Are you facing constant roof leaks, rising energy costs, or the worry of frequent roof replacements? Standing seam metal roofing systems, particularly Aluminum Standing Seam Roofing Panels, offer a transformative solution that addresses these common challenges while delivering unmatched durability and aesthetic appeal for commercial, industrial, and residential buildings.

Understanding Aluminum Standing Seam Metal Roofing Systems

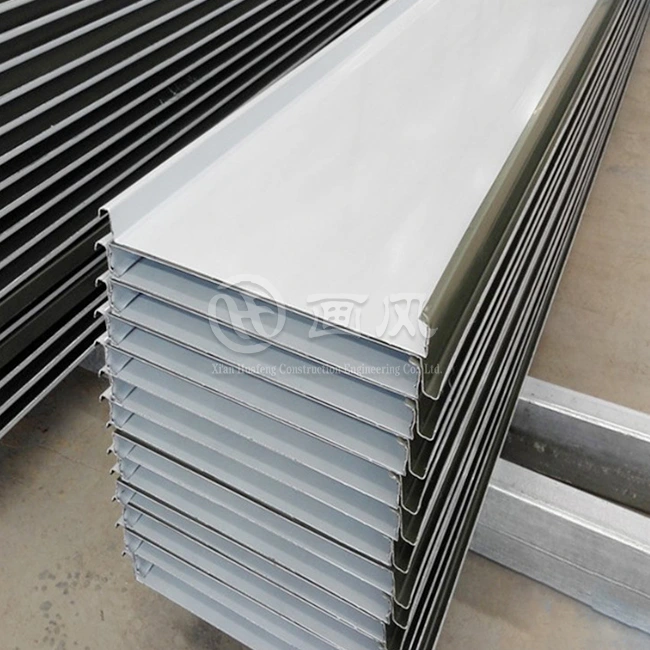

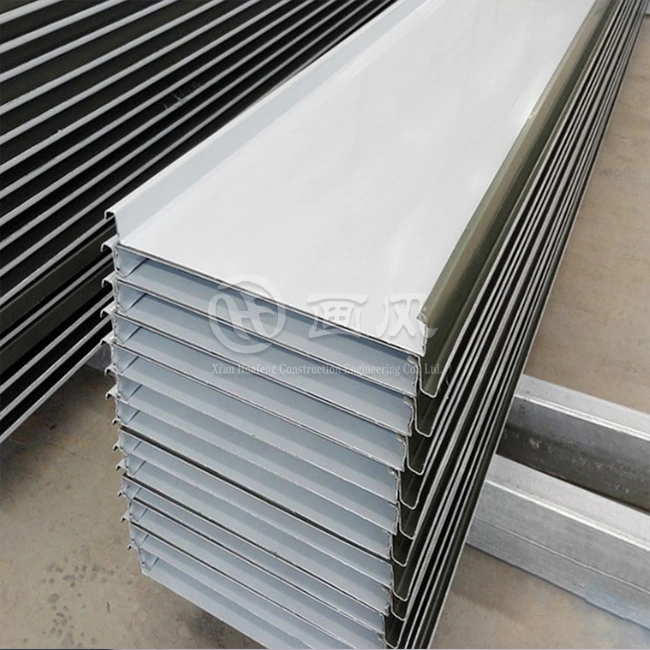

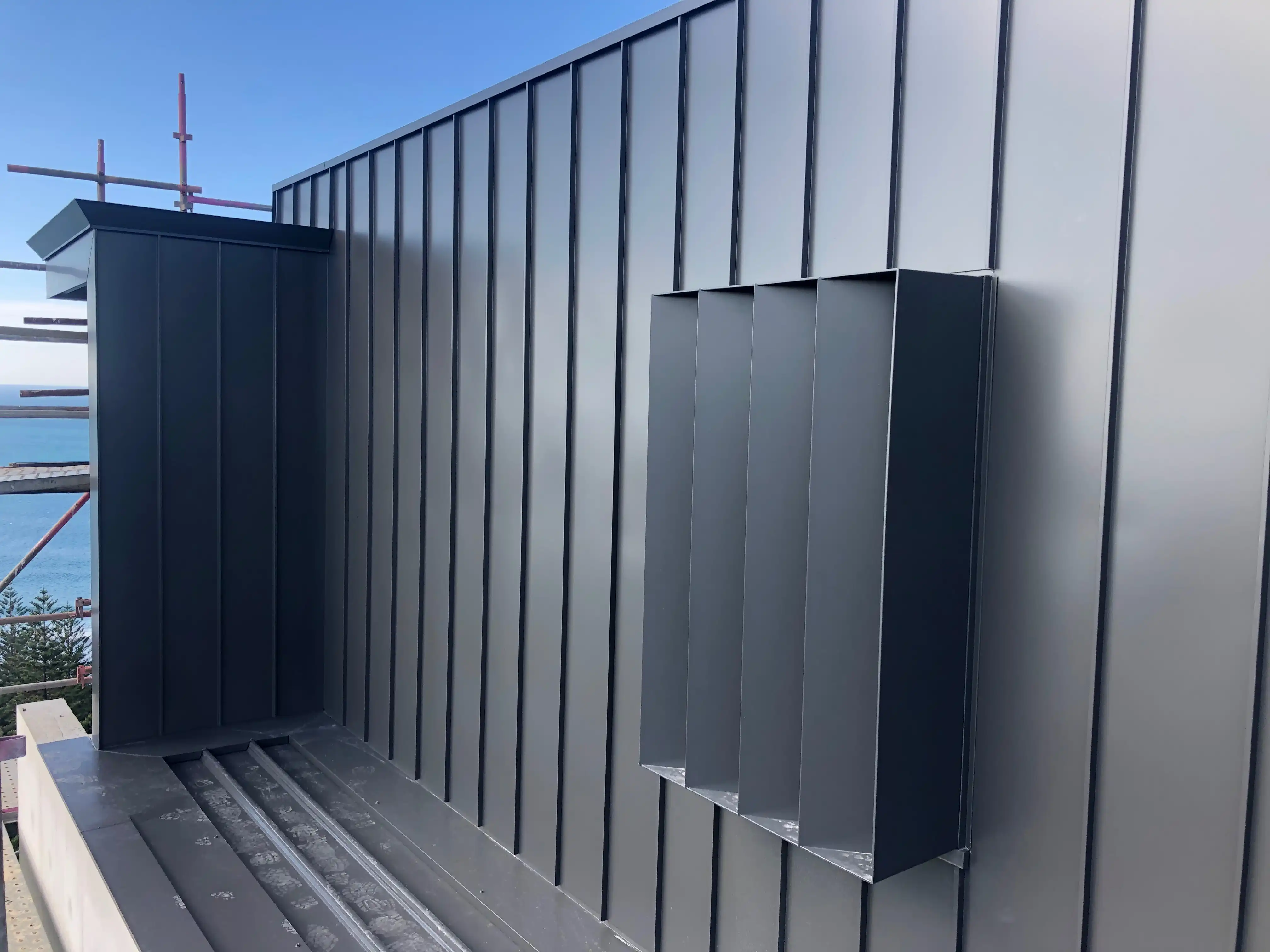

Standing seam metal roofing represents a revolutionary approach to building protection, featuring vertical panels with raised seams that interlock to create a completely watertight seal. Unlike traditional roofing materials that deteriorate over time, Aluminum Standing Seam Roofing Panels utilize advanced mechanical locking technology where panels connect at elevated seams running from eave to ridge. This innovative design eliminates exposed fasteners, allowing the panels to expand and contract freely during thermal cycles without compromising the roof's integrity. The concealed fastener system not only enhances weather resistance but also creates a sleek, contemporary appearance that elevates any building's architectural profile while providing superior protection against wind uplift, water infiltration, and environmental damage.

-

The Engineering Behind Standing Seam Technology

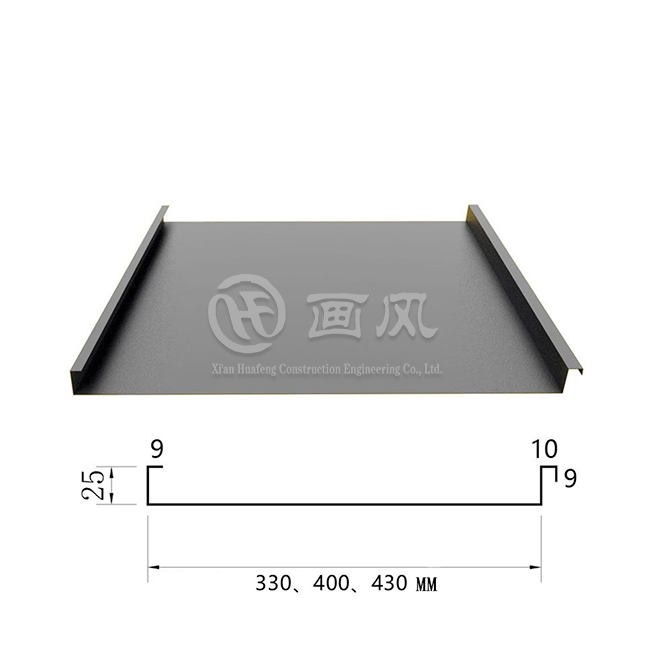

The fundamental advantage of standing seam systems lies in their sophisticated engineering design. Each aluminum panel features precisely rollformed edges that create either male and female legs for snap-lock connections or flat surfaces for mechanical seaming. The panels attach to the roof substrate through specialized clips positioned beneath the raised seams, completely concealing all fasteners from weather exposure. This hidden fastener approach represents a significant advancement over exposed fastener systems, as it eliminates thousands of potential leak points while allowing the metal to move naturally with temperature fluctuations. The raised seams typically stand between 25mm to 65mm above the roof surface, creating defined vertical lines that not only enhance visual appeal but also improve water drainage efficiency. Advanced Aluminum Standing Seam Roofing Panels manufactured by companies like Xi'an Huafeng Construction Engineering utilize high-grade aluminum alloys such as AA3003, AA3004, and AA5052, which provide exceptional corrosion resistance and structural performance across diverse climate conditions.

-

Material Composition and Performance Characteristics

Aluminum standing seam roofing panels distinguish themselves through their unique material properties that deliver long-term performance advantages. Aluminum weighs approximately one-third the density of steel, significantly reducing structural load requirements and installation labor while maintaining superior strength-to-weight ratios. The natural oxide layer that forms on aluminum surfaces provides inherent corrosion protection, making these panels ideal for coastal environments, industrial facilities with chemical exposure, and regions experiencing frequent precipitation. Modern manufacturing processes apply advanced surface treatments including PVDF coatings that enhance color retention, weather resistance, and UV protection for 30 years or more. The typical thickness range of 0.7mm to 1.2mm provides optimal balance between durability and formability, allowing panels to accommodate architectural curves and complex roof geometries without compromising structural integrity. These Aluminum Standing Seam Roofing Panels achieve remarkable longevity often exceeding 50 years with minimal maintenance requirements, representing a superior investment compared to traditional asphalt shingles that require replacement every 15-20 years.

Key Advantages of Aluminum Standing Seam Roofing Panels

-

Superior Weather Protection and Waterproofing

The primary concern for any building owner centers on protecting interior spaces from water infiltration, and standing seam aluminum roofing systems excel in this critical function. The interlocking seam design creates a continuous barrier that directs water flow vertically down the roof slope, preventing horizontal water migration that causes leaks in other roofing types. Quality underlayment installed beneath Aluminum Standing Seam Roofing Panels provides an additional moisture barrier layer, creating a comprehensive waterproofing system capable of withstanding extreme weather events including heavy rainfall, snow accumulation, and wind-driven precipitation. The concealed fastener configuration eliminates the primary failure point found in exposed fastener systems where screws gradually work loose through thermal cycling, creating pathways for water penetration. Standing seam systems can achieve UL2218 Class 4 impact resistance ratings, indicating they can withstand severe hail damage without compromising the roof's weather-tight integrity. This exceptional protection translates to reduced maintenance costs, extended service life, and peace of mind for property owners concerned about weather-related damage.

-

Energy Efficiency and Sustainability Benefits

Modern Aluminum Standing Seam Roofing Panels deliver significant energy performance advantages that reduce operational costs while supporting environmental sustainability goals. Aluminum's natural reflectivity, enhanced through specialized coatings in lighter colors, effectively deflects solar radiation away from building interiors, reducing cooling loads by up to 25% during peak summer months. This "cool roof" effect lowers HVAC energy consumption, extends air conditioning equipment lifespan, and improves occupant comfort in hot climates. The panels' thermal properties also facilitate above-sheathing ventilation systems that create air circulation channels between the metal and roof deck, further enhancing energy efficiency. Beyond operational benefits, aluminum represents one of the most environmentally responsible building materials available, being 100% recyclable without quality degradation through infinite recycling cycles. At the end of a standing seam roof's 50+ year service life, the entire system can be recovered and reprocessed into new products, eliminating landfill waste and conserving natural resources. Companies like Xi'an Huafeng Construction Engineering integrate green sustainable development concepts throughout their manufacturing processes, utilizing advanced production equipment across their 7 color coating production lines to minimize environmental impact while delivering high-performance roofing solutions.

-

Architectural Versatility and Design Flexibility

Aluminum Standing Seam Roofing Panels provide unprecedented design freedom that allows architects and building owners to realize distinctive aesthetic visions while maintaining functional performance. The material's exceptional formability enables creation of curved surfaces, radius formations, and complex geometric patterns that would be impossible or prohibitively expensive with traditional roofing materials. Panels can be manufactured in custom lengths up to building dimensions, eliminating horizontal seams and creating clean, continuous vertical lines that emphasize architectural proportions. The wide range of available colors through RAL and Pantone systems, combined with various finish options including PVDF coatings, anodized surfaces, and bare aluminum, allows precise color matching to complement any design palette or corporate branding requirements. Panel widths typically range from 300mm to 600mm with multiple rib height options between 25mm to 65mm, providing flexibility to achieve desired visual scale and shadow patterns. This design versatility makes standing seam aluminum roofing suitable for applications ranging from contemporary commercial facilities and industrial warehouses to high-end residential projects and historic renovation work where modern performance must blend with traditional aesthetics.

Critical Considerations for Standing Seam Aluminum Roof Installation

-

Professional Installation Requirements and Best Practices

Successful standing seam aluminum roof performance depends fundamentally on proper installation by experienced contractors familiar with metal roofing systems. The installation process requires specialized equipment including pneumatic seamers for mechanical lock systems, precision measurement tools, and panel-specific installation clips designed to integrate with particular panel profiles. Substrate preparation represents a critical first step, ensuring proper insulation installation, high-quality underlayment application, and structural support adequacy to handle anticipated loads including snow accumulation, wind uplift forces, and maintenance personnel access. Professional installers must carefully plan panel layout to accommodate thermal expansion, typically allowing for movement in panels exceeding 45 feet in length through appropriate clip selection and placement intervals. The mechanical seaming process itself demands skilled technique to achieve proper seam engagement without over-tightening that restricts panel movement or under-seaming that compromises weather tightness. Companies like Xi'an Huafeng Construction Engineering provide comprehensive installation support including on-site construction guidance, where installation technicians visit construction sites one day in advance to inspect work areas, verify tool completeness, and conduct technical briefing meetings reviewing work details and safety precautions to ensure zero-leakage performance upon completion.

-

Quality Control and Material Verification

Ensuring long-term standing seam roof performance requires rigorous quality control throughout the material procurement, manufacturing, and installation processes. Reputable manufacturers like Xi'an Huafeng implement comprehensive incoming material inspection protocols that verify raw aluminum quality through sampling and testing procedures, requiring material manufacturers to provide certification documents and third-party testing reports confirming alloy specifications meet ASTM, DIN, JIS, BS, and GB/T standards. Material testing encompasses numerous parameters including product appearance inspection, dimensional verification, salt spray resistance, adhesion performance, hardness measurements, impact resistance, coating thickness, acid resistance, weather resistance capability, and color consistency to prevent defective materials from entering production systems. During manufacturing, quality assurance departments conduct continuous monitoring using more than 40 specialized machines including shearing equipment, presses, and bending machines across multiple production facilities to maintain consistent panel specifications. Finished product inspection verifies appearance quality, dimensional accuracy, flatness, and curvature before specialized packaging divided into sections according to roof plans with identification cards containing section plans and product number lists facilitating efficient on-site installation. This comprehensive quality approach supported by ISO9001, ISO14000:14001, and SGS certifications ensures High Quality Aluminum Standing Seam Roofing Panels consistently meet performance specifications and deliver the promised 30-year warranty protection.

-

Maintenance and Long-Term Performance Optimization

While Aluminum Standing Seam Roofing Panels require significantly less maintenance compared to traditional roofing materials, implementing a proactive maintenance program maximizes system longevity and performance. Regular inspections conducted annually or bi-annually allow early detection of potential issues including loose seams resulting from improper installation, punctures from falling debris or maintenance equipment, and sealant deterioration around roof penetrations and flashing details. Simple cleaning procedures removing accumulated debris, dirt, leaves, and organic matter prevent moisture retention that could accelerate corrosion in damaged coating areas while maintaining optimal drainage performance. Property owners should pay particular attention to transition areas, valleys, and penetrations where different materials meet, as these locations represent higher risk areas for water infiltration if sealants degrade over time. Professional maintenance services provided by experienced metal roofing contractors can identify and address minor concerns before they develop into costly repair situations, extending roof service life well beyond initial warranty periods. The inherent durability of aluminum combined with protective PVDF coatings means well-maintained standing seam roofs often deliver 50+ years of reliable performance with minimal intervention, representing exceptional lifecycle value compared to alternatives requiring frequent repairs or premature replacement.

Comparing Standing Seam Systems: Investment and Value Analysis

-

Cost Considerations and Return on Investment

The initial investment required for Aluminum Standing Seam Roofing Panels typically exceeds costs for traditional roofing materials, representing a significant consideration for budget-conscious building owners. However, comprehensive lifecycle cost analysis reveals standing seam systems often provide superior financial value through combination of extended service life, reduced maintenance requirements, energy savings, and property value enhancement. While exposed fastener metal roofing might initially appear more economical, the hidden costs associated with periodic fastener replacement, increased leak risk, and shorter functional lifespan often result in higher total ownership costs over typical building lifespans. The premium investment in standing seam technology purchases decades of reliable performance with minimal ongoing expenses, avoiding the repetitive replacement cycles required for asphalt shingles every 15-20 years or the maintenance-intensive nature of built-up roofing systems. Energy efficiency benefits deliver measurable operational savings through reduced cooling costs, with reflective aluminum surfaces and ventilation capabilities potentially lowering energy consumption by 20-25% in appropriate climates. Property value appreciation represents another return dimension, with commercial real estate often commanding premium pricing when featuring modern, low-maintenance standing seam roofing that reduces prospective buyers' capital expenditure concerns and operating cost projections for years after acquisition.

-

Selecting the Right Aluminum Standing Seam Roofing Panels Manufacturer

Choosing a qualified Aluminum Standing Seam Roofing Panels manufacturer significantly impacts project success, product performance, and long-term satisfaction. Prospective buyers should evaluate potential suppliers across multiple dimensions including manufacturing capabilities, quality certifications, technical support resources, and proven project experience. Leading China Aluminum Standing Seam Roofing Panels manufacturers like Xi'an Huafeng Construction Engineering demonstrate comprehensive capabilities through extensive factory facilities including raw material production plants covering 200,000 square meters, multiple plate and accessories processing plants strategically located to serve diverse markets, and advanced manufacturing equipment encompassing 7 color coating production lines, laminating production capabilities, longitudinal and transverse shearing systems, and fully automatic punching production lines. Quality certifications including ISO9001, ISO14000:14001, CE, and SGS verification combined with more than 20 registered patents for roofing systems provide tangible evidence of technical expertise and commitment to product excellence. Comprehensive service offerings distinguishing premier China Aluminum Standing Seam Roofing Panels suppliers include custom design support with structural 3D modeling and load analysis, drainage system simulation, material specification advisory, detailed project drawing deepening with 1:1 node development, factory processing samples for customer confirmation, sequential numbering systems ensuring organized production and installation, rigorous material procurement from established brands, and complete installation support with on-site guidance and zero-leakage testing protocols. Companies offering true one-stop solutions from raw material sourcing through final installation with competitive Aluminum Standing Seam Roofing Panels prices and reliable 15-20 day delivery timelines provide maximum project efficiency and reduced coordination complexity.

Conclusion

Standing seam metal roofing, particularly Aluminum Standing Seam Roofing Panels, represents the optimal solution for building owners seeking durable, energy-efficient, and aesthetically distinguished roof systems. The combination of superior weather protection, minimal maintenance requirements, exceptional longevity exceeding 50 years, and architectural versatility makes aluminum standing seam technology a compelling investment that delivers measurable value throughout building lifecycles. Understanding key considerations including material specifications, proper installation requirements, quality control protocols, and manufacturer selection criteria empowers informed decision-making that ensures successful project outcomes and long-term performance satisfaction.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in Shaanxi Province, China in 2018, stands as a leading China Aluminum Standing Seam Roofing Panels factory, supplier, manufacturer, and wholesale provider specializing in comprehensive metal roofing solutions. Recognized as a high-tech enterprise in Shaanxi Province since 2020, we hold first-level qualification for building curtain walls and third-level qualification for building steel structures, demonstrating our technical capabilities and industry standing. Our extensive manufacturing infrastructure includes a 200,000 square meter raw material production plant in Anhui plus two plate and accessories processing facilities in Hangzhou and Xi'an, equipped with 7 color coating production lines, 1 laminating production line, 10 longitudinal and transverse shearing production lines, fully automatic punching production lines, and more than 40 specialized shearing machines, presses, and bending machines ensuring precision manufacturing of High Quality Aluminum Standing Seam Roofing Panels for sale at competitive Aluminum Standing Seam Roofing Panels prices.

Our company integrates green sustainable development principles throughout operations while focusing on design, development, promotion, and application of innovative materials in metal roof products. We provide true one-stop solutions encompassing custom metal roof engineering services including structural 3D modeling, load analysis, drainage system simulation, and material specification advisory, followed by precision manufacturing with roll-forming systems, real-time quality control, and raw material traceability, culminating in seamless installation with on-site project management and safety compliance documentation. Our product portfolio features standing seam metal roofing panels, aluminum-magnesium-manganese plates, titanium-zinc plates, standing seam metal wall sheets, corrugated roofing and wall sheets, flat lock panels, roofing system accessories, and color aluminum and steel coils manufactured from premium materials including AA3003, AA3004, and AA5052 aluminum alloys with PVDF coating, anodizing, or bare aluminum surface treatments in thicknesses ranging from 0.7mm to 1.2mm and rib heights between 25mm to 65mm.

We have successfully completed prestigious projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, Jinghe New City International Culture and Art Center, and Inner Mongolia Tongliao Art Museum, demonstrating our capability to serve Fortune 500 companies and deliver complex architectural visions. Backed by more than 20 registered patents, comprehensive quality certifications including ISO9001, ISO14000:14001, CE, and SGS compliance, and adherence to ASTM, DIN, JIS, BS, and GB/T standards, we guarantee 30-year warranties on our Aluminum Standing Seam Roofing Panels. Our experienced engineering team provides design support, custom solutions with quick 15-20 day delivery capabilities, competitive pricing structures for bulk orders, rigorous material procurement from established brands, comprehensive incoming material inspection protocols, systematic production processes with sequential numbering, finished product inspection and specialized packaging, and complete installation guidance ensuring zero-leakage performance. Whether you require a China Aluminum Standing Seam Roofing Panels manufacturer for commercial, industrial, or residential applications, Xi'an Huafeng Construction Engineering delivers unmatched expertise, quality, and service. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our comprehensive capabilities and commitment to customer success can transform your roofing challenges into lasting solutions. Save this information for future reference whenever roofing questions arise.

References

1. Baker, Michael C. "Metal Roofing Systems: Engineering Principles and Applications." Journal of Architectural Engineering Technology, Volume 12, Issue 3, 2023.

2. Wilson, Jennifer & Roberts, Thomas. "Comparative Life Cycle Analysis of Commercial Roofing Systems." Building Science Review, Volume 45, Number 2, 2024.

3. Anderson, David L. "Standing Seam Metal Roof Performance in Extreme Weather Conditions." Construction Materials Research Quarterly, Volume 38, 2023.

4. Chen, Li & Morrison, Sarah. "Sustainable Building Envelope Design: Modern Metal Roofing Solutions." International Journal of Sustainable Construction, Volume 29, Issue 4, 2024.