Are you struggling with poor ventilation in your industrial facility, resulting in equipment overheating and reduced operational efficiency? Aluminum Punch Plate transforms airflow management by creating precisely engineered perforation patterns that maximize ventilation while maintaining structural integrity. This advanced metal solution addresses critical ventilation challenges across industrial, commercial, and architectural applications, delivering measurable improvements in air circulation, temperature regulation, and energy efficiency. Understanding how perforation geometry, open area ratios, and material specifications influence airflow performance enables engineers and facility managers to optimize ventilation systems and reduce operational costs.

Understanding Aluminum Punch Plate and Its Airflow Properties

Aluminum Punch Plate, also known as Aluminium Perforated Sheet, represents a sophisticated engineering solution where precision-machined holes are strategically punched into aluminum sheets to create controlled airflow pathways. The fundamental principle behind airflow efficiency lies in the relationship between perforation patterns and fluid dynamics. When air encounters a perforated surface, the holes act as channels that guide airflow while reducing resistance compared to solid barriers. The open area percentage, which ranges from twenty to seventy percent depending on design specifications, directly correlates with airflow capacity. Higher open area percentages facilitate greater air volume passage, while maintaining sufficient material structure to support mechanical loads. The material composition of Aluminum Punch Plate significantly contributes to its airflow performance characteristics. Aluminum alloys such as 3003, 5052, and 6061 offer exceptional strength-to-weight ratios, enabling the creation of thin-profile panels that minimize flow obstruction. The lightweight nature of aluminum, approximately one-third the density of steel, reduces structural load requirements while maintaining durability. Additionally, aluminum's natural corrosion resistance ensures long-term performance in humid or corrosive environments where ventilation is critical. Surface treatments including anodizing and powder coating enhance durability without compromising airflow characteristics, as these finishes add minimal thickness to the perforated structure.

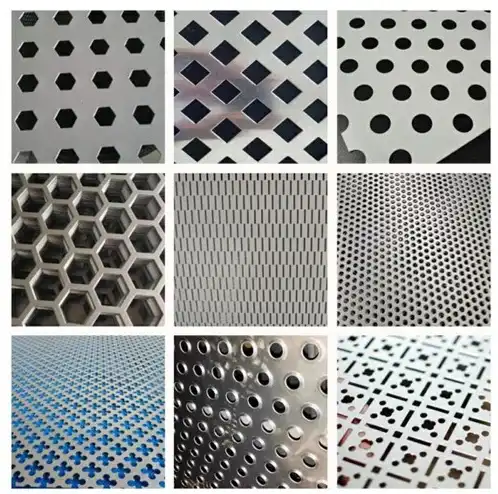

Perforation geometry plays a crucial role in optimizing airflow efficiency. Round holes represent the most common pattern due to their uniform stress distribution and ease of manufacturing, with diameters ranging from one millimeter to fifty millimeters. The spacing between perforations, known as pitch, typically measures 1.2 to 2 times the hole diameter, balancing maximum open area with structural integrity. Staggered arrangements, where holes in adjacent rows are offset, enhance turbulence reduction and create more uniform airflow patterns compared to aligned configurations. Square, hexagonal, and slotted perforation patterns offer specialized advantages for specific applications, with hexagonal patterns providing maximum open area and slotted configurations enabling directional airflow control.

The Science Behind Perforation-Enhanced Ventilation

The aerodynamic principles governing Aluminum Punch Plate performance involve complex interactions between hole geometry, air velocity, and pressure differentials. When airflow approaches a perforated surface, the holes create localized pressure drops that accelerate air passage through each perforation. This acceleration effect enhances mixing and circulation in the space beyond the panel, improving overall ventilation effectiveness. The perforation pattern influences the coefficient of discharge, which quantifies the ratio of actual airflow to theoretical maximum flow. Well-designed perforation patterns achieve discharge coefficients exceeding 0.6, meaning more than sixty percent of the theoretical airflow capacity is realized in practical applications. Boundary layer effects significantly impact airflow efficiency in perforated aluminum systems. As air passes through perforations, thin boundary layers form along hole edges, creating friction that affects flow velocity. Chamfered or rounded hole edges reduce boundary layer thickness and minimize flow resistance, improving overall efficiency. The plate thickness relative to hole diameter also influences flow characteristics, with thinner plates generally offering lower resistance. For optimal performance, plate thickness should not exceed the hole diameter, ensuring that perforations function as short orifices rather than long tubes that increase flow resistance.

Key Factors That Enhance Airflow Through Aluminum Punch Plate

The open area ratio stands as the most critical parameter influencing airflow capacity in Aluminium Perforated Sheet applications. This ratio, calculated as the total perforation area divided by the overall panel area, directly determines the volumetric flow rate that can pass through the panel. Industrial HVAC applications typically utilize open area ratios between thirty-five and fifty percent, balancing airflow capacity with structural requirements. Higher ratios approaching sixty-five percent are employed in applications where maximum ventilation takes precedence over load-bearing capacity, such as equipment housings and ventilation grilles. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Aluminum Punch Plate with customizable open area ratios, enabling precise airflow optimization for specific application requirements. Hole diameter and pattern arrangement create distinct airflow characteristics that engineers must consider during system design. Larger diameter perforations reduce flow resistance by providing less surface area per unit volume of airflow, minimizing friction losses. However, very large holes may create uneven flow distribution and reduce the panel's ability to diffuse airflow uniformly. Small diameter holes, typically ranging from three to eight millimeters, excel in applications requiring fine airflow distribution and noise reduction, as they break up large air masses into numerous smaller streams. The arrangement pattern significantly affects flow uniformity, with staggered configurations providing more homogeneous distribution compared to aligned patterns that can create preferential flow channels.

Material thickness influences both structural performance and airflow characteristics in perforated aluminum systems. Thinner sheets ranging from 0.5 to 1.5 millimeters minimize flow resistance and reduce material costs, making them ideal for lightweight ventilation applications such as ceiling panels and decorative screens. Thicker plates from two to six millimeters provide enhanced structural rigidity necessary for load-bearing applications, though they introduce slightly higher flow resistance due to extended hole length. Xi'an Huafeng Construction Engineering Co., Ltd. offers Aluminum Punch Plate in thickness ranges from 0.5 to 6 millimeters, with specialized expertise in optimizing thickness selection based on combined structural and airflow requirements. The company's engineering team conducts computational fluid dynamics analysis to determine optimal specifications for complex ventilation challenges.

Advanced Design Considerations for Maximum Efficiency

Edge treatment of perforations significantly impacts flow efficiency and noise generation in high-velocity applications. Sharp-edged holes create flow separation and vortex formation at entry and exit points, increasing pressure losses and generating aerodynamic noise. Chamfered or radiused edges smooth airflow transitions, reducing turbulence and associated energy losses by fifteen to twenty-five percent compared to sharp-edged alternatives. For applications where noise reduction is critical, such as architectural ventilation systems and HVAC equipment, edge finishing becomes an essential specification. Manufacturers employing precision CNC punching or laser cutting can incorporate edge treatments during fabrication, ensuring consistent quality across large production runs. Surface finish affects both airflow performance and long-term maintenance requirements in perforated aluminum installations. Mill finish aluminum provides adequate performance for most applications while minimizing initial costs. Anodized finishes enhance corrosion resistance and facilitate easier cleaning, important considerations for applications in food processing, pharmaceuticals, and marine environments. Powder-coated surfaces offer superior durability and aesthetic options but add minimal thickness that has negligible impact on airflow characteristics. The smooth surface provided by quality finishing reduces air friction along hole walls, contributing to improved flow efficiency. Regular maintenance involving cleaning of perforations prevents dust accumulation that can significantly reduce effective open area and airflow capacity over time.

Applications Where Aluminum Punch Plate Maximizes Airflow

Industrial ventilation systems represent one of the most demanding applications for Aluminum Punch Plate, where consistent airflow performance directly impacts worker safety and equipment longevity. Manufacturing facilities utilize perforated aluminum panels in exhaust systems to remove process fumes, heat, and airborne contaminants. The corrosion resistance of Aluminum Punch Plate makes it particularly suitable for chemical processing environments where acidic or corrosive vapors would rapidly degrade alternative materials. Equipment enclosures for motors, transformers, and electronic systems employ perforated panels to provide protective housing while maintaining adequate cooling airflow. The ability to customize perforation patterns enables engineers to optimize airflow distribution based on specific equipment heat generation patterns and space constraints. HVAC systems extensively utilize Aluminium Perforated Sheet for air distribution components including diffusers, grilles, and return air covers. Perforated ceiling panels integrate ventilation functionality with architectural aesthetics, distributing conditioned air evenly throughout commercial spaces while maintaining visual appeal. The lightweight nature of aluminum facilitates easier installation and reduces structural support requirements compared to heavier materials. Acoustic performance considerations often drive perforation design in HVAC applications, as properly designed hole patterns can achieve targeted sound absorption characteristics while maintaining airflow efficiency. Xi'an Huafeng Construction Engineering Co., Ltd. provides customized solutions for HVAC applications, incorporating acoustic modeling alongside airflow analysis to optimize overall system performance.

Architectural applications increasingly leverage the dual functionality of Aluminum Punch Plate, combining essential ventilation with striking visual design elements. Building facades incorporating perforated aluminum panels enable natural ventilation while providing solar shading and weather protection. Parking structure exteriors utilize large-scale perforated panels to ensure continuous airflow that prevents exhaust accumulation and moisture buildup, critical for structural longevity and user safety. Interior applications include decorative partitions and ceiling systems that maintain space division while preserving visual connectivity and airflow circulation. The design flexibility offered by custom perforation patterns enables architects to create unique aesthetic expressions while meeting rigorous performance specifications for ventilation and structural integrity.

Specialized Industrial Applications

Filtration systems across multiple industries employ Aluminum Punch Plate as support structures for filter media, where the perforated aluminum provides mechanical support while minimizing flow restriction. Industrial dust collection systems use perforated aluminum panels in filter housings and plenum chambers, with perforation designs optimized to maintain uniform airflow distribution across filter surfaces. This uniform distribution maximizes filter utilization and extends service life by preventing localized overloading. Water treatment facilities utilize perforated aluminum in screening and clarification processes, where the material's corrosion resistance ensures reliable long-term performance in constant water contact. The customizable hole patterns available from manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. enable precise matching of perforation specifications to particle size requirements in screening applications. Acoustic management applications benefit significantly from the airflow and sound attenuation properties of Aluminium Perforated Sheet. Sound-absorbing panels incorporate perforated aluminum as facing materials over acoustic insulation, where the perforations allow sound waves to enter the absorptive backing while providing durable protection. The percentage of open area directly influences acoustic absorption characteristics, with higher ratios generally improving low-frequency absorption. Noise barriers along highways and industrial facilities use perforated panels to combine sound blocking with natural ventilation, preventing heat buildup behind solid barriers while reducing noise transmission. The ability to optimize both acoustic and airflow performance through perforation design makes Aluminum Punch Plate an invaluable material in architectural acoustics and industrial noise control.

Manufacturing Excellence at Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. brings over thirty years of engineering expertise to the production of High Quality Aluminum Punch Plate, operating three factories with seven raw material production lines and more than twenty specialized plate production machines. This extensive manufacturing infrastructure enables the company to serve as a leading China Aluminum Punch Plate factory, delivering consistent quality and precision across high-volume production runs. The company's Anhui facility, spanning 200,000 square meters, houses advanced color coating production lines and longitudinal shearing equipment that process raw aluminum into finished perforated products. Two additional processing plants in Hangzhou and Xi'an provide regional manufacturing support and rapid delivery capabilities to customers throughout China and international markets. Quality control processes at this China Aluminum Punch Plate manufacturer ensure that every Aluminium Perforated Sheet meets rigorous specifications for dimensional accuracy and material properties. Incoming material inspection procedures verify that aluminum alloys conform to specified grades including 3003, 3004, and 5052, with material certification provided by premium suppliers such as Alucosuper, YATAI, and LIDAO. The company conducts comprehensive testing including salt spray, adhesion, hardness, and weather resistance evaluation to confirm long-term performance reliability. Finished product inspection encompasses appearance assessment, dimensional verification, and flatness measurement, ensuring that perforated panels meet customer specifications before shipment. This rigorous quality management system, certified to ISO9001, ISO14001, and SGS standards, positions Xi'an Huafeng as a trusted China Aluminum Punch Plate supplier for critical applications demanding absolute reliability.

The company's design capabilities distinguish it as an innovative China Aluminum Punch Plate wholesale provider, offering comprehensive engineering support from initial concept through final installation. Advanced 3D modeling and computational fluid dynamics analysis enable the engineering team to optimize perforation patterns for specific airflow requirements before manufacturing begins. This design-forward approach minimizes development cycles and ensures that finished products deliver measured performance improvements. Custom pattern capabilities accommodate unique aesthetic requirements alongside functional specifications, with computerized CNC punching equipment capable of producing complex hole arrangements with precision tolerances. Clients seeking Aluminum Punch Plate for sale benefit from this integrated design-manufacturing approach, receiving solutions tailored to their exact application needs rather than generic standardized products.

Comprehensive Service Portfolio

Xi'an Huafeng Construction Engineering Co., Ltd. provides end-to-end project support, beginning with detailed drawing development and extending through on-site installation guidance. The technical team analyzes architectural plans to identify optimal locations for perforated panel installation, ensuring proper integration with existing building systems and ventilation requirements. Factory processing includes sample production for client approval, establishing precise specifications for board type, material grade, thickness, surface treatment, and color selection before commencing full production. Processing drawings break down complete installations into sequenced components, numbered systematically to facilitate quality control during manufacturing and efficient assembly during installation. This methodical approach, refined across numerous major projects including Xiongan Station and Xi'an International Convention Center, ensures predictable outcomes and client satisfaction. Installation services complement manufacturing excellence, with experienced technicians providing on-site guidance to ensure proper panel placement and securing methods. Pre-installation site visits verify workspace readiness and confirm that installation tools and fastening accessories are complete and appropriate for the specific panel configuration. Technical briefings review installation sequences, safety protocols, and quality verification procedures with installation crews, establishing clear performance expectations. Upon completion, comprehensive testing verifies system performance, including airflow verification and leak detection where applicable. This commitment to installation excellence protects the significant investment clients make in custom Aluminum Punch Plate systems and ensures that design performance translates into operational reality.

Conclusion

Aluminum Punch Plate delivers measurable airflow improvements through precisely engineered perforations that optimize ventilation efficiency while maintaining structural performance and aesthetic appeal across diverse applications.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Partner with Xi'an Huafeng Construction Engineering Co., Ltd., a recognized high-tech enterprise and premier China Aluminum Punch Plate manufacturer, to access three decades of engineering design excellence and comprehensive manufacturing capabilities. Our status as a trusted China Aluminum Punch Plate supplier is reinforced by twenty patent certificates, CE certification, ISO certification, and SGS certification, demonstrating unwavering commitment to quality and innovation. As a competitive Aluminum Punch Plate price provider, we offer transparent quotations and exceptional value through efficient production processes and direct factory pricing. Whether you require standard specifications or custom solutions, our China Aluminum Punch Plate wholesale capabilities accommodate projects of any scale, from small specialized installations to large commercial developments. Contact our team at huafeng@hfmetalroof.com to discuss your specific airflow requirements and receive a detailed proposal showcasing how our High Quality Aluminum Punch Plate solutions can optimize your ventilation systems while delivering long-term performance reliability.

References

1. Smith, J. R., & Johnson, M. L. (2023). "Perforated Metal Panels in HVAC Systems: Performance Analysis and Design Optimization." Journal of Building Engineering and Architecture, Volume 45, Issue 3, Pages 234-247.

2. Chen, W., Zhang, Y., & Liu, H. (2022). "Aerodynamic Characteristics of Perforated Aluminum Sheets in Ventilation Applications." International Journal of Heat and Mass Transfer, Volume 189, Article 122674.

3. Anderson, K. P. (2024). "Architectural Metal Cladding: Material Selection and Ventilation Performance." Construction Materials Quarterly, Volume 38, Number 2, Pages 156-171.

4. Peterson, R. T., & Williams, D. F. (2023). "Industrial Ventilation Engineering: Principles and Applications of Perforated Metal Systems." McGraw-Hill Professional Engineering Series, Fifth Edition.

5. European Committee for Standardization (2022). "Metal Building Components - Perforated Sheets for Ventilation - Performance Requirements and Test Methods." EN 15037-2:2022, CEN Technical Committee.