If you're planning a commercial building project or renovating an existing structure, you've probably asked yourself: "Is standing seam roof aluminum?" The answer is yes—Aluminum Standing Seam Roofing Panels are one of the most popular and reliable roofing solutions available today. Whether you're concerned about durability, energy efficiency, or long-term maintenance costs, understanding the material composition and performance characteristics of standing seam roofs is essential for making an informed investment decision.

Understanding Aluminum Standing Seam Roofing Systems

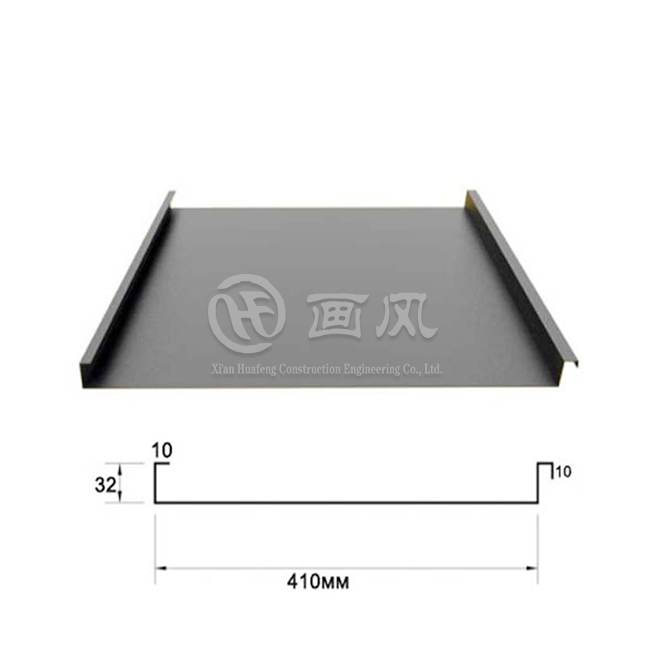

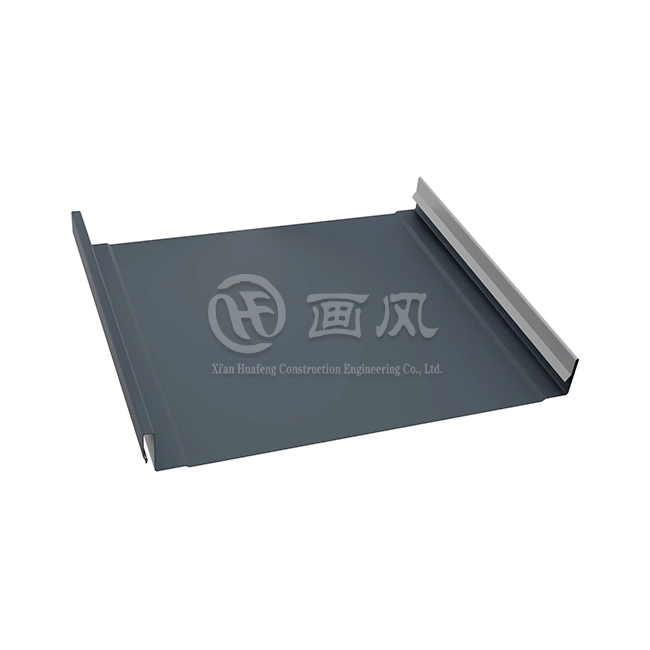

Standing seam metal roofing can be manufactured from several materials, including steel, copper, zinc, and aluminum. Among these options, Aluminum Standing Seam Roofing Panels have gained significant market share due to their exceptional performance characteristics. The standing seam design features raised vertical legs that interlock to create a continuous, weathertight seal without exposing any fasteners to the elements. This concealed fastener system is what distinguishes standing seam roofs from traditional exposed fastener metal roofing, offering superior protection against water infiltration, wind uplift, and thermal stress. Aluminum standing seam systems utilize high-grade aluminum alloys, typically AA3003, AA3004, or AA5052, which are specifically engineered for architectural applications. These alloys provide an optimal balance of strength, formability, and corrosion resistance. The panels are roll-formed into precise profiles with consistent dimensions, ensuring proper interlocking and alignment during installation. The raised seams typically range from 25mm to 65mm in height, creating distinctive vertical lines that define the modern aesthetic of standing seam roofing while providing structural rigidity and water-shedding capabilities.

Aluminum Standing Seam Roofing Panels

-

Material Composition and Alloy Selection

The aluminum alloys used in Aluminum Standing Seam Roofing Panels are carefully selected based on performance requirements. AA3003 aluminum alloy contains manganese as the primary alloying element, providing good formability and moderate strength suitable for most roofing applications. AA3004 alloy offers enhanced strength and durability through increased manganese content, making it ideal for installations in areas subject to high wind loads or thermal cycling. AA5052 alloy incorporates magnesium as the primary alloying element, delivering the highest strength among commonly used roofing alloys while maintaining excellent corrosion resistance, particularly in coastal or industrial environments where salt spray or chemical exposure is a concern. The thickness of Aluminum Standing Seam Roofing Panels typically ranges from 0.7mm to 1.2mm, with the selection depending on span requirements, local building codes, and performance expectations. Thicker panels provide greater resistance to oil canning—the visible waviness that can occur in flat metal surfaces—and improve the overall structural integrity of the roof system. The aluminum surface is often treated with advanced coating systems such as PVDF (Polyvinylidene Fluoride) resin-based paints, which offer exceptional resistance to ultraviolet radiation, chemical exposure, and atmospheric pollutants. These coatings maintain color stability and surface integrity for decades, significantly reducing maintenance requirements and preserving the building's aesthetic appeal throughout its service life.

-

Advantages of Aluminum Over Steel Standing Seam Systems

While steel standing seam roofing remains popular, Aluminum Standing Seam Roofing Panels offer several distinct advantages that make them the preferred choice for many applications. The most significant benefit is aluminum's natural corrosion resistance. Unlike steel, which requires protective coatings to prevent rust, aluminum forms a self-healing oxide layer when exposed to oxygen. This natural protective barrier continuously regenerates if scratched or damaged, ensuring long-term corrosion resistance without the need for galvanizing or additional protective treatments. This characteristic makes aluminum particularly valuable in coastal regions, industrial areas, or locations with high humidity where steel systems may experience premature corrosion despite protective coatings. Weight is another critical advantage of Aluminum Standing Seam Roofing Panels. Aluminum has approximately one-third the density of steel, resulting in significantly lighter roof systems. This reduced weight translates to lower structural loading requirements, potentially allowing for lighter framing systems and reduced foundation costs. For retrofit applications, the light weight of aluminum panels often enables installation over existing roofing materials without exceeding structural capacity limits. The ease of handling and installation also reduces labor requirements and safety risks during construction. Additionally, aluminum's excellent thermal conductivity, when combined with reflective coatings, creates highly energy-efficient roofing systems that can reduce cooling costs in warm climates by reflecting solar heat away from the building envelope.

Design Flexibility and Architectural Applications

Aluminum Standing Seam Roofing Panels excel in architectural applications where design flexibility and aesthetic appeal are paramount. The material's formability allows for creation of complex roof geometries, including curved surfaces, tapered panels, and custom profiles that would be difficult or impossible to achieve with stiffer materials. This design versatility enables architects to realize their creative visions while maintaining the functional performance characteristics essential for long-lasting roofing systems. The clean lines and contemporary appearance of standing seam aluminum roofing complement both modern architectural styles and traditional building designs, providing visual coherence across diverse project types. The color options available for Aluminum Standing Seam Roofing Panels are virtually limitless. Manufacturers offer extensive standard color collections based on RAL, Pantone, and custom color matching systems, allowing precise coordination with overall building aesthetics. Advanced PVDF coating technologies ensure that these colors remain vibrant and fade-resistant for 30 years or more, with many manufacturers offering non-prorated warranties guaranteeing color stability. The ability to specify custom colors with relatively low minimum order quantities makes aluminum standing seam systems accessible for projects of all sizes, from small commercial buildings to large institutional complexes. The reflective properties of lighter colors can be strategically employed to meet energy code requirements and achieve LEED or other green building certification credits.

-

Installation Methods and System Performance

Professional installation of Aluminum Standing Seam Roofing Panels requires specialized knowledge and equipment to ensure optimal system performance. The two primary installation methods—mechanical seaming and snap-lock systems—each offer distinct advantages depending on project requirements. Mechanical seaming involves field-seaming the panels using powered seaming equipment that creates a 180-degree or 90-degree fold, resulting in a watertight connection capable of withstanding extreme weather conditions. This method is typically specified for roofs with slopes as low as one-quarter inch per foot, providing hydrostatic resistance that prevents water infiltration even under ponding conditions. Snap-lock systems, by contrast, utilize pre-formed male and female legs that engage and lock together through applied pressure, eliminating the need for field-seaming equipment. This installation method reduces labor costs and installation time while still providing excellent weather resistance for roofs with minimum slopes of three inches per foot or greater. Both systems incorporate concealed clips that attach the panels to the roof deck or structural supports while allowing controlled thermal movement. This floating panel system prevents stress concentrations that could lead to fastener pullout, panel deformation, or coating damage. The clips are engineered to provide substantial uplift resistance, meeting stringent building code requirements for wind resistance in hurricane-prone and high-wind regions.

Performance Characteristics and Service Life Expectations

The exceptional durability of Aluminum Standing Seam Roofing Panels stems from the synergy between material properties, protective coatings, and system design. Field performance data demonstrates that properly installed aluminum standing seam systems routinely exceed 50-year service lives with minimal maintenance requirements. The material's inherent corrosion resistance eliminates the risk of rust staining or structural degradation that can affect steel systems, particularly at cut edges, fastener penetrations, or areas where protective coatings are compromised. This longevity translates to superior life-cycle cost performance, as the initial premium for aluminum systems is offset by reduced maintenance expenses and extended replacement intervals compared to alternative roofing materials. Environmental conditions that would challenge other roofing systems have minimal impact on Aluminum Standing Seam Roofing Panels. The material maintains structural integrity and coating performance across extreme temperature ranges, from arctic cold to desert heat. Thermal expansion and contraction are accommodated by the floating panel system, preventing stress-related failures while maintaining watertight seam integrity. Salt spray, industrial pollutants, acid rain, and other environmental contaminants that accelerate deterioration of many building materials have negligible effects on aluminum's protective oxide layer. This environmental resilience makes aluminum standing seam systems the logical choice for coastal installations, chemical processing facilities, food production plants, and other demanding applications where premature roofing failure could result in costly operational disruptions or contamination risks.

-

Energy Efficiency and Sustainability Benefits

Aluminum Standing Seam Roofing Panels contribute significantly to building energy efficiency through multiple mechanisms. The high solar reflectance of factory-applied cool roof coatings reduces heat gain through the roof assembly, lowering cooling loads and associated energy consumption. Research demonstrates that cool metal roofs can reduce peak cooling demand by 10-15 percent in commercial buildings, translating to substantial energy cost savings over the building's lifetime. The low thermal mass of aluminum panels allows rapid heat dissipation after sunset, preventing stored thermal energy from conducting into conditioned spaces during evening hours. When combined with appropriate insulation systems and reflective underlayments, aluminum standing seam roofs create high-performance thermal envelopes that meet or exceed the most stringent energy code requirements. The sustainability credentials of Aluminum Standing Seam Roofing Panels extend beyond operational energy efficiency. Aluminum is one of the most recyclable materials in construction, with typical recycled content ranging from 25 to 95 percent depending on the alloy and manufacturing source. At end-of-life, aluminum roofing panels retain significant scrap value and can be recycled indefinitely without loss of material properties, creating closed-loop material cycles that minimize environmental impact. The extended service life of aluminum roofing systems reduces the frequency of tear-offs and replacements, decreasing construction waste generation and associated landfill burdens. Many aluminum standing seam products qualify for multiple LEED credits, supporting achievement of green building certification goals while delivering measurable environmental and economic benefits throughout the building lifecycle.

Quality Manufacturing and Specification Considerations

Selecting high-quality Aluminum Standing Seam Roofing Panels requires careful attention to manufacturing standards and supplier capabilities. Reputable manufacturers operate under quality management systems certified to ISO 9001 standards, ensuring consistent production processes and material specifications. The aluminum coil stock should conform to ASTM, DIN, JIS, BS, or GB/T standards as appropriate for the project location and building code requirements. Factory-applied PVDF coatings must meet industry specifications for film thickness, adhesion, flexibility, and weathering resistance, with independent test data verifying performance claims. Third-party certifications from organizations such as SGS provide additional assurance of product quality and manufacturing consistency. The production process for Aluminum Standing Seam Roofing Panels significantly impacts final product quality and performance. Precision roll-forming equipment operating under controlled factory conditions produces panels with consistent dimensions and profiles that ensure proper field installation and long-term weather resistance. Color coating lines must maintain strict quality control over coating thickness, cure temperature, and line speed to achieve specified performance characteristics. Advanced manufacturers employ real-time quality monitoring systems that continuously verify panel dimensions, coating properties, and surface quality, rejecting any panels that fall outside specification tolerances. This commitment to quality control eliminates the variability and quality concerns associated with field-formed panels produced on portable equipment at job sites.

-

Project Delivery and Technical Support

Successful implementation of Aluminum Standing Seam Roofing Panels requires comprehensive technical support throughout the design, specification, and construction phases. Leading manufacturers provide experienced engineering teams capable of performing structural load analysis, drainage system design, and thermal movement calculations to optimize system performance for specific project conditions. Detailed shop drawings and installation manuals ensure that contractors understand proper installation procedures and sequencing. On-site technical representation during critical installation phases helps identify and resolve potential issues before they affect system performance or project schedules. Xi'an Huafeng Construction Engineering Co., Ltd. exemplifies this comprehensive approach to project support. The company's design department conducts detailed drawing reviews and provides feasible alternatives based on architectural plans, elevations, and node details. Following client approval, full-scale shop drawings are developed for all roof components, ensuring accurate fabrication and minimizing field modifications. Factory-produced samples allow verification of panel profiles, materials, surface treatments, and colors before full production commences. Each panel is sequentially numbered according to project specifications and installation sequence, streamlining quality control, packaging, and field installation processes. This systematic approach ensures project success while maintaining the highest quality standards throughout the supply chain.

Installation Best Practices and Quality Assurance

Proper installation of Aluminum Standing Seam Roofing Panels begins with thorough substrate preparation and verification of structural adequacy. The roof deck must provide adequate support for anticipated loads while maintaining specified flatness tolerances to prevent panel distortion or seam misalignment. Appropriate underlayment systems should be installed according to manufacturer specifications and local building codes, providing secondary weather protection and preventing condensation-related issues. Flashing details at roof penetrations, eaves, ridges, valleys, and wall intersections require careful attention to ensure weathertight transitions between roofing components. Using compatible materials and proven detail designs prevents galvanic corrosion and ensures long-term system integrity. Installation crews must receive comprehensive training on proper panel handling, seaming techniques, and quality control procedures. Aluminum panels require careful handling to prevent denting, scratching, or other cosmetic damage that could affect appearance or coating integrity. Seaming equipment must be properly maintained and adjusted to achieve specified seam dimensions and locking characteristics. Systematic quality checks throughout installation verify proper clip engagement, seam formation, and panel alignment, allowing immediate correction of any deficiencies before they affect larger roof areas. Post-installation testing, including water testing of critical details and visual inspection of completed work, confirms system performance before final acceptance. Comprehensive documentation of installation procedures, materials used, and test results provides valuable records for warranty administration and future maintenance planning.

-

Maintenance Requirements and Long-Term Performance

One of the most compelling advantages of Aluminum Standing Seam Roofing Panels is their minimal maintenance requirements throughout their extended service life. Unlike built-up or single-ply membrane systems that require regular inspections and repairs, aluminum standing seam roofs typically need only periodic cleaning to maintain appearance and performance. Accumulated debris such as leaves, dirt, or atmospheric deposits should be removed using low-pressure water washing or soft brushes to prevent surface staining and maintain drainage efficiency. In most environments, natural rainfall provides sufficient cleaning to keep panels looking new with minimal additional maintenance. Coastal installations or buildings in industrial areas may benefit from more frequent washing to remove salt deposits or airborne contaminants before they affect coating appearance. Routine inspections should focus on ancillary components such as gutters, downspouts, and roof-mounted equipment rather than the roofing panels themselves. Flashing details and sealant joints should be inspected for degradation or separation, with repairs made promptly to prevent water infiltration. Snow retention systems, solar panel attachments, or other roof-mounted equipment should be checked for proper attachment and structural integrity. The beauty of aluminum standing seam systems is that these routine maintenance activities can be performed by building maintenance staff without specialized roofing expertise, reducing ongoing operational costs. When professional roofing services are required, the accessibility and simplicity of aluminum standing seam systems minimize service time and associated expenses compared to more complex roofing assemblies.

Conclusion

Aluminum Standing Seam Roofing Panels represent the pinnacle of metal roofing technology, combining exceptional durability, aesthetic versatility, and long-term value. These systems deliver proven performance across diverse applications and environmental conditions.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Aluminum Standing Seam Roofing Panels factory, China Aluminum Standing Seam Roofing Panels supplier, and China Aluminum Standing Seam Roofing Panels manufacturer, Xi'an Huafeng Construction Engineering Co., Ltd. has established itself as a premier provider since 2018. We offer China Aluminum Standing Seam Roofing Panels wholesale solutions with competitive Aluminum Standing Seam Roofing Panels price structures and High Quality Aluminum Standing Seam Roofing Panels for sale to global markets. Our comprehensive capabilities include three strategically located manufacturing facilities with seven advanced production lines and over 40 specialized machines, ensuring efficient production and rapid delivery. We maintain first-level qualifications for building curtain walls and third-level qualifications for building steel structures, certified as a high-tech enterprise in Shaanxi Province. Our 200,000-square-meter raw material production facility in Anhui, combined with plate processing plants in Hangzhou and Xi'an, enables us to serve projects of any scale with consistent quality and reliable delivery schedules.

Xi'an Huafeng provides complete one-stop solutions from initial design consultation through final installation and maintenance support. Our engineering team performs structural 3D modeling, load analysis, and drainage system simulation to optimize every project. We conduct rigorous incoming material inspections with third-party testing, ensuring only premium AA3003, AA3004, and AA5052 aluminum alloys enter production. Each panel undergoes comprehensive quality verification including appearance inspection, dimensional accuracy, salt spray resistance, adhesion testing, and weathering performance evaluation. Our products meet ASTM, DIN, JIS, BS, and GB/T international standards, backed by ISO9001, ISO14001, CE, and SGS certifications, plus more than 20 registered patents.

We've successfully completed landmark projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, demonstrating our capability to handle complex architectural requirements. Our 30-year warranty on Aluminum Standing Seam Roofing Panels reflects our confidence in product quality and manufacturing excellence. With MOQ starting at just 500 square meters or one ton, we accommodate projects of all sizes with 15-20 day delivery times and customizable RAL colors. Contact Xi'an Huafeng Construction Engineering Co., Ltd. today to discuss your roofing requirements. Our experienced team is ready to provide technical guidance, project estimates, and customized solutions tailored to your specific needs. Email us at huafeng@hfmetalroof.com to begin your journey toward a superior roofing system that will protect and enhance your building for decades to come. Save this information for future reference as you plan your next construction or renovation project.

References

1. Metal Construction Association. "Guide Specification for Standing Seam Roof Systems." Technical documentation on standing seam metal roofing installation standards and material specifications.

2. American Society for Testing and Materials. "ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate." Official material standards for architectural aluminum products.

3. National Roofing Contractors Association. "The NRCA Roofing Manual: Metal Panel and SPF Roof Systems." Comprehensive technical guidance on metal roofing design and installation practices.

4. Cool Roof Rating Council. "Rated Products Directory: Metal Roofing Products." Independent testing and rating data for metal roofing thermal performance and solar reflectance values.