Picture this: heavy rainfall cascades off your roof, but instead of flowing smoothly through your drainage system, water spills over the edges, pooling dangerously near your foundation. This nightmare scenario stems from the most prevalent gutter issue plaguing homeowners worldwide—clogged gutters filled with leaves, twigs, and debris. When Roof Gutter System Parts fail to channel water effectively, the consequences extend far beyond mere inconvenience, threatening your home's structural integrity, landscaping, and costly foundation repairs that insurance policies rarely cover. Understanding common gutter problems and implementing quality Roof Gutter System Parts solutions can save property owners thousands in preventable damage while ensuring long-term protection for their investment. This comprehensive guide explores the most frequent gutter challenges, professional solutions, and how selecting premium aluminum gutter components from trusted manufacturers can transform your building's water management system.

Understanding Clogged Gutters and Drainage System Failures

The overwhelming majority of gutter-related problems originate from blockages that prevent proper water flow. When leaves, pine needles, twigs, and organic debris accumulate within gutter channels, they create obstructions that force rainwater to overflow rather than drain through designated downspouts. This seemingly minor issue carries devastating potential consequences for residential and commercial structures alike. Clogged Roof Gutter System Parts create excessive weight loads that the mounting hardware was never designed to support. Each gallon of trapped water weighs approximately eight pounds, and when combined with saturated debris, the cumulative mass can reach hundreds of pounds along a single gutter run. This extraordinary burden stresses fasteners, pulls gutters away from fascia boards, and causes the entire drainage system to sag or completely detach from the building. Beyond structural concerns, standing water in blocked gutters becomes a breeding ground for mosquitoes, promotes rust formation in metal components, and allows plant seeds to germinate directly within the channels. Property owners in regions with significant tree coverage face this challenge seasonally, requiring diligent maintenance schedules to prevent recurring blockages. Professional-grade Roof Gutter System Parts manufactured from corrosion-resistant AA3003 aluminum alloy offer superior longevity compared to traditional materials, particularly when paired with properly designed gutter guards that minimize debris entry while maintaining optimal water flow. The financial implications of neglected gutter maintenance compound rapidly. Foundation repairs resulting from improper water diversion can cost between fifteen thousand and thirty thousand dollars, while replacement of rotted fascia boards, damaged siding, and compromised roof edges adds thousands more to remediation expenses. These preventable costs underscore the critical importance of investing in quality Roof Gutter System Parts from the outset and maintaining them through regular inspections and cleaning protocols.

-

Seasonal Debris Accumulation Patterns

Different seasons present unique challenges for gutter system maintenance. Autumn brings massive leaf fall that can completely obstruct channels within days, while spring introduces seed pods, blossoms, and nesting materials from birds seeking shelter. Winter ice formation creates additional complications as freeze-thaw cycles expand trapped moisture, potentially cracking gutter seams and separating joint connections. Professional installers recommend inspecting Roof Gutter System Parts at minimum twice annually—once in late spring after flowering trees complete their cycles, and again in late autumn following deciduous leaf drop. Properties with mature oak, maple, or pine trees may require quarterly inspections to maintain optimal drainage performance. Advanced gutter protection systems featuring micro-mesh screens or solid covers with surface tension principles significantly reduce maintenance frequency while extending component lifespan.

Sagging and Improperly Pitched Gutter Systems

Proper gutter slope represents one of the most critical yet frequently overlooked aspects of effective water management. Gutters must maintain a consistent pitch toward downspouts, typically one-quarter inch decline per ten feet of horizontal run, to ensure gravity-driven water flow. When installation specifications deviate from this standard or when gutters shift over time, standing water accumulates in low spots, creating multiple cascading problems. Improperly pitched Roof Gutter System Parts fail to evacuate water efficiently, leading to premature corrosion, increased weight stress on mounting brackets, and overflow during even moderate rainfall events. The stagnant pools become mosquito breeding habitats and promote algae growth that further restricts water passage. In freezing climates, these trapped water pockets expand as ice, exerting tremendous outward pressure that can split seams and crack metal components. Sagging gutters typically result from inadequate hanger spacing, deteriorated fasteners, or oversized gutter sections attempting to span distances exceeding manufacturer specifications. Traditional spike-and-ferrule hangers, while economical, provide less secure attachment than hidden hanger systems or strap-style brackets. Premium Roof Gutter System Parts installations utilize heavy-duty concealed hangers spaced no more than twenty-four inches apart, with closer intervals in areas experiencing heavy snow loads or sustained high-volume rainfall. Correcting pitch problems often requires complete gutter removal and reinstallation rather than simple adjustments. Professional contractors employ laser levels and specialized measurement tools to establish precise slopes that account for thermal expansion, building settlement, and anticipated load factors. Xi'an Huafeng Construction Engineering Co., Ltd. engineers their Roof Gutter System Parts with standardized K-type configurations available in five-inch through eight-inch profiles, allowing precise matching to roof surface area and regional precipitation patterns while maintaining structural integrity across extended spans.

-

Load-Bearing Capacity and Hanger Specifications

The relationship between gutter profile dimensions, material thickness, and fastener density determines ultimate load-bearing capacity. Residential applications typically specify 0.7mm to 1.0mm aluminum thickness for gutter bodies, while commercial installations may require heavier gauges to accommodate larger drainage volumes and extended unsupported lengths. Corresponding downspout specifications range from 0.8mm to 1.0mm thickness in both rectangular and circular profiles. Advanced Roof Gutter System Parts incorporate reinforced mounting flanges that distribute stress loads across wider fascia contact areas, reducing point-loading that can split wooden trim boards or crack masonry surfaces. Industrial-strength hangers manufactured from galvanized steel or stainless steel resist corrosion while maintaining grip strength throughout decades of thermal cycling and moisture exposure. These engineering details separate premium systems from economy alternatives that fail prematurely under real-world conditions.

Leaks, Separated Seams, and Component Failures

Gutter leaks manifest through various failure modes, each requiring specific diagnostic approaches and repair methodologies. Joint separations occur where sectional gutters connect, typically resulting from thermal expansion cycles, impact damage, or inadequate sealant application during initial installation. Small holes and cracks develop from corrosion, hail damage, or stress concentration points near fastener locations. End caps and outlet fittings represent additional leak-prone areas requiring careful sealing and periodic inspection. Traditional sectional gutter systems inherently contain multiple potential failure points at each connection joint. Even properly sealed seams deteriorate over time as ultraviolet radiation breaks down sealant compounds and temperature fluctuations cause metal expansion and contraction. Water infiltration through these gaps damages fascia boards, promotes mold growth within wall cavities, and allows moisture migration into attic spaces where it compromises insulation effectiveness and wooden structural members.

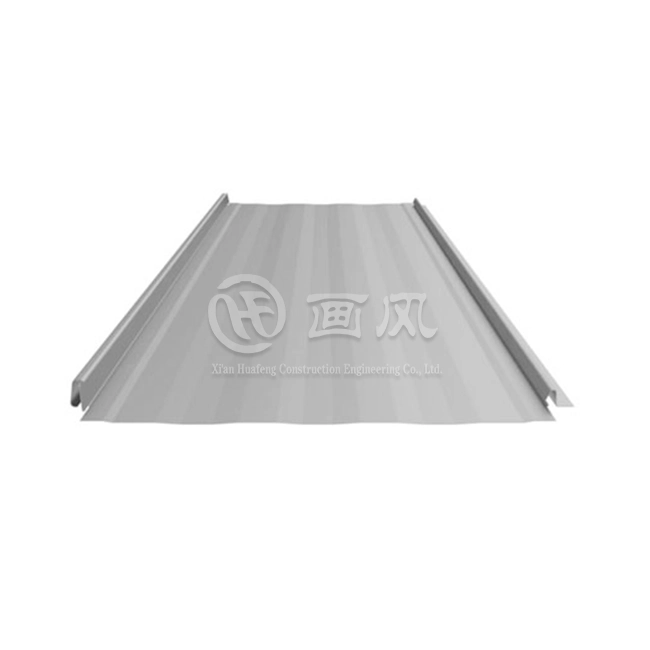

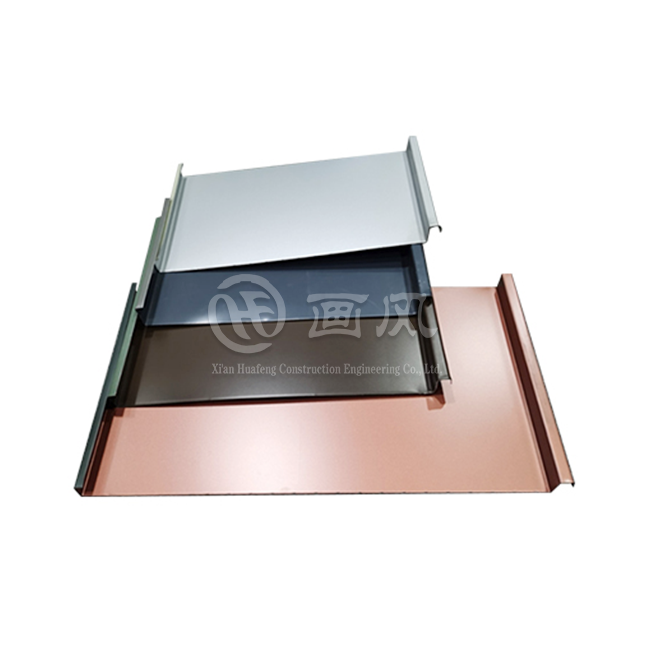

Seamless Roof Gutter System Parts manufactured through continuous roll-forming processes eliminate mid-span joints entirely, dramatically reducing leak potential while creating cleaner aesthetic lines. These custom-fabricated components arrive at installation sites cut to exact lengths, requiring connections only at inside and outside corners where professional-grade sealants and mechanical fasteners provide redundant sealing. Xi'an Huafeng Construction Engineering Co., Ltd. operates advanced roll-forming equipment capable of producing seamless sections exceeding forty feet in length, accommodating most residential facades without requiring intermediate joints. Material selection significantly influences leak resistance and overall system longevity. AA3003 aluminum alloy offers exceptional corrosion resistance compared to galvanized steel, particularly in coastal environments or industrial areas with elevated atmospheric pollution levels. The aluminum oxide layer that naturally forms on exposed surfaces provides continuous protection against oxidation, eliminating the rust-through failures common in ferrous metal gutters. Color-coated finishes available in white, gray, bronze, and brown tones enhance aesthetic integration while adding additional protective layers against environmental degradation.

-

Preventive Maintenance and Sealant Technologies

Regular inspection protocols should include examination of all joint connections, end caps, outlet tubes, and mounting hardware for signs of separation, corrosion, or mechanical damage. Early detection of minor leaks allows simple repairs using modern polyurethane or silicone-based sealants specifically formulated for metal-to-metal bonding applications. These advanced compounds maintain flexibility across wide temperature ranges while resisting ultraviolet degradation and moisture intrusion. Professional-grade Roof Gutter System Parts installations incorporate butyl rubber gaskets at critical connection points, providing mechanical seals that compress under fastener tension to create water-tight barriers independent of chemical sealants. This redundant sealing approach ensures continued leak protection even as traditional caulk compounds age and lose adhesion. Periodic re-sealing every five to seven years maintains optimal performance throughout the system's service life, which can extend beyond three decades with proper material selection and maintenance.

Ice Dam Formation and Cold Climate Challenges

Properties in northern climates face unique gutter challenges related to snow accumulation and ice formation. Ice dams develop when heat escaping through inadequately insulated attics warms roof surfaces, melting snow that then refreezes upon reaching colder eaves and gutter areas. The resulting ice barrier prevents subsequent meltwater from draining, forcing it to back up under shingles where it infiltrates roof decking and interior spaces. The weight of accumulated ice can exceed the design capacity of standard Roof Gutter System Parts, pulling gutters away from fascia boards or causing complete detachment. Ice expansion within gutter channels exerts outward pressure on sidewalls, potentially deforming profiles and creating permanent damage requiring component replacement. Downspouts filled with ice become completely non-functional, eliminating any drainage capacity until temperatures rise sufficiently to allow thawing. Preventing ice dam formation requires addressing root causes through improved attic insulation, enhanced ventilation, and strategic heat cable installation. However, gutter system design also plays crucial roles in minimizing ice-related damage. Wider gutter profiles provide increased volume for ice accumulation before overflow occurs, while heated gutter systems incorporating low-voltage resistance cables maintain above-freezing temperatures along drainage paths. Premium Roof Gutter System Parts manufactured from aluminum naturally conduct heat more efficiently than steel alternatives, promoting faster thaw cycles during temperature fluctuations.

-

Structural Reinforcement for Snow Load Regions

Building codes in heavy snowfall regions specify enhanced gutter mounting requirements to accommodate extreme weather events. Xi'an Huafeng Construction Engineering Co., Ltd. provides engineering consultation services that analyze roof surface area, historical precipitation data, and local building codes to recommend appropriate Roof Gutter System Parts sizing and reinforced mounting specifications. Their aluminum-magnesium-manganese alloy systems offer superior strength-to-weight ratios compared to pure aluminum, providing enhanced structural performance without requiring heavier gauge materials that increase installation costs and complexity. Strategic placement of additional downspouts reduces individual gutter section loads by dividing drainage volumes across multiple discharge points. Commercial applications and residential properties with complex roof geometries benefit particularly from computer-aided drainage system modeling that optimizes component sizing and placement for maximum efficiency under diverse weather conditions. These engineering investments pay long-term dividends through reduced maintenance requirements and extended system service life.

Selecting Premium Roof Gutter System Parts for Long-Term Performance

Material quality fundamentally determines gutter system longevity and maintenance requirements. While economy-grade vinyl gutters offer low initial costs, they become brittle in cold weather, warp under thermal stress, and typically require replacement within ten to fifteen years. Galvanized steel gutters provide moderate durability but inevitably succumb to rust formation, particularly along cut edges and fastener penetrations. Premium aluminum Roof Gutter System Parts deliver optimal combinations of corrosion resistance, structural strength, and aesthetic versatility. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Roof Gutter System Parts from AA3003 aluminum alloy sourced from certified suppliers including Alucosuper, YATAI, and LIDAO brands. This specification ensures consistent material properties including minimum tensile strength, elongation characteristics, and corrosion resistance that meet international standards including ASTM, DIN, JIS, BS, and GB/T requirements. Surface treatments incorporate anodizing processes followed by electrostatic powder coating in architect-specified colors, providing durable finishes that resist fading, chalking, and environmental degradation for decades.

The company's manufacturing capabilities encompass complete production integration from raw material coating through final component fabrication. Seven color coating production lines apply consistent finish thicknesses, while ten longitudinal and transverse shearing lines precisely dimension aluminum coil stock. Fully automated punching equipment creates mounting holes and outlet openings with computer-controlled accuracy, ensuring perfect fit during installation. Over forty specialized machines including shears, presses, and forming equipment enable custom component production matching any architectural specification. Quality control protocols verify material properties at multiple production stages. Incoming raw materials undergo verification testing including salt spray resistance, adhesion strength, impact resistance, hardness evaluation, film thickness measurement, acid resistance, weather resistance, and color consistency analysis. These comprehensive inspections prevent defective materials from entering production workflows, ensuring every component meets stringent performance standards. Finished products receive additional dimensional verification, flatness assessment, and curvature evaluation before packaging and shipment.

-

Comprehensive Warranty Coverage and Technical Support

Three-decade warranty coverage demonstrates manufacturer confidence in Roof Gutter System Parts performance and longevity. This extensive guarantee protects property owners against material defects, finish degradation, and premature component failure, providing peace of mind unavailable with economy alternatives. Technical support services include drainage system design assistance, load analysis calculations, and installation guidance that optimize system performance for specific building configurations and climate conditions. Xi'an Huafeng Construction Engineering Co., Ltd. maintains production capacity exceeding ten thousand tons monthly across three manufacturing facilities in Anhui, Hangzhou, and Xi'an. This substantial industrial capability ensures consistent product availability and rapid delivery schedules, typically fifteen to twenty days from order placement to jobsite delivery. ISO9001, ISO14000:14001, and SGS certifications validate quality management systems and environmental responsibility commitments, while over twenty registered patents protect proprietary innovations in gutter system design and manufacturing processes.

Conclusion

Clogged gutters represent the most common problem affecting drainage systems, but proper material selection, professional installation, and regular maintenance prevent most issues. Premium Roof Gutter System Parts manufactured from corrosion-resistant aluminum alloys deliver superior long-term performance compared to traditional alternatives.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Roof Gutter System Parts factory, China Roof Gutter System Parts supplier, and China Roof Gutter System Parts manufacturer offering premium Roof Gutter System Parts for sale at competitive Roof Gutter System Parts price points. Our High Quality Roof Gutter System Parts combine engineering excellence with aesthetic versatility, backed by ISO9001, ISO14000:14001, and SGS certifications. As a recognized high-tech enterprise with first-level building curtain wall qualifications and third-level steel structure certifications, we provide comprehensive design optimization, customized production capabilities, and one-stop solutions from raw materials through final installation. Our three factories operate seven production lines with over forty specialized machines, delivering ten thousand tons monthly capacity with fifteen to twenty day turnaround. Experience gained through landmark projects including Xiongan Station, Xi'an International Convention Center, and numerous cultural facilities demonstrates our commitment to architectural excellence. Contact our team at huafeng@hfmetalroof.com for China Roof Gutter System Parts wholesale inquiries, free samples, and expert consultation. Let our thirty-year warranty and proven track record protect your investment—bookmark this resource for future reference when planning your next project.

References

1. "Common Gutter Problems and Their Solutions" by Asher Lasting Exteriors, covering identification and repair of typical gutter system failures including clogs, leaks, and structural damage.

2. "The Top 7 Gutter Problems and How to Fix Them" by Universal Windows Direct, providing comprehensive analysis of separation, ice dam formation, and improper pitch issues.

3. "6 Common Problems Caused by Clogged Gutters" by Erie Insurance, examining financial implications and structural consequences of inadequate gutter maintenance.

4. "Top 7 Most Common Gutter Problems & How To Fix Them" by Legacy Service, detailing sagging mechanisms, hanger failures, and professional repair methodologies for residential applications.