Picture this scenario: you've invested thousands in a commercial building project, only to discover water leaking through your roof seams after the first winter storm. The culprit? Choosing the wrong standing seam profile for your climate and roof pitch. Understanding the critical differences between snap lock and Mechanical Lock Metal Roofing systems isn't just about aesthetics—it's about protecting your investment from costly failures and ensuring decades of weather-resistant performance.

Understanding Standing Seam Metal Roofing Systems

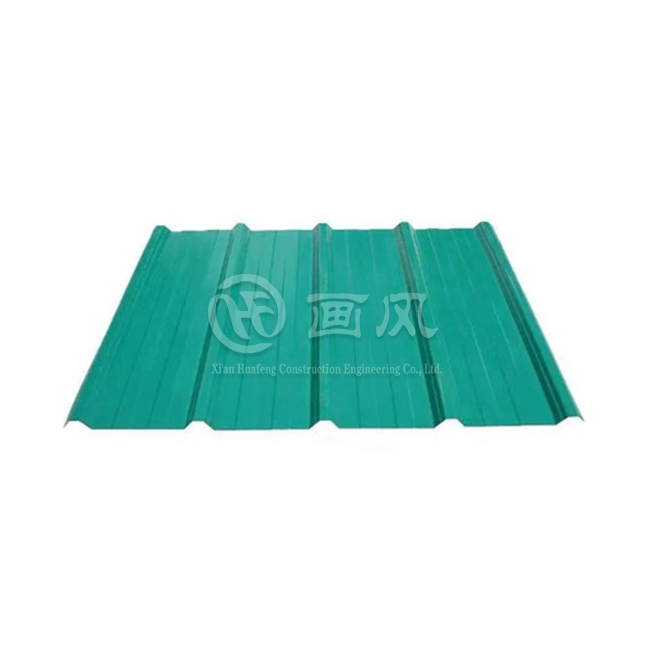

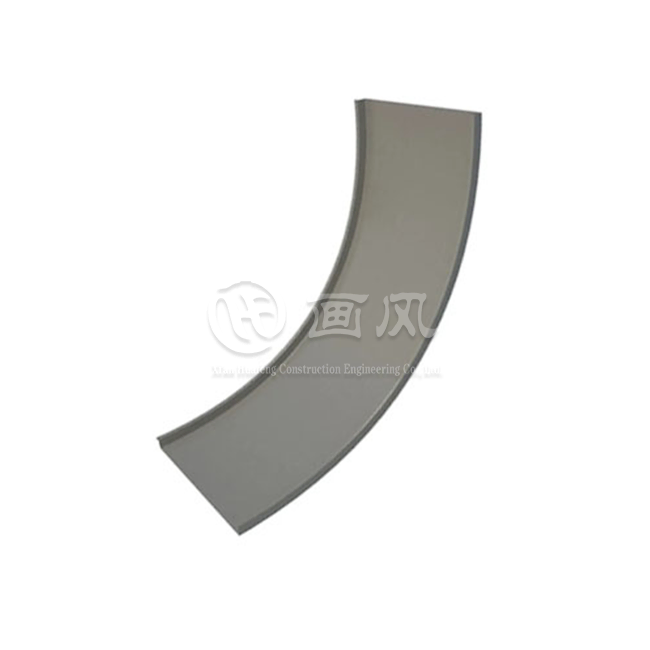

Standing seam metal roofing has revolutionized modern construction by offering unparalleled durability and aesthetic appeal for both residential and commercial applications. These sophisticated roofing systems feature vertical interlocking panels that run continuously from the roof's ridge to the eaves, creating distinctive raised seams that define their characteristic appearance. The fundamental distinction within standing seam technology lies in how these panels connect—either through snap lock mechanisms or Mechanical Lock Metal Roofing methods. Each approach delivers different performance characteristics, installation requirements, and long-term value propositions that construction professionals must carefully evaluate before specification. The evolution of standing seam technology reflects the construction industry's growing demand for roofing solutions that balance performance with installation efficiency. Modern Mechanical Lock Metal Roofing systems incorporate advanced engineering principles that address thermal movement, wind uplift resistance, and water penetration concerns that plagued earlier roofing technologies. These systems utilize concealed fastening methods that eliminate exposed screws—a critical vulnerability point in traditional roofing systems where weather infiltration typically begins. The choice between snap lock and mechanical seam profiles fundamentally impacts project budgets, installation timelines, and the roof's ability to withstand environmental stresses over its service life.

-

Key Components of Standing Seam Technology

Both snap lock and Mechanical Lock Metal Roofing systems share several foundational components that contribute to their superior performance compared to conventional roofing materials. The panel profiles themselves are precision roll-formed with specifically engineered male and female edges designed for secure interlocking. Hidden clip systems attach panels to the roof deck while allowing for thermal expansion and contraction—a critical feature in climates experiencing significant temperature fluctuations. The raised seam height, typically ranging from one to three inches, provides both aesthetic definition and functional water management by channeling moisture away from vulnerable connection points. Quality Mechanical Lock Metal Roofing installations utilize expansion clips that accommodate the natural movement of metal panels as they respond to temperature changes throughout the day and across seasons. Fixed clips work effectively for shorter panel runs where thermal movement remains minimal, while floating clip systems become essential for longer panels exceeding twenty-five feet. The selection of appropriate clip types directly influences the system's longevity and resistance to panel disengagement, particularly in regions where freeze-thaw cycles or extreme temperature swings place additional stress on roofing assemblies.

Snap Lock Standing Seam: Fast Installation and Cost Efficiency

Snap lock standing seam profiles represent an engineered evolution in metal roofing that prioritizes installation speed without sacrificing the core benefits of concealed fastener technology. These panels feature pre-formed edges—a male leg on one side and a female leg on the opposite—that mechanically interlock with an audible snap during installation, eliminating the need for specialized seaming equipment. The snap lock clip system attaches directly to the roof substrate with fasteners, then the male edge of the panel engages the clip before the female edge of the adjacent panel snaps over to complete the connection. This straightforward installation process significantly reduces labor requirements and project timelines compared to Mechanical Lock Metal Roofing alternatives. The economic advantages of snap lock systems extend beyond reduced installation time to encompass lower equipment costs and decreased skill requirements for installation crews. Professional roofing contractors can install snap lock panels without investing in expensive mechanical seaming tools, which can cost several hundred dollars per week to rent or thousands to purchase. This accessibility makes snap lock an attractive option for smaller roofing contractors entering the standing seam market or for projects with constrained budgets. However, construction professionals must recognize that snap lock profiles perform optimally under specific conditions—primarily on roof slopes of three-in-twelve pitch or greater, where gravity assists water drainage and reduces the risk of moisture accumulation at panel connections.

-

Performance Considerations for Snap Lock Systems

While snap lock standing seam delivers excellent weather resistance compared to exposed fastener systems, it provides less weather-tight performance than Mechanical Lock Metal Roofing options, particularly in extreme climate conditions. The snap-together connection, though secure under normal circumstances, creates a mechanical joint that remains susceptible to disengagement under severe wind uplift forces or during freeze-thaw cycles that cause repeated expansion and contraction of metal panels. Construction professionals specifying snap lock systems must carefully evaluate local climate conditions, historical weather patterns, and building code requirements to ensure the system's performance characteristics align with project demands. Engineering and testing protocols for snap lock systems have advanced significantly, with many manufacturers now offering engineered snap lock profiles that include comprehensive uplift testing data and code compliance documentation. These engineered systems undergo rigorous evaluation to determine their resistance to wind-driven rain, air infiltration, and structural wind loads—critical performance metrics for commercial applications where building code compliance drives specification decisions. However, even engineered snap lock systems typically cannot match the superior weather-tightness of double-locked Mechanical Lock Metal Roofing assemblies, which create virtually impenetrable seam connections through mechanical crimping processes.

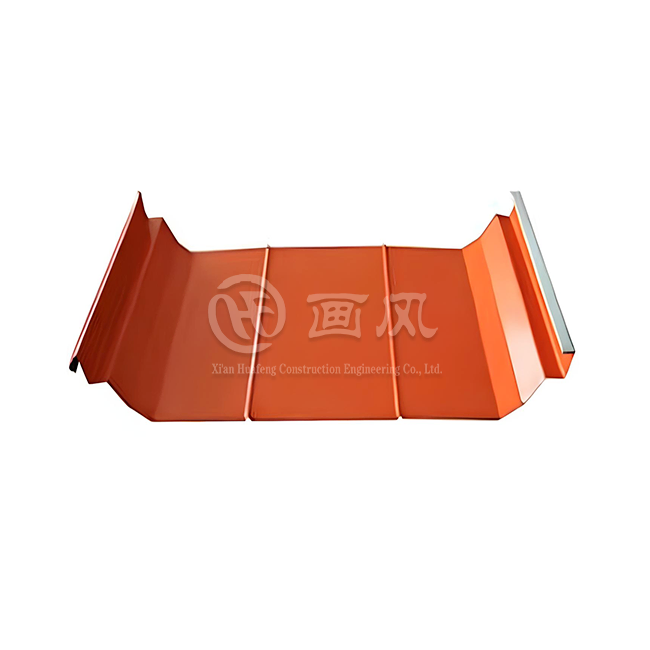

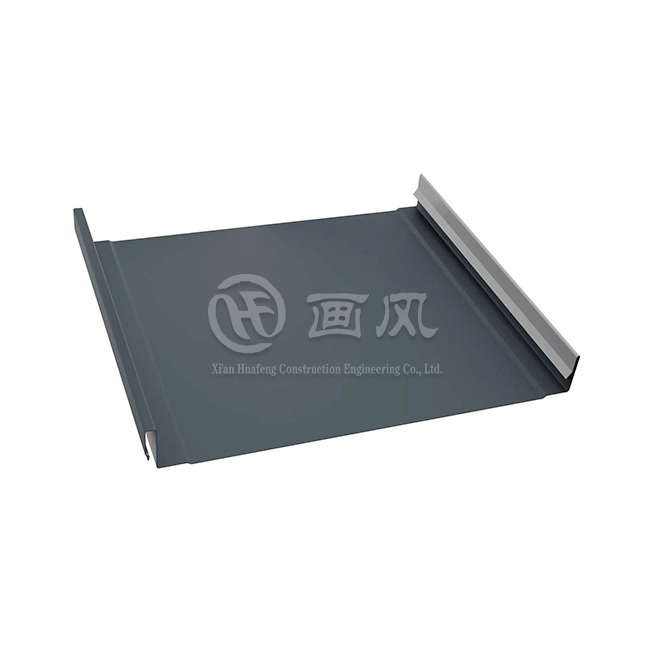

Mechanical Lock Metal Roofing: Superior Weather Protection

Mechanical Lock Metal Roofing represents the premium tier of standing seam technology, delivering unmatched weather resistance through mechanically crimped seam connections that create watertight barriers against even the most severe environmental conditions. The installation process requires specialized equipment—either hand-operated or robotic seamers—that precisely folds and crimps the panel edges together in either single-lock ninety-degree seams or double-lock one-hundred-eighty-degree seams. This mechanical seaming operation compresses the male and female panel edges so tightly that water infiltration becomes virtually impossible, making Mechanical Lock Metal Roofing the preferred specification for low-slope applications, extreme weather environments, and projects where absolute waterproofing represents a critical requirement. The performance advantages of Mechanical Lock Metal Roofing extend well beyond superior water-tightness to encompass enhanced structural integrity and wind uplift resistance. The mechanically crimped seam creates a continuous structural connection between adjacent panels that dramatically increases the roof system's ability to resist uplift forces during severe wind events. Independent testing consistently demonstrates that double-locked mechanical seam assemblies achieve significantly higher wind resistance ratings compared to snap lock alternatives—a critical consideration for coastal installations, tall buildings with high wind exposure, or regions prone to severe weather events including hurricanes and tornadoes.

-

Installation Requirements and Long-Term Value

Mechanical Lock Metal Roofing installations demand greater technical expertise, specialized equipment, and additional labor hours compared to snap lock systems—factors that translate directly into higher initial project costs. Professional installers must coordinate the deployment of mechanical seaming equipment, carefully manage the seaming process to ensure consistent compression throughout each joint, and maintain quality control to prevent panel distortion or finish damage during the seaming operation. Robotic seamers have largely replaced hand-operated tools for commercial projects due to their ability to deliver consistent seam quality while reducing the physical demands on installation crews, though these automated systems represent significant capital investments for roofing contractors. Despite higher upfront costs, Mechanical Lock Metal Roofing delivers superior long-term value through extended service life, reduced maintenance requirements, and enhanced performance reliability. The mechanically crimped seams resist degradation from thermal cycling, maintain their weather-tight integrity through decades of environmental exposure, and eliminate concerns about panel disengagement that occasionally affect snap lock systems in extreme conditions. Projects in regions experiencing harsh winters particularly benefit from mechanical seam technology, as the secure panel connections withstand repeated freeze-thaw cycles without compromising system integrity—a performance characteristic that protects building owners from costly leak repairs and interior damage.

-

Thermal Movement Management in Mechanical Systems

Advanced Mechanical Lock Metal Roofing installations incorporate sophisticated clip systems specifically engineered to accommodate thermal expansion and contraction while maintaining secure panel attachment. Two-piece expansion clips represent the premium solution for long panel runs, featuring a base component fixed to the roof deck and a sliding element that engages the panel seam, allowing controlled movement as metal temperatures fluctuate. This thermal management capability proves essential in climates with extreme temperature variations, where daily temperature swings or seasonal changes can cause significant dimensional changes in metal panels. Properly designed expansion clip systems prevent oil-canning distortions, reduce stress concentrations at connection points, and ensure the Mechanical Lock Metal Roofing assembly maintains its intended appearance and performance throughout its service life.

Selecting the Right Profile for Your Project

Choosing between snap lock and Mechanical Lock Metal Roofing requires comprehensive evaluation of multiple project-specific factors including roof geometry, local climate conditions, building code requirements, budget constraints, and long-term performance expectations. Roof slope emerges as a primary decision driver—snap lock systems require minimum pitches of three-in-twelve for reliable performance, while Mechanical Lock Metal Roofing systems perform effectively on slopes as low as one-quarter-in-twelve when properly detailed with double-lock seams. Projects in regions experiencing severe weather conditions including heavy snow loads, high winds, or extreme temperature fluctuations typically justify the additional investment in mechanical seam technology to ensure reliable long-term performance. Budget considerations must encompass both initial installation costs and long-term lifecycle expenses when comparing these roofing technologies. While snap lock systems deliver lower first costs through faster installation and reduced equipment requirements, Mechanical Lock Metal Roofing may provide superior value over the building's lifespan through enhanced durability and reduced maintenance needs. Construction professionals should conduct comprehensive lifecycle cost analyses that factor in expected service life, maintenance requirements, energy performance, and potential replacement costs to make informed specification decisions that optimize value rather than simply minimizing initial expenditure.

-

Technical Specifications and Material Selection

Contemporary Mechanical Lock Metal Roofing systems offer extensive customization options regarding material selection, panel dimensions, coating systems, and aesthetic finishes. Material choices span aluminum alloys including three-thousand and five-thousand series aluminum-magnesium-manganese compositions, galvanized and galvalume steel substrates, stainless steel for maximum corrosion resistance, copper for premium architectural applications, and titanium-zinc alloys for European-influenced design aesthetics. Panel widths typically range from twelve to twenty inches, with sixteen-inch coverage representing the most common specification, while rib heights vary from one to three inches depending on architectural preferences and structural requirements. High-performance coating systems significantly impact the long-term appearance retention and weather resistance of Mechanical Lock Metal Roofing installations. PVDF fluoropolymer coatings represent the premium finish option, delivering exceptional ultraviolet resistance, color stability, and chemical resistance that maintains aesthetic integrity for decades in harsh environmental conditions. These advanced coatings typically feature application thicknesses of twenty-five to forty microns on exposed surfaces, with lighter polyester backing coats on concealed panel undersides. Material specifications should align with project exposure conditions, with marine environments, industrial atmospheres, and high-pollution areas warranting premium coating systems to ensure long-term performance.

Manufacturing Excellence and Quality Assurance

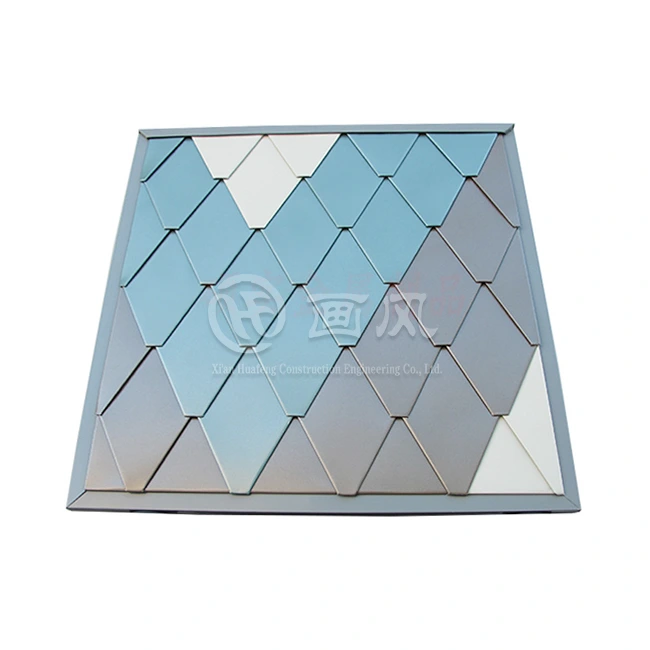

Xi'an Huafeng Construction Engineering Co., Ltd. operates state-of-the-art manufacturing facilities specifically designed for precision Mechanical Lock Metal Roofing production. Our three advanced factories house seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing production lines, supported by fully automated punching systems and more than forty specialized machines including shearing equipment, presses, and precision bending machinery. This extensive manufacturing infrastructure enables production capacity exceeding one thousand tons monthly while maintaining rigorous quality standards throughout every production stage from raw material verification through finished product inspection. Quality assurance protocols at our facilities encompass comprehensive incoming material inspection procedures that verify raw material certifications and third-party testing reports from approved suppliers. Our material selection exclusively sources premium brands including Alucosuper, YATAI, and LIDAO aluminum alloys in three-thousand, three-thousand-four, and five-thousand-fifty-two compositions, while steel products come from BAOSTEEL, GUANZHOU, and XINYU suppliers. Every production batch undergoes multiple inspection steps including appearance verification, dimensional accuracy checks, salt spray resistance testing, adhesion evaluation, hardness measurement, impact resistance, coating thickness verification, acid resistance, weather resistance assessment, and color consistency validation to ensure Mechanical Lock Metal Roofing products meet or exceed international quality standards.

-

Engineering Support and Technical Services

Our comprehensive engineering capabilities support clients throughout the entire project lifecycle, from initial design consultation through final installation verification. The technical design department provides detailed three-dimensional structural modeling, load analysis calculations, drainage system simulations, and material specification advisory services that optimize Mechanical Lock Metal Roofing system performance for specific project requirements. We conduct extensive project drawing deepening processes that analyze architectural plans, develop feasible technical alternatives, and create detailed node drawings at one-to-one scale to ensure precise coordination between design intent and manufacturing capabilities. Factory processing sample production represents a critical quality verification step where we manufacture physical samples based on confirmed specifications including panel profile, material composition, thickness, surface treatment methodology, and color selection. These sealed samples serve as production standards throughout manufacturing and provide definitive references for quality acceptance procedures. Our processing drawing development breaks down overall project drawings into detailed shop drawings that guide production operations, with sequential numbering systems that ensure accurate component tracking from manufacturing through quality assurance packaging to final installation, eliminating confusion and reducing field coordination challenges.

Installation Excellence and Project Execution

Professional Mechanical Lock Metal Roofing installation requires meticulous planning, skilled execution, and comprehensive quality control throughout the construction process. Our experienced installation teams conduct thorough site evaluations prior to material delivery, verifying substrate conditions, confirming site logistics including material storage locations and on-site processing areas, and coordinating construction schedules to optimize installation efficiency. Installation technicians arrive on-site at least one day before scheduled work commencement to inspect work areas, verify tool availability including specialized edge-locking equipment and mechanical seamers, and confirm adequate supplies of auxiliary materials including rivets, structural adhesives, fasteners, and accessory components. On-site construction follows rigorous protocols beginning with comprehensive technical briefings that review detailed installation procedures, safety requirements, and quality standards. Product verification procedures ensure materials arrive in proper sequence according to packaging identification systems that reference sectioned floor plans and component number lists. The mechanical seaming process requires careful attention to equipment settings, consistent seaming pressure, and continuous quality monitoring to achieve uniform seam appearance and structural integrity throughout the installation. Upon completion, comprehensive testing protocols verify zero-leakage performance, proper drainage function, and adherence to specified wind resistance ratings before final acceptance procedures.

-

Post-Installation Support and Maintenance

Long-term performance of Mechanical Lock Metal Roofing systems depends significantly on proper maintenance procedures and periodic inspection protocols. We provide comprehensive maintenance guidance to building owners and facility managers, including recommended inspection schedules, cleaning procedures that protect coating integrity, and documentation of warranty coverage including our thirty-year system warranty on properly installed assemblies. Regular maintenance typically involves bi-annual inspections focused on fastener security, sealant condition at penetrations and terminations, drainage component functionality, and general system condition assessment. Our maintenance support services include personnel training programs that educate facility staff on proper inspection techniques, minor repair procedures, and documentation protocols that maintain warranty validity. When issues arise, our technical support team provides rapid response guidance, replacement component sourcing, and field service coordination to minimize disruption and protect building integrity. This comprehensive lifecycle support differentiates our Mechanical Lock Metal Roofing solutions from commodity products, ensuring clients receive maximum value from their roofing investment throughout the system's multi-decade service life.

Conclusion

Selecting between snap lock and Mechanical Lock Metal Roofing ultimately depends on project-specific requirements including roof slope, climate exposure, performance expectations, and budget parameters. While snap lock offers faster installation and lower initial costs for moderate-climate applications, Mechanical Lock Metal Roofing delivers superior weather protection, enhanced durability, and optimal performance for demanding environments and low-slope installations.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Mechanical Lock Metal Roofing manufacturer, recognized as a high-tech enterprise in Shaanxi Province with first-level building curtain wall qualifications and third-level steel structure certifications. As a premier China Mechanical Lock Metal Roofing supplier, our comprehensive capabilities encompass design, manufacturing, and installation services delivered through three advanced factories spanning two hundred thousand square meters in Anhui, with processing facilities in Hangzhou and Xi'an. Our China Mechanical Lock Metal Roofing factory produces High Quality Mechanical Lock Metal Roofing systems with PVDF/PE surface treatments, thicknesses from 0.5 to 1.0mm, and customized RAL colors, meeting ASTM, DIN, JIS, BS, and GB/T standards.

We provide China Mechanical Lock Metal Roofing wholesale solutions with competitive Mechanical Lock Metal Roofing price structures, minimum order quantities of five hundred square meters, and delivery within fifteen to twenty days. Our Mechanical Lock Metal Roofing for sale includes comprehensive one-stop services from structural three-dimensional modeling and drainage system simulation through precision manufacturing with real-time quality control and seamless on-site installation management. With more than twenty registered patents, ISO9001, ISO14000:14001, and SGS certifications, we deliver engineering excellence backed by successful project completion at major facilities including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum.

Contact our team today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our engineering expertise, manufacturing capabilities, and comprehensive support services can deliver superior roofing solutions for your next construction project. Save this resource for future reference as you evaluate roofing specifications and system selections.

References

1. Sheffield Metals International. "Standing Seam Metal Roofing: Comprehensive Guide to Panel Profiles and Installation Methods." Metal Roofing Learning Center Technical Publication.

2. Zand, Rick. "Comparative Analysis of Standing Seam Metal Roof Systems: Performance Evaluation of Snap Lock and Mechanical Seam Technologies." New Tech Machinery Engineering Documentation.

3. Western States Metal Roofing. "Engineering Specifications and Performance Standards for Standing Seam Metal Roofing Systems." Technical Product Literature and Installation Guidelines.

4. Metal Construction Association. "Design Manual for Standing Seam Metal Roof Systems: Technical Standards and Best Practices." Industry Technical Standards Publication.