Are you facing the challenge of selecting a roofing solution that balances timeless aesthetics with long-term performance? Gray metal roofing has emerged as a leading choice for property owners seeking a versatile, durable, and sophisticated roofing system. Among the various options available, the grey standing seam metal roof stands out for its sleek appearance and exceptional weather resistance. This comprehensive guide explores the advantages and disadvantages of gray metal roofing to help you make an informed decision for your residential, commercial, or industrial project.

Understanding Grey Standing Seam Metal Roof Systems

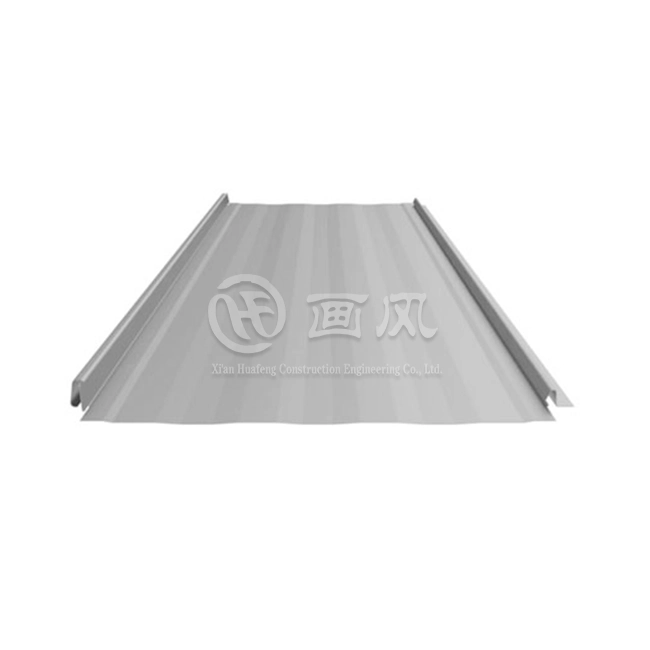

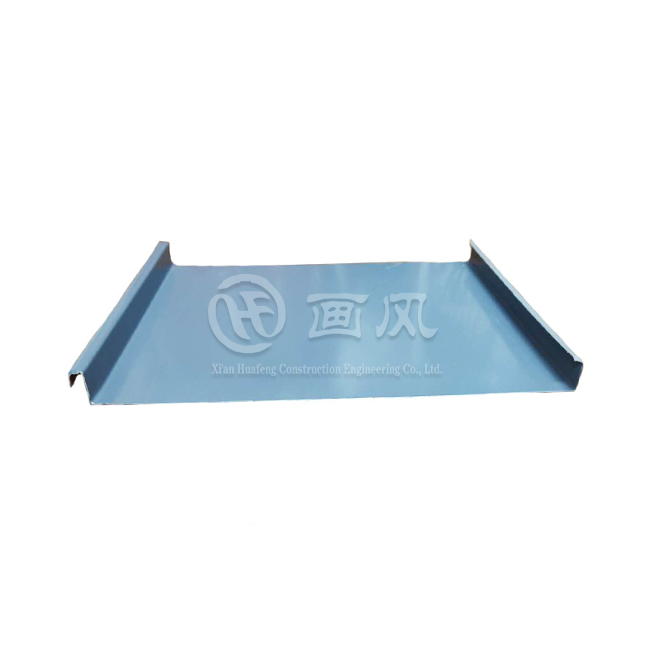

The grey standing seam metal roof represents one of the most advanced roofing technologies available in today's construction market. This roofing system features vertical panels with raised seams that interlock to create a watertight barrier, while the gray color provides a neutral yet sophisticated aesthetic that complements virtually any architectural style. Unlike traditional roofing materials, standing seam systems utilize concealed fasteners that protect against water infiltration and allow for thermal expansion and contraction without compromising the roof's integrity. The manufacturing process involves precision roll-forming of high-quality metal substrates, typically galvanized steel or aluminum, followed by the application of premium coatings such as PVDF or polyester finishes that ensure superior UV and weather resistance. These systems can be customized with various seam heights ranging from 25mm to 65mm and panel widths between 300mm and 600mm, depending on specific project requirements and aesthetic preferences. The gray color itself comes in multiple undertones, from cool grays with blue or green hints to warm grays with subtle brown or red undertones, allowing designers and property owners to select the perfect shade that harmonizes with their building's overall design concept and surrounding environment.

-

Material Composition and Surface Treatments

Grey standing seam metal roof panels are manufactured from premium-grade materials that undergo rigorous quality control processes to ensure consistent performance. The base metal substrate typically consists of galvanized steel with thicknesses ranging from 0.6mm to 0.8mm, though aluminum options are also available for applications requiring enhanced corrosion resistance. The surface treatment plays a crucial role in determining the roof's longevity and appearance, with PVDF coatings offering the highest level of protection against fading, chalking, and environmental degradation. These advanced coating systems incorporate specialized pigments and resins that create a molecular bond with the metal substrate, resulting in a finish that maintains its color integrity and gloss level for decades. The gray color options available include matte and gloss finishes, each providing distinct aesthetic qualities that can dramatically affect the building's overall appearance. Matte gray finishes offer a more subdued, contemporary look that minimizes glare and creates a sophisticated understated elegance, while gloss gray finishes provide a more reflective surface that can enhance architectural details and create visual interest through light interaction. The manufacturing process ensures that each panel meets strict dimensional tolerances and surface quality standards, with specifications conforming to international standards including ASTM, DIN, JIS, BS, and GB/T, guaranteeing compatibility with diverse building codes and performance requirements across different geographic regions.

-

Architectural Versatility and Design Integration

The architectural flexibility of grey standing seam metal roof systems makes them suitable for an extraordinarily wide range of building types and design philosophies. In residential applications, these roofing systems enhance modern homes and villas with their clean lines and contemporary aesthetic, while also complementing traditional architectural styles when paired with appropriate color schemes and exterior finishes. Commercial buildings benefit from the professional appearance and low maintenance requirements of gray metal roofing, with office complexes, retail centers, and hospitality facilities all utilizing these systems to project an image of quality and permanence. Industrial facilities appreciate the durability and weather resistance of standing seam systems, particularly in harsh environments where roof performance is critical to operational continuity. Public buildings such as schools, hospitals, and transportation terminals frequently specify gray metal roofing due to its combination of aesthetic appeal, fire resistance, and long service life that minimizes lifecycle costs. The neutral gray color serves as an ideal backdrop for architectural accent features, allowing designers to introduce contrasting colors through trim, siding, doors, and landscaping elements without creating visual conflicts. Additionally, grey standing seam metal roof systems integrate seamlessly with sustainable building practices, providing an excellent substrate for solar panel installations while maintaining their aesthetic integrity and structural performance.

Advantages of Gray Metal Roofing Systems

-

Exceptional Durability and Weather Performance

One of the most compelling advantages of grey standing seam metal roof systems is their exceptional durability and ability to withstand extreme weather conditions over extended periods. These roofing systems are engineered to resist corrosion, with multiple layers of metallic and organic coatings that protect the base metal from oxidation and chemical degradation. The standing seam design creates a mechanical interlock between adjacent panels that provides superior wind resistance, with properly installed systems capable of withstanding wind speeds exceeding 140 miles per hour without panel displacement or fastener failure. The concealed fastener design eliminates the most common point of water infiltration found in exposed fastener systems, ensuring a watertight envelope that prevents moisture damage to underlying roof decks and building interiors. Gray metal roofs demonstrate excellent impact resistance, maintaining their structural integrity when subjected to hail, falling branches, and other debris that would compromise traditional roofing materials. The thermal performance characteristics of metal roofing systems allow them to expand and contract with temperature fluctuations without warping or cracking, thanks to the clip-based attachment system that accommodates this natural movement. With proper installation and minimal maintenance, grey standing seam metal roof systems routinely achieve service lives of 30 to 50 years or more, significantly exceeding the lifespan of asphalt shingle, built-up, or single-ply membrane roofing systems, thereby reducing the frequency and cost of roof replacements over the building's operational life.

-

Energy Efficiency and Environmental Benefits

Grey standing seam metal roof systems offer significant energy efficiency advantages that translate directly into reduced operational costs and enhanced building sustainability. The reflective properties of metal roofing, particularly lighter gray shades, help deflect solar radiation away from the building envelope, reducing heat gain during warm months and lowering air conditioning loads by up to 25 percent compared to darker, more absorptive roofing materials. When combined with proper insulation and ventilation systems, gray metal roofs create a highly efficient thermal barrier that minimizes heat transfer in both directions, keeping buildings cooler in summer and warmer in winter. The environmental benefits of metal roofing extend beyond operational energy savings to include the material's inherent sustainability characteristics, with most metal roofing products containing 25 to 95 percent recycled content and being 100 percent recyclable at the end of their service life. This cradle-to-cradle recyclability reduces the environmental impact associated with roof replacement, as old panels can be reprocessed into new metal products without loss of material properties or performance characteristics. The long service life of grey standing seam metal roof systems also contributes to sustainability by reducing the frequency of material consumption and waste generation associated with more frequent roof replacements. Many manufacturers now offer metal roofing products with specialized cool roof coatings that achieve high Solar Reflectance Index values, qualifying for energy efficiency incentives and contributing to green building certification programs such as LEED and ENERGY STAR, providing additional financial and environmental benefits to building owners who prioritize sustainable construction practices.

-

Low Maintenance Requirements and Lifecycle Value

The maintenance demands of grey standing seam metal roof systems are remarkably minimal compared to alternative roofing materials, resulting in substantial cost savings and operational convenience over the building's lifetime. Unlike asphalt shingle roofs that require regular inspection for damaged, displaced, or deteriorating shingles, or built-up roofing systems that need periodic recoating and repair of blistered or split membranes, metal roofing systems maintain their integrity and performance with only occasional cleaning to remove accumulated debris, leaves, and dirt. The hard, smooth surface of metal panels resists the growth of moss, algae, and mildew that commonly affects organic roofing materials in humid climates, eliminating the need for chemical treatments or pressure washing to maintain appearance and prevent biological degradation. The PVDF and polyester coating systems applied to quality metal roofing products provide exceptional resistance to fading, chalking, and weathering, with manufacturers typically offering 30-year warranties against excessive color degradation, ensuring that the roof maintains its aesthetic appeal throughout its service life without requiring refinishing or repainting. The structural integrity of standing seam systems, with their concealed fasteners and mechanical seam connections, eliminates common failure points associated with exposed fasteners that can loosen, corrode, or allow water infiltration over time. When lifecycle costs are properly evaluated, including initial installation expenses, maintenance requirements, energy savings, and replacement frequency, grey standing seam metal roof systems consistently demonstrate superior value compared to alternative roofing materials, with the higher upfront investment being offset by decades of reliable performance and minimal ongoing costs.

Disadvantages and Considerations

-

Initial Investment and Installation Complexity

While grey standing seam metal roof systems offer exceptional long-term value, the initial investment required for materials and installation typically exceeds that of conventional roofing options, which can present a barrier for budget-constrained projects. The premium materials, specialized coatings, and precision manufacturing processes necessary to produce high-quality metal roofing panels result in higher material costs compared to asphalt shingles or basic membrane roofing systems. Installation of standing seam metal roofing requires specialized knowledge, tools, and skills that not all roofing contractors possess, with proper seam formation, panel alignment, and clip attachment being critical to system performance and weather resistance. The labor intensity associated with installing concealed fastener systems, fabricating custom flashings, and integrating roof penetrations and transitions adds significant time and expense to the installation process compared to simpler exposed fastener or overlapping shingle systems. Property owners considering grey standing seam metal roof systems should carefully evaluate the total project cost against the anticipated benefits, including extended service life, reduced maintenance expenses, and energy savings, to determine whether the investment aligns with their financial objectives and building performance goals. In many cases, financing options or lifecycle cost analyses demonstrate that the higher initial cost is justified by the substantial long-term savings and benefits, but projects with short-term budget constraints or limited financing capacity may find it challenging to accommodate the upfront expenditure required for premium metal roofing systems without compromising other essential building components or features.

-

Thermal and Acoustic Characteristics

The thermal properties of metal roofing, including grey standing seam metal roof systems, require careful consideration and appropriate design measures to optimize building comfort and energy performance. Darker shades of gray, such as charcoal or gunmetal tones, absorb more solar radiation than lighter colors, potentially increasing cooling loads during warm weather unless adequately compensated through proper insulation, ventilation, and reflective coating technologies. The thermal conductivity of metal can result in rapid heat transfer from the exterior surface to the building interior if adequate insulation is not installed beneath the roofing system, making proper thermal barrier design essential to achieving desired energy efficiency outcomes. Metal roofing also exhibits different acoustic properties compared to absorptive roofing materials, with rain, hail, and other impacts potentially creating audible noise that some building occupants find objectionable, particularly in residential applications or quiet institutional environments. However, these acoustic concerns can be effectively mitigated through the installation of appropriate insulation materials, sound-dampening underlayments, and proper attic or plenum space design that provides acoustic separation between the roof surface and occupied spaces. The phenomenon known as oil canning, which manifests as slight visual waves or ripples in flat metal panels, can occur in standing seam systems due to thermal expansion, installation stress, or material handling, though this cosmetic issue does not affect the roof's structural performance or weather resistance and can be minimized through proper material selection, installation techniques, and realistic aesthetic expectations that account for the natural behavior of metal building materials.

-

Color Selection and Aesthetic Considerations

Selecting the appropriate shade of gray for a standing seam metal roof requires thoughtful consideration of multiple factors that affect both immediate visual impact and long-term satisfaction with the building's appearance. The wide range of gray tones available, from light ash and silver to medium charcoal and dark gunmetal, each creates different aesthetic effects and interacts uniquely with surrounding architectural elements, landscaping, and neighborhood context. Cool gray shades with blue or green undertones may appear differently under various lighting conditions and can create unexpected color relationships with warm-toned siding, trim, or masonry elements, while warm grays with brown or red undertones may look dull or muddy in certain environments or clash with cool-toned exterior finishes. The selection of matte versus gloss finishes further influences the roof's appearance, with matte surfaces providing a more subdued, contemporary look that minimizes reflections and glare, while gloss finishes create a more dynamic surface that reflects light and emphasizes the roof's dimensional qualities but may show imperfections more readily. Property owners should utilize color visualizer tools, review physical samples under various lighting conditions, and consider how the selected gray shade will complement or contrast with existing and planned exterior elements to ensure a cohesive and visually satisfying result. The potential for gradual fading over decades, while minimized through advanced coating technologies, should also be considered when selecting darker gray shades that may show color shift more noticeably than lighter tones, though quality manufacturers back their products with substantial warranties against excessive fading that provide confidence in long-term color retention and aesthetic durability.

Conclusion

Gray metal roofing, particularly grey standing seam metal roof systems, offers an exceptional combination of aesthetic versatility, structural durability, and long-term performance that makes it an ideal choice for diverse building applications. While the initial investment exceeds conventional roofing options, the superior weather resistance, minimal maintenance requirements, energy efficiency benefits, and extended service life deliver substantial lifecycle value that justifies the premium cost for property owners seeking quality and permanence in their roofing investment.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

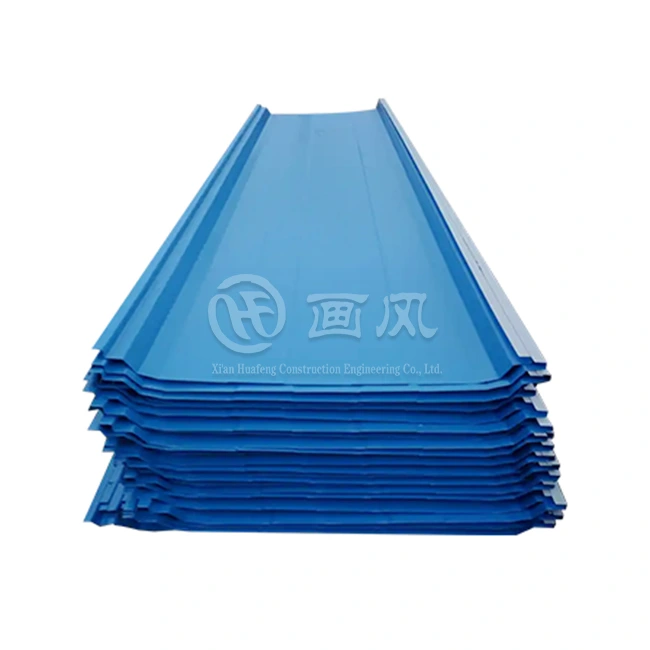

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 as a recognized high-tech enterprise in Shaanxi Province, specializes in comprehensive metal roofing solutions that integrate design excellence, precision manufacturing, and expert installation services. With three state-of-the-art production facilities featuring seven color coating lines and over 40 specialized machines, Huafeng delivers customized grey standing seam metal roof systems manufactured to the highest international standards including ASTM, DIN, JIS, BS, and GB/T specifications. Our extensive portfolio includes successful installations at prestigious projects such as Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, demonstrating our capability to execute large-scale commercial and public building projects with exceptional quality and precision. As a China Grey Standing Seam Metal Roof factory, China Grey Standing Seam Metal Roof supplier, China Grey Standing Seam Metal Roof manufacturer, and China Grey Standing Seam Metal Roof wholesale provider, we offer Grey Standing Seam Metal Roof for sale at competitive Grey Standing Seam Metal Roof price points while maintaining High Quality Grey Standing Seam Metal Roof standards throughout our product line. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and discover how our one-stop solution approach, backed by more than 20 registered patents, ISO9001 and ISO14000:14001 certifications, and 30-year product warranties, can transform your building with premium metal roofing systems that deliver lasting value and architectural distinction.

References

1. Sheffield Metals International. "Metal Roofing Color Selection and Performance Guide." Metal Roofing Learning Center. Sheffield Metals, 2024.

2. Green Tree Metals. "Standing Seam Metal Roofing Systems: Technical Specifications and Applications." Green Tree Metals Technical Publications, 2025.

3. Western States Metal Roofing. "Comprehensive Guide to Metal Roof Materials, Coatings, and Installation Practices." Western States Metal Roofing Educational Resources, 2021.

4. Metal Roofing Alliance. "Energy Performance and Lifecycle Analysis of Metal Roofing Systems." Metal Roofing Industry Research, 2023.