You're standing in front of a building with roof leakage issues after just five years, watching expensive repairs drain your budget while wondering if there's a better solution. Metal Standing Seam Roofing Systems offer a transformative alternative: concealed fastener technology that eliminates leak pathways, vertical panel designs that channel water efficiently, and mechanical locking systems that withstand extreme weather for decades. This comprehensive guide explores everything you need to know about standing seam metal roofing, from material options and installation methods to performance comparisons and real-world applications, helping you make an informed decision that protects your investment for 30 years or more.

Understanding Metal Standing Seam Roofing Systems: Definition and Core Features

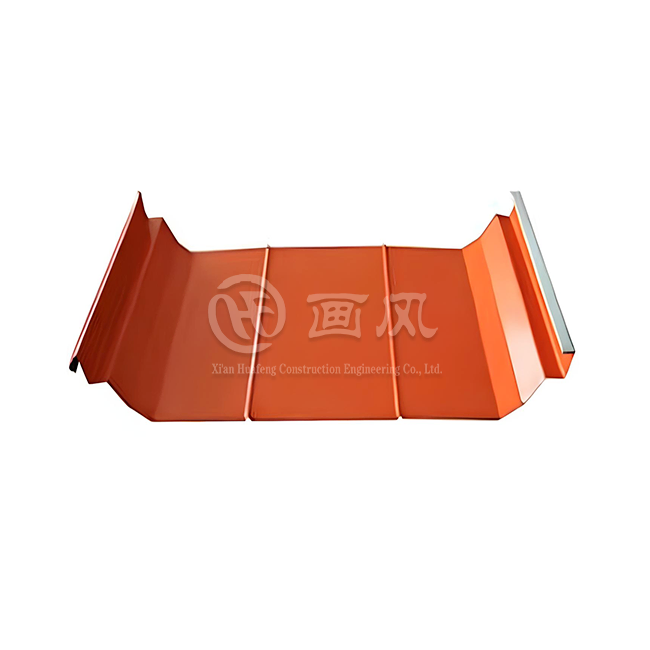

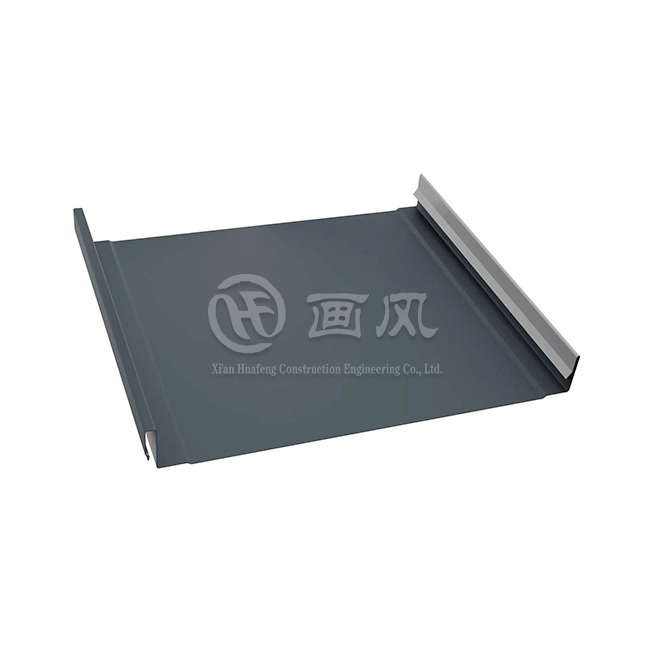

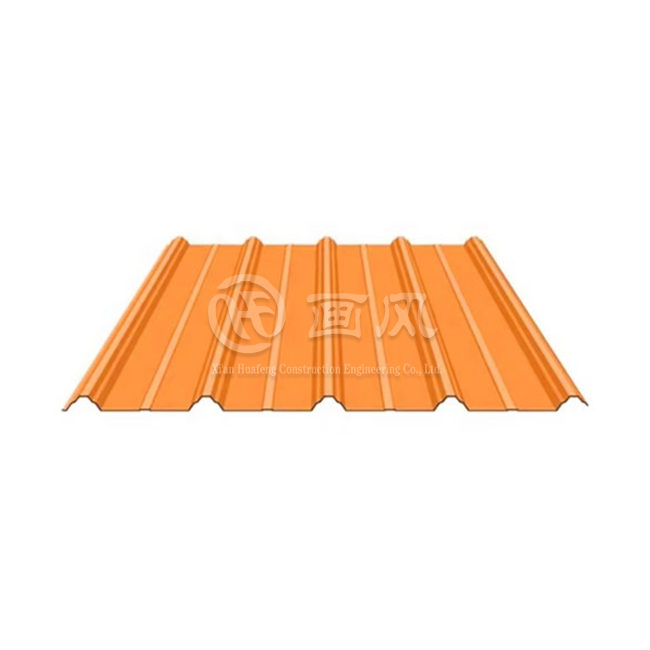

Metal Standing Seam Roofing Systems represent a premium roofing solution characterized by vertical metal panels with raised seams running continuously from ridge to eave. Unlike traditional roofing where fasteners penetrate the surface, these systems utilize concealed fastener technology, positioning screws underneath the panels where they remain protected from weather exposure. The defining feature is the standing seam itself, typically rising 65mm or higher above the flat panel surface, which creates a distinctive architectural profile while serving critical functional purposes including enhanced water drainage, structural rigidity, and thermal expansion accommodation. The panel construction involves wide, flat areas between the raised vertical legs, with each panel interlocking at the seams through either mechanical seaming or snap-lock engagement. This concealed fastener approach fundamentally changes the roof's vulnerability profile. Exposed fastener systems create thousands of potential water entry points that degrade over time as gaskets deteriorate and screws work loose through thermal cycling. Metal Standing Seam Roofing Systems eliminate this weakness by hiding all penetrations beneath overlapping metal, creating a weather-tight envelope that maintains integrity for decades. The raised seam height not only accommodates clips and fastening mechanisms but also provides superior drainage capacity, preventing water pooling even on low-slope applications as shallow as one-quarter inch per foot.

Metal Standing Seam Roofing Systems

-

Material Options for Standing Seam Panel Construction

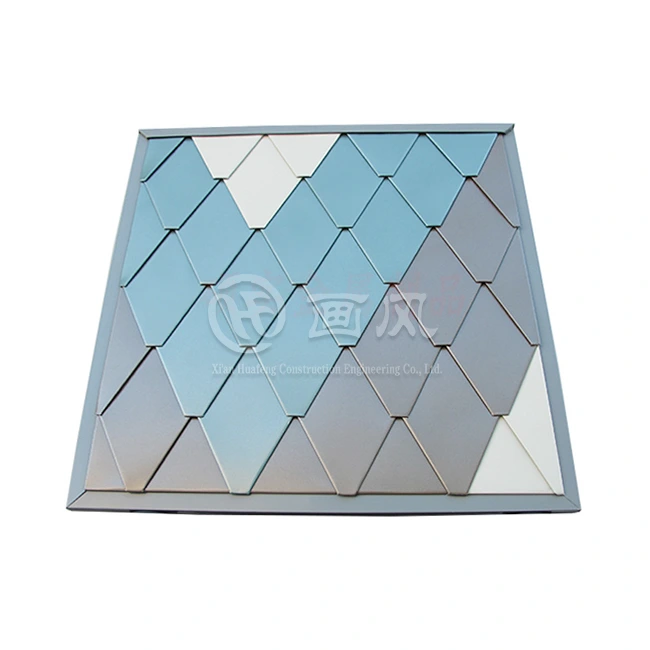

The substrate material selection significantly impacts the Metal Standing Seam Roofing Systems performance characteristics, cost structure, and aesthetic outcomes. Aluminum panels ranging from 0.9mm to 1.2mm thickness offer exceptional corrosion resistance, particularly in coastal environments where salt spray accelerates steel degradation. The 3003 and 3004 aluminum alloys in H44 hardened condition provide optimal strength-to-weight ratios, reducing structural load requirements while maintaining panel rigidity. Galvalume steel, consisting of cold-rolled steel coated with an aluminum-zinc alloy at 150 grams per square meter, represents the most cost-effective option for projects requiring strong corrosion resistance across diverse climate conditions. This substrate combines the strength of steel with aluminum's corrosion resistance, creating a material that performs reliably for three decades or more. For projects demanding maximum longevity and premium aesthetics, stainless steel, titanium-zinc, and copper substrates offer exceptional performance characteristics. Type 304 stainless steel at 0.5mm to 0.8mm thickness provides superior corrosion resistance in industrial environments or high-humidity coastal zones where standard materials struggle. Titanium-zinc panels feature self-healing properties where surface scratches naturally oxidize and blend into the patina over time, supporting lifespans exceeding 80 years with minimal maintenance requirements. Copper roofing, typically specified at 0.8mm to 1.0mm using TU1 oxygen-free copper, develops a distinctive green patina over decades while providing structural performance lasting a century or more. Each material option integrates with protective coatings including PVDF fluoropolymer finishes containing 70% fluororesin at 25 to 30 micron thickness, ensuring color retention and UV resistance for 20-plus years while maintaining the substrate's inherent advantages.

-

Surface Treatment Technologies and Performance Enhancement

Surface treatment selection critically influences the Metal Standing Seam Roofing Systems long-term appearance retention, corrosion resistance, and thermal performance. PVDF coatings, also marketed as Kynar 500, represent the premium finish option with 70% fluororesin content applied at 25 to 30 microns thickness. This coating technology delivers exceptional UV stability, preventing color fade even under intense solar exposure, while providing chemical resistance against acid rain, industrial pollutants, and coastal salt spray. The molecular structure of PVDF creates a self-cleaning surface where dirt and organic materials struggle to adhere, reducing maintenance requirements while preserving the roof's aesthetic appeal for two decades or more. Color retention warranties typically span 30 years for PVDF-finished metal panels, reflecting the coating's proven durability in demanding environments. Polyester coatings offer an economical alternative for projects where budget constraints outweigh maximum longevity requirements. Applied at 20 to 25 microns, PE coatings provide adequate weather protection for moderate climates while reducing material costs by approximately 15 to 20 percent compared to PVDF finishes. However, the performance tradeoff includes accelerated color fading, typically noticeable within 10 to 15 years, and reduced resistance to chemical exposure and mechanical abrasion. For copper and titanium-zinc applications, natural oxidation eliminates the need for applied coatings. These materials develop protective patinas through atmospheric interaction, creating self-maintaining surfaces that require no periodic refinishing while offering maintenance-free service lives spanning 50 to 100 years. The natural finish also provides environmental benefits through eliminating coating manufacturing processes and associated volatile organic compound emissions.

Types of Standing Seam Panel Systems and Installation Methods

Metal Standing Seam Roofing Systems divide into three primary installation methodologies, each optimized for specific project requirements, budget parameters, and performance expectations. Understanding these system types enables appropriate specification matching project demands to technical capabilities, ensuring optimal long-term performance while managing capital expenditure constraints effectively.

-

Mechanically Seamed Systems: Maximum Weather Resistance

Mechanically seamed installations represent the most weather-resistant configuration within the Metal Standing Seam Roofing Systems category. This approach utilizes panels with upstanding legs designed to interlock through mechanical seaming equipment that folds the adjacent panel edges together. The process creates either single-lock seams, where material folds once at 90 degrees, or double-lock seams featuring two 180-degree folds that completely encapsulate the seam connection. Double-lock mechanical seaming achieves the highest waterproofing integrity available in metal roofing, enabling successful application on ultra-low slopes down to one-half inch per foot where hydrostatic water conditions can develop during heavy rainfall events. The mechanical seaming process requires specialized equipment including powered seamers or hand seamers that progressively fold the metal while traveling the panel length. Fixed clips or floating clips attach to the roof substrate at predetermined intervals, typically 12 to 18 inches, providing the structural connection while accommodating thermal expansion and contraction through the clip's engineered movement capability. Floating clip systems prove essential for panel lengths exceeding 30 feet, allowing the metal to expand and contract freely without inducing oil-canning distortion or fastener stress. Installation labor requirements for mechanically seamed systems substantially exceed other standing seam options, with experienced crews typically completing 800 to 1,200 square feet per day compared to 1,500 to 2,000 square feet for snap-lock alternatives. However, the superior weather performance, wind uplift ratings exceeding 300 pounds per square foot, and extended service life justify the additional installation investment for critical applications including airport terminals, sports facilities, and large-span commercial structures.

-

Snap-Lock Systems with Concealed Clip Fastening

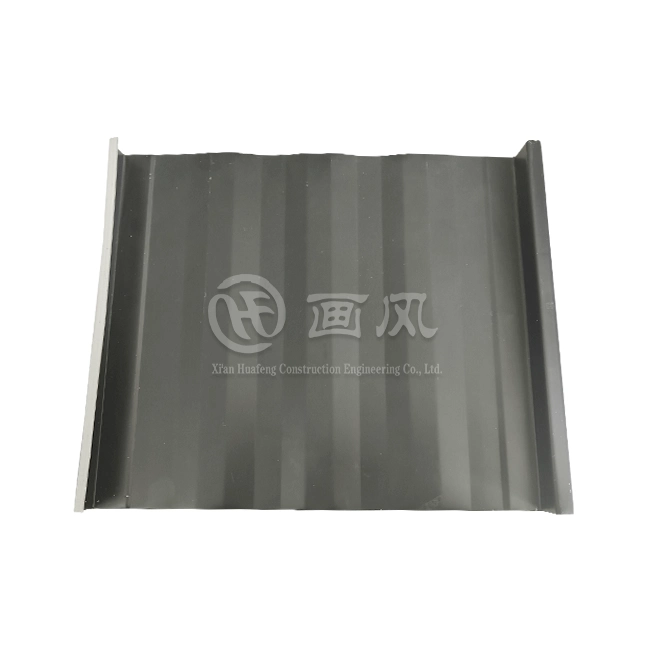

Snap-lock Metal Standing Seam Roofing Systems streamline installation processes while maintaining concealed fastener benefits through panels engineered with male and female legs that mechanically interlock without seaming equipment. The female leg features an internal catch mechanism that accepts the male leg's profile, creating an audible snap when proper engagement occurs. Concealed clips fasten directly to the roof substrate through slotted holes accommodating thermal movement, with the next panel's female leg snapping over the clip and male leg assembly to create the weather-resistant connection. This installation approach balances performance and cost-effectiveness, making it the most popular standing seam configuration for commercial and high-end residential applications. Panel widths typically range from 12 to 18 inches with seam heights of 1.5 to 2 inches, providing adequate water drainage capacity for roofs sloped at 3:12 or steeper. The snap-lock engagement creates weather-resistant connections suitable for most climate conditions, though performance in extreme wind or hydrostatic situations remains inferior to mechanically seamed alternatives. Installation efficiency represents a key advantage, with experienced crews completing snap-lock installations 40 to 50 percent faster than mechanically seamed systems while maintaining the concealed fastener aesthetic and reduced maintenance benefits. Panel lengths accommodate runs up to 52 feet for shop-fabricated panels, with longer lengths requiring on-site roll forming equipment to eliminate problematic horizontal seams that compromise waterproofing integrity. The system's moderate complexity makes it accessible to trained contractors while delivering reliable performance across diverse building types from warehouses and retail facilities to custom homes and institutional structures.

-

Nail Strip Systems: Economical Standing Seam Entry Point

Nail strip configurations represent the most economical standing seam option by eliminating the clip system entirely. The male panel leg incorporates one-inch slotted holes spaced six inches apart that fasten directly to the roof substrate, with the female leg of the adjacent panel snapping over to conceal the fasteners. This design reduces both material costs through clip elimination and installation labor through simplified attachment procedures. Material cost savings typically range from 50 cents to one dollar per square foot compared to clip-based systems, making nail strip panels attractive for budget-conscious projects seeking standing seam aesthetics without premium performance requirements. However, the performance compromises prove substantial. Direct fastening through the panel leg restricts thermal expansion and contraction, potentially inducing oil-canning distortion as the metal binds against fixed penetration points. The lack of movement accommodation also increases fastener stress during thermal cycling, accelerating potential failure modes. Wind uplift ratings for nail strip systems fall significantly below clip-based alternatives, typically limiting applications to sheltered locations or regions with moderate wind exposure. The direct substrate attachment also creates slightly more penetration points compared to floating clip systems, marginally increasing long-term water intrusion risk. Despite these limitations, nail strip Metal Standing Seam Roofing Systems offer legitimate value for appropriate applications including residential roofs in moderate climates, secondary structures, and projects where standing seam aesthetics justify modest performance trade-offs compared to exposed fastener alternatives. Proper installation requires meticulous attention to fastener torque and panel alignment to minimize oil-canning risk while maximizing the system's moderate performance capabilities.

Performance Comparisons: Standing Seam Versus Alternative Metal Roofing Options

Evaluating Metal Standing Seam Roofing Systems against alternative metal roofing configurations reveals critical performance differentials that justify the premium investment for appropriate applications while identifying scenarios where simpler systems provide adequate functionality.

-

Standing Seam Versus Exposed Fastener Metal Roofing

The fundamental distinction between standing seam and exposed fastener systems centers on fastener positioning and the resulting maintenance implications. Exposed fastener metal roofing, commonly called screw-down panels, attaches directly through the panel face using self-drilling screws with neoprene washers penetrating into the structural substrate. This creates thousands of potential water entry points across the roof surface, with each fastener location subject to gasket degradation, screw loosening, and eventual water infiltration. The panels themselves cannot accommodate thermal expansion freely, as screws physically restrain movement, creating stress concentrations that work fasteners loose over time. Maintenance requirements for exposed fastener systems prove substantial, with screw replacement typically required every 10 to 15 years and complete fastener system overhaul needed within 20 years to maintain weather integrity. Metal Standing Seam Roofing Systems eliminate these vulnerabilities through concealed fasteners positioned beneath panel overlaps where they remain protected from weather exposure and UV degradation. The clip or hidden flange attachment allows panels to expand and contract freely along their length, eliminating stress concentrations while maintaining fastener engagement integrity. This design difference translates directly into lifespan disparities: exposed fastener roofs typically achieve 20 to 30 years service life with regular maintenance, while properly installed standing seam systems reliably perform for 40 to 60 years with minimal intervention beyond periodic inspections. The aesthetic distinction also proves significant, with standing seam's clean lines and concealed attachments providing a premium appearance versus exposed fastener systems' visible screw pattern. Cost differentials reflect these performance advantages, with standing seam installations typically costing twice the expense of exposed fastener alternatives at $12 to $16 per square foot compared to $4 to $6 per square foot for screw-down panels.

-

Structural Performance and Load Resistance Capabilities

The raised seam profile inherent to Metal Standing Seam Roofing Systems provides superior structural performance compared to lower-profile metal roofing alternatives. The vertical ribs function as structural stiffeners, dramatically increasing panel moment of inertia and load-bearing capacity. High-seam profiles at 65mm height enable wind pressure resistance exceeding 4.5 kilopascals, sufficient for hurricane-prone coastal regions experiencing sustained winds above 150 miles per hour with gusts substantially higher. This performance meets or exceeds requirements specified in ASTM E1592 and GB 50223 standards for high-wind applications, providing building owners with confidence in extreme weather scenarios. Snow load capacity similarly benefits from the structural enhancement provided by raised seams. Properly designed Metal Standing Seam Roofing Systems accommodate snow loads exceeding 1.5 kilonewtons per square meter, suitable for northern climates experiencing substantial winter precipitation. The panels' structural rigidity prevents sagging between purlins even under sustained loading, maintaining roof integrity throughout seasonal freeze-thaw cycles. Impact resistance testing demonstrates exceptional performance, with panels withstanding one-kilogram steel ball drops from three-meter heights without penetration or permanent deformation, exceeding ASTM D3746 requirements. The thermal performance of standing seam systems also surpasses alternative configurations through the air space created between the raised seam and roof substrate, which provides additional insulation value while facilitating air circulation that moderates temperature extremes and reduces condensation potential.

Applications and Project Suitability for Metal Standing Seam Roofing Systems

The versatile performance characteristics of Metal Standing Seam Roofing Systems enable successful application across diverse building types, each benefiting from specific system attributes that address unique performance requirements and aesthetic objectives.

-

Large-Span Commercial and Public Infrastructure Projects

Large-span structures including airports, exhibition centers, sports stadiums, and transportation terminals represent ideal applications for Metal Standing Seam Roofing Systems. These buildings demand exceptional weather resistance across expansive roof areas where water management becomes critical during heavy precipitation events. The continuous panel runs possible with standing seam technology, extending up to 13 meters without horizontal seams, eliminate vulnerable cross-joints that plague other roofing systems. This seamless approach proves particularly valuable for buildings housing moisture-sensitive activities or valuable contents where any water intrusion creates substantial damage potential. The structural efficiency of high-seam profiles reduces purlin requirements for long-span applications, enabling wider bay spacing that translates into material cost savings offsetting the premium panel investment. Wind uplift performance becomes critical for large, low-slope roofs in exposed locations where negative pressures during storms can exceed positive design loads. The mechanical seam or clip-fastened connections provide tested uplift resistance surpassing 300 pounds per square foot, maintaining roof integrity during extreme weather events. Aesthetic considerations also favor standing seam for high-visibility public buildings where architectural expression matters. The clean lines and monolithic appearance of standing seam installations complement contemporary design vocabularies while supporting corporate branding or civic identity objectives. Projects including Xi'an International Convention and Exhibition Center, Xiongan Station Commercial Body, and Inner Mongolia Tongliao Art Museum demonstrate successful large-scale Metal Standing Seam Roofing Systems implementation across diverse functional programs.

-

Industrial Facilities and Corrosive Environment Applications

Industrial buildings exposed to corrosive atmospheres, chemical processes, or coastal conditions benefit substantially from Metal Standing Seam Roofing Systems material options and protective coating technologies. Manufacturing facilities producing corrosive byproducts require roofing materials that withstand aggressive chemical exposure without premature degradation. Stainless steel substrates with PVDF coatings provide exceptional resistance to acid and alkaline environments, maintaining structural integrity and appearance over decades of exposure. Coastal industrial facilities face combined challenges of salt spray, high humidity, and often elevated temperatures that accelerate corrosion in standard materials. Aluminum-magnesium-manganese alloy panels offer superior performance in these conditions, with the aluminum content providing natural corrosion resistance while magnesium and manganese alloying enhances strength and formability. The concealed fastener design proves particularly valuable in corrosive environments by eliminating exposed metal-to-metal contacts where galvanic corrosion accelerates material breakdown. The continuous panel lengths possible with standing seam technology reduce joint complexity, minimizing water retention locations where corrosion initiation commonly occurs. Industrial facility owners appreciate the low maintenance requirements of Metal Standing Seam Roofing Systems, as production disruptions for roof repairs create costly downtime beyond the repair expense itself. The 30-year warranty periods typical for premium standing seam installations provide operational predictability that supports facility management planning. Projects like Weihua Cadre College and multiple industrial facilities demonstrate how proper material selection and system design deliver exceptional service life even in demanding exposure conditions.

-

Photovoltaic Integration and Sustainable Building Systems

The growing emphasis on renewable energy generation creates substantial opportunity for Metal Standing Seam Roofing Systems optimized for photovoltaic panel integration. The raised seams provide ideal mounting locations for PV attachment hardware without roof membrane penetration. Specialized clamps designed to engage standing seams create secure solar array foundations while maintaining the roof's waterproofing integrity. This non-penetrating attachment approach eliminates the leak risks and warranty complications associated with traditional rack mounting that drills through roofing membranes. The structural capacity of 65mm high-seam profiles accommodates photovoltaic loads without roof reinforcement in most applications, simplifying installation while reducing total project costs. The metal substrate's high solar reflectance and thermal emittance support cool roof performance, reducing building cooling loads and improving photovoltaic efficiency through lower panel operating temperatures. Metal Standing Seam Roofing Systems meet cool roof standards with reflectivity values exceeding 0.65, qualifying for energy efficiency incentives and green building certification programs. The extended service life of standing seam installations aligns with solar panel longevity expectations, ensuring the roof remains serviceable throughout the PV system's productive life without requiring panel removal for roof replacement. Environmental benefits extend beyond energy generation to include complete material recyclability at end-of-life, with steel and aluminum substrates retaining full value in secondary markets. This cradle-to-cradle sustainability appeals to organizations pursuing aggressive environmental goals while delivering practical performance advantages that justify the technology selection on purely functional grounds.

Conclusion

Metal Standing Seam Roofing Systems deliver unmatched performance combining superior weather resistance through concealed fasteners, extended service life spanning 40 to 60 years, minimal maintenance requirements, and versatile aesthetic options suitable for diverse architectural applications from industrial facilities to prestigious public buildings.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a Shaanxi Province high-tech enterprise, specializes in comprehensive metal roofing solutions with first-level curtain wall qualifications and third-level steel structure certifications. Our 200,000-square-meter Anhui production facility and processing plants in Hangzhou and Xi'an operate 7 color coating lines, 10 shearing production lines, and over 40 specialized equipment units, manufacturing premium Metal Standing Seam Roofing Systems with specifications from 65-300mm seam heights, PE/HDP/PVDF coating options, and customizable colors meeting ISO9001, ISO14000:14001, and SGS standards. As a China Metal Standing Seam Roofing Systems factory, China Metal Standing Seam Roofing Systems supplier, and China Metal Standing Seam Roofing Systems manufacturer offering China Metal Standing Seam Roofing Systems wholesale with competitive Metal Standing Seam Roofing Systems price, we provide High Quality Metal Standing Seam Roofing Systems for sale backed by 30-year warranties, 500-square-meter minimum orders, 15-20 day delivery, and complete customization capabilities. Our one-stop service encompasses design optimization, raw material quality testing using premium brands including Baosteel and NedZink, precision manufacturing with real-time quality control, and professional installation with comprehensive project management for landmark projects including Xi'an International Convention Center and Xiongan Station Commercial Body. Contact huafeng@hfmetalroof.com today to transform your building with superior roofing technology—bookmark this guide for reference as you plan your project.

References

1. Sheffield Metals. "Standing Seam Metal Roofing: Types, Benefits, and Installation." Metal Roofing Learning Center.

2. Western States Metal Roofing. "Standing Seam Metal Roofing Types: Mechanically Seamed, Snap-Lock, and Nail Strip Systems." Metal Roofing Technical Guide.

3. McElroy Metal. "Standing Seam Metal Roof Systems: Technical Specifications and Performance Standards." Commercial Roofing Solutions Manual.

4. Bill Ragan Roofing. "Standing Seam vs. Screw Down Metal Roofing: Performance Comparison and Lifecycle Analysis." Roofing Systems Technical Review.