Picture this scenario: You're designing a commercial building that needs to meet strict sustainability certifications, but you're facing budget constraints and tight deadlines. Traditional roofing materials offer either durability or affordability, rarely both. Meanwhile, your project requires a solution that delivers exceptional weather resistance, minimal maintenance, and genuine environmental credentials. The Corrugated Galvanized Metal Panel emerges as the answer to this modern construction dilemma, bridging the gap between sustainable building practices and practical performance requirements.

Environmental Advantages of Corrugated Galvanized Metal Panels in Contemporary Architecture

Modern construction increasingly prioritizes environmental responsibility alongside aesthetic appeal and structural integrity. The Corrugated Galvanized Metal Panel stands at the forefront of this sustainable building revolution, offering architects and developers a material that reduces environmental impact throughout its entire lifecycle. These panels represent more than just a roofing or cladding solution; they embody a commitment to responsible resource management and long-term ecological thinking. The sustainability credentials of corrugated galvanized metal begin with its composition and manufacturing process. Most high-quality panels contain significant recycled content, with some manufacturers utilizing steel that comprises up to seventy percent recycled materials. This substantial recycled content dramatically reduces the energy consumption and carbon emissions associated with raw material extraction and processing. When you specify corrugated galvanized metal for your project, you're actively participating in the circular economy, giving new life to materials that might otherwise occupy landfill space.

Beyond its recycled origins, the Corrugated Galvanized Metal Panel offers complete recyclability at the end of its service life. Unlike composite materials or treated wood that become waste products after removal, metal panels can be melted down and reformed into new steel products without any loss of quality or structural properties. This closed-loop recyclability means that today's roofing panel could become tomorrow's automotive component or structural beam. The environmental mathematics are compelling when you consider that recycling steel saves approximately seventy-four percent of the energy required to produce new steel from virgin ore. The longevity of corrugated galvanized metal further amplifies its environmental benefits. While traditional roofing materials like asphalt shingles require replacement every fifteen to twenty years, properly installed Corrugated Galvanized Metal Panels routinely last fifty years or more. This extended lifespan translates directly into reduced resource consumption over time. Fewer replacement cycles mean less manufacturing energy, reduced transportation emissions, and decreased construction waste. When you multiply these savings across thousands of buildings, the cumulative environmental impact becomes substantial.

Energy efficiency represents another critical sustainability dimension where corrugated galvanized metal excels. Modern coating technologies, including PE, HDP, and PVDF finishes, enhance the panels' ability to reflect solar radiation rather than absorb it. This reflective property significantly reduces heat transfer into building interiors, lowering cooling loads during warm months. Buildings clad with properly coated Corrugated Galvanized Metal Panels can experience cooling cost reductions of up to twenty-five percent compared to structures using heat-absorbing roofing materials. These energy savings compound annually, reducing both operational costs and carbon emissions throughout the building's lifecycle. The manufacturing efficiency of corrugated galvanized metal also contributes to its sustainable profile. Modern roll-forming production lines, like those operated by Xi'an Huafeng Construction Engineering Co., Ltd., generate minimal waste compared to other building material production processes. The continuous forming process creates panels to exact specifications, with cutting waste typically limited to less than three percent of total material input. Advanced production facilities featuring seven color coating lines and multiple shearing systems ensure consistent quality while maximizing material utilization. Water conservation represents an often-overlooked sustainability benefit of metal roofing systems. The Corrugated Galvanized Metal Panel's inherent design facilitates rainwater harvesting, allowing building owners to capture and utilize precipitation for irrigation, cooling systems, or non-potable water applications. The smooth, non-porous surface of galvanized metal doesn't leach chemicals or biological contaminants into collected water, making it an ideal material for sustainable water management strategies. This capability becomes increasingly valuable as water scarcity concerns intensify globally.

Versatile Applications Across Modern Building Projects

The adaptability of Corrugated Galvanized Metal Panel extends far beyond traditional roofing applications, positioning it as a comprehensive solution for contemporary architectural challenges. Modern designers recognize that sustainability and versatility are inseparable qualities in effective building materials. These panels respond to this demand by offering performance characteristics that serve multiple building envelope functions while maintaining consistent quality and appearance across diverse applications.

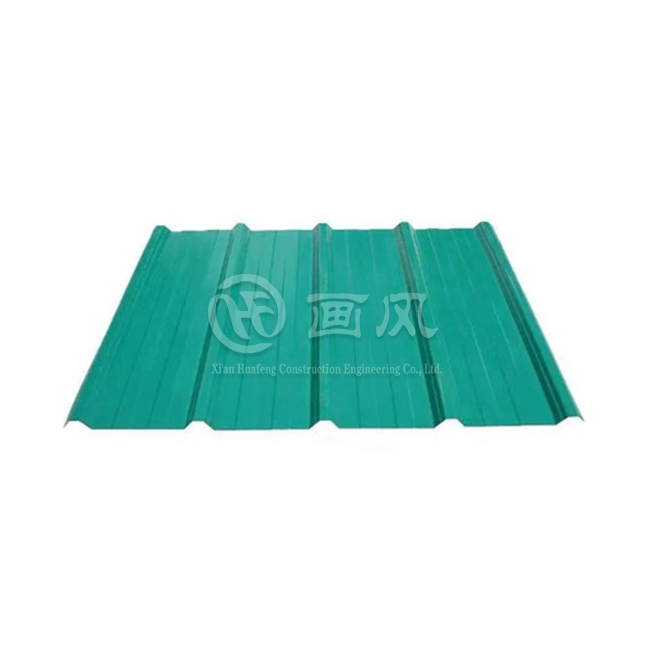

Industrial and Commercial Roofing Systems

Industrial facilities and commercial buildings present unique challenges that corrugated galvanized metal addresses with exceptional effectiveness. Large-span roof structures common in warehouses, manufacturing plants, and distribution centers require materials that combine light weight with structural strength. The Corrugated Galvanized Metal Panel's wave pattern geometry provides inherent rigidity that allows for extended spans between support members, reducing structural framing requirements and construction costs. This structural efficiency becomes particularly valuable in retrofitting existing buildings where load-bearing capacity may be limited. The panels' resistance to chemical exposure, moisture penetration, and thermal cycling makes them ideal for industrial environments where harsh conditions are routine. Factories producing chemicals, food products, or metal goods benefit from roofing that withstands corrosive atmospheres without degradation. Xi'an Huafeng Construction Engineering Co., Ltd.'s panels feature hot-dip galvanizing with coating weights ranging from Z80 to Z275 grams per square meter, providing exceptional barrier protection against environmental corrosion. This robust protection extends service life even in challenging industrial applications, reducing lifecycle costs and maintenance interruptions. Commercial retail centers, office complexes, and institutional buildings increasingly specify corrugated galvanized metal for both functional and aesthetic reasons. The material's clean lines and contemporary appearance complement modern architectural styles while delivering the practical performance commercial property owners demand. Advanced coating options, including PVDF and HDP finishes, provide color stability that maintains visual appeal for decades without fading or chalking. This enduring appearance protects property values and reduces the need for costly aesthetic refreshes.

Agricultural and Rural Building Solutions

Agricultural applications were among the original uses for corrugated metal, and modern versions continue this tradition while offering significantly enhanced performance. Barn roofing, equipment storage buildings, and livestock shelters all benefit from the Corrugated Galvanized Metal Panel's combination of weather resistance, durability, and cost-effectiveness. The material's ability to shed snow and rain quickly prevents moisture accumulation that could damage stored crops, equipment, or structural components. Rural building projects often face budget constraints that make value engineering critical. Corrugated galvanized metal provides an attractive cost-per-square-meter ratio while delivering superior longevity compared to alternative materials. The lightweight nature of these panels, typically ranging from 0.3 to 0.6 millimeters in common applications, reduces both structural requirements and installation labor costs. This efficiency makes large agricultural buildings economically feasible, supporting agricultural operations that require substantial covered space. Modern farming operations increasingly incorporate sustainable practices, and building material choices reflect these values. The recyclable nature of corrugated galvanized metal aligns with agricultural sustainability initiatives, while its long service life reduces the frequency of building updates. Many agricultural buildings remain in service for multiple generations, and choosing materials that age gracefully without extensive maintenance supports this multi-decade utility.

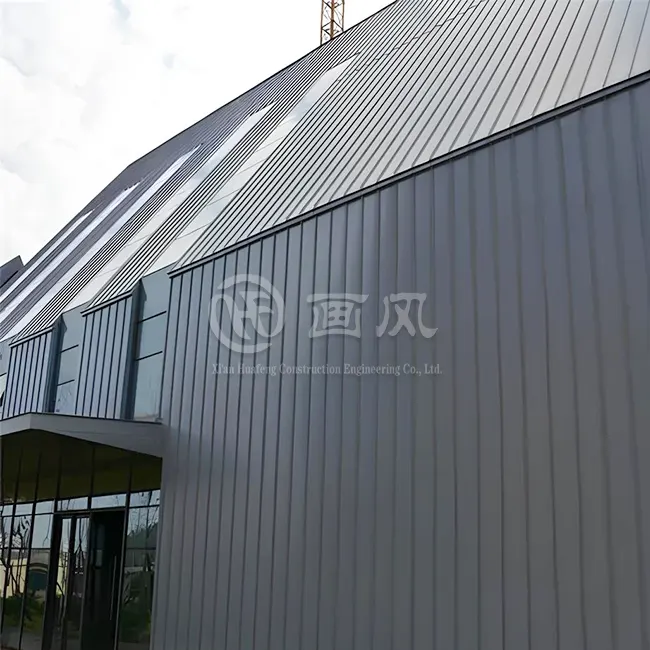

Residential and Light Commercial Applications

Residential architecture has embraced corrugated galvanized metal as homeowners and builders recognize its unique aesthetic appeal combined with practical benefits. The material transcends its industrial heritage to serve contemporary, farmhouse, and even traditional residential styles. Standing seam variations and careful detailing allow corrugated metal to integrate seamlessly with residential design vocabulary while providing superior performance compared to conventional roofing materials. The installation flexibility of Corrugated Galvanized Metal Panels accommodates the complex roof geometries common in residential construction. Panels can be custom-fabricated to exact lengths, minimizing field cutting and ensuring proper overlap at seams. This customization capability, offered by manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. with panels ranging from one to twelve meters in length, streamlines installation and improves weather tightness. Residential applications benefit from this precision, resulting in roofs that perform reliably for decades with minimal maintenance. Light commercial applications, including retail shops, restaurants, and professional offices, increasingly specify corrugated galvanized metal for both primary structures and accent elements. The material adds textural interest and contemporary character while maintaining the practical performance businesses require. Wall cladding applications using corrugated metal create distinctive facades that help establishments stand out in competitive commercial environments. The variety of available finishes and profiles allows designers to achieve specific aesthetic goals while maintaining material consistency across roofing and wall applications.

Technical Specifications and Performance Characteristics

Understanding the technical properties of Corrugated Galvanized Metal Panel enables informed specification decisions that optimize performance for specific applications. The material's engineering characteristics derive from both its base metal composition and the corrugation geometry that provides structural efficiency. Modern manufacturing processes ensure consistent properties that designers can confidently incorporate into structural calculations and performance predictions.

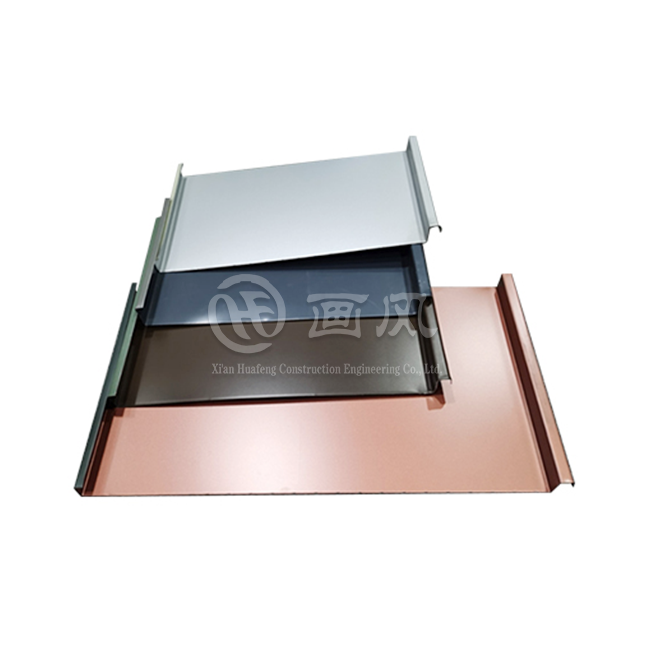

Material Composition and Coating Systems

High-quality corrugated galvanized metal begins with low-carbon steel substrates, typically Q235 or SGCC grades, selected for their combination of formability, strength, and weldability. These base materials provide the fundamental structural properties while accepting the galvanizing process that imparts corrosion resistance. The steel's tensile strength typically exceeds 300 MPa, with yield strength above 240 MPa and elongation of at least fifteen percent, ensuring adequate ductility for forming operations and installed performance. The galvanizing process applies a metallurgically bonded zinc coating that serves as both a barrier and sacrificial protection against corrosion. Hot-dip galvanizing creates multiple zinc-iron alloy layers that anchor the coating securely to the steel substrate. Standard galvanizing weights range from Z80 to Z275 grams per square meter, with heavier coatings specified for aggressive environments or extended service life requirements. This zinc coating provides decades of maintenance-free corrosion protection even in challenging coastal or industrial atmospheres. Additional organic coatings enhance both appearance and performance beyond what galvanizing alone provides. PE (polyester) coatings offer economical color options with good general-purpose protection. HDP (high-durability polyester) formulations deliver enhanced UV resistance and color retention suitable for most architectural applications. PVDF (polyvinylidene fluoride) coatings represent the premium choice, offering exceptional weathering resistance, color stability, and dirt resistance for projects demanding maximum long-term appearance retention. Xi'an Huafeng Construction Engineering Co., Ltd. offers all these coating options with thicknesses from 0.12 to 1.5 millimeters and widths from 600 to 1200 millimeters, allowing precise specification for each project's requirements.

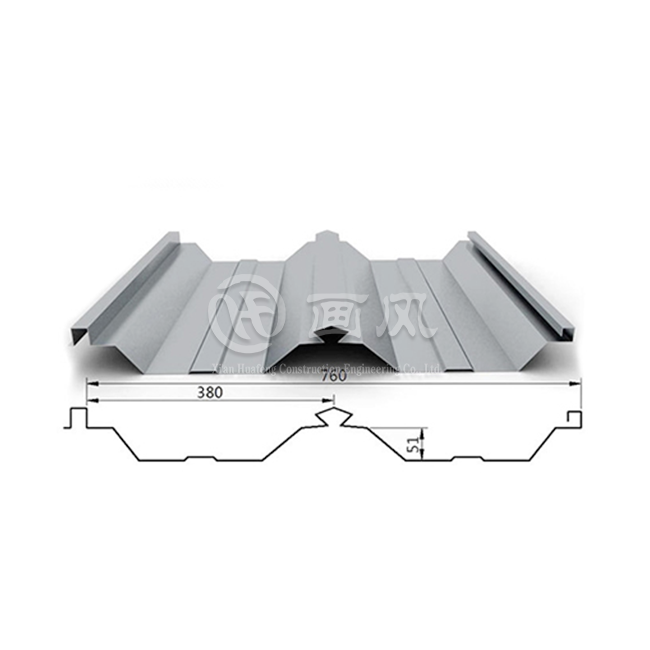

Structural Performance and Load Resistance

The corrugation geometry transforms thin metal sheets into structural panels capable of spanning significant distances and resisting substantial loads. The wave pattern creates a beam effect, with alternating peaks and valleys functioning as compression and tension flanges separated by web sections. This geometry provides moment of inertia values far exceeding those of flat sheets with equivalent material weight, enabling efficient structural performance. Common corrugation profiles include wave heights from eight to eighty millimeters, with twenty-five and thirty-five millimeter heights being most prevalent in architectural applications. Wave spacing typically ranges from sixty to three hundred millimeters, with seventy-six and one hundred thirty millimeter spacings common. These dimensions balance structural efficiency with aesthetic considerations and material economy. Deeper corrugations provide greater spanning capability but may appear too industrial for some architectural contexts, while shallower profiles offer subtler texture with reduced spanning capacity. Load resistance testing demonstrates that properly installed Corrugated Galvanized Metal Panels easily meet or exceed structural code requirements for roofing and wall applications. Wind uplift resistance, critical for roof systems, depends on attachment spacing and edge detailing as well as panel properties. Snow load capacity relates to panel spanning capability and deflection limits. Modern design software allows engineers to model specific panel profiles and support configurations, ensuring adequate performance margins for project-specific loading conditions while optimizing material efficiency.

Installation Methods and Quality Assurance

Professional installation practices maximize the performance and longevity of corrugated galvanized metal systems. Xi'an Huafeng Construction Engineering Co., Ltd. exemplifies comprehensive installation support through their documented procedures covering site preparation, panel handling, fastener selection, and quality verification. Their approach includes pre-installation site assessment, where technicians verify substrate conditions, confirm tool readiness, and review safety protocols before work begins. Panel attachment methodology significantly influences system performance. Fasteners must penetrate at panel crests to avoid creating water entry points, with spacing calculated to resist design loads while avoiding panel distortion. Galvanized or stainless steel fasteners with neoprene washers ensure compatible corrosion resistance and reliable sealing. Proper fastener torque prevents both under-tightening that compromises weather resistance and over-tightening that dimples panels or crushes washers. Quality control throughout installation verifies that theoretical design performance translates into built reality. This includes confirming proper panel overlap at seams, verifying adequate edge attachment, and inspecting flashing details at penetrations and terminations. Final testing, such as water tests conducted upon completion, validates that the assembled system performs as intended. Xi'an Huafeng's practice of zero-leakage verification before customer acceptance demonstrates the quality assurance standards appropriate for professional metal roofing installation.

Long-Term Value and Lifecycle Cost Analysis

Evaluating building materials purely on initial cost overlooks the total economic picture that determines true project value. The Corrugated Galvanized Metal Panel demonstrates its economic advantages most clearly through lifecycle cost analysis that accounts for longevity, maintenance requirements, energy impacts, and end-of-service considerations. This comprehensive financial perspective reveals why specification professionals increasingly recommend metal panels despite sometimes higher upfront costs compared to alternatives. The extended service life of corrugated galvanized metal fundamentally alters the economic calculation. A properly installed system routinely provides fifty years of reliable performance, with many installations exceeding this expectation. During this service period, alternative roofing materials may require two or three complete replacements, each involving material costs, labor expenses, building disruption, and waste disposal fees. When you amortize the initial investment in Corrugated Galvanized Metal Panel over its actual service life, the annualized cost often proves substantially lower than materials with shorter lifespans. Maintenance requirements directly impact lifecycle costs through both direct expenses and indirect costs associated with building access, occupant disruption, and business interruption. Corrugated galvanized metal's inherent durability and corrosion resistance minimize maintenance needs compared to materials requiring periodic sealing, painting, or component replacement. Routine maintenance typically involves only periodic inspection and debris removal, activities requiring minimal time and expense. This maintenance efficiency proves particularly valuable for large commercial or industrial buildings where access costs and weather exposure make maintenance operations expensive and logistically challenging.

Energy cost implications extend throughout the building's operational life, making energy performance a significant lifecycle cost factor. The reflective properties of coated Corrugated Galvanized Metal Panels reduce cooling loads, generating annual energy savings that compound over decades. For a typical commercial building, these savings can accumulate to tens of thousands of dollars over the roof's service life. Additionally, many jurisdictions offer tax incentives or expedited permitting for buildings meeting energy efficiency standards, providing further financial benefits for projects specifying high-performance materials like advanced-coated metal panels. Insurance considerations may also favor buildings with metal roofing systems. Many insurers recognize that non-combustible roofing materials reduce fire risk, potentially qualifying property owners for premium reductions. The wind and hail resistance of corrugated metal similarly reduces damage risk during severe weather events, further supporting favorable insurance treatment. While individual policy terms vary, these potential insurance benefits contribute to the overall financial case for metal roofing specification. Resale value and property marketability benefit from high-quality, long-lived building systems. Commercial properties with recently installed or well-maintained Corrugated Galvanized Metal Panel roofing command premium values compared to properties requiring near-term roof replacement. The thirty-year warranty offered by quality manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. provides transferable assurance to future owners, enhancing property attractiveness and supporting premium valuations. This value preservation represents an often-overlooked economic benefit of durable building materials.

Conclusion

Sustainable building practices demand materials that deliver environmental responsibility alongside practical performance and economic value. The Corrugated Galvanized Metal Panel meets these requirements through recyclable composition, extended longevity, energy efficiency, and versatile application capability. Modern manufacturing ensures consistent quality while minimizing production waste, and professional installation practices maximize system performance throughout decades of reliable service.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Corrugated Galvanized Metal Panel factory, supplier, and manufacturer offering comprehensive solutions from design through installation. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, Huafeng operates three strategically located facilities: a 200,000-square-meter raw material production plant in Anhui, plus plate and accessories processing plants in Hangzhou and Xi'an. This infrastructure supports seven color coating production lines, ten longitudinal and transverse shearing lines, and over forty specialized machines producing High Quality Corrugated Galvanized Metal Panel products meeting ASTM, DIN, JIS, BS, and GB/T standards.

Our one-stop service encompasses structural 3D modeling, load analysis, drainage system simulation, and material specification advisory during the design phase, followed by precision roll-forming manufacturing with real-time quality control and raw material traceability. Installation services include on-site project management, safety compliance documentation, and zero-leakage verification. With over twenty registered patents, CE, ISO9001, ISO14000:14001, and SGS certifications, plus successful projects including Xiongan Station Commercial Body and Xi'an International Convention and Exhibition Center, Huafeng delivers proven expertise. We offer Corrugated Galvanized Metal Panel for sale with competitive Corrugated Galvanized Metal Panel price, customizable in width (600-1200mm), thickness (0.12-1.5mm), and finishes (PE, HDP, PVDF coating), with 1000-ton monthly capacity, 500㎡ MOQ, and 15-20 day delivery. As a trusted China Corrugated Galvanized Metal Panel wholesale partner to Fortune 500 companies, contact huafeng@hfmetalroof.com to discuss your project requirements and experience comprehensive metal roofing solutions backed by engineering excellence.

References

1. "Sustainable Building Materials in Contemporary Architecture" by Dr. Michael Green, Journal of Green Building Technology, 2023

2. "Lifecycle Assessment of Metal Roofing Systems" by the Metal Construction Association Research Division, Building Science Quarterly, 2024

3. "Corrosion Protection in Galvanized Steel Applications" by Professor Sarah Chen, International Journal of Materials Engineering, 2023

4. "Energy Performance of Reflective Roofing in Commercial Buildings" by the Building Energy Research Institute, ASHRAE Technical Papers, 2024

5. "Recyclability and Circular Economy in Construction Materials" by Dr. James Robertson, Sustainable Construction Journal, 2023