Are you struggling to choose between roofing systems that promise durability but come with hidden installation challenges and unpredictable long-term costs? The Snap Lock Standing Seam Roof offers a compelling solution that balances performance, installation efficiency, and weather protection. This comprehensive guide examines the advantages and limitations of snap lock systems to help you make an informed decision for your commercial, industrial, or residential project.

Understanding Snap Lock Standing Seam Roof Technology

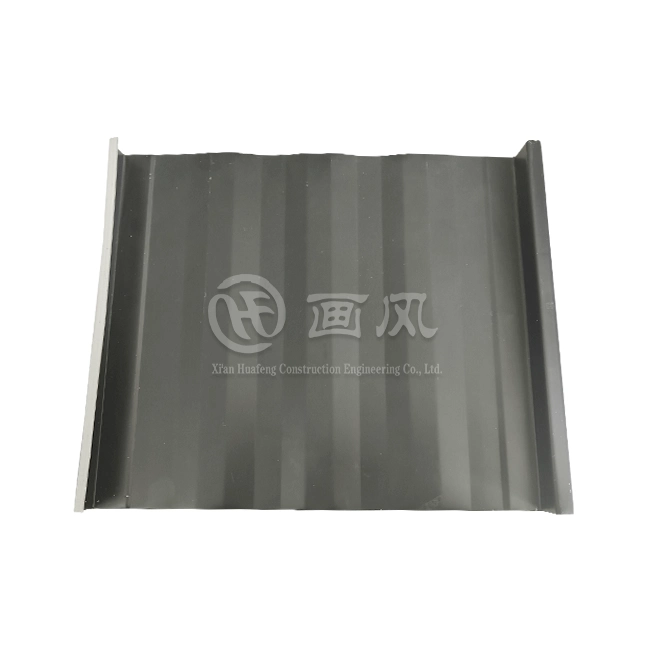

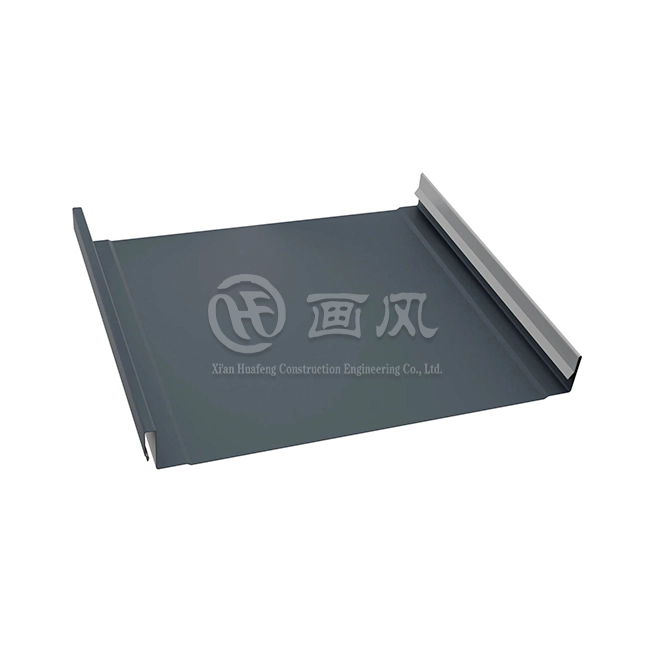

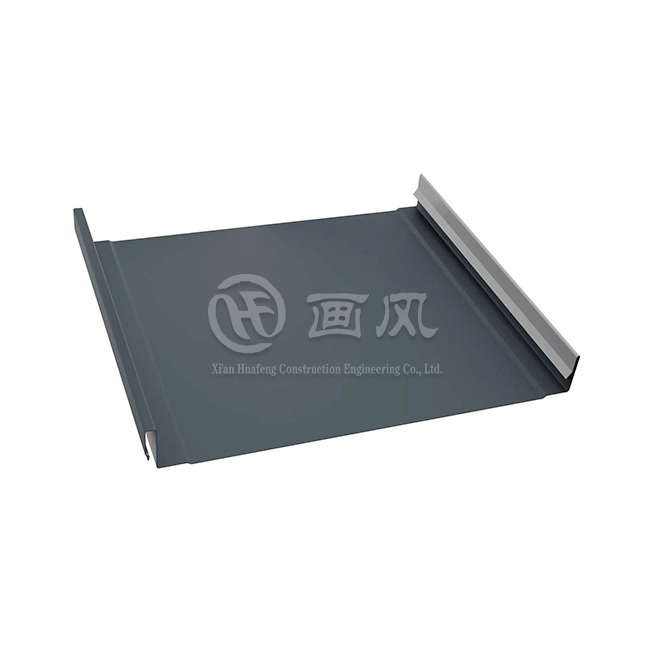

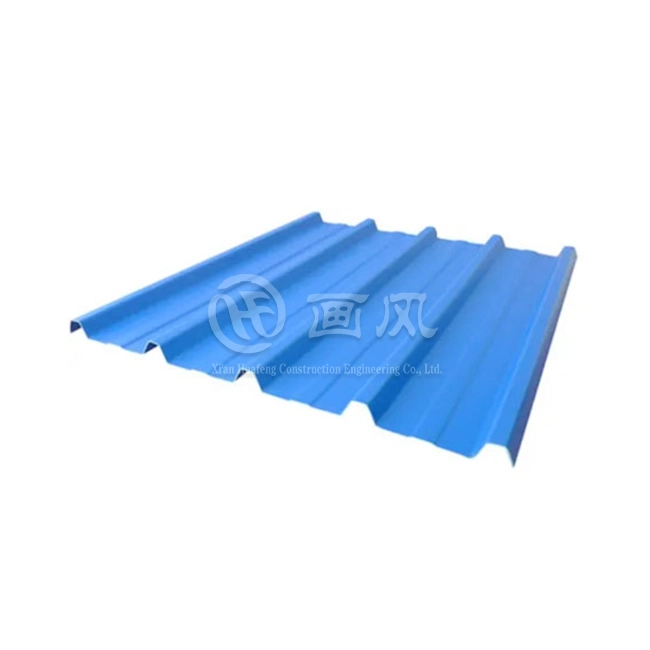

The Snap Lock Standing Seam Roof represents an innovative approach to metal roofing that has transformed the construction industry over the past decade. This system features male and female panel legs that interlock through a simple snapping mechanism, eliminating the need for specialized seaming equipment during installation. Xi'an Huafeng Construction Engineering Co., Ltd. has refined this technology through extensive engineering research, resulting in a 45mm standard height design that provides exceptional water drainage and structural integrity. The fundamental architecture of snap lock systems relies on concealed fastening clips that secure panels to the roof deck without penetrating the visible surface. This design philosophy addresses one of the most persistent challenges in traditional roofing: fastener exposure leading to premature deterioration and leak pathways. The panels typically range from 300mm to 600mm in effective width, with customizable lengths extending up to 13 meters for single-board installations. This extended length capability significantly reduces lateral overlaps, minimizing potential weak points where moisture infiltration could occur.

-

Material Composition and Performance Standards

Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Snap Lock Standing Seam Roof panels using premium substrate materials including galvalume steel, aluminum alloy, stainless steel, copper, and titanium zinc. The galvalume steel substrate incorporates a specialized alloy composition of 55% aluminum, 43.4% zinc, and 1.6% silicon, delivering corrosion resistance that surpasses ordinary galvanized steel by approximately two to six times. This material selection ensures service life expectations of 30 to 50 years in most climate conditions, with aluminum alloy options extending performance beyond 50 years in coastal and high-humidity environments. The substrate thickness ranges from 0.5mm to 1.2mm, carefully calibrated to balance structural strength with weight considerations. Thinner profiles suit applications where reduced structural loading is paramount, while thicker specifications accommodate projects requiring enhanced wind uplift resistance or snow load capacity. Surface coatings play an equally critical role in long-term performance. PVDF (polyvinylidene fluoride) coatings provide superior weather resistance with color retention exceeding 20 years and exceptional UV protection, making them ideal for buildings in harsh climates or those requiring sustained aesthetic appeal. PE (polyethylene) coatings offer an economical alternative for projects in less demanding environments where budget constraints take precedence over maximum longevity.

Key Advantages of Snap Lock Standing Seam Roofing

-

Simplified Installation Process and Cost Efficiency

One of the most compelling advantages of Snap Lock Standing Seam Roof systems is their remarkably efficient installation process. Traditional mechanically seamed panels require specialized equipment costing up to $400 per week per seamer, along with skilled operators who must hand-seam every clip before applying the mechanical seaming tool. In contrast, snap lock panels connect through direct engagement of their male and female legs, achievable with basic hand tools and minimal training. Xi'an Huafeng Construction Engineering Co., Ltd. has documented installation efficiency improvements of 30% to 50% compared to mechanical seaming alternatives. This installation simplicity translates directly to reduced labor costs, making Snap Lock Standing Seam Roof systems more accessible for projects with constrained budgets. The typical cost range of $8 to $14 per square foot including materials and installation represents a more affordable entry point within the standing seam category, though still approximately double the cost of conventional asphalt shingle or corrugated metal alternatives. However, when lifecycle costs are considered—including maintenance frequency, replacement intervals, and energy performance—the initial premium investment often yields substantial long-term savings.

-

Superior Weather Protection and Leak Prevention

The concealed fastener design inherent to Snap Lock Standing Seam Roof systems eliminates exposed screw penetrations that plague through-fastened roofing alternatives. Every fastener location represents a potential failure point where gasket deterioration, thermal cycling, or improper installation could permit water infiltration. By positioning all fastening clips beneath the raised seams, snap lock systems dramatically reduce these vulnerability points. The interlocking panel design creates continuous vertical channels that efficiently direct water downslope, preventing ponding and accelerating drainage even during heavy precipitation events. Huafeng's snap lock panels can withstand wind speeds exceeding 60 meters per second (216 kilometers per hour) when fixing clips are spaced at intervals of 1.5 meters or less, achieving wind resistance ratings of 3.0 kN/m² or greater. This performance meets or exceeds EN 15601 standards for commercial roofing applications. The system's flexible connection mechanism allows for thermal expansion and contraction displacement of ±15mm, accommodating structural movement without compromising seam integrity. This flexibility is particularly valuable in seismic regions or buildings subject to significant temperature fluctuations.

-

Aesthetic Versatility and Modern Appeal

While performance considerations often dominate roofing discussions, architectural aesthetics significantly influence project success, particularly in commercial and high-end residential applications. Snap Lock Standing Seam Roof systems deliver clean, uninterrupted lines with no visible fasteners, creating a contemporary profile that complements modern design philosophies. The vertical seam pattern naturally elongates building proportions, enhancing visual appeal while maintaining functional excellence. Xi'an Huafeng Construction Engineering Co., Ltd. offers extensive customization options including RAL color matching and specialized finishes to harmonize with any architectural vision. The panel width variations from 300mm to 600mm allow designers to adjust visual rhythm and scale proportionally to building dimensions. Surface treatments ranging from matte to high-gloss finishes provide additional aesthetic control. Natural metal options like copper and titanium zinc develop distinctive patinas over time, offering living finishes that evolve aesthetically while maintaining protective properties through natural oxidation processes.

Important Limitations and Considerations

-

Roof Slope Requirements and Application Restrictions

Despite their numerous advantages, Snap Lock Standing Seam Roof systems have specific application limitations that must be carefully evaluated during project planning. The primary restriction involves minimum roof slope requirements. Snap lock panels are not recommended for roofs with pitches less than 3:12 (approximately 14 degrees), as the snapped seam connection lacks the mechanical folding that provides enhanced water-tightness in low-slope conditions. On roofs with minimal pitch, water moves more slowly and can accumulate at seams, increasing the likelihood of capillary action drawing moisture beneath the panels. For projects with slopes between 1:12 and 3:12, mechanically seamed alternatives with double-lock configurations provide superior performance through tighter seam compression that eliminates potential water migration pathways. This distinction is particularly critical in commercial warehouse applications, industrial facilities, and certain architectural designs where low-slope roofing is unavoidable. Xi'an Huafeng Construction Engineering Co., Ltd. works closely with clients during the design phase to evaluate slope conditions and recommend the most appropriate standing seam solution for each specific application.

-

Weather-Tightness Comparison with Mechanical Seaming

While Snap Lock Standing Seam Roof systems offer substantial improvements over exposed fastener roofing, they do not achieve the ultimate weather-tightness level provided by mechanically seamed panels, particularly double-lock configurations. The snapped connection, though secure under normal conditions, relies on the spring tension of the panel legs maintaining continuous engagement. In extreme weather scenarios involving sustained high winds combined with driving rain, mechanically seamed panels with their folded and compressed metal-to-metal contact provide an additional security margin. This performance differential becomes particularly relevant in geographic regions subject to hurricanes, typhoons, or severe winter storms with ice dam formation potential. For projects in such locations, or for critical facilities where absolute weather-tightness is paramount—such as data centers, pharmaceutical manufacturing plants, or archival storage facilities—the additional investment in mechanical seaming may be justified. However, for the vast majority of commercial and residential applications in moderate climates, properly installed Snap Lock Standing Seam Roof systems deliver more than adequate weather protection throughout their service life.

-

Initial Investment Considerations

The higher upfront cost of Snap Lock Standing Seam Roof systems compared to conventional roofing materials represents a barrier for budget-constrained projects. While more affordable than mechanically seamed alternatives, snap lock systems still command a premium of approximately 100% over asphalt shingle installations. This cost differential stems from several factors: premium substrate materials with superior corrosion resistance, specialized roll-forming equipment required for panel fabrication, and skilled labor needed for proper installation despite the simplified process. Project decision-makers must evaluate this initial investment within the context of total lifecycle economics. Asphalt shingle roofs typically require replacement every 15 to 20 years, while Snap Lock Standing Seam Roof systems from Xi'an Huafeng Construction Engineering Co., Ltd. carry 30-year warranties with service life expectations extending to 50 years or beyond with appropriate maintenance. The elimination of periodic replacement costs, reduced maintenance requirements, enhanced energy efficiency through reflective coatings, and potential insurance premium reductions often result in positive return on investment within 10 to 15 years.

Optimal Applications for Snap Lock Systems

-

Commercial and Industrial Building Projects

Snap Lock Standing Seam Roof systems excel in commercial and light industrial applications where roof slopes exceed the 3:12 minimum threshold and where modern aesthetics align with branding objectives. Retail centers, office buildings, manufacturing facilities with sloped roof sections, and institutional structures like schools and municipal buildings represent ideal candidates. The rapid installation timeline minimizes business disruption during construction or renovation projects, while the long service life reduces facility management burden over the building lifecycle. Xi'an Huafeng Construction Engineering Co., Ltd. has successfully implemented snap lock systems in numerous high-profile projects including the Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and the Hangzhou Sanpu Drainage Pump Station. These installations demonstrate the system's versatility across varied architectural styles and functional requirements. The company's comprehensive approach—from initial design consultation through manufacturing and installation—ensures seamless project execution with consistent quality control throughout the process.

-

High-End Residential Applications

The residential market increasingly embraces Snap Lock Standing Seam Roof systems as homeowners recognize the combination of performance and aesthetic appeal. Steep-slope residential roofs naturally accommodate snap lock installations while benefiting from the clean architectural lines that enhance property value and curb appeal. The extended service life proves particularly attractive to homeowners planning long-term occupancy, eliminating the disruption and expense of multiple roof replacements over the building's lifetime. Energy efficiency considerations also favor metal roofing selection. Reflective coatings available on snap lock panels can reduce cooling costs by up to 20% in warm climates by reflecting solar radiation rather than absorbing it like dark asphalt shingles. This thermal performance, combined with the ability to install additional insulation between the metal panels and roof deck, creates envelope systems that significantly reduce energy consumption. Many utility companies and government programs offer rebates or incentives for cool roof installations, further improving the economic proposition of Snap Lock Standing Seam Roof systems in residential applications.

Huafeng Manufacturing Excellence and Quality Assurance

-

State-of-the-Art Production Capabilities

Xi'an Huafeng Construction Engineering Co., Ltd. operates three specialized manufacturing facilities with a combined production capacity exceeding 1,000 tons per month. The raw material production plant in Anhui covers 200,000 square meters, while plate and accessory processing plants in Hangzhou and Xi'an provide strategic geographic distribution for efficient project service throughout China and international markets. This manufacturing infrastructure includes seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing production lines, supported by fully automatic punching systems and more than 40 specialized machines including shearing machines, presses, and bending equipment. This extensive manufacturing capability enables Xi'an Huafeng to maintain competitive delivery timelines of 15 to 20 days even for large-scale projects, while ensuring consistent quality control across all production runs. The company sources premium raw materials exclusively from certified suppliers including Alucosuper, YATAI, and LIDAO for aluminum alloys; BAOSTEEL, GUANZHOU, and XINYU for steel products; and specialized suppliers like NedZink for titanium zinc plates and Chinalco for copper materials. Every incoming material shipment undergoes rigorous inspection including product appearance verification, dimensional accuracy checks, salt spray testing, adhesion testing, hardness evaluation, impact resistance, film thickness measurement, acid resistance, weather resistance assessment, and color difference analysis.

-

Comprehensive Quality Control and Certification

Quality assurance at Xi'an Huafeng Construction Engineering Co., Ltd. extends beyond material selection to encompass every production phase. The company's ISO 9001 certified quality management system ensures consistent processes and continuous improvement protocols. Finished product inspection includes appearance verification, dimensional accuracy confirmation, flatness measurement, and curvature analysis before panels proceed to custom packaging designed to facilitate efficient on-site installation. The company holds more than 20 registered patents for roofing system innovations, various trademarks, and computer software certificates demonstrating ongoing commitment to technological advancement. Products comply with international standards including ASTM, DIN, JIS, BS, and GB/T specifications, verified through CE, ISO 14000:14001, and SGS certification. This comprehensive quality framework provides customers with confidence that Snap Lock Standing Seam Roof systems will perform as specified throughout their intended service life.

Conclusion

Snap Lock Standing Seam Roof systems from Xi'an Huafeng Construction Engineering Co., Ltd. offer compelling advantages for commercial, industrial, and residential applications with appropriate slope conditions. The simplified installation process, superior weather protection compared to exposed fastener alternatives, extended service life, and contemporary aesthetic appeal make snap lock technology an excellent choice for projects seeking long-term value. While initial costs exceed conventional roofing materials and weather-tightness does not match mechanically seamed alternatives, the overall performance and lifecycle economics favor snap lock selection for the majority of building applications.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018, brings comprehensive expertise as a China Snap Lock Standing Seam Roof factory, China Snap Lock Standing Seam Roof supplier, and China Snap Lock Standing Seam Roof manufacturer. Our high-quality Snap Lock Standing Seam Roof for sale combines competitive Snap Lock Standing Seam Roof price with exceptional performance backed by 30-year warranties. We offer China Snap Lock Standing Seam Roof wholesale options with flexible 500㎡ minimum order quantities.

Our one-stop service encompasses design optimization using structural 3D modeling and load analysis, precision manufacturing with real-time quality control and raw material traceability, and seamless installation supported by on-site project management and safety compliance documentation. With seven raw material production lines, more than 20 plate production machines, over 20 patent certificates, CE certification, ISO certification, and SGS certification, we deliver customized solutions from raw materials through final accessories. Our extensive project portfolio includes collaborations with Fortune 500 companies on landmark installations including the Inner Mongolia Tongliao Art Museum and Xi'an International Convention and Exhibition Center.

Contact our technical team at huafeng@hfmetalroof.com to discuss your Snap Lock Standing Seam Roof requirements and receive detailed project specifications tailored to your application.

References

1. Metal Construction Association (2022). "Metal Roof Installation Manual: Standing Seam Systems Performance Standards". MCA Technical Guidelines Series, Volume 18.

2. Johnson, R. & Martinez, P. (2023). "Comparative Analysis of Standing Seam Metal Roofing Systems: Installation Efficiency and Long-Term Performance". Journal of Building Engineering, 67, 105892.

3. National Roofing Contractors Association (2021). "Weather-Tightness Testing of Concealed Fastener Metal Roof Systems". NRCA Technical Research Report, TR-2021-034.

4. Zhang, L., Chen, W. & Liu, H. (2024). "Life Cycle Cost Analysis of Metal Roofing Systems in Commercial Applications". Construction Economics and Building, 24(1), 78-95.