Are you frustrated by water leaks at roof edges, inconsistent panel alignments, or a building envelope that looks unfinished? Standing seam trims are precision-engineered components designed to solve these exact challenges. These specialized metal accessories create watertight seals while delivering a professional, polished appearance that transforms your roofing and siding projects from functional to exceptional. Whether you're managing a commercial warehouse retrofit, designing a residential masterpiece, or overseeing an industrial facility expansion, understanding how to properly select and implement standing seam trims can mean the difference between a project that merely works and one that exceeds performance expectations for decades.

Understanding Standing Seam Trims and Their Critical Role in Modern Construction

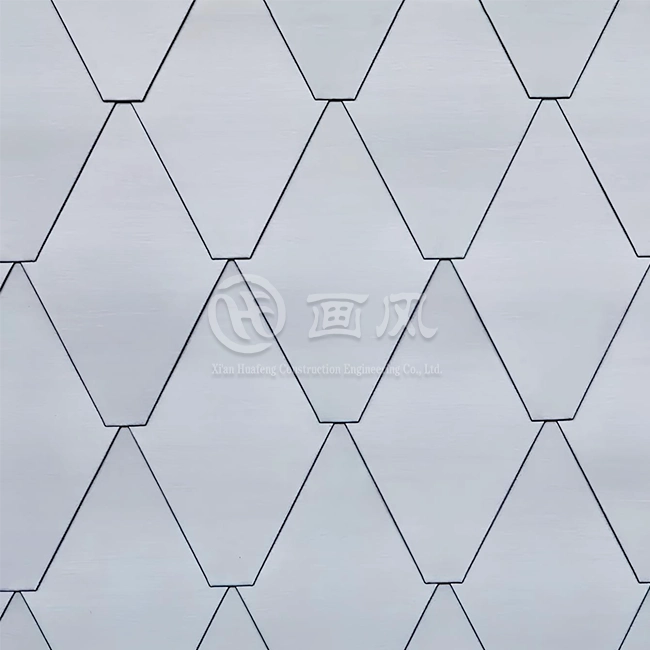

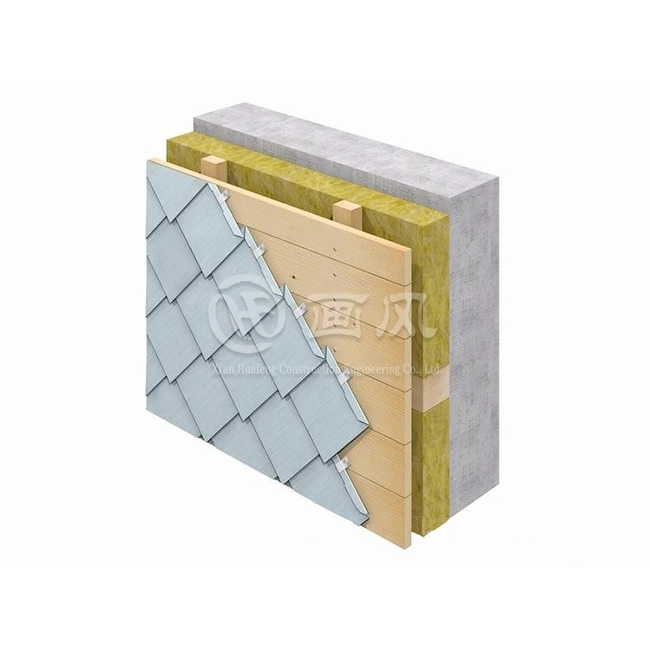

Standing seam trims represent far more than simple finishing pieces in contemporary metal roofing and siding systems. These components serve as the crucial interface between metal panels and building structures, performing multiple essential functions simultaneously. When properly specified and installed, standing seam trims create continuous weather barriers that prevent moisture infiltration, accommodate thermal expansion and contraction of metal panels, provide secure attachment points that resist wind uplift forces, and deliver clean visual transitions that enhance architectural aesthetics. The evolution of metal roofing technology has elevated trim components from afterthought accessories to engineered systems that require careful consideration during the design phase.

-

The Engineering Behind Effective Standing Seam Trim Systems

Modern standing seam trims incorporate sophisticated design elements that address real-world performance challenges. These components must withstand extreme temperature fluctuations, resist corrosion from environmental exposure, maintain structural integrity under significant wind loads, and accommodate building movement without compromising weatherproofing. Quality trim systems utilize material specifications that match or exceed the performance characteristics of the primary roofing panels, ensuring compatible thermal expansion rates and equivalent service lifespans. The geometric profiles of standing seam trims are carefully calculated to direct water away from vulnerable junctions, create positive drainage slopes, and establish secure mechanical connections with panel systems. Understanding these engineering principles helps project teams make informed decisions that prevent costly failures and premature replacement cycles.

-

Material Selection for Standing Seam Trims: Aluminum Alloy, Color Steel, and Galvanized Steel

The choice of material for standing seam trims dramatically impacts both immediate installation success and long-term system performance. Aluminum alloy trims offer exceptional corrosion resistance particularly valuable in coastal environments or chemical processing facilities, lightweight characteristics that simplify handling and reduce structural loading, and excellent formability that accommodates complex architectural details. Color steel trims provide superior strength-to-weight ratios ideal for large-span applications, broad color palette options that support diverse design visions, and cost-effectiveness for budget-conscious projects without compromising quality. Galvanized steel trims deliver robust durability in demanding industrial settings, excellent resistance to mechanical damage during construction, and time-proven performance in extreme climate conditions. Each material category brings distinct advantages, and experienced manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. maintain comprehensive material libraries including premium aluminum alloys such as 3003, 3004, and 5052 grades, high-quality steel from established suppliers like BAOSTEEL and XINYU, and specialized stainless steel options including 316 and 304 grades for the most challenging environments.

Essential Applications of Standing Seam Trims in Building Envelope Systems

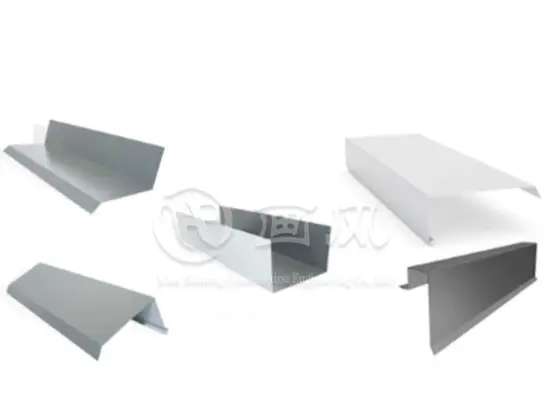

Standing seam trims serve critical functions at virtually every transition point in metal roofing and siding installations. Ridge applications require trims that seal the uppermost roof junction while providing adequate ventilation pathways and accommodating panel movement from both roof planes. Eave treatments demand components that establish the crucial first line of defense against water infiltration, create proper drip edges that protect fascia boards, and provide secure panel attachment without visible fasteners. Gable installations need trims that seal vertical end walls, resist wind-driven rain penetration, and maintain aesthetic consistency with horizontal eave treatments. Inner corner applications present particular challenges requiring trims that navigate three-dimensional geometries, maintain continuous water barriers through complex transitions, and accommodate differential movement between intersecting building planes. Flashing panel trims bridge the interface between roofing systems and wall cladding, creating weathertight seals while allowing independent movement of each system component.

-

Design Optimization Through Proper Standing Seam Trim Integration

Successful metal building envelope projects begin with comprehensive design development that fully integrates trim components into the overall system strategy. This approach considers how trim profiles affect water management by creating positive drainage slopes and eliminating potential ponding locations, ensures adequate thermal movement accommodation through properly sized expansion joints and slip connections, addresses aesthetic objectives by coordinating trim profiles with architectural design intent, and anticipates maintenance access requirements for long-term building operation. Advanced manufacturers employ three-dimensional modeling capabilities that visualize trim integration within complete building assemblies, perform structural load analysis to verify trim adequacy under design conditions, simulate drainage system performance to identify potential problem areas, and provide material specification advisory services that optimize performance-to-cost ratios. These comprehensive design services transform trim selection from a construction afterthought into a strategic decision that enhances overall project success.

-

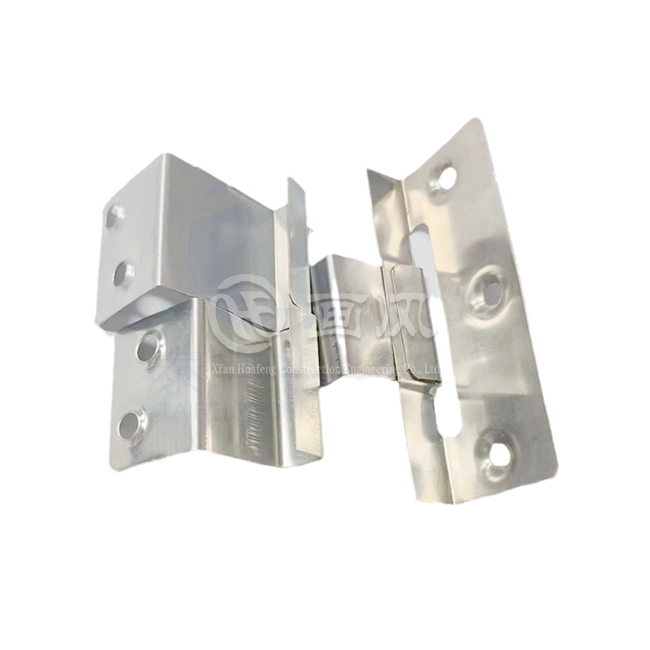

Manufacturing Excellence: From Raw Material to Precision-Formed Standing Seam Trims

The transformation of raw materials into high-performance standing seam trims requires sophisticated manufacturing capabilities and rigorous quality control protocols. Leading manufacturers like Xi'an Huafeng maintain extensive production infrastructure including seven color coating production lines that apply durable finish systems, one laminating production line for specialized composite applications, ten longitudinal and transverse shearing lines that process materials to precise dimensions, fully automatic punching production lines that create fastening holes with micron-level accuracy, and more than forty specialized machines including shearing equipment, hydraulic presses, and precision bending machines. This manufacturing capacity enables production of custom trim profiles that address unique project requirements, maintains tight dimensional tolerances essential for proper system function, and delivers consistent quality across production runs ranging from small custom orders to large-scale commercial projects.

-

Quality Assurance Through Comprehensive Testing and Certification

Reliable standing seam trim performance depends on rigorous incoming material inspection and finished product verification processes. Raw material testing protocols include product appearance examination to detect surface defects or contamination, dimensional verification ensuring materials meet specified thickness and width tolerances, salt spray testing evaluating corrosion resistance over extended exposure periods, adhesion testing confirming coating systems bond properly to substrate materials, hardness and impact testing validating mechanical properties, film thickness measurement ensuring adequate coating protection, acid resistance evaluation for chemical processing environments, and accelerated weathering simulation predicting long-term appearance retention. These comprehensive inspection procedures prevent defective materials from entering production streams and ensure finished trims meet stringent performance standards. Quality manufacturers provide material certifications and third-party testing reports documenting compliance with international standards including ISO9001 quality management systems, ISO14000 environmental management protocols, and SGS verification services.

Installation Best Practices for Standing Seam Trims

Proper installation techniques determine whether carefully engineered and precisely manufactured standing seam trims deliver their intended performance benefits. Successful installations begin with thorough site preparation including verification that substrate conditions meet manufacturer specifications, confirmation that proper underlayment systems are correctly installed, and validation that fastening surfaces provide adequate attachment strength. Trim component placement requires attention to critical details such as maintaining specified overlap dimensions at joints, ensuring continuous bead application of compatible sealants, achieving proper alignment with panel systems to avoid binding or gaps, and securing components with appropriate fastener types at recommended spacing intervals. Installation teams must understand thermal movement considerations that require intentional gaps at expansion joints, recognize that different materials exhibit different expansion coefficients requiring compatible detailing, and implement proper sequencing that allows each component to move independently while maintaining weather barrier integrity.

-

Technical Guidance and On-Site Support for Complex Standing Seam Trim Installations

Complex architectural projects often benefit from manufacturer technical support during the installation phase. Experienced providers dispatch installation specialists who conduct pre-construction site inspections to identify potential challenges, review shop drawings and installation sequences with field crews, verify that required tools and auxiliary materials are available and properly maintained, provide hands-on guidance during critical installation phases, and conduct quality verification inspections ensuring work meets specified standards. This collaborative approach bridges the gap between engineering intent and field execution, preventing costly errors that compromise system performance or require extensive remediation efforts. Projects incorporating unusual geometries, extreme climate conditions, or accelerated construction schedules particularly benefit from this technical partnership approach.

-

Standing Seam Trim Selection for Specific Building Types and Performance Requirements

Different building types and occupancy classifications impose varying performance requirements on standing seam trim systems. Industrial facilities housing manufacturing operations may require trims resistant to chemical exposure, capable of withstanding frequent thermal cycling, and designed to accommodate significant structural movement from heavy equipment vibration. Commercial buildings in high-visibility locations prioritize aesthetic consistency with corporate branding, demand pristine appearance retention over extended service lives, and specify premium color options with enhanced UV stability. Public assembly buildings including convention centers and transportation terminals must satisfy stringent fire resistance ratings, accommodate exceptionally high occupancy loads driving increased ventilation requirements, and deliver maintenance-friendly details that minimize operational disruption. Agricultural buildings housing livestock or crop storage require trims that resist corrosive atmospheres from animal waste or fertilizer chemicals, accommodate large thermal movements from uninsulated building envelopes, and provide cost-effective solutions appropriate for agricultural economics. Understanding these application-specific requirements guides appropriate trim selection and detailing strategies.

Advanced Standing Seam Trim Solutions for Challenging Applications

Some projects present unique challenges requiring specialized trim solutions beyond standard product offerings. Curved roof applications need trims that maintain weathertight seals while following compound curvatures, accommodate the geometric complexity of panel transitions along curved surfaces, and deliver aesthetic consistency despite non-planar geometries. Historic restoration projects must match existing architectural profiles while incorporating modern performance enhancements, utilize traditional material aesthetics with contemporary durability, and navigate regulatory requirements for landmark buildings. Coastal installations demand exceptional corrosion resistance to salt spray exposure, enhanced wind uplift capacity addressing hurricane-force wind loads, and materials resistant to galvanic corrosion in marine environments. Solar panel integration applications require trims that accommodate rooftop equipment attachments while maintaining roof warranties, create pathways for electrical conduit without compromising weather barriers, and provide adequate clearance for maintenance access to photovoltaic arrays. Manufacturers with comprehensive engineering capabilities and flexible production facilities can develop custom solutions addressing these specialized requirements.

-

Lifecycle Performance and Maintenance Considerations for Standing Seam Trims

Long-term building performance depends on maintaining standing seam trim systems throughout their service lives. Properly specified and installed trims should provide decades of reliable service with minimal intervention, but periodic inspection and maintenance optimize performance and extend service life. Recommended maintenance protocols include annual visual inspections examining trims for loose fasteners, degraded sealant joints, coating damage, or deformation from impact or thermal stress, quinquennial detailed inspections documenting overall system condition and identifying developing issues before they become critical failures, immediate attention to any identified deficiencies preventing minor problems from escalating into major repairs, and systematic documentation creating maintenance history records that inform long-term facility management strategies. Standing seam trim systems manufactured from premium materials with durable coating systems and installed according to industry best practices regularly achieve fifty-year service lives with modest maintenance investment, delivering exceptional lifecycle value that far exceeds initial cost differentials compared to economy alternatives.

Conclusion

Standing seam trims represent critical components in high-performance metal roofing and siding systems, delivering essential weatherproofing protection while enhancing architectural aesthetics and ensuring long-term system integrity across diverse building applications.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a trusted China Standing Seam Trims manufacturer and China Standing Seam Trims supplier, offering comprehensive solutions from design through installation. Recognized as a high-tech enterprise in Shaanxi Province in 2020, Huafeng maintains first-level qualifications for building curtain walls and third-level qualifications for building steel structures. Our extensive manufacturing infrastructure includes a 200,000 square meter raw material production plant in Anhui and two processing facilities in Hangzhou and Xi'an, housing seven color coating lines, ten shearing production lines, and more than forty specialized equipment units. As a leading China Standing Seam Trims factory, we serve global markets with High Quality Standing Seam Trims at competitive Standing Seam Trims price points. Our engineering team provides design optimization services, raw material quality testing, customized product development, secure packaging solutions, and flexible transportation options. We maintain more than twenty registered patents, ISO9001, ISO14000, CE, and SGS certifications guaranteeing product excellence. Whether you need Standing Seam Trims for sale or China Standing Seam Trims wholesale quantities, our one-stop service model covers every project phase. Contact us at huafeng@hfmetalroof.com to discuss your requirements and experience the Huafeng difference in metal roofing excellence.

References

1. Metal Building Systems Manual: Design and Construction Guidelines. Metal Building Manufacturers Association, 2021.

2. Johnson, Robert K. Architectural Metal Roofing: Design Principles and Installation Practices. Construction Industry Press, 2019.

3. Standards for Metal Roof Systems: Installation and Performance Requirements. American Society for Testing and Materials (ASTM), 2023.

4. Zhang, Wei and Thompson, James L. Sustainable Building Envelopes: Advanced Materials and Systems Integration. International Journal of Construction Engineering, 2022.