Are you tired of dealing with leaking roofs, costly repairs, and constant maintenance headaches? Traditional roofing systems with exposed fasteners often fail under extreme weather conditions, leading to water infiltration and structural damage. Standing seam mechanical lock panels offer a revolutionary solution that eliminates these persistent problems. This comprehensive guide explores how mechanical lock metal roofing delivers unmatched durability, weather resistance, and long-term performance for commercial, industrial, and residential applications worldwide.

Understanding Mechanical Lock Metal Roofing Systems

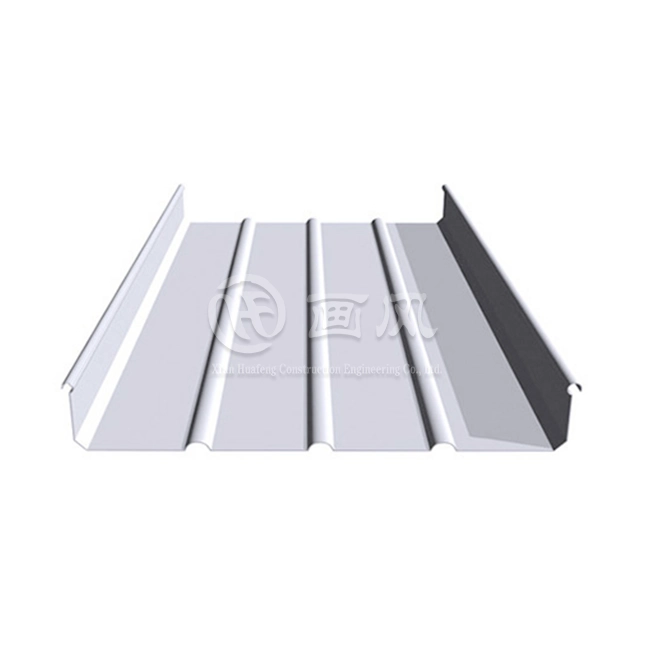

Mechanical lock metal roofing represents a sophisticated advancement in architectural roofing technology. Unlike conventional roofing systems that rely on exposed screws and fasteners, mechanical lock panels feature concealed interlocking joints that create a continuous, watertight barrier across the entire roof surface. This innovative design eliminates penetration points where water can seep through, significantly reducing the risk of leaks and extending the roof's service life to over 30 years with proper maintenance. The system operates through precision-engineered standing seam profiles that mechanically interlock along vertical seams. Each panel edge features specially designed ribs with heights ranging from 25mm to 32mm, allowing adjacent panels to snap or fold together without visible fasteners. This concealed connection method not only enhances aesthetic appeal but also provides superior wind resistance exceeding 90 mph, making it ideal for regions prone to severe weather conditions including hurricanes, typhoons, and heavy snowfall.

-

Technical Specifications and Material Options

Modern mechanical lock metal roofing systems accommodate diverse architectural requirements through extensive material selection. Premium options include aluminum alloys (3003, 3004, 5052), galvalume steel, galvanized steel, stainless steel grades 304 and 316, copper, and titanium zinc. Each material offers distinct advantages: aluminum provides lightweight corrosion resistance, galvalume steel delivers exceptional strength-to-weight ratios, stainless steel ensures maximum durability in corrosive environments, while copper and titanium zinc develop attractive patinas over time. Panel specifications typically range from 300mm to 500mm in width, with thickness options between 0.5mm and 1.0mm depending on structural requirements and local building codes. Surface treatments include PVDF fluorocarbon coatings (25-40 microns on top surfaces) and PE polyester coatings, both delivering outstanding weather resistance and color retention. The coating thickness ensures protection against UV degradation, acid rain, and industrial pollutants, maintaining the roof's appearance and structural integrity throughout its service life.

-

Installation and Performance Advantages

The mechanical lock metal roofing installation process demands precision engineering and specialized expertise. Professional installation begins with thorough substrate preparation, ensuring proper slope (minimum 5 degrees) for effective water drainage. Hidden fastening systems anchor panels securely to the structural deck while allowing thermal expansion and contraction, preventing stress-related failures common in rigidly fastened systems. Edge-locking mechanisms provide additional wind uplift resistance, critical for high-rise buildings and exposed coastal locations. Performance characteristics exceed industry standards across multiple metrics. The system achieves IPX4 waterproof ratings through seamless interlocking design, Class A fire ratings using non-combustible materials compliant with ASTM E108 and EN 13501 standards, and load capacities exceeding 1.5 kN/m² for snow accumulation and maintenance access. These specifications ensure reliable performance across diverse climate zones, from arctic conditions with heavy snow loads to tropical environments with intense UV exposure and high humidity levels.

Why Professional Expertise Matters in Mechanical Lock Metal Roofing?

Selecting mechanical lock metal roofing represents a significant investment requiring partnership with experienced manufacturers and installers. The complexity of these systems demands comprehensive understanding of material science, structural engineering, and installation techniques. Inferior products or improper installation can compromise system performance, leading to premature failures, voided warranties, and costly remediation work. Working with established manufacturers ensures access to quality materials, proven installation methodologies, and long-term technical support.

-

Manufacturing Excellence and Quality Control

Superior mechanical lock metal roofing begins with advanced manufacturing capabilities. State-of-the-art production facilities employ precision roll-forming equipment that shapes metal coils into exact panel profiles with tolerances measured in fractions of millimeters. Seven dedicated color coating production lines apply protective finishes through continuous processes, ensuring uniform coverage and adhesion. Automated punching and shearing systems create precise fastening holes and trim panels to exact dimensions, eliminating field measurement errors and reducing installation time. Quality control protocols throughout manufacturing prevent defects from reaching project sites. Incoming raw materials undergo rigorous inspection including material certification verification, third-party testing report review, and physical property testing. Production monitoring includes appearance inspection, dimensional verification, salt spray testing, adhesion measurement, hardness evaluation, impact resistance testing, film thickness assessment, acid resistance evaluation, weather resistance simulation, and color difference analysis. Only products meeting stringent specifications proceed to final packaging and shipment.

-

Customization and Engineering Support

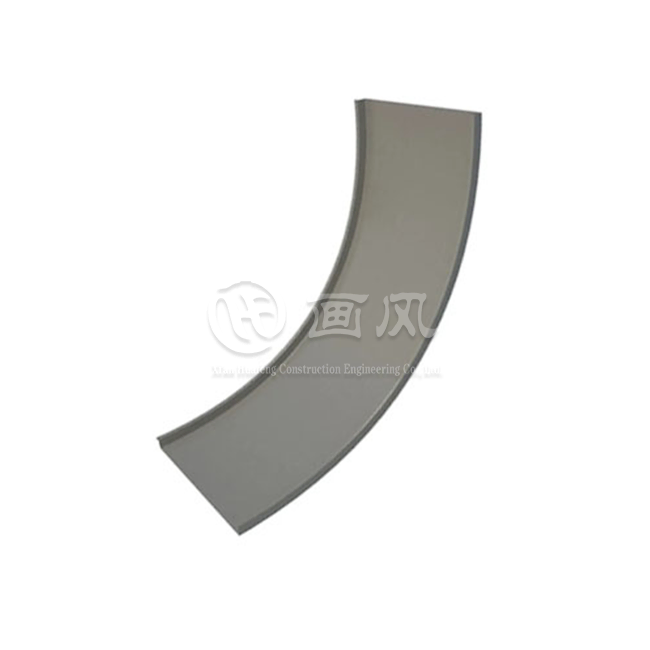

Complex architectural projects require customized roofing solutions tailored to specific design requirements and performance criteria. Professional manufacturers provide comprehensive engineering services including structural 3D modeling, load analysis, drainage system simulation, and material specification advisory. Design teams analyze architectural drawings to identify optimal panel configurations, develop detailed installation drawings with 1:1 node deepening, and create sequential numbering systems ensuring correct panel placement during installation. Factory processing capabilities extend beyond standard panel production. Custom profiles accommodate unique architectural features including curved sections, complex transitions, and specialized trim details. Sample production allows clients to verify material selection, color accuracy, and finish quality before full-scale manufacturing begins. This iterative approach ensures final products precisely match design intent while maintaining structural integrity and weather performance requirements.

Comprehensive Project Implementation Process

Successful mechanical lock metal roofing projects require meticulous planning and execution across design, manufacturing, and installation phases. Professional suppliers offer integrated project management services coordinating all activities from initial concept through final acceptance. This comprehensive approach minimizes delays, prevents costly errors, and ensures optimal system performance throughout the building's operational life.

-

Design Development and Technical Documentation

Project implementation begins with thorough analysis of architectural engineering drawings including floor plans, elevations, and node diagrams. Engineering teams evaluate feasible alternatives considering structural constraints, aesthetic preferences, budget parameters, and schedule requirements. Client collaboration determines appropriate panel types, material selections, and finish options for each roof section. Design departments then develop detailed technical drawings with precise dimensions, connection details, and installation sequences. Processing drawing development translates design concepts into production-ready documentation. Detailed manufacturing drawings specify exact panel dimensions, hole locations, bend angles, and trim configurations. Sequential numbering systems correlate each component with specific roof locations, enabling efficient production scheduling, quality assurance tracking, secure packaging, and systematic installation. This documentation ensures seamless coordination between factory production and field installation teams.

-

Manufacturing and Quality Assurance

Material procurement initiates manufacturing processes with purchasing departments sourcing premium raw materials from approved suppliers. Preferred brands for aluminum include Alucosuper, YATAI, and LIDAO, while steel products come from BAOSTEEL, GUANZHOU, and XINYU. Stainless steel sourcing emphasizes Baosteel and Tsingshan products, titanium zinc from NedZink, and copper from Chinalco. Supplier certification and testing documentation undergoes verification before material acceptance into production inventory. Production workflows incorporate multiple inspection checkpoints ensuring consistent quality. Roll-forming operations create precise panel profiles from coil stock, with real-time monitoring verifying dimensional accuracy. Surface treatment applications receive scrutiny for coating thickness, adhesion quality, and color consistency. Finished panel inspection evaluates appearance, dimensions, flatness, and curvature before packaging approval. Strategic packaging divides products by roof sections with identification cards containing sectioned floor plans and component lists, facilitating efficient site logistics and installation sequencing.

Conclusion

Standing seam mechanical lock panels deliver unmatched performance through concealed fastening systems that eliminate leak points while providing superior wind resistance and aesthetic appeal for demanding architectural applications worldwide.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, specializes in comprehensive metal roofing solutions combining design excellence, manufacturing precision, and professional installation services. Our 200,000 square meter raw material production facility in Anhui, complemented by processing plants in Hangzhou and Xi'an, houses 7 color coating lines, 1 laminating line, 10 shearing production lines, and over 40 specialized machines ensuring consistent quality and timely delivery.

As a leading China mechanical lock metal roofing factory, China mechanical lock metal roofing supplier, and China mechanical lock metal roofing manufacturer, we offer China mechanical lock metal roofing wholesale with competitive mechanical lock metal roofing prices. Our high quality mechanical lock metal roofing for sale includes aluminum-magnesium-manganese plates, titanium-zinc plates, color-coated steel, and stainless steel options. With first-level building curtain wall qualifications, third-level steel structure qualifications, over 20 registered patents, and ISO9001, ISO14000:14001, CE, and SGS certifications, we deliver turnkey solutions from structural 3D modeling through on-site installation and maintenance support. Contact us at huafeng@hfmetalroof.com for customized solutions meeting your project requirements.

References

1. "Metal Roofing Systems: Design and Installation Guide" - American Institute of Architects, Technical Publication Committee

2. "Standing Seam Metal Roof Performance in Extreme Weather Conditions" - Journal of Architectural Engineering, Dr. Robert Chen and Dr. Maria Rodriguez

3. "Sustainable Building Envelope Design: Metal Roofing Applications" - International Council for Building Research Studies and Documentation

4. "Specification Guide for Metal Roofing and Wall Systems" - Metal Construction Association, Technical Standards Division