Is your commercial building facade deteriorating faster than expected, costing you thousands in maintenance while failing to impress clients? Vertical Metal Siding Sheets offer a transformative solution that combines architectural elegance with exceptional durability. This comprehensive guide explores everything business owners and facility managers need to know about vertical metal siding panels, from material selection and installation processes to long-term performance benefits. Whether you're constructing a new facility or renovating existing structures, understanding these advanced cladding systems will help you make informed decisions that protect your investment for decades to come.

Understanding Vertical Metal Siding Sheets and Their Business Applications

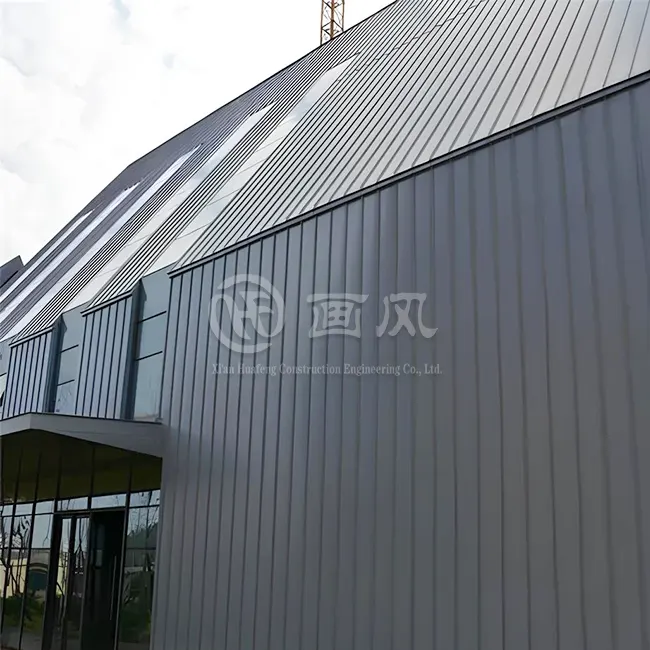

Vertical Metal Siding Sheets represent a sophisticated exterior cladding solution engineered specifically for commercial, industrial, and institutional buildings. Unlike traditional horizontal siding, vertical orientation provides superior water drainage, reduced dirt accumulation, and a contemporary aesthetic that enhances brand perception. These panels are manufactured from high-grade materials including galvanized steel, galvalume, aluminum alloys, and stainless steel, each offering distinct advantages depending on your environmental conditions and performance requirements. The fundamental appeal of Vertical Metal Siding Sheets lies in their versatility across diverse business sectors. Manufacturing facilities benefit from the panels' resistance to industrial chemicals and temperature fluctuations, while retail establishments appreciate the clean, modern appearance that attracts customers. Office complexes utilize these systems to achieve energy efficiency through reflective coatings, and warehouses value the rapid installation process that minimizes operational disruption. The panels are available in specifications ranging from 25-330mm to 65-500mm width configurations, accommodating virtually any architectural design requirement.

Vertical Metal Siding Sheets

-

Material Selection for Maximum Performance

Choosing the appropriate substrate material for your Vertical Metal Siding Sheets directly impacts longevity, maintenance costs, and aesthetic outcomes. Galvanized steel provides exceptional strength and cost-effectiveness, featuring a zinc coating that prevents corrosion through sacrificial protection. This material works particularly well for inland locations with moderate environmental exposure. Galvalume, an aluminum-zinc alloy coating, delivers enhanced rust resistance and heat reflectivity, making it ideal for facilities in humid climates or those requiring superior thermal performance. Aluminum Vertical Metal Siding Sheets offer the lightest weight option, reducing structural load requirements and simplifying installation on existing buildings. The material's natural corrosion resistance makes it the preferred choice for coastal environments where salt spray accelerates deterioration of ferrous metals. Stainless steel represents the premium tier, providing unmatched durability in aggressive industrial atmospheres with chemical exposure or extreme weather conditions. Each material accepts various surface treatments including PE polyester, HDP high-durability polyester, and PVDF polyvinylidene fluoride coatings, which dramatically extend service life while offering extensive color customization options.

-

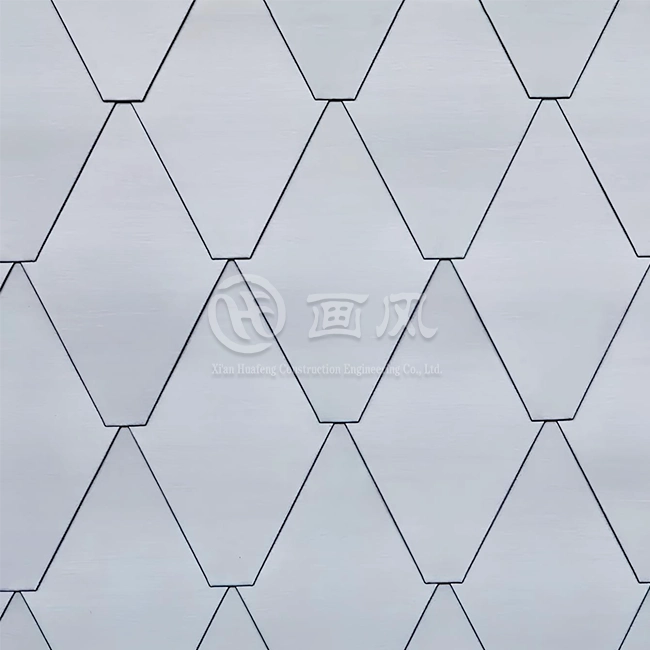

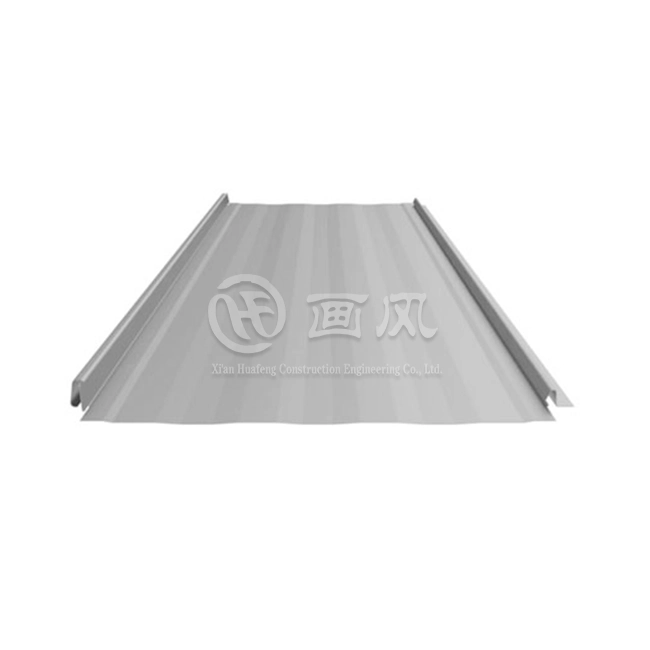

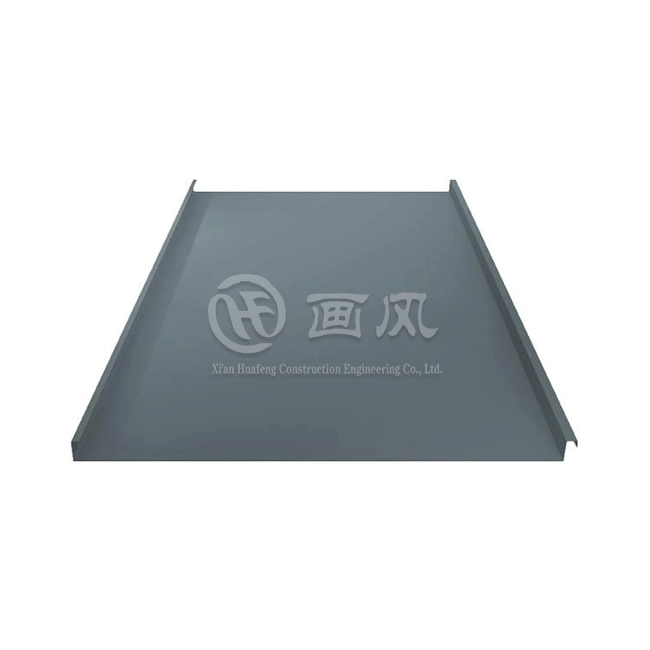

Profile Configurations and Architectural Impact

The visual character of your building envelope depends significantly on the profile geometry selected for your Vertical Metal Siding Sheets installation. Flat lock panels create smooth, uninterrupted surfaces with concealed fastening systems that deliver a minimalist, contemporary appearance perfect for corporate headquarters and design-forward commercial spaces. The interlocking edges provide weather-tight performance while maintaining clean sight lines that emphasize building proportions and architectural details. Ribbed panel profiles introduce vertical emphasis through regular grooves or raised ribs that add dimensional texture and shadow lines to building facades. These configurations offer enhanced structural rigidity, allowing for wider panel spans between support framing, which can reduce overall installation costs. The vertical ribbing also naturally channels water downward, improving drainage efficiency and reducing moisture-related maintenance issues. Corrugated Vertical Metal Siding Sheets feature distinctive wave patterns traditionally associated with agricultural and industrial buildings, though modern finishing techniques have elevated their aesthetic appeal for contemporary commercial applications seeking an industrial-chic aesthetic. Batten-seam profiles utilize raised vertical seams at panel joints, creating bold architectural statements that emphasize building height and verticality. This traditional design element has been reimagined for modern applications, offering both classical elegance and cutting-edge performance. The raised seams accommodate building movement and thermal expansion while maintaining weatherproof integrity, making them particularly suitable for large-scale facilities experiencing significant temperature variations.

Installation Excellence and Long-Term Performance

Professional installation of Vertical Metal Siding Sheets requires meticulous attention to substrate preparation, fastening methodology, and flashing integration. The process begins with comprehensive evaluation of existing wall assemblies or new construction framing to ensure adequate structural support and proper moisture management. High-quality installations incorporate continuous insulation layers, weather-resistant barriers, and ventilation cavities that work synergistically with the metal cladding to optimize energy efficiency and prevent condensation damage.

-

Technical Installation Considerations

Proper fastening techniques distinguish successful Vertical Metal Siding Sheets installations from problematic ones. Concealed fastening systems utilize clips that attach to structural supports while allowing controlled panel movement, preventing stress concentrations that cause premature failures. These systems maintain clean exterior appearances while accommodating thermal expansion and contraction cycles that occur throughout the building's service life. Exposed fastener applications require careful attention to fastener placement, penetration depth, and weatherproofing details to prevent water infiltration and material fatigue. Flashing integration represents a critical installation component often overlooked in budget-focused projects. Custom-fabricated flashings at windows, doors, roof intersections, and grade transitions ensure water management system continuity, directing moisture away from vulnerable building envelope components. Quality installations feature redundant drainage pathways and capillary breaks that function reliably even when primary systems become compromised through debris accumulation or minor damage. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive technical guidance throughout the installation process, including on-site support to verify proper execution of critical details. The company's proven installation methodology includes thorough pre-installation site surveys, detailed layout drawings with sequenced panel numbering systems, and quality assurance protocols that verify dimensional accuracy before panels leave the factory. Their technical teams conduct briefing sessions with installation crews, reviewing project-specific requirements and safety procedures to ensure consistent execution standards. Upon completion, zero-leakage testing confirms system integrity before final acceptance, protecting your investment through documented performance verification.

-

Durability and Maintenance Benefits

Vertical Metal Siding Sheets deliver exceptional longevity when properly specified and installed, with service lives regularly exceeding thirty years under normal environmental conditions. The inherent durability stems from multiple protective layers working together: substrate material corrosion resistance, advanced coating technologies that resist UV degradation and chemical exposure, and proper installation practices that prevent moisture intrusion and mechanical damage. This multi-tiered protection strategy minimizes lifecycle costs by virtually eliminating the need for periodic painting, repairs, or premature replacement common with alternative cladding materials. Maintenance requirements prove remarkably minimal compared to traditional building envelope systems. Routine care involves periodic washing with mild detergent solutions to remove accumulated dirt and atmospheric pollutants that can diminish aesthetic appearance over time. The smooth, non-porous surfaces of Vertical Metal Siding Sheets resist organic growth and don't provide suitable substrate for insect infestation, eliminating common maintenance headaches associated with wood and fiber-cement products. Annual inspections focusing on fastener integrity, flashing conditions, and sealant joints identify minor issues before they escalate into costly problems. The recyclability of metal siding materials aligns with contemporary sustainability initiatives increasingly important to corporate stakeholders and regulatory authorities. At end-of-service life, Vertical Metal Siding Sheets retain significant scrap value and can be completely recycled without quality degradation, contributing to circular economy principles while reducing landfill burdens. This environmental advantage, combined with energy efficiency benefits during the use phase, positions metal siding as a responsible choice for organizations committed to reducing their environmental footprint.

Customization Options and Design Flexibility

Modern Vertical Metal Siding Sheets transcend purely functional applications to become integral architectural elements expressing corporate identity and design vision. Extensive customization capabilities allow businesses to specify precise color matches to brand standards, create distinctive patterns through strategic panel arrangement, and incorporate mixed-material compositions that add visual interest to large building facades. Advanced coating technologies deliver colors ranging from subtle earth tones to vibrant contemporary hues, all formulated to maintain color stability throughout decades of exposure to intense sunlight and weather extremes. Finish selection significantly impacts both aesthetic character and functional performance of your Vertical Metal Siding Sheets installation. PVDF coatings represent the premium option, offering superior color retention, chalk resistance, and chemical durability that justifies their higher initial cost through extended maintenance intervals and sustained appearance quality. These fluoropolymer-based finishes excel in harsh environments including coastal zones, industrial areas with airborne contaminants, and regions experiencing intense UV radiation. The finish maintains gloss levels and resists fading far longer than conventional paint systems, preserving your building's professional appearance with minimal intervention.

Standard polyester coatings provide cost-effective solutions for projects with budget constraints or moderate environmental exposure, delivering reliable performance and acceptable color stability for typical commercial applications. Metallic and matte finish options expand design possibilities, creating sophisticated visual effects that differentiate your facility within competitive markets. Some installations incorporate bare metal finishes that develop natural patina over time, offering unique aesthetic evolution particularly valued in contemporary architectural design. Xi'an Huafeng Construction Engineering Co., Ltd. maintains extensive finish libraries and can produce custom colors matched to specific requirements, ensuring your building envelope perfectly reflects your brand identity. Pattern customization extends beyond color selection to encompass panel arrangement strategies that create visual rhythm and architectural interest across expansive wall surfaces. Alternating panel widths, incorporating accent colors at strategic locations, and varying profile depths generates dimensional complexity that prevents monotonous appearance while maintaining system integrity. These design techniques prove particularly effective on large industrial or warehouse facilities where uninterrupted wall surfaces might otherwise appear visually overwhelming. Technical consultation services help optimize these design elements while ensuring practical installation feasibility and maintaining budget parameters.

Quality Assurance and Manufacturing Excellence

The performance reliability of Vertical Metal Siding Sheets depends fundamentally on manufacturing quality control throughout the production process. Superior products begin with carefully selected raw materials sourced from established suppliers providing comprehensive material certifications and third-party testing documentation. Xi'an Huafeng Construction Engineering Co., Ltd. maintains rigorous supplier qualification programs, conducting independent verification testing on incoming materials including aluminum alloys from Alucosuper, YATAI, and LIDAO, steel products from BAOSTEEL, GUANZHOU, and XINYU, and specialty materials from Baosteel and Tsingshan for stainless applications. Manufacturing precision ensures dimensional consistency critical for efficient installation and proper system performance. Modern roll-forming equipment produces panels with tolerances measured in fractions of millimeters, guaranteeing consistent fit-up and minimizing field modifications that compromise installation efficiency. The company operates seven color coating production lines alongside specialized laminating capabilities, producing finished panels that meet exacting specifications for coating thickness, adhesion strength, and surface quality. Comprehensive quality control protocols verify each production batch through systematic testing encompassing appearance inspection, dimensional verification, salt spray resistance, adhesion testing, hardness measurement, impact resistance, film thickness confirmation, acid resistance evaluation, weather resistance assessment, and color consistency verification.

Finished product inspection occurs prior to packaging, with trained quality assurance personnel examining every panel for surface defects, dimensional accuracy, flatness conformity, and proper curvature where designed profiles require curved geometries. This meticulous attention prevents defective products from reaching project sites, eliminating costly delays and ensuring installation crews receive materials that meet specification requirements. The packaging system facilitates efficient site logistics through sequential numbering coordinated with installation drawings, allowing installers to quickly locate required panels and maintain proper installation sequence without confusion or errors. With production capacity exceeding one thousand tons monthly and minimum order quantities as low as five hundred square meters, the company accommodates projects ranging from small renovations to major commercial developments. Standard delivery timeframes of fifteen to twenty days ensure project schedules remain on track, while the 30-year warranty demonstrates manufacturer confidence in product longevity. Certification compliance including ISO9001 quality management systems, ISO14000:14001 environmental standards, and SGS verification provides independent confirmation of manufacturing excellence and corporate commitment to quality principles.

Conclusion

Vertical Metal Siding Sheets deliver unmatched combination of durability, aesthetic versatility, and lifecycle value for business facilities across all sectors. Strategic material selection, proper installation execution, and minimal maintenance requirements position these systems as intelligent investments that protect building envelopes while enhancing corporate image through contemporary architectural expression that endures for decades.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a Shaanxi Province high-tech enterprise since 2020, specializes in comprehensive metal roofing and wall system solutions with first-level building curtain wall qualifications and third-level steel structure credentials. Operating from a 200,000-square-meter Anhui production facility plus dedicated processing plants in Hangzhou and Xi'an, the company leverages advanced equipment including seven color coating lines and over forty precision machines to deliver customized Vertical Metal Siding Sheets backed by more than twenty patents and ISO9001, ISO14000:14001, SGS certifications.

As a leading China Vertical Metal Siding Sheets factory, China Vertical Metal Siding Sheets supplier, and China Vertical Metal Siding Sheets manufacturer offering China Vertical Metal Siding Sheets wholesale, we provide Vertical Metal Siding Sheets for sale at competitive Vertical Metal Siding Sheets price points without compromising High Quality Vertical Metal Siding Sheets standards. Our Fortune 500 partnerships demonstrate capability in delivering one-stop solutions from design optimization through raw material procurement, customized production, rigorous quality testing, secure packaging, and flexible transportation. Contact huafeng@hfmetalroof.com today to discuss your project requirements and discover how our engineering expertise transforms your building envelope vision into lasting architectural excellence.

References

1. Metal Construction Association. "Guide Specifications for Architectural Sheet Metal Wall Panels." Technical Standards Committee, 2023.

2. Smith, Robert J. and Chen, Michael. "Performance Evaluation of Vertical Metal Cladding Systems in Commercial Applications." Journal of Building Envelope Design, Vol. 45, 2024.

3. American Institute of Architects. "Metal Wall Panel Systems: Design and Installation Best Practices." Architectural Specifications Institute, 2023.

4. Thompson, Sarah K. "Sustainable Building Envelopes: Long-term Performance of Metal Facade Systems." Green Building Research Quarterly, Vol. 18, No. 3, 2024.