When managing large-scale commercial construction projects, facility managers and architects face a critical challenge: selecting a roofing system that delivers durability, weather resistance, and long-term value while meeting tight deadlines and budget constraints. Traditional roofing solutions often fail to address these concerns, leading to frequent repairs, water infiltration issues, and premature roof replacement that disrupts business operations and drains capital reserves. This comprehensive guide explores how seam metal roof systems provide the solution to these pain points, offering proven performance for warehouses, convention centers, transportation facilities, and industrial complexes. Understanding the technical specifications, installation requirements, and material selections for standing seam metal roof systems empowers decision-makers to make informed choices that protect their investment for decades to come.

Understanding Seam Metal Roof Systems for Commercial Applications

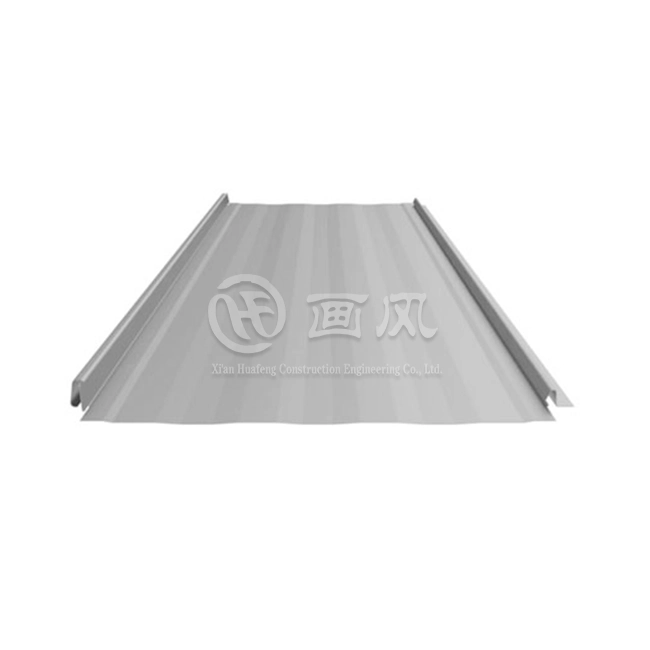

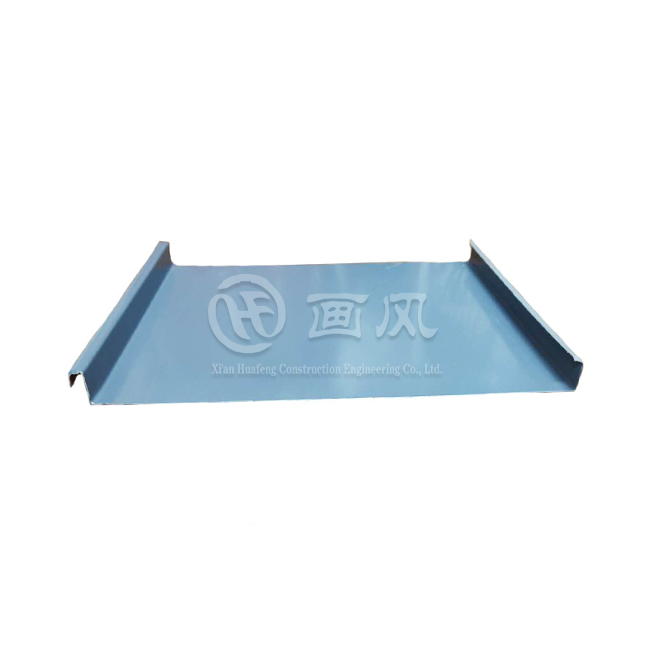

Seam metal roof systems represent a sophisticated engineering solution specifically designed for large-scale commercial projects where performance cannot be compromised. Unlike traditional roofing materials that rely on exposed fasteners susceptible to weathering and thermal expansion, standing seam metal roof panels utilize concealed clip systems that create continuous barriers against water infiltration while accommodating the natural expansion and contraction of metal materials. The defining characteristic of these systems lies in their raised vertical seams that interlock adjacent panels, typically ranging from 65mm to over 100mm in height depending on project specifications and drainage requirements. The construction of seam metal roof systems begins with precision-engineered panels manufactured from aluminum-magnesium-manganese alloys (AA3003, AA3004, or AA5052 grades) or high-grade galvanized steel, materials selected for their exceptional strength-to-weight ratios and corrosion resistance properties. For large-scale commercial projects, panel widths typically range from 300mm to 600mm with effective coverage areas calculated based on seam height and overlap requirements. The surface treatment significantly impacts longevity, with PVDF coatings at 25-30μm thickness containing 70% fluororesin providing superior UV resistance and color retention compared to standard polyester finishes.

-

System Components and Structural Integration

A comprehensive standing seam metal roof system comprises multiple integrated layers working in concert to deliver thermal performance, moisture management, and structural integrity. The exposed metal panels serve as the primary weather barrier, but the system's effectiveness depends equally on properly specified underlayment materials, insulation layers, and vapor control mechanisms. Waterproof breathable membranes constructed from high-density polyethylene non-woven fabrics create secondary protection lines that block wind-driven rain while permitting interior moisture to escape, preventing the mold growth and condensation issues that plague improperly designed roofing assemblies. Thermal insulation layers typically employ rock wool materials with densities and thicknesses engineered through heat transfer calculations specific to building location, usage patterns, and local climate data. For large commercial facilities with expansive roof areas, proper insulation selection directly impacts operational energy costs by reducing heating and cooling loads. Sound-absorbing cotton layers, usually glass wool with calculated bulk densities, provide acoustic dampening particularly valuable for facilities near airports, highways, or in urban settings where exterior noise pollution affects interior working conditions. The structural base plate, commonly perforated galvanized corrugated steel with thickness determined by purlin spacing, supports the overlying insulation assemblies while contributing to the overall acoustic performance through strategic perforation patterns.

-

Material Selection and Performance Standards

Selecting appropriate materials for seam metal roof systems on large-scale commercial projects requires understanding how different metal alloys and surface treatments perform under specific environmental conditions and structural loading scenarios. Aluminum-magnesium-manganese alloys offer superior corrosion resistance in coastal environments or industrial settings where atmospheric contaminants accelerate metal deterioration, while their lower density reduces dead loads on supporting structures. The 3003 and 3004 alloy designations indicate specific magnesium and manganese content optimized for formability and strength, with 3004 providing enhanced strength characteristics beneficial for longer panel spans or areas subject to higher wind loads. Surface coating systems protect base metals while providing aesthetic options matching architectural requirements. PE coatings serve economical applications with moderate durability expectations, while HDP formulations offer enhanced weather resistance for mid-tier performance requirements. PVDF coatings represent the premium choice for large-scale commercial projects demanding maximum longevity, typically warranted for 30 years or more against chalking, fading, and coating degradation. These fluoropolymer-based finishes maintain color integrity and gloss retention even under intense solar radiation and temperature cycling, making them essential for visible roofing applications where aesthetic deterioration reflects poorly on corporate image.

Design Considerations for Large-Scale Commercial Installations

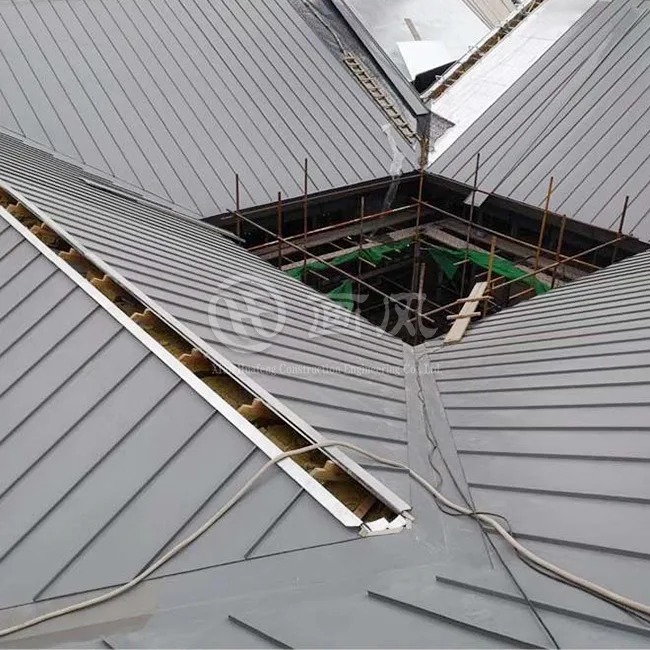

Implementing seam metal roof systems on large-scale commercial projects demands meticulous design planning addressing structural loads, thermal movement, drainage management, and interface conditions with adjacent building elements. The concealed fastener approach fundamental to standing seam metal roof design allows panels to expand and contract freely along their length in response to temperature variations, eliminating the panel buckling and fastener loosening common in exposed fastener systems. This thermal movement accommodation becomes particularly critical for large commercial roofs where panel lengths may extend 10-15 meters or more, potentially experiencing expansion and contraction exceeding several centimeters over seasonal temperature ranges. Structural engineering for large commercial roofs must account for multiple loading scenarios including dead loads from the roofing assembly and any mounted equipment, live loads from maintenance personnel and snow accumulation, and dynamic wind loads that create both uplift and lateral forces. Seam metal roof systems distribute these loads through the concealed clip assemblies into underlying structural purlins, with clip spacing and fastener specifications engineered to resist calculated wind uplift pressures. For projects in high-wind regions or hurricane-prone areas, mechanical seaming techniques that crimp adjacent panel seams together provide superior wind resistance compared to snap-lock systems, though installation requires specialized seaming equipment and trained technicians.

-

Drainage System Design and Water Management

Effective water management represents perhaps the single most critical design consideration for large-scale commercial roofing projects using standing seam metal systems. Unlike smaller residential applications where simple gravity drainage suffices, expansive commercial roofs must address substantial water volumes during intense rainfall events while maintaining positive drainage under all conditions including structural deflection. The raised seam configuration inherent to these systems actually enhances drainage performance by channeling water efficiently toward designed collection points, with seam height selection influencing drainage capacity—taller seams accommodate higher water volumes but increase material costs and structural loads. Minimum slope requirements for standing seam metal roof installations typically specify 1:4:12 pitch (approximately 2 degrees) though project-specific drainage calculations may justify shallower slopes when combined with larger panel widths and optimized drainage patterns. For large commercial facilities, internal roof drains positioned at low points collect runoff through scupper systems or internal drain piping, with sizing calculations accounting for rainfall intensity based on local meteorological data and roof drainage area. Panel layouts should direct water flow away from penetrations, expansion joints, and parapet conditions where water accumulation accelerates deterioration of flashing components and sealant materials.

-

Architectural Integration and Aesthetic Considerations

Modern commercial architecture increasingly embraces exposed structural systems and honest material expressions, making standing seam metal roof systems ideal for projects seeking contemporary aesthetic character. The clean horizontal lines created by raised seams produce strong visual rhythms that complement modernist and industrial design vocabularies, while the availability of numerous color options through factory-applied coatings enables design coordination with corporate branding or contextual color schemes. For projects requiring distinctive architectural statements, manufacturers can fabricate curved panels following complex geometries—positive arcs, negative arcs, and compound curves—that traditional roofing materials cannot accommodate. Large-scale commercial projects often feature roofs visible from elevated surrounding buildings or aerial perspectives, making the roofing system itself an architectural element rather than purely functional component. Standing seam metal roof profiles provide visual interest through shadow patterns created by raised seams while maintaining the unified, monolithic character appropriate for commercial facilities. Panel orientation and seam direction should respond to building geometry and sight lines, with longitudinal seams typically running along the primary slope direction to emphasize building proportions and optimize water shedding performance.

Manufacturing Excellence and Quality Assurance

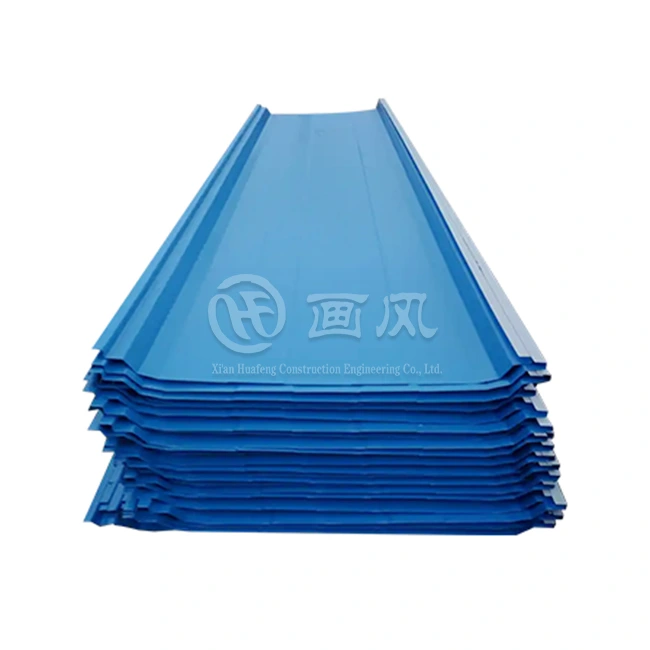

The performance and longevity of seam metal roof systems installed on large-scale commercial projects depend fundamentally on manufacturing quality and process control throughout material production and panel fabrication. Xi'an Huafeng Construction Engineering Co., Ltd. operates comprehensive manufacturing facilities including a 200,000 square meter raw material production plant in Anhui alongside two dedicated plate and accessories processing plants strategically located in Hangzhou and Xi'an. This integrated production capacity enables complete quality control from coil coating through final panel fabrication, eliminating the quality inconsistencies and coordination delays common when sourcing components from multiple suppliers. Modern panel fabrication employs automated roll-forming equipment that progressively shapes flat metal coils into profiled panels with precise dimensional tolerances essential for proper field assembly. The seven color coating production lines operated by Huafeng ensure consistent coating thickness and adhesion meeting international standards, while the single laminating line provides specialized finishing options for projects requiring unique surface characteristics. Ten longitudinal and transverse shearing lines dimension panels and accessories to project-specific measurements, supported by fully automatic punching production lines that create fastener holes and other features with repeatability impossible to achieve through manual fabrication methods.

-

Material Procurement and Testing Protocols

Quality assurance for standing seam metal roof systems begins with rigorous material procurement standards ensuring base metals and coating systems meet performance specifications before entering production workflows. Huafeng maintains an approved supplier registry including premium brands such as Alucosuper, YATAI, and LIDAO for aluminum products; BAOSTEEL, GUANZHOU, and XINYU for steel materials; and specialized suppliers like Baosteel and Tsingshan for stainless steel grades 316 and 304. Each material delivery undergoes comprehensive incoming inspection procedures verifying that supplier-provided mill certifications and third-party testing reports accurately represent delivered material properties. Incoming material inspection encompasses both full inspection protocols for small quantities or high-value materials and statistically valid random sampling for bulk commodities, preventing defective materials from contaminating production inventories. Testing procedures examine over a dozen quality parameters including surface appearance inspection identifying coating defects or handling damage; dimensional verification confirming thickness, width, and coil weight specifications; and performance testing covering salt spray corrosion resistance, coating adhesion through crosshatch and tape tests, surface hardness, impact resistance, film thickness measurements, acid resistance for chemical exposure scenarios, accelerated weathering simulating years of outdoor exposure, and color matching against approved standards. Materials failing any inspection criteria receive rejection preventing their use in customer projects, maintaining the quality standards upon which Huafeng's reputation depends.

-

Production Processing and Finished Product Verification

Panel fabrication transforms quality-verified coil materials into finished standing seam metal roof components through precisely controlled forming operations that maintain material properties while achieving required profiles and dimensions. Roll-forming equipment progressively bends metal through multiple forming stations, with tooling designed specifically for each panel profile ensuring consistent seam heights, panel widths, and geometric accuracy across thousands of linear meters of production. For large commercial projects requiring hundreds or thousands of individual panels, sequential numbering systems track each component from fabrication through packaging and field installation, eliminating the confusion and assembly errors that delay project completion and compromise installation quality. Finished product inspection represents the final quality verification before panels leave manufacturing facilities for project sites. Inspection technicians examine each panel for surface defects, dimensional accuracy, flatness within specified tolerances, and proper curvature for panels requiring bent profiles. The packaging process itself serves quality purposes beyond mere protection, with products organized according to roof section plans facilitating efficient site handling and installation sequencing. External packaging includes identification cards containing section drawings and component lists enabling installation crews to quickly locate required materials without unpacking multiple containers, reducing site congestion and weather exposure of stored materials.

Installation Excellence for Commercial Projects

Successful implementation of seam metal roof systems on large-scale commercial projects requires experienced installation teams combining technical knowledge, specialized equipment, and rigorous quality control procedures. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation services encompassing pre-construction planning, site logistics coordination, technical installation oversight, and post-installation verification ensuring delivered systems meet performance specifications and aesthetic expectations. The one-stop service model eliminates the coordination challenges and responsibility gaps common when design, fabrication, and installation involve separate entities with competing interests and limited accountability. Installation planning begins well before materials arrive at project sites, with pre-construction site visits documenting existing conditions, verifying substrate preparation compliance, and confirming material storage areas and equipment staging locations. For large commercial projects, phased installation scheduling coordinates roofing work with other construction activities, minimizing weather exposure of partially completed areas while maintaining overall project momentum. Installation technicians must possess specialized skills including proper clip installation techniques maintaining required spacing and engagement; seaming machine operation for mechanically seamed systems creating watertight seam connections; and flashing fabrication and installation addressing penetrations, transitions, and termination conditions.

-

Technical Installation Standards and Safety Protocols

The concealed fastener design fundamental to standing seam metal roof systems demands precise installation technique ensuring clips properly engage panel seams while allowing required thermal movement. Installation crews must understand how sliding clip systems accommodate panel expansion and contraction, positioning fixed and floating clips according to engineered layouts preventing panel distortion from restrained movement. Seaming operations for mechanically seamed systems require specialized equipment operated by trained technicians, with seaming machines precisely crimping adjacent panel seams through multiple passes creating weathertight connections resistant to wind-driven rain and panel separation under uplift loads. Safety considerations for large commercial roofing projects encompass fall protection systems, material handling procedures, and environmental hazard management protecting installation personnel and adjacent building occupants. Standing seam metal roof installation on steep slopes or at significant heights requires properly engineered fall arrest systems including anchor points, lifelines, and personal protective equipment inspected and maintained according to safety standards. Material handling protocols address the size and weight of long panels, typically requiring multiple workers and mechanical lifting equipment for safe placement without panel damage or worker injury. Weather monitoring ensures installation suspends during high winds, lightning conditions, or precipitation that compromises worker safety and installation quality.

-

Quality Verification and Performance Testing

Upon completing seam metal roof system installation on large commercial projects, comprehensive quality verification procedures confirm system performance before final acceptance and warranty activation. Visual inspections examine seam engagement, fastener installation, flashing integration, and surface conditions identifying any installation defects requiring correction. Water testing conducted through controlled application simulating rainfall or hose testing of critical areas like penetrations, valleys, and transitions verifies weathertight performance under realistic conditions, with zero leakage representing the only acceptable standard for commercial applications where interior water damage destroys valuable equipment and inventory while disrupting business operations. Documentation completion assembles as-built drawings recording actual installation details including panel layouts, clip locations, flashing configurations, and any field modifications addressing unexpected site conditions. Warranty registration formally activates manufacturer coverage protecting building owners against material defects and system failures, with warranty terms typically ranging 30 years or more for premium systems using quality materials and proper installation techniques. Maintenance guidance educates building operators on proper roof care including periodic inspections identifying minor issues before they escalate, vegetation removal preventing debris accumulation in valleys and gutters, and restrictions on roof traffic protecting coating integrity and preventing panel damage.

Proven Performance in Major Commercial Projects

The technical capabilities and practical benefits of seam metal roof systems find validation through successful implementation on numerous large-scale commercial projects across diverse building types and environmental conditions. Xi'an Huafeng Construction Engineering Co., Ltd. has delivered comprehensive roofing solutions for landmark facilities including the Xiongan Station Commercial Body with its extensive aluminum-magnesium-manganese metal roof protecting high-traffic transportation infrastructure, and the Xi'an International Convention and Exhibition Center where architectural aesthetics combine with functional performance for a world-class facility hosting international events and exhibitions. Transportation facilities present particularly demanding requirements for standing seam metal roof applications, combining massive roof areas, complex geometries accommodating functional spaces and mechanical systems, and elevated performance expectations befitting critical infrastructure. The Metal Roof Project at Xi'an Station East Auxiliary Building demonstrates how properly engineered and installed seam metal roof systems deliver reliable weather protection while contributing to the architectural character of contemporary transportation architecture. These projects validate material selection criteria, design methodologies, and installation techniques while providing performance data informing future project specifications and quality standards. Cultural and institutional facilities including the South Hall 2-2 of Jinghe New City International Culture and Art Center and the Inner Mongolia Tongliao Art Museum Metal Roof Wall showcase how standing seam metal roof systems adapt to diverse architectural expressions while maintaining uncompromising functional performance. Educational facilities like the Weihua Cadre College Teaching Building and Office Building demonstrate aluminum-magnesium-manganese metal roof applications in environments demanding durability, low maintenance, and long service life supporting institutional missions. Infrastructure projects including the Hangzhou Sanpu Drainage Pump Station and the Liyuanping Highway Station Metal Roof Project prove system viability under challenging environmental exposures and operational conditions.

Conclusion

Standing seam metal roof systems deliver unmatched performance for large-scale commercial projects through superior weather resistance, thermal efficiency, and longevity exceeding traditional roofing materials while providing contemporary aesthetics appropriate for modern commercial architecture.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Partner with Xi'an Huafeng Construction Engineering Co., Ltd., a China Seam Metal Roof Systems factory and leading China Seam Metal Roof Systems supplier established in 2018 in Shaanxi Province. As a recognized high-tech enterprise and China Seam Metal Roof Systems manufacturer, we provide China Seam Metal Roof Systems wholesale solutions with High Quality Seam Metal Roof Systems for sale at competitive Seam Metal Roof Systems price points. Our comprehensive facilities include 200,000 square meters of raw material production capacity in Anhui plus processing plants in Hangzhou and Xi'an, operating seven color coating production lines, one laminating line, and over 40 specialized equipment pieces ensuring precision manufacturing. With over 20 registered patents, ISO9001, ISO14000:14001, and SGS certifications, we deliver customized one-stop services from engineering design through construction. Our proven track record includes landmark projects such as Xiongan Station and Xi'an International Convention Center, demonstrating our expertise in Seam Metal Roof Systems installations. Benefit from our 30-year warranty, 15-20 day delivery, 1000-ton monthly capacity, and 500㎡ minimum order supporting projects worldwide. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our engineering experience, Fortune 500 partnerships, and customized production capabilities deliver superior value for your commercial roofing investment.

References

1. Metal Construction Association. "Guide Specification for Standing Seam Metal Roof Systems." Technical Standards for Commercial Roofing Applications.

2. National Roofing Contractors Association. "The NRCA Metal Panel and SPF Roof Systems Manual." Commercial Roofing Installation Standards and Best Practices.

3. American Society for Testing and Materials. "ASTM E1592: Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference." Testing Standards for Metal Roof Systems.

4. Sheet Metal and Air Conditioning Contractors' National Association. "Architectural Sheet Metal Manual." Design and Installation Guidelines for Commercial Metal Roofing Projects.