Picture this: you're standing in your driveway, looking up at your aging roof, knowing replacement is inevitable but dreading the decision. You want something that won't look dated in five years, won't clash with future exterior updates, and won't make you second-guess your choice every time you pull up to your home. Grey Standing Seam Metal Roof systems offer the perfect solution to this dilemma, providing a timeless, versatile option that combines modern sophistication with practical benefits. Grey has dominated neutral palettes in recent years precisely because it delivers both aesthetic appeal and functional performance, making it an intelligent choice for residential, commercial, and industrial applications alike.

Why Grey Standing Seam Metal Roof Systems Lead the Market?

The popularity of grey metal roofing has experienced remarkable growth over the past two decades, and this trend shows no signs of slowing down. Grey has been holding strong among the top five most-sold colors for metal roofing, and understanding why reveals much about what makes this color choice so compelling for diverse projects. Grey Standing Seam Metal Roof panels represent more than just a color selection; they embody a design philosophy that prioritizes longevity, adaptability, and visual harmony with surrounding architecture. The neutral character of grey provides exceptional versatility across architectural styles. Whether you're working on a contemporary commercial facility, a traditional residential property, or an industrial warehouse, Grey Standing Seam Metal Roof systems integrate seamlessly into the existing design language. This adaptability stems from grey's unique position as a true neutral that neither competes with nor dominates other design elements. Instead, it serves as a sophisticated backdrop that allows accent colors, landscaping, and architectural features to take center stage. For building owners who anticipate future renovations or exterior updates, grey offers insurance against color coordination challenges that might arise with more assertive color choices. From a practical standpoint, grey metal roofing delivers measurable advantages in maintenance and appearance retention. Grey metal roofs fade less than other colors due to their neutral pigmentation and the inherent stability of grey tones, which means your investment maintains its visual appeal longer. This slower fading rate translates directly into extended periods between potential recoating needs and sustained curb appeal that protects property values. The sophisticated appearance of Grey Standing Seam Metal Roof installations communicates quality and attention to detail, characteristics that resonate with clients, customers, and visitors alike.

-

Understanding Grey Metal Roof Energy Performance

Energy efficiency represents a critical consideration in modern roofing decisions, and grey offers a balanced approach to thermal management. Grey colors have mid-range Solar Reflective Index values, which typically result in medium energy savings, positioning them between the high reflectivity of white roofs and the heat absorption of dark colors. This middle ground makes Grey Standing Seam Metal Roof systems particularly suitable for mixed climates where both heating and cooling demands fluctuate throughout the year. The thermal performance of grey roofing varies depending on the specific shade selected. Lighter grey tones approaching charcoal provide better solar reflectance, helping reduce cooling loads during hot summer months. Darker grey shades absorb more thermal energy, which can actually benefit buildings in colder climates by reducing heating demands during winter. This dual functionality makes grey an intelligent choice for regions experiencing significant seasonal temperature variations. Modern Grey Standing Seam Metal Roof panels often incorporate advanced PVDF coatings that enhance both reflective properties and long-term durability, ensuring that energy performance benefits persist throughout the roof's service life. When comparing grey to alternatives, the energy equation becomes more nuanced than simple color choice. Installation quality, insulation levels, ventilation design, and substrate materials all significantly impact overall thermal performance. A properly installed Grey Standing Seam Metal Roof system with appropriate underlayment and ventilation can outperform lighter-colored roofs installed without attention to these critical details. The hidden fastener design characteristic of standing seam systems also contributes to energy efficiency by creating a continuous thermal envelope without penetrations that might compromise insulation effectiveness.

-

Design Versatility and Color Coordination with Grey Standing Seam Metal Roof

Grey's reputation as the ultimate neutral color in architectural design stems from its remarkable compatibility with virtually any color palette. Whether your building features warm earth tones like brick red and tan, cool shades like blue and green, or contemporary combinations of black and white, Grey Standing Seam Metal Roof panels provide cohesive visual integration. This universal compatibility proves especially valuable in mixed-use developments, campus settings, or neighborhoods with diverse architectural styles where maintaining visual harmony becomes paramount. The sophisticated character of grey roofing elevates both traditional and modern architectural expressions. Grey can appear traditional or ultra-modern depending on the application and shade chosen, making it adaptable to evolving design trends without appearing dated. For contemporary designs featuring clean lines, large glass expanses, and minimalist details, darker grey tones complement the aesthetic with understated elegance. Traditional buildings benefit from lighter grey shades that echo historical materials like slate or weathered metal while providing superior performance characteristics. This chameleon-like quality means Grey Standing Seam Metal Roof installations age gracefully alongside the buildings they protect, maintaining relevance through design cycles that might render more trendy color choices obsolete. Professional designers particularly appreciate grey's ability to unify diverse materials and textures within a single project. Buildings incorporating stone veneer, wood siding, metal cladding, and glass surfaces can appear disjointed with the wrong roof color. Grey Standing Seam Metal Roof systems act as a visual anchor that brings these varied elements into a cohesive whole, creating architectural harmony that enhances overall project success. The clean, modern lines of standing seam profiles amplify this unifying effect, with raised vertical seams adding dimensional interest that prevents grey from appearing flat or monotonous.

Technical Advantages of Grey Standing Seam Metal Roof Systems

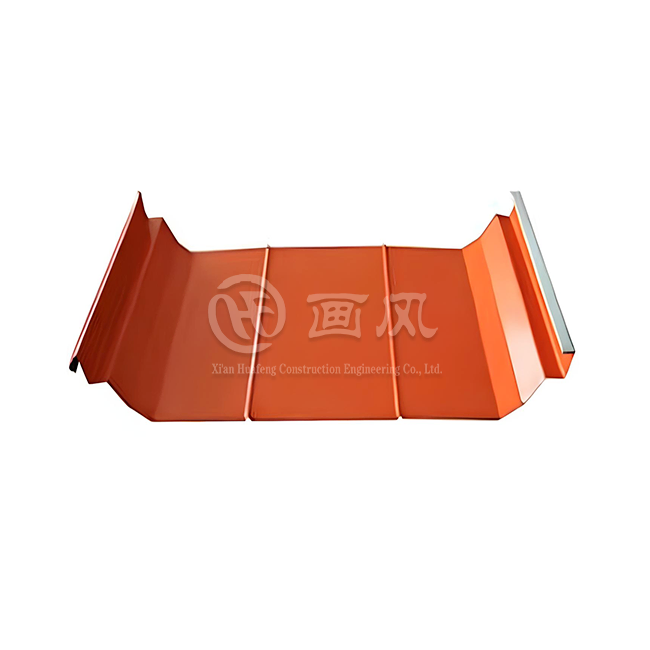

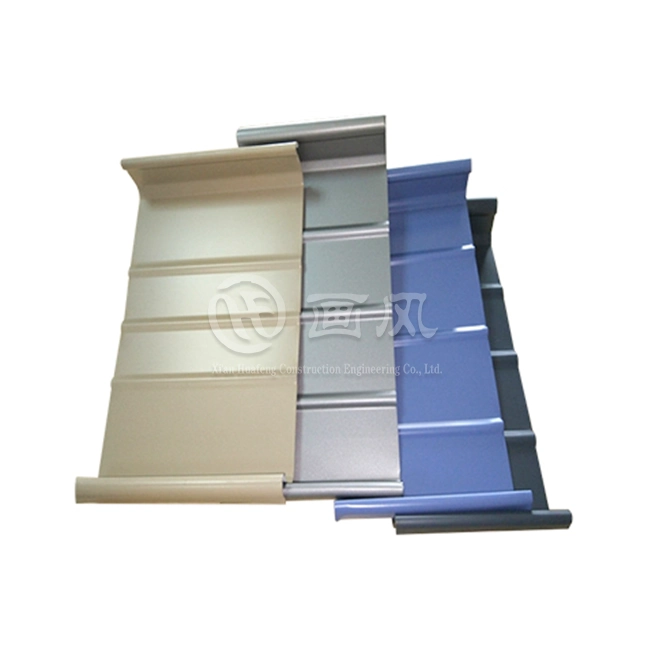

Beyond aesthetic considerations, Grey Standing Seam Metal Roof panels deliver significant technical benefits that justify their popularity among architects, contractors, and building owners. The standing seam profile itself represents an evolved roofing technology designed to address common failure points found in traditional roofing systems. Hidden fasteners eliminate penetrations through the roofing surface that might become leak pathways over time, while concealed clip systems allow panels to expand and contract with temperature fluctuations without inducing stress that could compromise weathertightness. Manufacturing precision directly impacts Grey Standing Seam Metal Roof performance, and advanced production facilities ensure consistent quality across large projects. Xi'an Huafeng Construction Engineering Co., Ltd. operates three state-of-the-art factories with seven production lines and over forty specialized machines dedicated to metal roofing fabrication. This industrial capacity supports production volumes exceeding 1000 tons monthly while maintaining rigorous quality control standards. Panel specifications ranging from 25-330 to 65-430 millimeters accommodate diverse structural requirements, while thickness options from 0.6 to 0.8 millimeters balance performance characteristics with weight considerations. Surface treatments including PVDF and PE coatings provide superior weather resistance and color retention, with both matte and gloss grey finishes available to match specific design visions.

Material selection significantly influences Grey Standing Seam Metal Roof longevity and performance. Premium installations utilize galvanized steel, aluminum, or specially coated metals that resist corrosion in challenging environmental conditions. These base materials accept advanced coating systems that provide ultraviolet resistance, prevent chalking and fading, and maintain appearance characteristics for decades. Compliance with international standards including ASTM, DIN, JIS, BS, and GB/T ensures that panels meet stringent performance requirements regardless of installation location. A thirty-year warranty backing these systems demonstrates manufacturer confidence in product durability and provides building owners with long-term peace of mind.

-

Weather Resistance and Durability of Grey Metal Roofing

Metal roofing inherently provides superior weather resistance compared to alternative materials, and grey standing seam systems maximize these protective capabilities. The interlocking seam design creates continuous weathertight barriers that shed water efficiently while resisting wind uplift forces that might compromise lesser roof assemblies. Standing seam metal roofing features concealed fasteners and raised interlocking seams that provide superior protection against harsh weather conditions, making these systems ideal for regions experiencing high winds, heavy precipitation, or extreme temperature swings. Corrosion resistance represents a critical performance factor in coastal environments, industrial areas, or locations with significant atmospheric pollutants. Grey Standing Seam Metal Roof panels manufactured with premium coating systems resist chemical attack from salt spray, acid rain, and industrial emissions that would rapidly degrade inferior materials. The neutral grey coloration actually benefits long-term appearance by minimizing the visual impact of any minor surface changes that might occur over decades of exposure. While lighter colors might show soiling more readily and darker colors could fade more noticeably, grey maintains consistent appearance through varying environmental challenges. The proven service life of metal roofing systems consistently exceeds alternatives, with properly installed Grey Standing Seam Metal Roof assemblies routinely delivering fifty or more years of reliable protection. This longevity stems from multiple factors: the inherent durability of metal substrates, the protective qualities of advanced coating systems, the weathertight integrity of standing seam designs, and the dimensional stability that prevents the warping, cracking, or deterioration common in organic roofing materials. Minimal maintenance requirements throughout this extended service life reduce lifecycle costs substantially, making grey metal roofing an economically sound investment that delivers value far beyond initial installation expenses.

-

Installation Considerations for Grey Standing Seam Metal Roof Projects

Successful Grey Standing Seam Metal Roof installations require careful planning, skilled execution, and attention to numerous technical details that impact long-term performance. Professional installation begins with comprehensive project documentation including detailed drawings that address every interface condition, penetration, edge treatment, and transition. Xi'an Huafeng Construction Engineering Co., Ltd. provides complete one-stop solutions encompassing design optimization, custom fabrication, and expert installation guidance that ensures project success from concept through completion. The manufacturing process for Grey Standing Seam Metal Roof panels incorporates advanced quality control measures at every stage. Material procurement focuses on certified suppliers providing documented performance characteristics and third-party testing verification. Incoming inspection protocols verify material specifications before production begins, with comprehensive testing including appearance evaluation, dimensional verification, salt spray resistance, adhesion strength, hardness measurements, impact resistance, film thickness, acid resistance, weather resistance, and color consistency. Roll-forming operations transform flat coil stock into precision-profiled panels cut to exact project dimensions, with sequential numbering systems ensuring proper installation sequence and eliminating field confusion. Site-specific installation planning addresses unique project conditions that might impact roof performance. Substrate preparation, underlayment selection, ventilation design, drainage planning, and thermal movement accommodation all require careful consideration based on building geometry, climate conditions, and performance expectations. Installation technicians must understand proper clip engagement, seam forming techniques, panel alignment procedures, and accessory integration to achieve weathertight assemblies that meet warranty requirements. Comprehensive testing upon completion verifies zero-leakage performance and confirms that the installed system meets all design specifications. This systematic approach to Grey Standing Seam Metal Roof installation produces reliable results that protect building investments for decades.

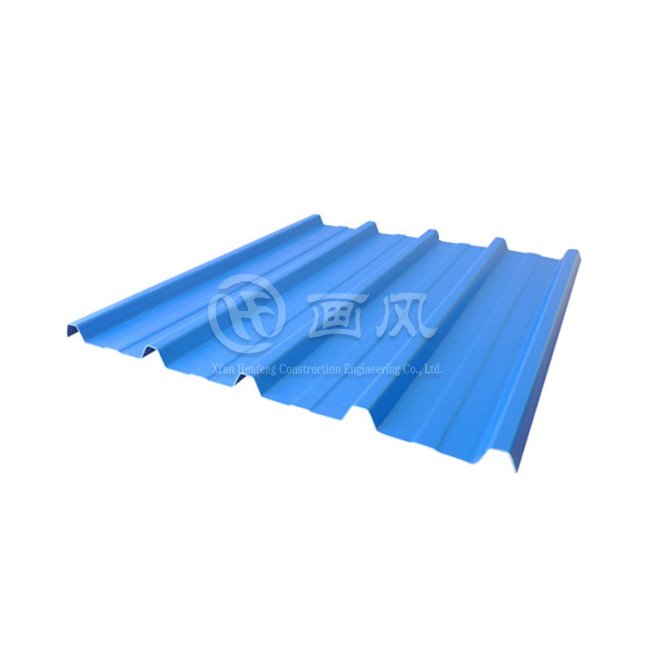

Comparing Grey Metal Roof Options and Specifications

The market offers numerous grey metal roofing products with varying characteristics, performance capabilities, and price points. Understanding these differences helps building owners make informed decisions aligned with project requirements and budget constraints. Grey Standing Seam Metal Roof systems generally command premium pricing compared to exposed-fastener profiles, but this investment delivers substantially enhanced performance, appearance, and longevity that justify the differential for many applications. Panel profile selection significantly impacts both aesthetics and functionality. Standing seam systems feature vertical ribs with concealed fastening that creates clean, modern appearances while providing superior weather protection. Alternative profiles like corrugated panels, five-vee crimp, and purlin-bearing rib configurations offer cost advantages but compromise appearance and potentially durability through exposed fastener penetrations. For projects prioritizing architectural quality and long-term performance, Grey Standing Seam Metal Roof panels represent the optimal choice despite higher initial investment. Coating technology directly determines appearance retention and weather resistance throughout the roof's service life. PVDF-based finishes provide the highest performance, with proven resistance to fading, chalking, and environmental degradation that maintains appearance for decades. Polyester coatings offer adequate performance at lower cost but may show accelerated weathering in harsh environments. Finish options including matte and gloss treatments affect both appearance and practical performance, with low-gloss finishes minimizing the visual impact of minor surface imperfections while standard gloss finishes provide slightly easier cleaning. Grey Standing Seam Metal Roof installations utilizing premium PVDF coatings justify their cost through extended service life and sustained appearance that protects property values.

-

Real-World Applications of Grey Standing Seam Metal Roof Systems

Grey metal roofing proves its versatility across diverse building types and applications, from residential homes to large commercial and industrial facilities. Xi'an Huafeng Construction Engineering Co., Ltd. has successfully completed numerous high-profile projects demonstrating the adaptability and performance of Grey Standing Seam Metal Roof systems. Major installations include the Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, Jinghe New City International Culture and Art Center South Hall, and the Inner Mongolia Tongliao Art Museum, among others. These projects showcase grey roofing's ability to enhance architectural expression while delivering reliable weather protection across varying climates and building geometries. Residential applications benefit from grey metal roofing's combination of aesthetic appeal and practical performance. Modern home designs featuring clean lines and contemporary materials pair naturally with Grey Standing Seam Metal Roof installations that complement rather than compete with architectural intentions. Traditional homes gain updated character while maintaining neighborhood compatibility through careful shade selection that bridges classic and contemporary sensibilities. The energy efficiency benefits of metal roofing help reduce utility costs throughout the roof's extended service life, while low maintenance requirements free homeowners from the ongoing costs and disruption associated with frequent repairs or premature replacement common with alternative roofing materials.

Commercial and industrial facilities prioritize roofing performance, lifecycle cost effectiveness, and minimal maintenance demands alongside aesthetic considerations. Grey Standing Seam Metal Roof systems excel in these applications through their proven durability, weathertight integrity, and ability to span long distances without intermediate supports. The neutral appearance integrates well with corporate branding initiatives and maintains professional appearances that reflect positively on business operations. Large-format manufacturing capabilities ensure timely project delivery even for extensive facilities requiring thousands of square meters of roofing material, with minimum order quantities starting at just 500 square meters or one ton of material.

Conclusion

Grey proves to be an excellent color choice for metal roofing through its combination of timeless aesthetics, practical performance advantages, and remarkable versatility across architectural styles and applications. Grey Standing Seam Metal Roof systems deliver superior weather protection, extended service life, and minimal maintenance requirements while maintaining sophisticated appearances that enhance property values and protect building investments for decades.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Grey Standing Seam Metal Roof manufacturer and China Grey Standing Seam Metal Roof supplier, offering comprehensive solutions that integrate design expertise, precision manufacturing, and professional installation support. Recognized as a high-tech enterprise in Shaanxi Province with first-level curtain wall qualifications and third-level steel structure credentials, Huafeng delivers exceptional quality backed by more than twenty registered patents, multiple trademarks, and rigorous quality certifications including ISO9001, ISO14000:14001, and SGS compliance.

Our integrated manufacturing capabilities span three facilities totaling over 200,000 square meters, housing seven color coating production lines, ten shearing lines, and more than forty specialized processing machines that support monthly production exceeding 1000 tons. As a trusted China Grey Standing Seam Metal Roof factory, we maintain strict quality control throughout material procurement, incoming inspection, production processing, finished product verification, and specialized packaging designed for efficient site installation. Our material selection includes premium brands like Alucosuper, YATAI, and BAOSTEEL, with comprehensive testing protocols ensuring every panel meets international standards before delivery.

Choose High Quality Grey Standing Seam Metal Roof solutions from a China Grey Standing Seam Metal Roof wholesale provider committed to creating added value through innovative design, sustainable development principles, and one-stop service encompassing project drawing optimization, factory sample production, precision manufacturing, and seamless installation support. Our competitive Grey Standing Seam Metal Roof price structures, combined with fifteen-to-twenty-day delivery timelines and thirty-year warranties, demonstrate our confidence in product excellence and commitment to customer success. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and discover why leading architects and contractors trust Huafeng for Grey Standing Seam Metal Roof for sale that transforms architectural visions into lasting reality.

References

1. Sheffield Metals International. "Gray Metal Roofing: Pros, Cons, and Design Considerations." Metal Roofing Learning Center, 2024.

2. Western States Metal Roofing. "Comprehensive Guide to Gray Metal Roof Color Selection and Applications." Metal Roofing Design Resources, 2021.

3. Green Tree Metals. "Energy Efficiency and Performance Characteristics of Gray Metal Roofing Systems." Technical Documentation Series, 2025.

4. McElroy Metal. "Color Selection Strategies for Metal Roofing: Current Trends and Best Practices." Building Design Publications, 2025.

(1)_1763110678300.webp)