Picture this: water seeping through your commercial building's roof during heavy rain, causing costly damage to inventory, disrupting operations, and forcing emergency repairs. Traditional roofing systems often fail to provide the long-term protection commercial properties desperately need. Seam Metal Roof Systems offer a comprehensive solution that addresses these critical challenges while delivering exceptional value, durability, and performance that can transform your building's protection for decades to come.

Understanding Seam Metal Roof Systems for Modern Commercial Applications

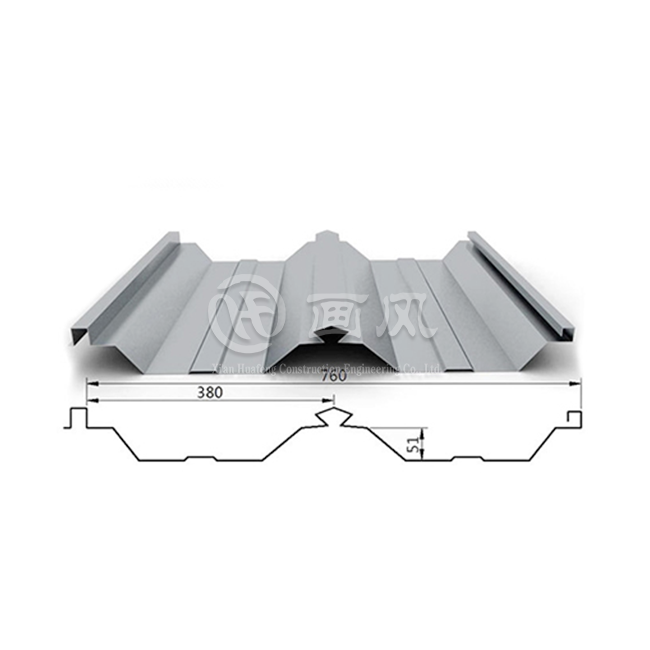

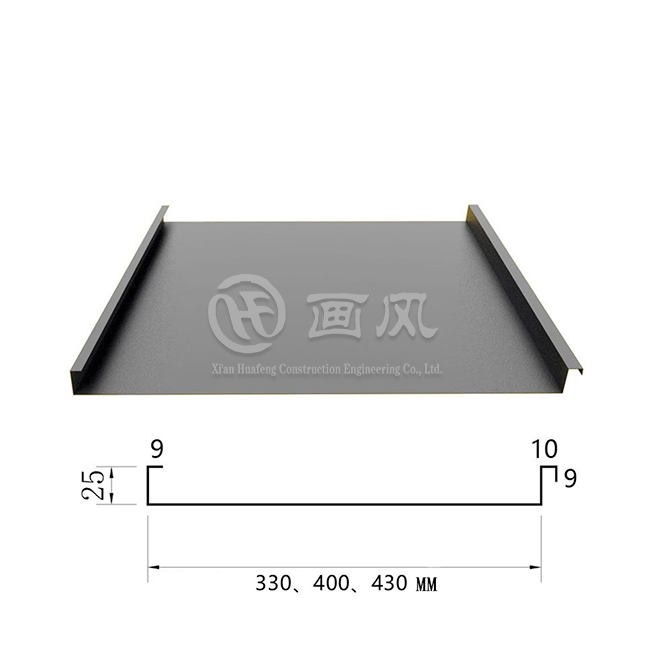

Commercial building owners face mounting pressure to reduce operational costs while maintaining superior protection against increasingly severe weather conditions. Seam Metal Roof Systems represent a revolutionary approach to commercial roofing that combines advanced engineering with proven performance characteristics. These sophisticated roofing solutions feature vertically oriented metal panels with raised, interlocking seams that create a watertight barrier from ridge to eave. Unlike conventional roofing materials that rely on exposed fasteners and horizontal overlaps, standing seam metal roof panels utilize concealed clip systems that eliminate potential leak points while accommodating thermal expansion and contraction. This innovative design methodology ensures that your commercial property remains protected regardless of environmental conditions or seasonal temperature fluctuations. The engineering behind Seam Metal Roof Systems incorporates multiple protective layers that work synergistically to deliver comprehensive building protection. The primary standing seam metal roof panel typically ranges from 0.9mm to 1.2mm in thickness, manufactured from premium-grade aluminum-magnesium-manganese alloy that provides exceptional corrosion resistance without requiring additional protective coatings. These panels feature customizable widths between 300mm and 600mm with effective coverage capabilities, while seam heights of 65mm create elevated channels that facilitate rapid water drainage even during torrential downpours. The system's waterproof and breathable membrane constructed from high-density polyethylene non-woven fabric blocks wind and rain penetration while simultaneously allowing interior moisture to escape, preventing the formation of destructive mold and condensation that compromise structural integrity.

-

Advanced Structural Components and System Integration

Modern Seam Metal Roof Systems integrate multiple specialized components that collectively deliver superior performance characteristics unavailable in traditional roofing approaches. The insulation and sound reduction layer typically utilizes rock wool with calculated thickness specifications that provide thermal retention during winter months while significantly reducing noise transmission from heavy rain or hail impacts. This acoustic performance enhancement proves particularly valuable for commercial facilities where interior noise levels directly impact employee productivity and customer experience. The vapor barrier layer employs polyester film or high-density spunbond polyethylene that limits water vapor migration from building interiors into the roof assembly, minimizing condensation occurrence that leads to premature material degradation and reduced thermal performance. The structural base plate component generally consists of perforated galvanized or galvanized corrugated steel plate with thickness specifications designed according to purlin spacing requirements and perforation rates calculated for optimal acoustic performance. This engineered approach supports sound-absorbing materials and thermal insulation while providing attractive interior ceiling finishes that enhance commercial space aesthetics. The roof purlin system incorporates lining purlins and steel purlins that deliver essential structural support while enabling precise slope adjustments that optimize drainage performance across complex roof geometries. This comprehensive system integration ensures that standing seam metal roof installations deliver consistent performance across diverse commercial applications from warehouses and manufacturing facilities to retail centers and office complexes.

Superior Waterproofing Protection and Weather Resistance

Commercial property owners consistently cite water infiltration as their primary roofing concern, and with good reason. Traditional roofing systems rely on exposed fasteners that create thousands of potential leak points where water can penetrate during storms or as materials age and deteriorate. Seam Metal Roof Systems eliminate this vulnerability through their innovative concealed fastener methodology combined with mechanical seaming techniques that create impenetrable barriers against moisture intrusion. The fixing approach adopts concealed buckle mechanisms plus mechanical locking methods that ensure absolutely no screws penetrate the roof surface, completely avoiding water leakage pathways that plague conventional installations. This fundamental design advantage means your commercial building remains dry and protected even during the most severe weather events that would compromise traditional roofing materials. The panel cross-sectional area optimization maximizes drainage efficiency by channeling water rapidly toward designated drainage points, preventing pooling that accelerates material degradation and increases structural loading. Horizontal overlapped edges utilize specialized hinge machine connections that deliver excellent sealing performance with robust anti-capillary action measures preventing water migration through microscopic gaps. The sliding fixing seat implementation avoids panel damage resulting from temperature-induced deformation, ensuring that thermal expansion and contraction cycles never compromise the roof's watertight integrity throughout decades of service life. Mobile profiling equipment utilization breaks through transportation-related length restrictions, dramatically reducing longitudinal board overlaps that create additional potential failure points in traditional installations.

-

Exceptional Durability Through Premium Material Selection

The anti-corrosion base material selection represents a critical factor distinguishing Seam Metal Roof Systems from inferior alternatives. By adopting grade AA3003 and AA3004 aluminum-magnesium-manganese alloy compositions, these systems deliver strong anti-corrosion performance that withstands harsh environmental exposure without degradation. Surface damage incurred during transportation or construction activities does not compromise the material's inherent anti-corrosion characteristics, ensuring long-term protection remains intact despite inevitable handling impacts. British National Standards Bureau certification confirms that these products maintain service life exceeding 40 years in ordinary environments, with many installations demonstrating reliable performance well beyond this conservative estimate. The PVDF coating application provides additional protection through 25-30μm thickness layers containing 70 percent fluororesin that resists ultraviolet degradation, chemical exposure, and atmospheric pollutants. Standing seam metal roof panels manufactured from these premium alloys possess both considerable strength and remarkable flexibility, making them particularly suitable for roofs featuring complex shapes including three-dimensional curved surfaces that challenge conventional materials. The unique production technology for fan plates, curved plates, and fan curved plates perfectly realizes various design shapes while maintaining full waterproof capabilities that never compromise aesthetic aspirations. This adaptability allows architects and building owners to achieve distinctive visual statements without sacrificing the fundamental performance characteristics that protect their substantial property investments. The original color panels exhibit very strong metallic luster that creates dramatic visual impact, while PE or PVDF coating options accommodate specific color requirements that align with corporate branding or architectural design preferences.

Energy Efficiency and Operational Cost Reduction

Energy expenses represent one of the largest ongoing operational costs for commercial building owners, making energy-efficient building envelope solutions increasingly valuable as utility rates continue rising. Seam Metal Roof Systems deliver exceptional energy performance through multiple mechanisms that work together to minimize heating and cooling demands throughout the year. The highly reflective metal surface naturally deflects solar radiation rather than absorbing heat energy like traditional dark-colored roofing materials, keeping building interiors significantly cooler during summer months when air conditioning costs peak. This solar reflectance capability can reduce cooling energy consumption by 20 to 30 percent compared to conventional roofing systems, generating substantial utility cost savings that accumulate year after year throughout the roof's extended service life. The comprehensive insulation layer integration within standing seam metal roof assemblies provides superior thermal performance that minimizes heat transfer in both directions. During winter months, the rock wool insulation layer retains interior heat that would otherwise escape through inadequately insulated roofs, reducing heating system demands and associated fuel costs. The calculated thickness specifications ensure optimal thermal resistance values that meet or exceed building code requirements while providing additional performance margins that deliver measurable energy savings. The vapor barrier component prevents warm, moisture-laden interior air from migrating into the roof assembly where condensation would compromise insulation effectiveness and reduce overall thermal performance. This moisture management capability maintains consistent insulation performance throughout the building's operational life rather than experiencing the gradual degradation that plagues systems lacking proper vapor control.

-

Long-Term Value Through Reduced Maintenance Requirements

Commercial building owners who select Seam Metal Roof Systems benefit from dramatically reduced maintenance requirements compared to traditional roofing alternatives that demand frequent inspections, repairs, and eventual replacement. The concealed fastener design eliminates the exposed screws and washers that deteriorate from ultraviolet exposure, temperature cycling, and weather impacts, removing the maintenance burden of regularly inspecting and replacing thousands of individual fasteners before they fail and create leak pathways. The aluminum-magnesium-manganese alloy material composition resists rust, corrosion, and material degradation that necessitates ongoing maintenance interventions with steel-based systems requiring regular protective coating applications. Generally, no washing or maintenance activities are required during normal use, allowing facility managers to redirect maintenance resources toward value-generating activities rather than constant roof repairs. The mechanical seaming methodology creates permanent connections between adjacent panels that maintain their watertight integrity throughout decades of thermal cycling, wind loading, and precipitation exposure without requiring periodic re-sealing or joint maintenance. This set-it-and-forget-it reliability proves particularly valuable for large commercial facilities where roof access challenges and safety concerns make routine maintenance inspections expensive and logistically complex. When occasional inspections do occur, the durable PVDF coating maintains its protective characteristics and aesthetic appearance without chalking, fading, or deteriorating like inferior coating systems, ensuring that your commercial building continues presenting an attractive, well-maintained appearance that reinforces positive brand perception and property value retention.

Architectural Versatility and Design Flexibility

Modern commercial architecture increasingly demands distinctive visual statements that differentiate properties in competitive markets while reflecting corporate identity and brand values. Seam Metal Roof Systems accommodate diverse architectural visions through exceptional design flexibility unavailable with rigid, conventional roofing materials. The aluminum-magnesium-manganese alloy material possesses both considerable strength and good flexibility characteristics, proving particularly suitable for roofs featuring complex shapes such as three-dimensional curved surfaces, dramatic slopes, and custom geometries that create memorable architectural impact. The unique production technology for fan plates, curved plates, and fan curved plates perfectly realizes various design shapes while ensuring waterproof capabilities remain fully intact regardless of geometric complexity. Standing seam metal roof panels can be manufactured in customized lengths up to 13 meters, eliminating transverse seams that interrupt visual flow and create additional potential leak points. This extended panel length capability allows architects to create clean, uninterrupted roof surfaces that emphasize horizontal lines and contemporary design aesthetics. Shape options including straight panels, positive arc configurations, inverted arc profiles, and fan-shaped plates provide designers with extensive creative freedom to develop signature rooflines that distinguish their projects from generic commercial construction. The original color panels display very strong metallic luster that creates dramatic visual interest through natural material characteristics, while PE or PVDF coating applications accommodate virtually any color specification to meet design requirements or corporate branding standards.

-

Customization Capabilities for Unique Project Requirements

Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive customization services that transform standard Seam Metal Roof Systems into tailored solutions addressing specific project requirements. Color customization options ensure that roof surfaces complement or contrast with building facades according to architectural intent, while pattern customization capabilities create visual interest through textured surfaces or distinctive profiles. Design customization services leverage advanced 3D modeling technology and structural load analysis to optimize system specifications for individual buildings, considering factors such as local climate conditions, structural support capabilities, and drainage requirements. This personalized approach ensures that every installation delivers optimal performance characteristics rather than forcing buildings to accept compromise solutions designed for generic applications. The on-site press production methodology provides high flexibility that allows production parameter adjustments based on actual construction site conditions, facilitating shortened production cycles and ensuring product quality remains consistently high throughout project execution. This adaptive manufacturing capability proves particularly valuable for complex projects requiring multiple panel profiles, varied seam orientations, or specialized flashing details that conventional prefabrication approaches cannot efficiently accommodate. The company's extensive project portfolio including the Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum demonstrates proven capabilities delivering sophisticated Seam Metal Roof Systems for high-profile commercial and institutional projects where performance and aesthetics both demand uncompromising excellence.

Professional Installation Excellence and Quality Assurance

Even the highest-quality Seam Metal Roof Systems cannot deliver their full performance potential without expert installation that ensures every component functions as engineered. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation services backed by rigorous quality control processes that guarantee reliable, long-lasting results. The company's one-stop solution approach integrates custom metal roof engineering services including structural 3D modeling, load analysis, drainage system simulation, and material specification advisory that optimize system design before installation begins. Project drawing deepening analyzes architectural engineering drawings to identify feasible alternatives, followed by collaborative customer communication that determines appropriate roof panel types for specific structural requirements. The factory processing samples phase produces physical specimens based on confirmed parameters including board type, material thickness, surface treatment methodology, and color specifications. After customer approval, samples become sealed standards guiding subsequent product processing, production activities, and final acceptance procedures. Processing drawing deepening breaks down detailed architectural drawings into comprehensive manufacturing documents that production departments utilize to fabricate components meeting exact specifications. Sequential numbering systems applied to each unit according to project specifications ensure that production processing, quality assurance inspection, packaging operations, and on-site installation proceed according to designated sequences that prevent confusion or installation errors.

-

Rigorous Quality Control and Material Certification

Xi'an Huafeng Construction Engineering Co., Ltd. implements stringent quality control protocols throughout the entire supply chain from raw material procurement through final installation acceptance. Material procurement procedures require purchasing departments to complete inventory assessments and execute purchases based on processing lists and technical drawings submitted by design departments. The company's material selection brand library includes premium suppliers such as Alucosuper, YATAI, and LIDAO for aluminum alloys in 3003, 3004, and 5052 grades, while steel products sourced from BAOSTEEL, GUANZHOU, and XINYU include cold rolled sheet, galvanized sheet, galvalume sheet, and color coated sheet specifications. Stainless steel components from Baosteel and Tsingshan in 316 and 304 grades ensure corrosion resistance in demanding applications, while titanium zinc plates from NedZink and copper materials from Chinalco in T2 and TP2 grades provide specialized solutions for premium architectural applications. Incoming material inspection protocols verify quality through sampling and testing procedures that determine whether supplier-delivered batches meet acceptance standards or require rejection. Raw material manufacturers must provide material certifications and third-party testing reports documenting compliance with specified performance characteristics. Inspection methodologies include full inspection approaches for small quantities and high unit price materials, while random inspection procedures apply to large quantities or frequently ordered materials, preventing defective materials from entering warehouse inventory. The comprehensive inspection regimen encompasses more than a dozen evaluation steps including product appearance inspection, dimensional verification, salt spray testing, adhesion assessment, hardness measurement, impact resistance evaluation, film thickness confirmation, acid resistance testing, weather resistance validation, and color difference analysis. This multilayered quality assurance approach ensures that only materials meeting stringent performance standards progress to production processing phases.

Conclusion

Seam Metal Roof Systems deliver unmatched value for commercial building owners through superior waterproofing protection, exceptional durability, significant energy cost reductions, architectural design flexibility, and professional installation excellence that traditional roofing materials simply cannot match.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 in Shaanxi Province, China, specializes as a professional manufacturer focusing on design, production, sales, and construction of metal roofing systems, building curtain wall systems, and building steel structure enclosure systems for construction projects. Recognized as a high-tech enterprise in Shaanxi Province in 2020, the company holds first-level qualification for building curtain walls and third-level qualification for building steel structures. The company operates a raw material production plant covering 200,000 square meters in Anhui, plus two plate and accessories processing plants located in Hangzhou and Xi'an respectively. Manufacturing capabilities include 7 color coating production lines, 1 laminating production line, 10 longitudinal shearing and transverse shearing production lines, fully automatic punching production lines, and more than 40 shearing machines, presses, and bending machines.

As a leading China Seam Metal Roof Systems factory, China Seam Metal Roof Systems supplier, and China Seam Metal Roof Systems manufacturer offering China Seam Metal Roof Systems wholesale solutions, we provide Seam Metal Roof Systems for sale at competitive Seam Metal Roof Systems price points while maintaining High Quality Seam Metal Roof Systems standards throughout our product portfolio. Our company integrates green sustainable development concepts into operations while remaining committed to design, development, promotion, and application of new materials in metal roof products. Our corporate goal integrates architecture, technology, and aesthetics into comprehensive solutions, while our mission develops metal roofs that add production capacity benefits, solve waste of idle building roofs, and add new beauty to buildings. With more than 20 registered patents for roofing systems, various trademarks, computer software certificates, and compliance with ISO9001, ISO14000:14001, and SGS guidelines, we deliver one-stop services from design through construction. Contact us today at huafeng@hfmetalroof.com to discuss your commercial roofing project requirements and discover how our expertise can protect your valuable property investment.

References

1. Metal Roofing Alliance. "Technical Guidelines for Standing Seam Metal Roof Systems in Commercial Construction." Metal Construction Association Publications.

2. National Roofing Contractors Association. "Energy Performance Standards for Metal Roofing Systems." NRCA Technical Services Department.

3. Building Envelope Research Institute. "Comparative Analysis of Commercial Roofing System Lifecycle Performance." Journal of Building Science and Technology.

4. American Society of Civil Engineers. "Structural Design Specifications for Metal Roof Panel Systems." ASCE Standards Committee on Cold-Formed Steel Structures.