Every winter, commercial property managers face a critical safety dilemma: tons of accumulated snow and ice suddenly releasing from metal roofs, threatening employees, customers, and valuable property below. This dangerous phenomenon, known as roof avalanche, has resulted in countless injuries, damaged vehicles, destroyed landscaping, and costly liability claims. The solution lies in implementing professional metal roofing snowguards—engineered devices that transform how commercial buildings manage winter precipitation while protecting both people and assets.

Understanding Metal Roofing Snowguards for Commercial Applications

Metal roofing snowguards represent sophisticated engineering solutions specifically designed to address the unique challenges commercial buildings face during winter months. These precision-manufactured devices serve as retention systems that control snow and ice movement on sloped metal roofs, preventing catastrophic avalanches while allowing controlled melting and drainage. When winter precipitation accumulates on metal roofing surfaces, the material's smooth finish and thermal conductivity create perfect conditions for sudden snow releases. Commercial facilities—from warehouses and manufacturing plants to retail centers and office complexes—require robust snow guards on standing seam metal roof systems to mitigate these risks effectively. The fundamental principle behind metal roofing snowguards involves creating strategic friction points and physical barriers across the roof surface. Rather than allowing entire snow blankets to slide off simultaneously, these systems break up accumulations into manageable sections that melt gradually. For commercial applications, this controlled release prevents damage to expensive HVAC equipment, loading docks, pedestrian walkways, and parked vehicles. Modern snow guards on standing seam metal roof installations utilize advanced attachment methods that maintain roof integrity while providing exceptional holding strength against substantial snow loads common in commercial environments.

Types of Commercial Metal Roofing Snowguards

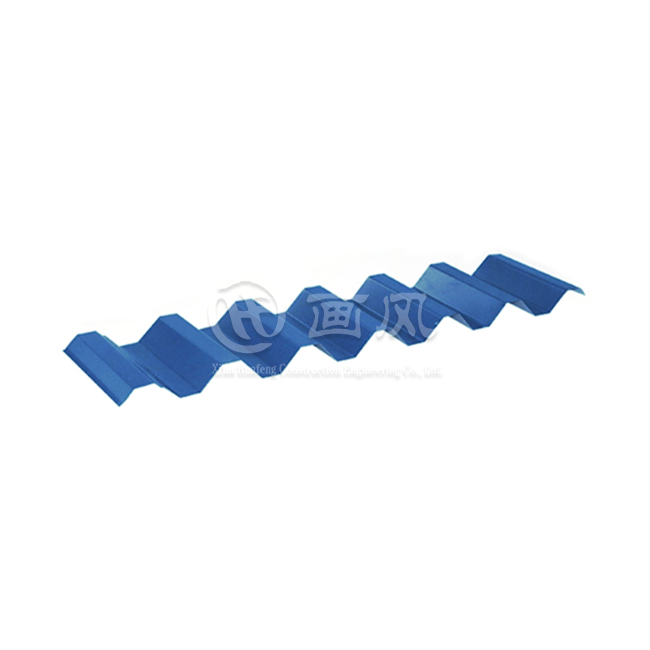

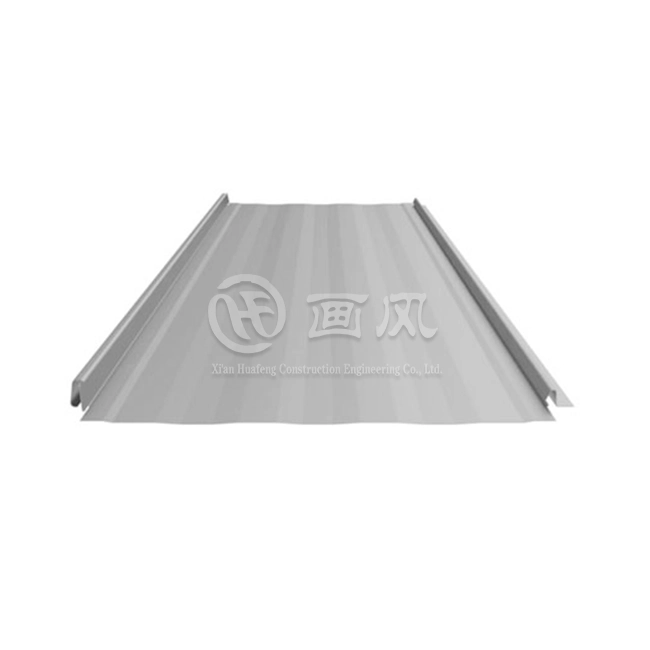

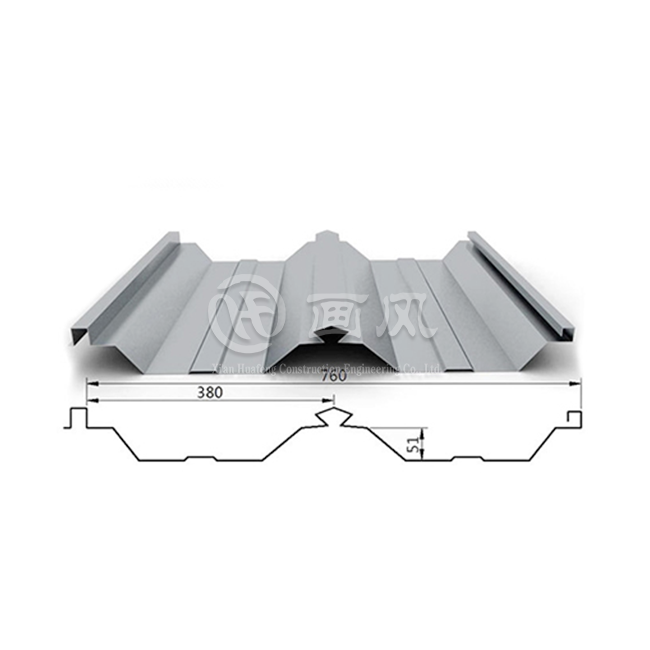

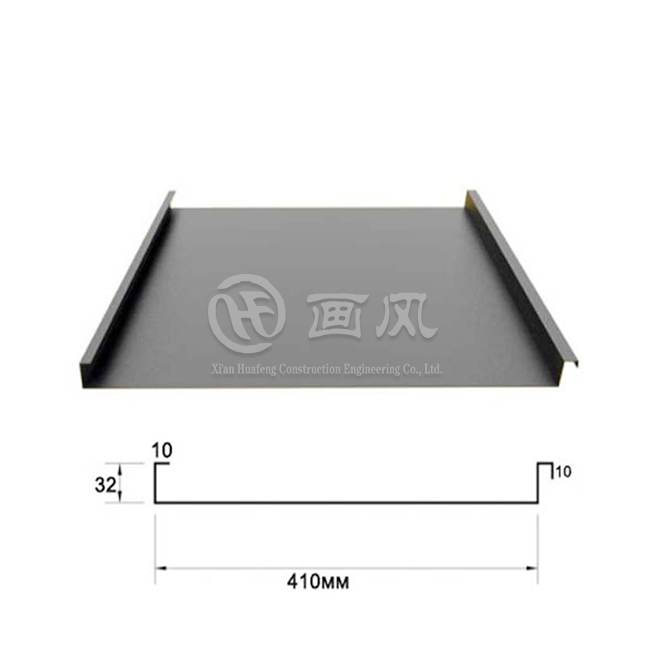

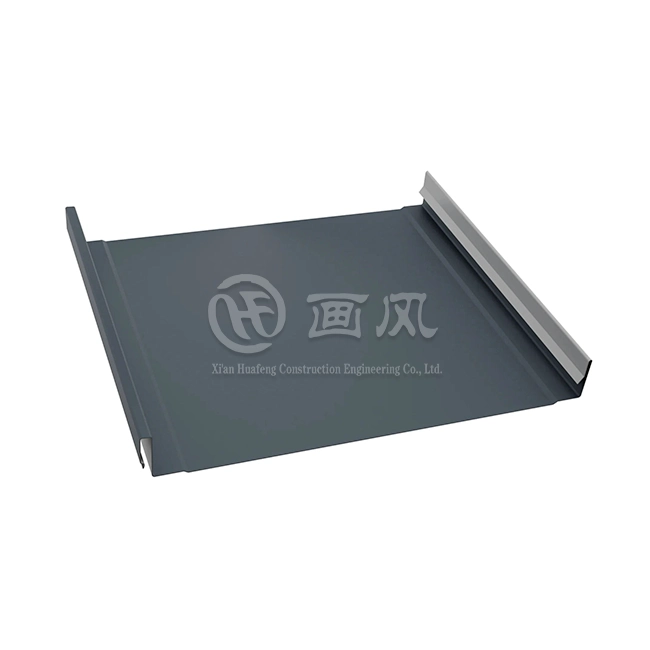

Commercial facilities benefit from several specialized metal roofing snowguards configurations, each engineered for specific roof profiles and snow load requirements. Pad-style snow guards, manufactured from industrial-grade polycarbonate or metal alloys, attach directly to roof surfaces in calculated patterns to create distributed resistance points. These compact units excel in applications where aesthetic considerations matter, as they maintain relatively low profiles while delivering substantial retention capabilities. For standing seam metal roofs, clamp-style snow guards on standing seam metal roof systems offer non-penetrating attachment solutions that preserve waterproofing integrity—a critical consideration for commercial property managers concerned about warranty compliance and long-term roof performance. Fence-style or rail systems represent another category of metal roofing snowguards particularly suited to heavy commercial snow loads. These continuous barrier installations feature horizontal rails supported by vertical brackets, creating formidable retention systems capable of managing substantial accumulations. Commercial projects often combine multiple snow guard types, deploying pad-style units across upper roof sections while installing rail systems near vulnerable eaves and entry points. This hybrid approach optimizes protection while managing installation costs effectively. Materials selection for commercial metal roofing snowguards typically involves aluminum alloy, stainless steel, or magnesium-aluminum-zinc sheet compositions—each offering specific advantages in terms of strength-to-weight ratios, corrosion resistance, and thermal expansion compatibility with underlying roof panels.

Load Calculation and Placement Strategy

Professional implementation of metal roofing snowguards for commercial buildings demands rigorous engineering analysis rather than arbitrary placement patterns. Load calculations must account for multiple variables: local snow density, roof pitch angle, panel length, building orientation relative to prevailing winds, and potential drift accumulation patterns. Commercial facilities in high-snowfall regions require significantly denser snow guard spacing compared to moderate climate installations. Engineers utilize specialized software to model snow behavior on specific roof configurations, determining optimal snow guards on standing seam metal roof layouts that provide adequate retention without over-engineering the system. The placement strategy for commercial metal roofing snowguards typically employs staggered row patterns that distribute resistance forces across the roof structure. Lower rows near eaves bear the greatest stress as gravity pulls accumulated snow downward, necessitating closer spacing and potentially stronger attachment points. Upper sections may utilize wider spacing since they primarily serve to break up snow movement rather than support full gravitational loads. Valleys, transitions between roof planes, and areas above critical infrastructure like transformers or emergency exits receive special attention during layout design. Professional installation teams verify substrate conditions, ensuring adequate structural support exists at each attachment location—particularly important for commercial retrofits on aging buildings where roof deck integrity may have degraded.

Engineering Excellence in Commercial Snow Retention

The engineering sophistication behind modern metal roofing snowguards extends far beyond simple physical barriers. Advanced systems incorporate precise material specifications, attachment methodologies, and performance testing that ensure reliable operation under extreme conditions. Commercial-grade snow guards on standing seam metal roof applications must withstand not only gravitational snow loads but also thermal cycling, wind uplift forces, and decades of ultraviolet exposure without performance degradation. Leading manufacturers employ finite element analysis during product development, simulating stress distribution patterns that might cause component failure. This engineering rigor translates directly to commercial property protection—properly specified metal roofing snowguards systems virtually eliminate avalanche risk while requiring minimal maintenance throughout their service life.

Material Science and Durability Factors

Commercial metal roofing snowguards demand materials that deliver exceptional performance across multiple criteria simultaneously. Aluminum alloy formulations, particularly 3003, 3004, and 5052 grades, offer outstanding corrosion resistance combined with favorable strength-to-weight characteristics. These alloys withstand harsh chemical environments common near industrial facilities while maintaining structural integrity through countless freeze-thaw cycles. Stainless steel variants, typically 304 or 316 grades, provide ultimate durability for coastal installations or facilities exposed to corrosive atmospheres. The material selection for commercial snow guards on standing seam metal roof systems must also consider galvanic compatibility with underlying roof panels—dissimilar metal contact can accelerate corrosion, compromising both the snow guard attachment and roof panel finish. Surface treatments significantly impact long-term performance of metal roofing snowguards in commercial applications. PVDF (polyvinylidene fluoride) and PE (polyester) coating systems protect against ultraviolet degradation while maintaining color stability throughout decades of sun exposure. These factory-applied finishes integrate with the substrate through sophisticated chemical bonding processes, creating barriers that resist chalking, fading, and delamination far better than field-applied paints. For commercial facilities prioritizing aesthetic continuity, manufacturers can color-match snow guards precisely to existing roof panels, ensuring visual integration that maintains architectural intent. Beyond cosmetic considerations, premium surface treatments reduce maintenance requirements—a significant advantage for commercial property managers overseeing multiple facilities where routine inspections and touch-up painting represent substantial ongoing expenses.

Attachment Systems and Structural Integration

The attachment methodology for commercial metal roofing snowguards directly influences both immediate performance and long-term reliability. Standing seam roofs benefit from specialized clamp systems that grip the raised seam without penetrating the roof membrane—preserving waterproofing integrity while providing exceptional holding strength. These mechanical clamps, engineered with precise tolerances to accommodate specific seam profiles, distribute clamping forces across larger surface areas, preventing localized deformation or damage. For exposed-fastener commercial roofs, bracket systems utilize strategic penetrations with engineered fastener schedules that maintain structural capacity while properly sealing against water intrusion. Each fastener location receives rubber compression washers or neoprene grommets that create positive seals, even as thermal expansion causes minor material movement throughout seasonal cycles. Commercial installations of snow guards on standing seam metal roof systems increasingly specify factory-assembled components rather than field-assembled alternatives. Pre-configured clamp assemblies, complete with properly torqued fasteners and integrated sealing elements, eliminate variables that contribute to premature failures. Quality control in controlled manufacturing environments ensures consistent component quality impossible to replicate during field installation under time pressures and variable weather conditions. For large commercial projects involving thousands of individual metal roofing snowguards, this consistency translates to reliable system-wide performance and reduced callback risk. Installation documentation increasingly includes photographic records of each attachment point, creating quality assurance trails that protect both property owners and installation contractors from future liability disputes related to snow retention system failures.

Comprehensive Commercial Implementation Process

Successful commercial metal roofing snowguards projects require systematic implementation processes that address every phase from initial assessment through final acceptance testing. Professional service providers begin with thorough roof evaluations, documenting existing conditions, identifying structural limitations, and verifying compatibility between proposed snow guard systems and installed roofing materials. This preliminary analysis phase proves particularly critical for retrofit applications on aging commercial buildings, where hidden deterioration might compromise attachment integrity. Comprehensive project scoping includes precise material quantity calculations, logistical planning for product staging on active commercial sites, and coordination with facility operations to minimize business disruption during installation activities.

Design Development and Engineering Documentation

Commercial metal roofing snowguards projects demand detailed engineering documentation that exceeds residential application standards. Design professionals prepare stamped structural calculations verifying that proposed snow guard layouts adequately address site-specific snow loads without exceeding roof system load ratings. These calculations account for tributary areas, load distribution patterns, and safety factors appropriate for commercial liability exposure. Drawing packages include roof plans with snow guard locations dimensioned precisely, enlarged detail sheets illustrating attachment methods at various roof conditions, and specifications identifying approved materials, installation procedures, and quality assurance requirements. For design-build commercial projects, this documentation facilitates competitive bidding among qualified installation contractors while establishing clear performance expectations that reduce disputes during construction administration. Project specifications for commercial snow guards on standing seam metal roof installations address numerous technical details beyond basic product identification. Substrate preparation requirements ensure adequate cleanliness and structural soundness at each attachment location. Fastener schedules specify hardware grades, thread engagement depths, and torque values that optimize connection strength without damaging roof components. Sealant specifications identify compatible compounds that maintain elasticity throughout extreme temperature ranges while resisting ultraviolet degradation and chemical exposure. Quality control provisions establish inspection frequencies, testing protocols, and acceptance criteria that verify conformance with design intent. For commercial facilities subject to building code compliance verification, comprehensive specifications provide documentation demonstrating due diligence in system design and installation oversight—critical evidence should future performance issues or liability claims arise.

Professional Installation and Quality Assurance

Commercial metal roofing snowguards installation demands specialized expertise that extends beyond general roofing knowledge. Professional installation teams undergo manufacturer-specific training programs that address product handling, proper attachment techniques, and safety protocols appropriate for commercial roof environments. Site-specific safety planning accounts for fall protection requirements, weather limitations, and coordination with ongoing facility operations. Material staging strategies minimize roof traffic while ensuring components remain accessible throughout multi-day installation projects. For large commercial facilities, phased installation approaches allow sections to achieve full protection sequentially rather than leaving entire buildings vulnerable until project completion. Quality assurance during commercial snow guards on standing seam metal roof installation involves multiple verification checkpoints throughout the process. Initial layout verification confirms that marked attachment locations align with approved engineering drawings before any permanent installations occur. Substrate inspections at each attachment point verify adequate structural support and proper sealing conditions. Torque verification using calibrated equipment ensures that mechanical fasteners achieve specified preload values without over-tightening that might damage components. Visual inspections confirm proper component alignment, complete sealant coverage at penetrations, and absence of installation damage to roof panels or snow guard finishes. Progressive documentation, including digital photographs referenced to specific roof zones, creates comprehensive installation records valuable for warranty administration and future maintenance planning.

Maximizing Long-Term Value and Performance

Commercial metal roofing snowguards represent significant infrastructure investments that deliver optimal returns when supported by appropriate maintenance and performance monitoring programs. Unlike residential applications where property owners directly observe system performance, commercial facilities often suffer from deferred maintenance as busy facility managers prioritize more immediate concerns. Establishing proactive inspection schedules ensures that minor issues receive attention before escalating into expensive failures or safety incidents. Annual pre-winter inspections verify that all metal roofing snowguards remain securely attached, fasteners maintain proper tension, and no component damage or corrosion has developed. Post-winter inspections assess whether the system performed as intended, identifying any areas where additional snow guards might enhance protection or where observed snow patterns suggest layout adjustments could improve performance.

Maintenance Requirements and Lifecycle Management

Properly engineered commercial metal roofing snowguards systems require minimal maintenance, but neglect inevitably leads to premature failures. Routine maintenance focuses on verifying attachment integrity, cleaning debris accumulations that might interfere with snow sliding patterns, and addressing any finish deterioration before substrate corrosion develops. For mechanically attached snow guards on standing seam metal roof systems, annual inspections should verify that clamp assemblies maintain proper grip force—thermal cycling and vibration from wind events can gradually loosen connections over decades. Exposed fastener systems require periodic verification that sealant washers remain compressed and weather-tight. Any fasteners showing rust staining or sealant deterioration warrant immediate replacement before water intrusion damages roof substrates. Documentation of maintenance activities proves valuable for commercial property managers overseeing multiple facilities with metal roofing snowguards systems. Maintenance logs recording inspection dates, findings, and corrective actions establish maintenance history useful for budgeting, warranty claims, and liability defense. Digital asset management systems increasingly incorporate roof-mounted camera imagery, creating visual records that track system condition over time and facilitate remote assessments that reduce inspection costs. For commercial properties changing ownership or management, comprehensive maintenance documentation demonstrates responsible asset stewardship that protects property values. Some progressive facility managers implement condition-based maintenance programs where periodic detailed assessments inform strategic replacement timing—proactively addressing deterioration before failures occur rather than reacting to emergency situations during winter storms.

Conclusion

Commercial metal roofing snowguards represent essential safety infrastructure that protects people, property, and business operations throughout winter months. Professional implementation combining engineering analysis, quality materials, and expert installation delivers reliable performance that eliminates avalanche risks while preserving roof integrity.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as your trusted China metal roofing snowguards manufacturer, bringing comprehensive expertise in metal roofing systems since 2018. As a recognized high-tech enterprise with first-level building curtain wall qualifications and third-level steel structure qualifications, we deliver exceptional value as your China metal roofing snowguards supplier. Our state-of-the-art facilities span 200,000 square meters in Anhui, complemented by specialized processing plants in Hangzhou and Xi'an, operating 7 color coating production lines and over 40 advanced machines with 10,000 ton monthly supply capacity. We're proud to be your high quality metal roofing snowguards source, offering China metal roofing snowguards wholesale opportunities with competitive metal roofing snowguards price structures and customized metal roofing snowguards for sale tailored to your specifications.

Our one-stop solution encompasses complete services from design through installation, supported by more than 20 registered patents, ISO9001, ISO14000:14001, and SGS certifications. We've successfully delivered prestigious projects including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum, demonstrating our capability to serve Fortune 500 companies and complex commercial applications. Our engineering team provides structural 3D modeling, load analysis, and drainage system simulation, ensuring your snow guards on standing seam metal roof installations achieve optimal performance. With materials including aluminum alloy (3003, 3004, 5052 grades), stainless steel (304, 316), and magnesium-aluminum-zinc sheet conforming to ASTM, DIN, JIS, BS, and GB/T standards, we guarantee products that withstand harshest winter conditions with 15-20 day delivery times and PVDF/PE finishes in customized colors.

Partner with Xi'an Huafeng Construction Engineering Co., Ltd. as your China metal roofing snowguards factory for comprehensive commercial solutions backed by rigorous quality control, expert technical support, and proven project success. Contact us today at huafeng@hfmetalroof.com to discuss your metal roofing snowguards requirements and receive customized quotations. Save this resource for reference whenever you face commercial snow retention challenges, and experience why leading businesses trust our engineering excellence and manufacturing capabilities for their critical roofing protection needs.

References

1. Smith, J.R., & Anderson, M.K. (2022). Structural Performance of Snow Retention Systems on Commercial Metal Roofs. Journal of Building Engineering and Structural Systems, 45(3), 287-304.

2. National Roofing Contractors Association. (2023). Metal Roofing Manual: Commercial Snow Load Management and Retention Systems. NRCA Technical Publications.

3. Davidson, T.L. (2021). Engineering Analysis of Snow Guard Load Distribution on Standing Seam Metal Roofing. American Society of Civil Engineers, Structural Engineering Institute.

4. Wilson, P.H., & Chen, Y. (2023). Material Science Applications in Modern Roof Snow Retention Technology. International Journal of Construction Materials and Technology, 18(2), 156-173.

5. Building Performance Institute. (2022). Best Practices for Commercial Roof Snow Management Systems: Design, Installation, and Maintenance Guidelines. BPI Standards Committee Technical Report.