Are you struggling with premature corrosion damage to your perforated metal installations in harsh industrial or coastal environments? Understanding the corrosion resistance properties of Aluminum Punch Plate is essential for ensuring long-term structural integrity and avoiding costly replacements. This comprehensive guide explores how aluminum alloy perforated sheets naturally resist oxidation, what factors can compromise their protective oxide layer, and proven surface treatment methods that extend service life beyond 30 years. Whether you're specifying materials for architectural facades, industrial filtration systems, or marine applications, knowing the science behind aluminum corrosion resistance will save you time, money, and prevent unexpected project failures.

Understanding Aluminum Punch Plate Natural Corrosion Protection

Aluminum punch plate benefits from an inherent protective mechanism that distinguishes it from other perforated metal materials. When exposed to atmospheric conditions, aluminum atoms on the surface rapidly react with oxygen to form aluminum oxide, creating a compact passive layer that typically measures between one and two microns in thickness. This naturally occurring aluminum trioxide film adheres strongly to the underlying metal substrate and provides the first line of defense against environmental degradation. Unlike steel or iron, which develop flaky rust that progressively consumes the base material, the oxide layer on Aluminum Punch Plate remains stable and self-healing. When the surface becomes scratched or mechanically damaged, fresh aluminum immediately oxidizes and repairs the protective barrier within seconds of exposure to air. The effectiveness of this natural protection depends significantly on the aluminum alloy composition used in Aluminium Perforated Sheet manufacturing. Pure aluminum and certain alloy series demonstrate exceptional corrosion resistance, while alloys containing copper or zinc may exhibit reduced protective qualities. Common aluminum alloys used for perforated applications include 1050, 1060, 1100, 3003, 5052, and 6061, each offering distinct performance characteristics. The 3003 aluminum alloy, frequently specified for architectural and industrial Aluminum Punch Plate installations, provides an optimal balance of strength and corrosion resistance due to its manganese content. This alloy maintains its protective oxide layer effectively in most industrial, urban, and marine environments without requiring additional surface treatments. The 5052 alloy, with its magnesium content between 2.2 and 2.8 percent, offers even higher corrosion resistance and is particularly suited for harsh coastal environments where salt spray and high humidity present ongoing challenges.

The Science Behind Aluminum's Self-Protecting Oxide Layer

The aluminum oxide passivation layer functions as an impermeable barrier that prevents further oxidation of the base metal by blocking oxygen and moisture penetration to deeper material layers. This protective film remains stable within a pH range of approximately four to nine, which covers most normal atmospheric and industrial environments encountered by Aluminum Punch Plate installations. The oxide layer possesses remarkable stability because aluminum has a strong chemical affinity for oxygen, creating a thermodynamically favored reaction that occurs spontaneously. When properly maintained, this natural protection allows Aluminium Perforated Sheet products to function reliably for decades without significant material degradation or loss of structural properties. The self-healing characteristic of the aluminum oxide layer represents a critical advantage for perforated metal applications where mechanical damage or abrasion might occur during installation or service. Any breach in the protective film exposes fresh aluminum metal, which immediately oxidizes upon contact with atmospheric oxygen and recreates the protective barrier. This continuous regeneration process occurs without human intervention or additional protective treatments, making Aluminum Punch Plate an exceptionally low-maintenance material choice. The oxide layer also provides electrical insulation properties and enhances the aesthetic appearance of the metal by creating a uniform matte gray surface finish that many architects and designers find appealing. For applications requiring specific visual qualities or enhanced protection, various surface treatment options can be applied to modify or enhance the natural oxide layer properties.

Environmental Factors That Impact Aluminum Punch Plate Corrosion Resistance

While Aluminum Punch Plate possesses inherent corrosion resistance, certain environmental conditions can compromise the protective oxide layer and accelerate material degradation. The pH level of the surrounding environment plays a critical role in determining the long-term performance of Aluminium Perforated Sheet installations. Strongly acidic environments with pH values below four and alkaline conditions above pH nine can chemically attack and dissolve the aluminum oxide protective film, exposing the reactive aluminum metal beneath to ongoing corrosion. Construction sites present particular risks during concrete curing phases, as wet concrete maintains a pH between 12.5 and 13.5, which rapidly degrades any aluminum surfaces in direct contact. Protective coverings or barrier materials should be used to prevent aluminum contact with fresh concrete until the curing process completes and pH levels stabilize. Chloride ions present in marine environments and coastal regions represent another significant threat to Aluminum Punch Plate longevity. Salt water and airborne salt particles can penetrate the oxide layer at microscopic weak points or around intermetallic particles within the aluminum alloy, initiating localized pitting corrosion that appears as small cavities on the material surface. While this pitting typically develops slowly and affects appearance before compromising structural integrity, prolonged exposure without proper surface treatments can eventually reduce load-bearing capacity in critical applications. Industrial atmospheres containing sulfur dioxide or other acidic pollutants also pose challenges, as these compounds can react with moisture to form weak acids that slowly attack the protective oxide layer. Temperature fluctuations and condensation cycles accelerate these corrosion mechanisms by repeatedly wetting and drying the Aluminum Punch Plate surface, providing optimal conditions for electrochemical reactions.

Galvanic Corrosion Risks in Mixed Metal Installations

Galvanic corrosion occurs when Aluminum Punch Plate comes into electrical contact with more noble metals such as copper, brass, stainless steel, or certain types of carbon steel in the presence of an electrolyte like moisture or salt water. This electrochemical reaction creates a weak battery effect where electrons flow from the more active aluminum to the nobler metal, causing accelerated corrosion of the aluminum component. The aluminum sacrifices itself to protect the more noble metal, leading to rapid material loss that can compromise structural integrity within months in severe marine environments. Proper design practices require electrical insulation between dissimilar metals using nonconductive gaskets, sleeves, or coatings to prevent galvanic cell formation. When insulation is impractical, selecting fasteners and hardware manufactured from aluminum alloys or materials with similar electrochemical potential minimizes galvanic current flow. The relative surface area ratio between the dissimilar metals significantly influences the severity of galvanic corrosion on Aluminium Perforated Sheet installations. Large areas of noble metal in contact with small aluminum components produce the most aggressive corrosion, as the electrochemical current concentrates on the smaller anodic aluminum surface. Conversely, large aluminum surfaces with small stainless steel fasteners typically experience minimal corrosion because the cathodic current disperses across the extensive aluminum area. Understanding these principles allows engineers and designers to develop installation details that minimize galvanic corrosion risks through intelligent material selection and geometric configuration. For high-risk applications such as marine structures or chemical processing facilities, zinc-plated steel fasteners can provide an intermediate sacrificial layer that corrodes preferentially to both the aluminum and underlying steel, offering extended protection for the Aluminum Punch Plate assembly.

Surface Treatment Options to Enhance Aluminum Punch Plate Durability

Anodizing represents the most widely used surface treatment for enhancing Aluminum Punch Plate corrosion resistance and aesthetic properties. This electrochemical process artificially thickens the natural oxide layer by immersing the aluminum in an acid electrolyte bath and passing electrical current through the material. The controlled oxidation reaction grows the aluminum oxide layer from the base metal to depths ranging from five to twenty-five microns or more, depending on the anodizing type and processing parameters. Sulfuric acid anodizing produces clear or slightly gray coatings that can be dyed various colors before sealing, making it popular for architectural applications. Hard anodizing creates extremely durable surfaces exceeding fifty microns thick that resist wear and abrasion while maintaining excellent corrosion protection. The porous structure of anodized layers before sealing allows incorporation of dyes, lubricants, or additional sealants that further enhance performance characteristics. The sealing process following anodization permanently closes the microscopic pores in the oxide layer, creating an impermeable barrier that locks in any dyes or additives while preventing ingress of corrosive agents. Hot water sealing, the most common method, hydrates the aluminum oxide to form boehmite, a stable crystalline structure that fills the pores and provides long-term environmental stability. Alternatively, mid-temperature or cold sealing processes using proprietary chemical solutions offer faster processing with equivalent protection. Properly anodized and sealed Aluminium Perforated Sheet can withstand decades of exposure in harsh marine, industrial, and urban atmospheres while maintaining structural integrity and visual appearance. The anodized surface also provides an excellent base for additional protective coatings like polyurethane or fluorocarbon paints when specific color requirements or enhanced chemical resistance becomes necessary.

Powder Coating and Paint Systems for Maximum Protection

Powder coating technology delivers durable, attractive finishes on Aluminum Punch Plate while providing superior corrosion protection compared to traditional liquid paints. The electrostatic application process deposits thermosetting polymer powder onto the metal surface, which then melts and cures when heated to form a continuous protective film. Polyester, polyurethane, and fluoropolymer powder formulations offer varying levels of UV resistance, chemical durability, and color retention for different application requirements. The resulting coating thickness typically ranges from sixty to one hundred twenty microns, significantly exceeding the protection provided by liquid paint systems while eliminating solvent emissions and volatile organic compounds. Proper surface preparation prior to powder coating or painting critically determines long-term adhesion and corrosion protection performance. Chemical conversion coatings, also known as chromate or non-chromate passivation treatments, chemically modify the aluminum surface to create a thin protective layer that enhances paint adhesion while providing additional corrosion inhibition. Modern trivalent chromium or chrome-free conversion coatings offer environmentally responsible alternatives to traditional hexavalent chromium treatments while delivering comparable performance. These pretreatments form a network of chemical bonding sites that mechanically and chemically anchor the subsequent paint or powder coating to the Aluminium Perforated Sheet substrate. For maximum durability in extreme environments, multi-layer coating systems combining conversion coating, epoxy primer, and fluoropolymer topcoat can achieve service lives exceeding thirty years with minimal maintenance requirements.

Selecting the Right Aluminum Punch Plate Alloy for Your Application

Material selection significantly impacts the long-term corrosion performance of Aluminum Punch Plate installations across different environmental exposures. For general architectural and industrial applications in non-marine environments, 3003 aluminum alloy provides an economical choice with adequate strength and excellent corrosion resistance. This alloy contains approximately 1.2 percent manganese, which enhances the protective oxide layer while maintaining good formability for the punching process. The H14 temper, achieved through strain hardening to a half-hard condition, offers optimal balance between strength and workability for perforated sheet applications. Natural weathering produces a uniform gray patina that many designers find aesthetically acceptable for industrial facilities, transportation infrastructure, and utilitarian applications. For coastal installations, chemical processing environments, or applications requiring maximum corrosion resistance, 5052 aluminum alloy represents the premium choice for Aluminium Perforated Sheet products. The magnesium content in this alloy significantly enhances corrosion resistance, particularly against salt water and marine atmospheres, while providing higher strength than 3003 alloy. Marine architects and coastal construction engineers frequently specify 5052 alloy for applications where replacement costs and access difficulties make long-term reliability paramount. The 6061 alloy, containing magnesium and silicon for precipitation hardening, offers the highest strength among common architectural aluminum alloys while maintaining good corrosion resistance after proper heat treatment. However, the copper content in some aluminum alloys, particularly the 2xxx series, reduces corrosion resistance and makes these materials unsuitable for Aluminum Punch Plate applications in corrosive environments despite their exceptional strength properties.

Customization Options for Enhanced Performance

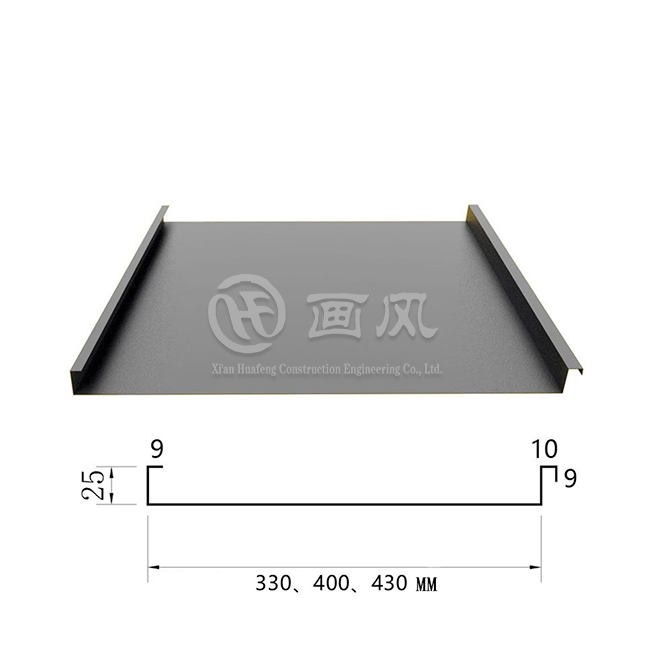

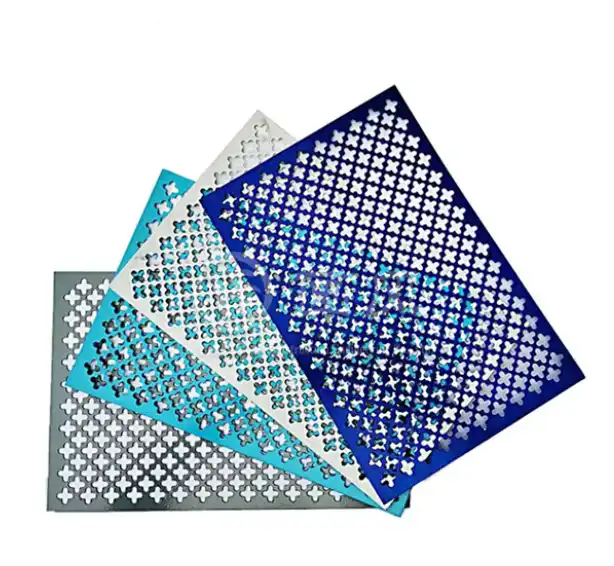

Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Aluminum Punch Plate in material grades including 1050, 1060, 1100, 3003, 5052, and 6061 aluminum alloys, with thickness options ranging from 0.5 to 6 millimeters to accommodate diverse structural and functional requirements. Hole patterns can be fully customized, including round, square, oblong, hexagonal, and special-shaped perforations with apertures from 1 to 50 millimeters and adjustable center spacing. Surface treatment options include anodizing in clear or colored finishes, powder coating in virtually unlimited colors, electrophoresis for uniform coverage, brushing for distinctive visual effects, and polishing for reflective applications. This comprehensive customization capability allows architects, engineers, and industrial designers to optimize Aluminium Perforated Sheet performance for specific corrosion resistance requirements while achieving desired aesthetic outcomes. The opening rate of perforated patterns, ranging from 20 to 70 percent, can be engineered to balance structural requirements, air flow characteristics, visual transparency, and acoustical properties. Higher opening rates reduce material weight and cost while increasing ventilation and light transmission, but may compromise strength in load-bearing applications. The company's engineering team provides structural analysis and load calculations to ensure specified perforation patterns meet project performance requirements without sacrificing corrosion protection or longevity. With three manufacturing facilities, seven raw material production lines, and more than forty specialized machines, Huafeng maintains rigorous quality control throughout the production process, from incoming material inspection through finished product packaging. Each Aluminum Punch Plate batch undergoes comprehensive testing including appearance inspection, dimensional verification, salt spray testing, adhesion evaluation, hardness measurement, and weather resistance assessment to ensure consistent quality and compliance with ISO9001 and ISO14000 standards.

Maintenance Strategies for Long-Term Aluminum Punch Plate Performance

Regular cleaning and inspection programs significantly extend Aluminum Punch Plate service life by removing corrosive deposits before they compromise the protective oxide layer. For most installations in moderate environments, annual or bi-annual washing with mild soap solution and fresh water removes accumulated dirt, dust, and atmospheric pollutants that could otherwise trap moisture against the metal surface. Soft brushes or non-woven abrasive pads effectively remove stubborn deposits without damaging the protective coating or oxide layer. High-pressure water cleaning should be used cautiously to avoid forcing water into joints, fastener holes, or concealed spaces where it might become trapped and create localized corrosion cells. Harsh chemical cleaners, strong acids, alkaline solutions, and abrasive materials like steel wool must be avoided, as these can damage or remove protective surface treatments and expose reactive aluminum to environmental attack. Visual inspection during cleaning operations identifies early signs of corrosion damage that can be addressed before significant material loss occurs. White powdery deposits, small pits, or discolored areas on Aluminium Perforated Sheet surfaces indicate oxide layer breakdown and require investigation of the underlying cause. In many cases, simply removing the corrosive agent and cleaning the affected area allows the natural self-healing properties of aluminum to restore protection. For more severe pitting or corrosion that penetrates beyond the oxide layer, localized repairs may include cleaning, mechanical polishing, application of conversion coatings, and touch-up painting or sealing. Fastener inspection should verify that dissimilar metal contact remains properly insulated and that gaskets or isolation materials have not degraded. Early intervention prevents minor corrosion issues from developing into structural problems requiring extensive repairs or premature replacement of Aluminum Punch Plate components.

Conclusion

Aluminum Punch Plate delivers exceptional corrosion resistance through its natural protective oxide layer, enhanced by proper alloy selection, surface treatments, and maintenance practices. Understanding environmental factors and implementing appropriate protective measures ensures reliable service life exceeding 30 years across diverse applications. Smart material specification, professional installation, and regular inspection maximize the durability and performance of perforated aluminum investments.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

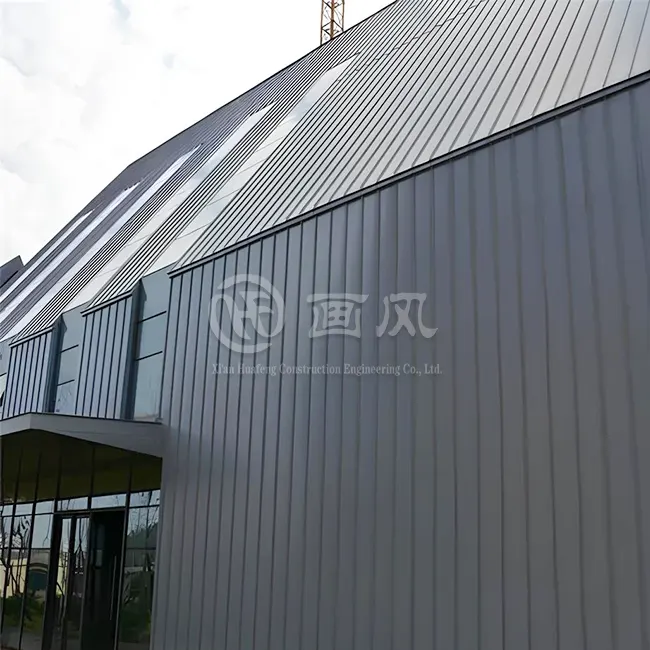

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, specializes in comprehensive metal roofing systems, building curtain walls, and steel structure enclosure solutions from design through construction. Our manufacturing capabilities include a 200,000 square meter raw material production facility in Anhui, processing plants in Hangzhou and Xi'an, seven color coating lines, and more than twenty plate production machines equipped with advanced punching, shearing, and forming technology. As a China Aluminum Punch Plate manufacturer, China Aluminum Punch Plate supplier, and China Aluminum Punch Plate factory offering China Aluminum Punch Plate wholesale, we provide High Quality Aluminum Punch Plate for sale at competitive Aluminum Punch Plate price points backed by 20+ patent certificates, CE, ISO9001, ISO14000, and SGS certifications. Our one-stop service encompasses engineering design optimization, raw material quality testing verified by third-party reports, fully customized production in color, pattern, and design specifications, multiple packaging options, and flexible transportation methods to ensure your project success. With proven collaboration experience with Fortune 500 companies and complete quality traceability from raw material procurement through finished product delivery, we deliver exceptional value for architectural facades, industrial screening, environmental protection barriers, and mechanical equipment applications. Contact our engineering team at huafeng@hfmetalroof.com to discuss your Aluminium Perforated Sheet requirements and receive free samples demonstrating our superior manufacturing quality and technical capabilities.

References

1. Ahmad, Z. (2006). "Principles of Corrosion Engineering and Corrosion Control." Butterworth-Heinemann, Society of Chemical Industry.

2. Davis, J.R. (1999). "Corrosion of Aluminum and Aluminum Alloys." ASM International Materials Park.

3. Vargel, C. (2004). "Corrosion of Aluminium." Elsevier Science Publishers.

4. Talbot, D.E.J. and Talbot, J.D.R. (2018). "Corrosion Science and Technology." CRC Press Taylor and Francis Group.

5. Revie, R.W. and Uhlig, H.H. (2008). "Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering." Fourth Edition, John Wiley and Sons.