Are you struggling with frequent roof leaks, high maintenance costs, or inadequate weather protection on your commercial or industrial building? Traditional roofing systems often fail to withstand harsh environmental conditions, leading to costly repairs and operational disruptions. Trapezoidal Standing Seam Roofing offers the ultimate solution, combining exceptional durability, weather resistance, and aesthetic versatility to protect your investment for decades. At Xi'an Huafeng Construction Engineering Co., Ltd., we specialize in delivering premium trapezoidal standing seam metal roof systems that eliminate these pain points while adding significant value to your property.

Understanding Trapezoidal Standing Seam Roofing Systems

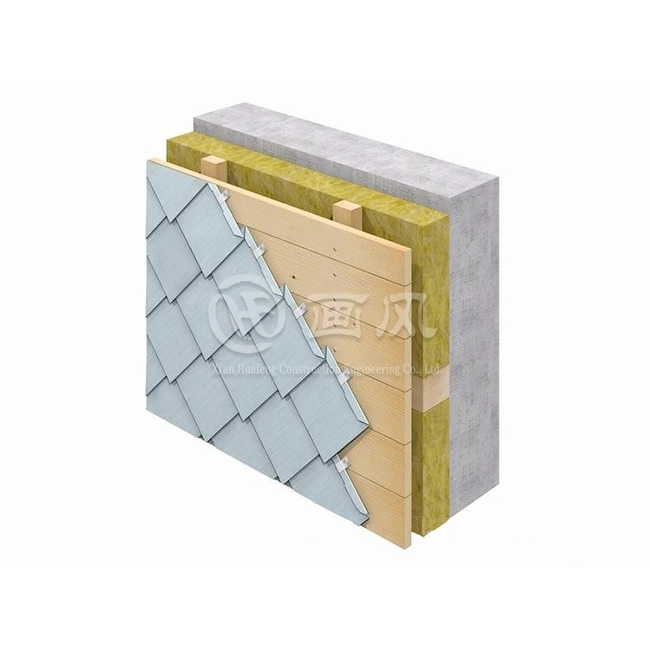

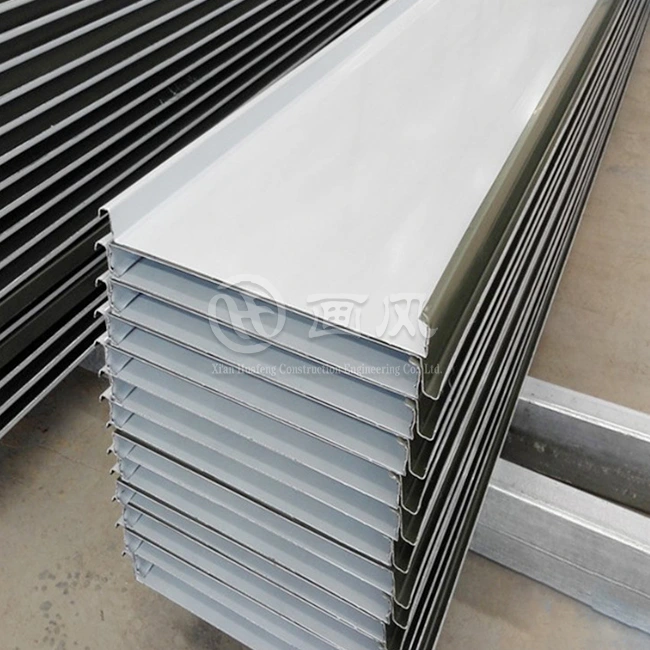

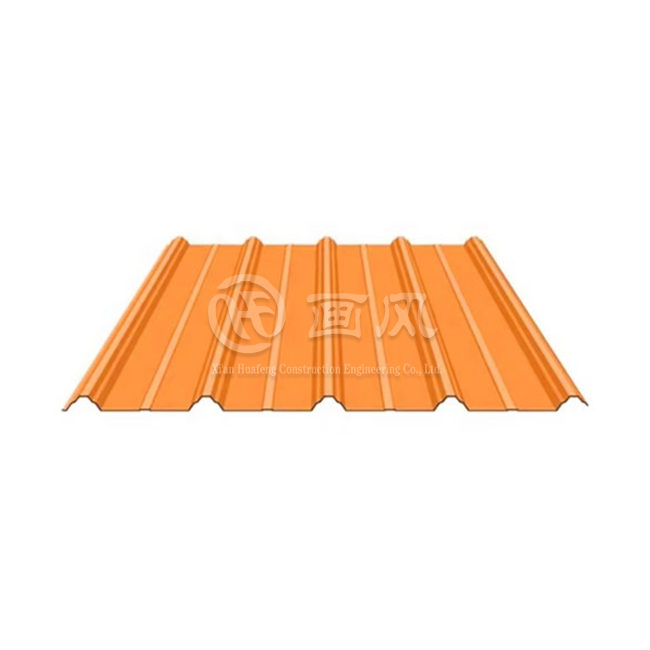

Trapezoidal Standing Seam Roofing represents a revolutionary advancement in metal roofing technology, engineered specifically to address the critical challenges faced by modern commercial and industrial buildings. This innovative roofing system features a distinctive trapezoidal leg profile with elevated seams that create a continuous, watertight barrier across the entire roof surface. Unlike traditional exposed fastener systems that leave your roof vulnerable to water infiltration and premature failure, Trapezoidal Standing Seam Roofing utilizes concealed fastening mechanisms that protect against moisture penetration while accommodating thermal expansion and contraction. The unique design incorporates standing seams ranging from 50mm to 115mm in height, providing superior structural integrity and drainage capabilities even on roofs with slopes as low as one-quarter inch per foot. At Xi'an Huafeng Construction Engineering Co., Ltd., our trapezoidal standing seam panels are manufactured from premium materials including aluminum alloy grades 3003, 3004, and 5052, galvanized steel, galvalume steel, and stainless steel grades 316 and 304, ensuring optimal performance across diverse climatic conditions and architectural requirements.

-

Key Performance Characteristics of Trapezoidal Standing Seam Metal Roofing

The engineering excellence behind Trapezoidal Standing Seam Roofing delivers measurable performance advantages that directly impact your building's operational efficiency and long-term value. Our systems achieve wind resistance ratings exceeding 5.0 kPa, making them ideal for structures in high-wind zones and coastal environments where conventional roofing systems frequently fail. The non-penetrating clip attachment system eliminates thousands of potential leak points while allowing panels to move freely with temperature fluctuations, preventing the buckling and distortion that plague fixed-fastener roofs. With load capacities exceeding 1.5 kN per square meter and Class A fire ratings, these roof systems provide comprehensive protection for your valuable assets and personnel. The waterproofing performance meets stringent ASTM D7344 standards, ensuring absolute moisture exclusion even during severe weather events. Xi'an Huafeng's Trapezoidal Standing Seam Roofing systems offer panel widths ranging from 300mm to 600mm and thicknesses from 0.7mm to 1.2mm, with customizable lengths up to 13 meters to minimize seams and maximize weather resistance. Our advanced PE and PVDF coating systems provide exceptional color retention and corrosion resistance, backed by comprehensive 30-year warranties that protect your investment.

-

Material Selection and Durability Engineering

Selecting the appropriate materials for your Trapezoidal Standing Seam Roofing installation requires careful consideration of environmental exposure, structural requirements, and lifecycle cost expectations. Aluminum alloy options provide exceptional corrosion resistance and lightweight properties, making them ideal for coastal installations and structures with weight restrictions. Our 3003 and 3004 aluminum grades offer excellent formability and weldability, while the 5052 grade delivers superior strength for applications requiring enhanced structural performance. Galvalume steel combines the formability of aluminum with the strength of steel, coated with an aluminum-zinc alloy that provides four times the corrosion resistance of standard galvanized steel. For the most demanding environments, our stainless steel options in grades 304 and 316 deliver unparalleled longevity, with grade 316 specifically engineered for extreme coastal and industrial atmospheres where salt spray and chemical exposure occur regularly. Each material undergoes rigorous incoming inspection procedures including salt spray testing, adhesion verification, hardness measurement, impact resistance evaluation, and comprehensive weathering simulation to ensure it meets our strict quality standards. The thickness selection directly influences thermal performance, structural capacity, and acoustic properties, with our engineering team providing detailed specification guidance to optimize your roof system for specific application requirements.

Installation Excellence and System Integration

-

Professional Design and Engineering Services

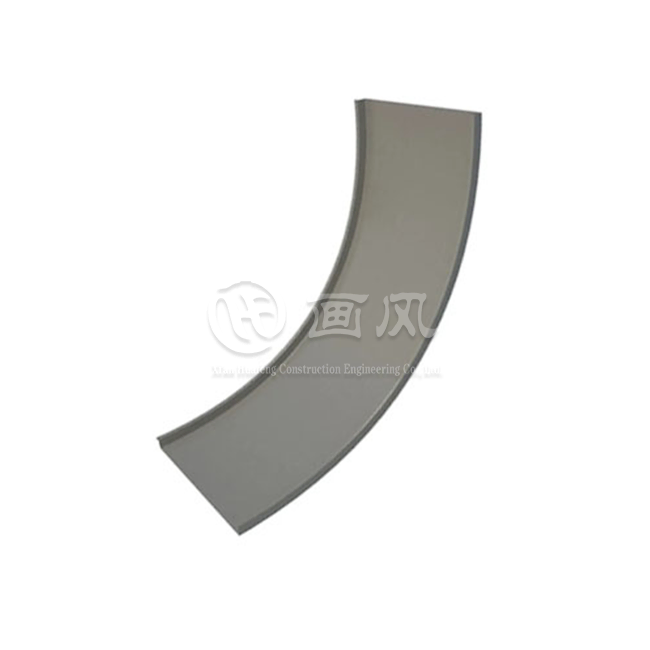

The foundation of every successful Trapezoidal Standing Seam Roofing installation begins with comprehensive design engineering and project-specific customization. At Xi'an Huafeng Construction Engineering Co., Ltd., our technical design department conducts thorough analysis of architectural drawings, structural calculations, and site-specific conditions to develop optimized roofing solutions that address unique project challenges. We perform detailed 3D structural modeling and load analysis to verify that the roof system will perform reliably under all anticipated loading conditions, including snow accumulation, wind uplift, seismic events, and maintenance traffic. Our drainage system simulation capabilities ensure proper water management, preventing ponding and accelerating water removal to protect building contents and extend roof life. The material specification advisory process considers factors including chemical exposure, thermal cycling, aesthetic requirements, and budget constraints to select the optimal combination of substrate material, coating system, and profile geometry. Through detailed node-by-node drawing development conducted at full scale, we identify and resolve potential installation challenges before fabrication begins, eliminating costly field modifications and ensuring seamless integration with adjacent building components including walls, skylights, penetrations, and expansion joints.

-

Quality-Controlled Manufacturing Processes

Xi'an Huafeng's state-of-the-art manufacturing facilities transform premium raw materials into precision-engineered Trapezoidal Standing Seam Roofing panels through meticulously controlled production processes. Our 200,000-square-meter raw material production plant in Anhui, combined with specialized processing facilities in Hangzhou and Xi'an, provides comprehensive manufacturing capabilities backed by seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing lines. The roll-forming systems utilize advanced servo controls and real-time quality monitoring to maintain dimensional tolerances within 0.5mm across panel lengths exceeding 12 meters, ensuring perfect fit-up during installation. Raw material traceability systems document the complete chain of custody from certified suppliers through final panel production, with each material batch accompanied by mill certificates and third-party testing verification. Our incoming material inspection protocols verify more than a dozen critical parameters including appearance quality, dimensional accuracy, coating thickness, color consistency, adhesion strength, salt spray resistance, and weathering performance before materials enter production. Finished panel inspection procedures evaluate flatness, straightness, seam geometry, coating integrity, and proper identification marking to guarantee that every component meets or exceeds project specifications. The systematic production approach includes sequential numbering of all panels according to installation location, simplifying field logistics and eliminating confusion during erection.

Comprehensive Installation Support and Long-Term Performance

-

On-Site Construction Management and Technical Guidance

Successful Trapezoidal Standing Seam Roofing installation requires precise coordination between design intent, manufactured components, and field execution under constantly varying site conditions. Xi'an Huafeng provides experienced technical supervisors who visit project sites in advance of material delivery to verify substrate preparation, confirm storage arrangements, and coordinate staging areas for efficient material flow. Upon panel arrival, our team conducts thorough verification of all components against packing lists and installation drawings, organizing materials according to the sectioned floor plan to streamline the installation sequence. Installation technicians receive comprehensive briefings covering work details, quality control checkpoints, and safety protocols specific to standing seam roof construction. The floating clip attachment methodology allows panels to expand and contract freely with temperature changes while maintaining weathertight integrity, requiring specialized tooling and techniques that our trained installers execute with precision. Critical details including eave conditions, ridge treatments, end wall terminations, and penetration flashings receive particular attention to ensure that these vulnerable transition areas perform as reliably as the field of the roof. Upon installation completion, comprehensive water testing verifies zero-leak performance across the entire roof area, with any deficiencies immediately corrected before final acceptance.

-

Ongoing Maintenance and Performance Optimization

While Trapezoidal Standing Seam Roofing systems require minimal maintenance compared to conventional roofing alternatives, establishing a proactive care program maximizes service life and preserves warranty coverage. Xi'an Huafeng provides detailed maintenance guidance tailored to specific material selections, environmental exposures, and building uses, empowering facility managers to protect their roofing investment through simple routine procedures. Regular inspections should focus on sealant conditions at terminations, clip engagement verification, debris removal from valleys and gutters, and coating surface examination for any signs of mechanical damage or excessive soiling. The self-cleaning properties of modern coil coating systems minimize dirt accumulation, but periodic gentle washing with mild detergent solutions restores original appearance and removes corrosive deposits in industrial atmospheres. Our technical support team remains available throughout the roof's service life to address questions, provide guidance on repair procedures, and assist with any performance concerns that may arise. The comprehensive documentation package provided at project completion includes detailed as-built drawings, material certifications, installation records, and maintenance recommendations that future facility managers will rely upon for decades. This commitment to long-term customer success distinguishes Xi'an Huafeng as a partner invested in your building's performance rather than simply a product supplier.

Proven Project Success and Application Versatility

Xi'an Huafeng Construction Engineering Co., Ltd. has successfully delivered Trapezoidal Standing Seam Roofing solutions for landmark projects across diverse applications including the Xiongan Station Commercial Body featuring extensive aluminum-magnesium-manganese metal roofing, the Xi'an International Convention and Exhibition Center requiring precision installation across complex geometries, and the Xi'an Station East Auxiliary Building demanding coordination with sensitive rail operations. Our portfolio extends to cultural facilities like the Jinghe New City International Culture and Art Center South Hall, infrastructure projects including the Liyuanping Highway Station, educational campuses such as the Weihua Cadre College teaching and office buildings, industrial facilities like the Hangzhou Sanpu Drainage Pump Station, and museum projects including archaeological museum design development and the Inner Mongolia Tongliao Art Museum. These projects demonstrate our capability to deliver exceptional results regardless of project scale, architectural complexity, or performance requirements, consistently meeting aggressive schedules while maintaining uncompromising quality standards.

Conclusion

Trapezoidal Standing Seam Roofing from Xi'an Huafeng Construction Engineering Co., Ltd. delivers unmatched performance, durability, and value for commercial and industrial buildings facing demanding environmental conditions and stringent aesthetic requirements.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a leading China Trapezoidal Standing Seam Roofing manufacturer, China Trapezoidal Standing Seam Roofing supplier, and China Trapezoidal Standing Seam Roofing factory, Xi'an Huafeng Construction Engineering Co., Ltd. offers comprehensive one-stop solutions from initial design through long-term maintenance support. Established in Shaanxi Province in 2018 and recognized as a high-tech enterprise in 2020, we maintain first-level qualifications for building curtain walls and third-level qualifications for building steel structures. Our 200,000-square-meter raw material production facility in Anhui, complemented by processing plants in Hangzhou and Xi'an, operates seven color coating lines, one laminating line, and ten shearing production lines supported by over 40 specialized machines. With more than 20 registered patents, CE certification, ISO9001 and ISO14001 compliance, and SGS verification, we deliver High Quality Trapezoidal Standing Seam Roofing backed by rigorous quality control. Whether you need China Trapezoidal Standing Seam Roofing wholesale pricing or customized Trapezoidal Standing Seam Roofing for sale with specific colors, patterns, and designs, our expert team provides tailored solutions with competitive Trapezoidal Standing Seam Roofing price structures. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and discover why Fortune 500 companies worldwide trust Xi'an Huafeng for their critical roofing applications.

References

1. National Roofing Contractors Association. (2023). "Metal Roofing Systems: Design, Installation, and Performance Standards." NRCA Technical Manual for Steep-Slope Roofing Systems, 8th Edition.

2. American Society of Civil Engineers. (2022). "Minimum Design Loads and Associated Criteria for Buildings and Other Structures." ASCE/SEI 7-22 Standard, Chapter 29: Wind Loads on Components and Cladding.

3. Metal Construction Association. (2024). "Technical Bulletin: Standing Seam Metal Roof Systems - Design Considerations and Best Practices." MCA Technical Publication Series, Volume 12.

4. International Building Code. (2024). "Chapter 15: Roof Assemblies and Rooftop Structures - Requirements for Metal Roof Systems." ICC IBC-2024, Section 1507.4: Metal Roof Panels.