Picture this: you've just invested heavily in a commercial building or industrial facility, and within a decade, you're facing unexpected roof replacement costs. For facility managers and property owners, this nightmare scenario is all too common with traditional roofing materials. The question that keeps many decision-makers up at night is straightforward yet critical: how long will your roofing investment actually last? When it comes to Metal Standing Seam Roofing Systems, the answer brings relief. These advanced roofing solutions typically deliver between thirty to seventy-five years of reliable performance, with many installations exceeding expectations when properly maintained. Understanding the lifespan of Metal Standing Seam Roofing Systems isn't just about numbers; it's about calculating your return on investment, planning facility budgets, and ensuring uninterrupted operations for decades to come.

Understanding Metal Standing Seam Roofing Systems Longevity

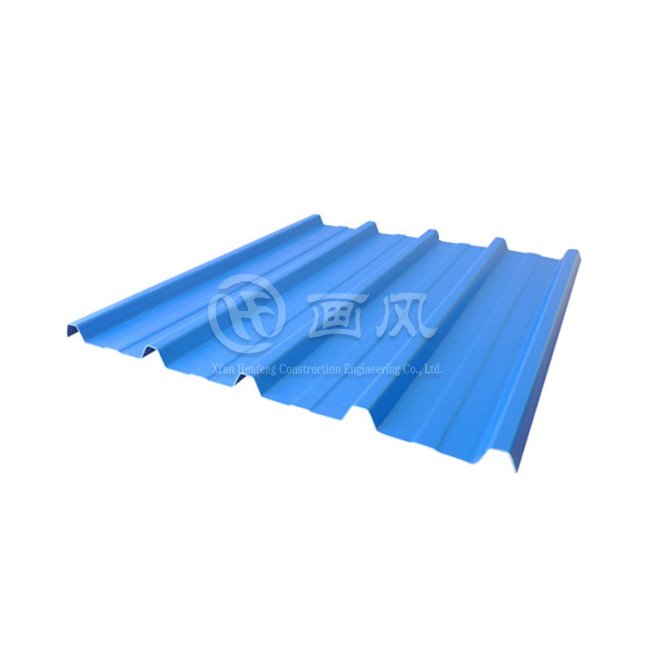

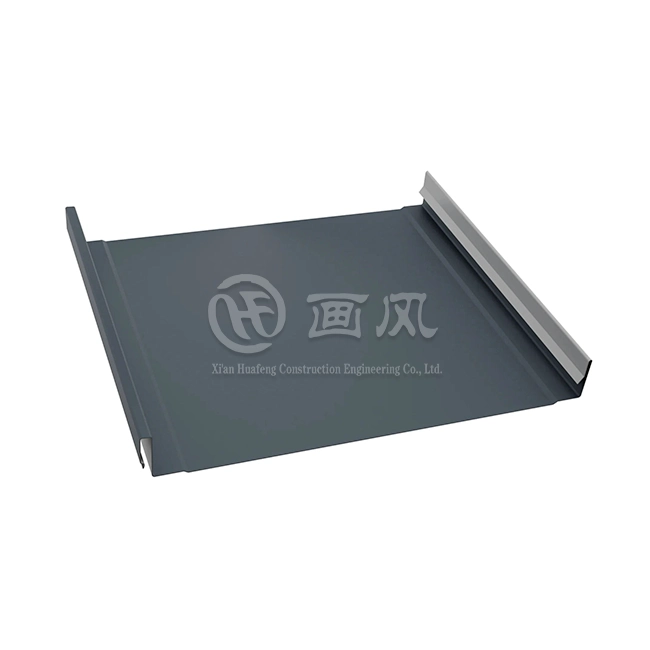

The exceptional durability of Metal Standing Seam Roofing Systems stems from their sophisticated engineering and premium materials. Unlike conventional roofing solutions that deteriorate rapidly under environmental stress, these systems are specifically designed to withstand the harshest conditions while maintaining structural integrity. The core advantage lies in their unique concealed fastener design, which eliminates the primary failure points that plague traditional metal roofing. When fasteners remain hidden beneath the roofing panels, they're protected from direct exposure to ultraviolet radiation, moisture infiltration, and thermal cycling that would otherwise compromise their effectiveness over time. The material composition plays an equally critical role in determining longevity. Modern Metal Standing Seam Roofing Systems utilize advanced metallic substrates including aluminum-magnesium-manganese alloys, galvalume steel with AZ150 coating, stainless steel, titanium-zinc, and copper. Each material brings distinct advantages: aluminum alloys offer lightweight corrosion resistance ideal for coastal environments; galvalume provides exceptional cost-effectiveness with robust weather protection; stainless steel delivers superior performance in industrial settings with chemical exposure; titanium-zinc develops self-healing properties that extend service life beyond eighty years; and copper installations have documented lifespans exceeding one hundred years. The selection of substrate material directly impacts not only the initial cost but also the long-term maintenance requirements and ultimate lifespan of your Metal Standing Seam Roofing Systems installation.

-

Material Quality and Surface Protection

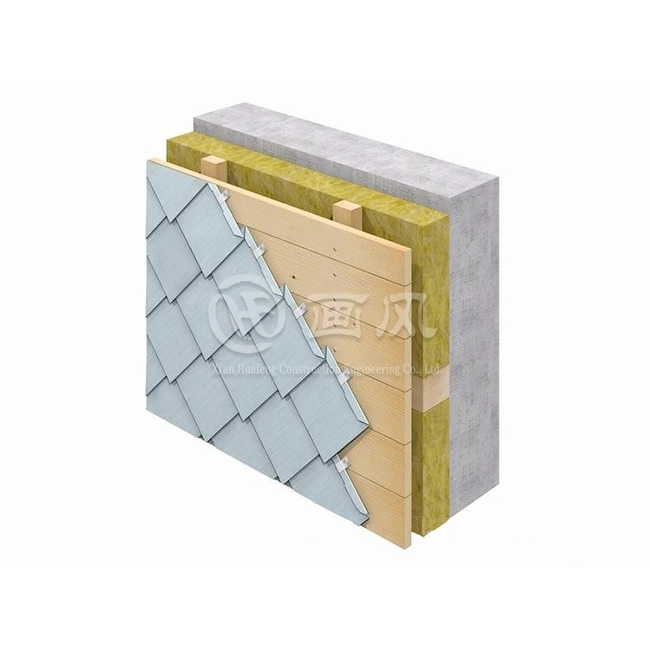

The protective coating systems applied to Metal Standing Seam Roofing Systems represent a critical factor in achieving maximum longevity. High-performance PVDF coatings containing seventy percent fluororesin create a barrier twenty-five to thirty micrometers thick that resists ultraviolet degradation and chemical corrosion for over twenty years while maintaining color integrity. These specialized coatings don't simply disappear when warranties expire; instead, they continue providing protection well beyond their rated period, which explains why many Metal Standing Seam Roofing Systems installations remain functional for fifty to seventy-five years. The coating technology prevents the underlying metal from oxidizing, which would otherwise lead to premature failure through rust formation and structural weakening. Beyond the primary coating, the complete Metal Standing Seam Roofing Systems assembly incorporates multiple protective layers that work synergistically to maximize service life. The waterproof and breathable membrane positioned beneath the metal panels serves dual purposes: blocking wind-driven rain while allowing interior moisture to escape, thereby preventing condensation damage that could compromise the roof deck and structural supports. The insulation layer, typically rock wool with calculated thickness, provides thermal protection while simultaneously reducing noise transmission during heavy precipitation events. The vapor barrier limits moisture migration from the building interior, minimizing condensation risk within the roof assembly. This comprehensive multi-layer approach ensures that Metal Standing Seam Roofing Systems maintain their protective function across decades of service, even as individual components age at different rates.

Factors Affecting Standing Seam Metal Roof Lifespan

Environmental conditions exert profound influence on how long Metal Standing Seam Roofing Systems will perform effectively. Installations in regions experiencing moderate weather patterns—characterized by limited temperature extremes, infrequent severe storms, and low pollution levels—regularly achieve or exceed seventy-five-year service lives. Conversely, roofs subjected to intense environmental stressors face accelerated aging. Coastal installations must contend with salt-laden air that accelerates corrosion despite protective coatings. Industrial areas expose Metal Standing Seam Roofing Systems to acidic pollutants and chemical fallout that can degrade surface finishes prematurely. Regions with extreme temperature fluctuations subject the roofing to continuous thermal cycling, causing expansion and contraction that stresses panel connections and fastening systems. However, the inherent design of Metal Standing Seam Roofing Systems—specifically their ability to accommodate thermal movement through floating panel connections—provides superior resistance to thermal stress compared to fixed-fastener alternatives. Precipitation patterns and snow loading represent additional environmental factors that impact longevity. Areas receiving substantial rainfall require robust drainage design to prevent standing water, which could eventually find pathways through even the most carefully installed seams. Snow accumulation creates static loads that stress the structural supports and can lead to ice damming at roof edges, potentially forcing moisture beneath the panels during freeze-thaw cycles. The high-rib design characteristic of Metal Standing Seam Roofing Systems, particularly those featuring sixty-five-millimeter seam heights, provides enhanced structural rigidity and improved drainage performance that helps mitigate these environmental challenges. The mechanical locking technology employed in these systems creates weathertight seals capable of withstanding wind-driven rain and resisting wind uplift forces exceeding 4.5 kilopascals, equivalent to category sixteen typhoon conditions.

-

Installation Quality and Maintenance Practices

The expertise demonstrated during installation fundamentally determines whether Metal Standing Seam Roofing Systems will achieve their theoretical maximum lifespan. Improper installation techniques can introduce defects that compromise performance from day one, regardless of material quality. Critical installation considerations include proper panel alignment to ensure consistent seam engagement, correct seaming pressure to create weathertight connections without deforming the panels, adequate provision for thermal expansion through appropriately placed expansion joints, precise flashing installation around penetrations and roof edges, and careful material handling to avoid scratching protective coatings that could expose bare metal to corrosion. When installation is performed by experienced professionals following manufacturer specifications and industry best practices, Metal Standing Seam Roofing Systems installations routinely deliver fifty to seventy-five years of leak-free performance with minimal maintenance intervention. Maintenance requirements for Metal Standing Seam Roofing Systems remain remarkably modest compared to alternative roofing technologies, yet regular inspections prove essential for identifying minor issues before they evolve into costly problems. Annual or biannual roof inspections should focus on several critical areas: examining penetration flashings around vent pipes, exhaust stacks, and other roof-mounted equipment to verify that sealants remain pliable and effective; removing accumulated debris including leaves, pine needles, and dirt that could trap moisture against the metal surface; checking for algae or moss growth in humid climates and cleaning when necessary; inspecting seam integrity along panel connections; and verifying that drainage systems remain unobstructed. In environments where deciduous leaves or atmospheric fallout accumulate significantly, periodic cleaning at six-month intervals proves prudent. This proactive approach to Metal Standing Seam Roofing Systems maintenance maximizes return on investment by preventing localized corrosion that could otherwise necessitate premature panel replacement.

Performance Specifications of Metal Standing Seam Roofing Systems

Modern Metal Standing Seam Roofing Systems deliver exceptional structural performance that directly contributes to their extended service life. The engineering specifications demonstrate capabilities that exceed minimum building code requirements across multiple performance categories. Wind pressure resistance testing confirms these systems can withstand loads of 4.5 kilopascals or greater, corresponding to sustained winds approaching two hundred kilometers per hour. Snow load capacity ratings of 1.5 kilonewtons per square meter enable safe installation in regions experiencing heavy winter precipitation. Impact resistance testing, where one-kilogram steel balls dropped from three-meter heights cause no panel perforation, validates the system's ability to withstand hail damage that would destroy conventional roofing materials. These robust performance characteristics ensure that Metal Standing Seam Roofing Systems maintain their protective function throughout their service life, even when subjected to extreme weather events that would compromise lesser roofing technologies. The thermal performance of Metal Standing Seam Roofing Systems contributes significantly to their longevity by managing heat transfer and controlling condensation. The system's reflectivity coefficient typically exceeds 0.65, meeting cool roof standards that reduce solar heat absorption and minimize thermal cycling stress on the metal substrate. The multi-layer assembly incorporating insulation, vapor barriers, and air-sealing components creates a comprehensive building envelope that prevents condensation formation—a critical consideration since trapped moisture represents the primary threat to long-term durability of any roofing system. The airtightness specification of 0.1 cubic meters per square meter per hour demonstrates superior weather protection compared to conventional roof assemblies. Fire resistance classification as A1 non-combustible material provides additional safety benefits while ensuring the roofing won't contribute fuel during fire events, protecting your facility investment even during catastrophic circumstances.

-

Material Specifications and Technical Standards

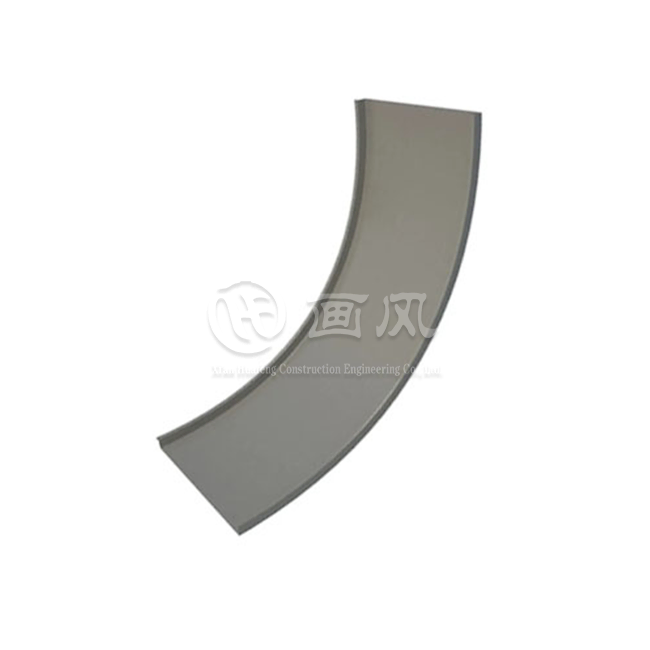

The technical specifications governing Metal Standing Seam Roofing Systems reflect decades of materials science research and field performance data. Panel materials span a range of options carefully engineered for specific applications and environmental conditions. Aluminum panels ranging from 0.9 to 1.2 millimeters thickness utilize 3003 or 3004 series alloys in H44 hardened condition, providing optimal strength-to-weight ratios with excellent corrosion resistance particularly suited for coastal installations where salt spray accelerates degradation of lesser materials. Galvalume steel panels from 0.6 to 1.0 millimeters thickness feature AZ150 coating providing 150 grams per square meter of aluminum-zinc protection, combined with PVDF topcoats for enhanced durability and aesthetic longevity. Stainless steel options from 0.5 to 0.8 millimeters using 304 grade material excel in high-humidity or chemically aggressive environments where other metals would fail prematurely. For ultimate longevity, titanium-zinc and copper options represent premium choices with documented service lives extending far beyond conventional materials. Titanium-zinc panels from 0.7 to 1.0 millimeters thickness develop natural patina over time while exhibiting self-repairing properties that enable eighty-year-plus service lives with essentially zero maintenance requirements. Copper installations using 0.8 to 1.0 millimeters TU1 oxygen-free copper have documented lifespans exceeding one hundred years, developing distinctive aesthetics as they age. The panel dimensions for Metal Standing Seam Roofing Systems accommodate project-specific requirements with widths from 300 to 600 millimeters effective coverage, sixty-five-millimeter seam heights providing enhanced structural rigidity and drainage performance, and custom lengths extending up to thirteen meters to minimize transverse seams and potential leak points. Manufacturing tolerances of ±0.02 millimeters ensure consistent quality meeting ASTM A924 and A755 standards for dimensional accuracy.

Xi'an Huafeng's Metal Standing Seam Roofing Systems Advantages

When selecting a supplier for Metal Standing Seam Roofing Systems, the manufacturing capabilities and quality control systems directly impact the longevity you'll ultimately achieve. Xi'an Huafeng Construction Engineering Co., Ltd. operates comprehensive production facilities spanning 200,000 square meters in Anhui, with additional processing plants in Hangzhou and Xi'an equipped with advanced manufacturing equipment. The seven color coating production lines ensure consistent finish quality with precise control over coating thickness and adhesion properties. Ten longitudinal and transverse shearing production lines enable accurate panel fabrication to tight dimensional tolerances. Fully automatic punching systems produce consistent hole patterns for accessories and fasteners. This integrated manufacturing approach from raw material processing through finished panel production ensures quality consistency throughout every Metal Standing Seam Roofing Systems installation, eliminating the variability that can compromise longevity when components from multiple suppliers must interface during construction. The company's material selection standards demonstrate commitment to longevity through partnerships with premium suppliers. Aluminum panels source from Alucosuper, YATAI, and LIDAO brands meeting 3003, 3004, and 5052 specifications. Steel substrates utilize BAOSTEEL, GUANZHOU, and XINYU products including cold-rolled sheet, galvanized sheet, galvalume sheet, and color-coated sheet with documented performance histories. Stainless steel components from Baosteel and Tsingshan in 316 and 304 grades provide corrosion resistance for challenging environments. Titanium-zinc from NedZink and copper from Chinalco in T2/TP2 grades represent premium options for projects demanding maximum longevity. Every incoming material undergoes rigorous inspection including appearance verification, dimensional checks, salt spray testing, adhesion measurement, hardness verification, impact resistance, film thickness confirmation, acid resistance, weather resistance testing, and color difference analysis. This comprehensive quality assurance program ensures that only materials meeting stringent standards become part of Metal Standing Seam Roofing Systems installations.

-

Comprehensive Service and Certification

Beyond manufacturing excellence, Xi'an Huafeng provides complete design-through-installation services that optimize Metal Standing Seam Roofing Systems performance and longevity. The engineering team conducts structural 3D modeling and load analysis to verify that roof designs accommodate expected snow loads, wind pressures, and seismic forces throughout the projected service life. Drainage system simulation identifies potential water accumulation zones and optimizes slope configurations to prevent standing water that could compromise seam integrity over decades of service. Material specification advisory services match substrate materials, coating systems, and accessory components to specific environmental conditions and project requirements, ensuring optimal longevity for each unique installation. The company's certifications validate their commitment to quality and environmental responsibility. Recognition as a high-tech enterprise in Shaanxi Province in 2020 confirms innovation leadership. First-level qualification for building curtain walls and third-level qualification for building steel structures demonstrate technical competence. Over twenty registered patents for roofing systems document ongoing research and development. ISO9001 and ISO14000:14001 certifications verify quality management and environmental management systems. SGS guideline compliance ensures products meet international standards. These certifications provide assurance that Metal Standing Seam Roofing Systems from Xi'an Huafeng will deliver the extended service lives property owners expect when making substantial roofing investments.

Maximizing Your Metal Standing Seam Roofing Systems Investment

Achieving maximum longevity from Metal Standing Seam Roofing Systems requires strategic planning from project inception through decades of service. The design phase establishes the foundation for long-term performance through careful consideration of multiple factors. Climate analysis determines appropriate material selection, coating specifications, and insulation requirements. Structural evaluation ensures adequate support for expected loads throughout the projected service life. Drainage design prevents water accumulation that could compromise seam integrity. Expansion joint placement accommodates thermal movement without stressing panel connections. Penetration planning minimizes roof interruptions while ensuring proper flashing details around unavoidable openings. This comprehensive design approach, leveraging expertise from experienced suppliers like Xi'an Huafeng who provide detailed drawing services and processing specifications, establishes the framework for Metal Standing Seam Roofing Systems that will perform reliably for fifty to seventy-five years. The installation phase transforms design intent into physical reality, and execution quality determines whether theoretical longevity becomes actual performance. Professional installers following manufacturer specifications and industry best practices prevent the defects that compromise longevity regardless of material quality. Proper panel handling avoids coating damage that would expose bare metal to corrosion. Correct seaming pressure creates weathertight connections without deforming panels. Accurate flashing installation around penetrations prevents the leak points that account for most premature roof failures. Thorough final inspection and zero-leakage testing before project completion verify that the Metal Standing Seam Roofing Systems installation meets performance expectations. Xi'an Huafeng's comprehensive installation services, including on-site technical guidance, tool verification, safety protocols, and post-installation testing, ensure that projects begin their service lives with optimal conditions for achieving maximum longevity.

-

Long-Term Performance Monitoring

Sustaining Metal Standing Seam Roofing Systems performance throughout multi-decade service lives requires ongoing attention through systematic inspection and maintenance programs. Implementing a structured monitoring approach prevents minor issues from evolving into major problems that could necessitate costly repairs or premature replacement. Annual inspections conducted after severe weather events or seasonal transitions should evaluate several critical aspects. Seam integrity verification confirms that panel connections maintain weathertight seals without separation or distortion. Penetration flashing condition assessment checks that sealants around vent pipes, equipment supports, and roof-mounted accessories remain pliable and effective. Drainage system functionality inspection ensures that gutters, scuppers, and internal drains remain unobstructed. Surface condition evaluation identifies any coating degradation, staining, or localized corrosion requiring attention. Fastener and accessory component inspection confirms that all hardware maintains proper function and shows no signs of deterioration. Documentation of inspection findings and maintenance activities creates valuable historical records that inform long-term facility management decisions. Tracking the condition of your Metal Standing Seam Roofing Systems over time reveals performance trends, validates material selections, and guides budgeting for future maintenance needs. When minor issues are identified and addressed promptly—such as replacing deteriorated sealants, cleaning accumulated debris, or touching up scratched coatings—the incremental cost remains minimal compared to addressing extensive damage from neglect. This proactive maintenance philosophy, combined with the inherent durability of Metal Standing Seam Roofing Systems, enables facility managers to confidently project five to seven decades of reliable protection from their roofing investment.

Conclusion

Metal Standing Seam Roofing Systems deliver exceptional longevity ranging from thirty to seventy-five years depending on material selection, environmental conditions, installation quality, and maintenance practices. This extended service life provides substantial return on investment through reduced replacement frequency, minimal maintenance requirements, and consistent protection throughout decades of operation.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as your trusted China Metal Standing Seam Roofing Systems factory, China Metal Standing Seam Roofing Systems supplier, and China Metal Standing Seam Roofing Systems manufacturer offering China Metal Standing Seam Roofing Systems wholesale solutions. As a professional company established in 2018, we specialize in comprehensive design, production, sales, and construction services for metal roofing systems, building curtain wall systems, and steel structure enclosure systems. Our recognition as a high-tech enterprise in Shaanxi Province, combined with first-level qualification for building curtain walls and third-level qualification for building steel structures, validates our technical expertise.

Our facilities include a 200,000-square-meter raw material production plant in Anhui, plus processing plants in Hangzhou and Xi'an featuring seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, and over forty specialized machines. We deliver Metal Standing Seam Roofing Systems for sale with competitive Metal Standing Seam Roofing Systems price and High Quality Metal Standing Seam Roofing Systems meeting ISO9001, ISO14000:14001, and SGS standards. Our thirty-year warranty, customization capabilities for color, pattern, and design, fifteen to twenty-day delivery times, and one-stop procurement from raw materials to accessories ensure your project success. With over twenty patent certificates and successful installations at prestigious projects including Xiongan Station, Xi'an International Convention and Exhibition Center, and multiple cultural centers, we bring proven expertise to every engagement. Contact us at huafeng@hfmetalroof.com to discover how our engineering design experience, advanced manufacturing capabilities, and comprehensive service approach can maximize the longevity and performance of your Metal Standing Seam Roofing Systems investment.

References

1. Metal Construction Association. "Service Life Assessment of Low-Slope Metal Roof Systems: Field Performance Analysis of Standing Seam Installations."

2. National Roofing Contractors Association. "Metal Roofing Longevity and Performance Standards: Technical Guidelines for Standing Seam Systems."

3. American Society for Testing and Materials. "ASTM Standards for Metal Roofing Materials: Coating Performance and Durability Testing Protocols."

4. Building Research Establishment. "Metal Roofing Service Life Prediction: Environmental Impact Assessment and Maintenance Best Practices."