maintenance activities years after original construction.

How Xi'an Huafeng Delivers Superior Standing Seam Trim Solutions?

Xi'an Huafeng Construction Engineering Co., Ltd. brings comprehensive manufacturing capabilities and extensive project experience to standing seam trim production and application. Established in 2018 in Shaanxi Province, China, the company has rapidly developed into a recognized industry leader through strategic investments in manufacturing technology and systematic development of engineering expertise. Recognition as a high-tech enterprise in Shaanxi Province reflects the company's commitment to innovation and technical excellence in metal roofing systems. Manufacturing infrastructure supporting Huafeng's trim production includes a 200,000-square-meter raw material production facility in Anhui province, supplemented by specialized plate and accessories processing plants in Hangzhou and Xi'an. This distributed manufacturing network enables efficient production scheduling, reduced transportation costs, and responsive service to projects throughout China and international markets. Advanced production equipment including seven color coating lines, specialized roll-forming machinery, and automated punching systems ensures consistent product quality and dimensional precision. Quality management systems embedded throughout Huafeng's operations reflect industry-leading standards and certifications. ISO 9001 quality management certification, ISO 14001 environmental management certification, and SGS product testing verification demonstrate the company's commitment to systematic quality control and continuous improvement. More than twenty registered patents covering roofing system innovations document ongoing research and development efforts that advance product performance and installation efficiency.

-

Comprehensive Service Model Supporting Standing Seam Trim Applications

Huafeng's service approach extends beyond simple product supply to encompass complete project support from initial design through final acceptance. Engineering teams work with clients to optimize trim specifications for specific project requirements, conducting detailed drawing reviews, structural analysis, and material selection recommendations. Advanced 3D modeling capabilities enable visualization of complex trim configurations and identification of potential installation challenges before manufacturing begins. Custom manufacturing capabilities allow Huafeng to produce trims tailored to unique project geometries and performance requirements. Factory sample production enables clients to verify dimensions, materials, and surface finishes before full production commitment. Sequential numbering systems implemented during manufacturing facilitate efficient quality control, organized packaging, and streamlined installation. Comprehensive packaging includes section identification, product listings, and handling instructions that simplify jobsite logistics. Installation support services distinguish Huafeng's offering from commodity product suppliers. Technical teams provide onsite guidance to ensure proper installation procedures, verify material handling practices, and conduct quality inspections throughout construction. Post-installation testing protocols confirm watertight performance before project acceptance. Maintenance guidance helps building owners implement preventive care programs that maximize system longevity and preserve aesthetic appearance.

Conclusion

Standing seam trims deliver premium finishes for commercial roofing through precision engineering, quality materials, and professional installation practices. These components protect vulnerable roof transitions while creating the clean, refined appearance that distinguishes superior installations. Selecting quality trims from experienced manufacturers ensures long-term performance and aesthetic consistency.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Partner with Xi'an Huafeng Construction Engineering Co., Ltd., the leading China standing seam trims factory, China standing seam trims supplier, and China standing seam trims manufacturer offering high-quality standing seam trims for sale at competitive standing seam trims price points. Our China standing seam trims wholesale programs deliver exceptional value supported by ISO, CE, and SGS certifications. With extensive engineering design experience, proven construction expertise, seven raw material production lines, more than twenty production machines, and over twenty patent certificates, we provide customized solutions through one-stop service from raw materials to finished accessories. Our collaboration with Fortune 500 companies demonstrates our capability to deliver high quality standing seam trims for demanding commercial applications. Contact us at huafeng@hfmetalroof.com for customized quotations and technical support.

References

1. Metal Construction Association. "Guidelines for Standing Seam Metal Roof Systems: Design, Installation and Performance Standards." Technical Document Series, Metal Construction Association Standards Committee.

2. Thompson, Robert J. and Wilson, Sarah M. "Durability and Performance of Metal Roofing Trim Components in Commercial Applications." Journal of Building Envelope Design, Vol. 15, No. 3.

3. American Society of Civil Engineers. "Metal Roof System Design Manual: Structural Requirements and Weather Protection Details." ASCE Technical Publication Series.

4. National Roofing Contractors Association. "Metal Roofing Installation Best Practices: Quality Control and Performance Verification." NRCA Technical Manual Division.