Choosing the wrong roofing supplier can turn a premium construction project into a maintenance nightmare, with premature corrosion, color fading, and water infiltration destroying your building's structural integrity within just a few years. When you're investing in Aluminum Standing Seam Metal Roof Panels for commercial, industrial, or high-end residential projects, selecting a reliable OEM supplier with proven manufacturing capabilities, comprehensive quality certifications, and end-to-end service support is not just important—it's critical to protecting your investment and ensuring decades of leak-free performance.

What Makes a Top-Tier Aluminum Standing Seam Metal Roof Panel Supplier?

The global market for Aluminum Standing Seam Metal Roof Panels has experienced significant growth as architects, contractors, and building owners recognize the superior longevity, energy efficiency, and aesthetic appeal these systems offer compared to traditional roofing materials. However, not all suppliers deliver the same level of quality, technical expertise, and project support. Distinguishing characteristics of elite OEM manufacturers include integrated design-to-installation capabilities, multi-facility production capacity, advanced roll-forming technology, rigorous quality control protocols, and extensive industry certifications that demonstrate compliance with international standards such as ISO9001, ISO14001, ASTM, DIN, JIS, and GB/T specifications. Top suppliers maintain complete vertical integration across the manufacturing chain, from raw material procurement and surface treatment to precision fabrication and final product testing. This comprehensive control ensures consistency in panel dimensions, coating adhesion, color matching, and mechanical properties across large-volume orders. Furthermore, leading manufacturers invest in research and development to innovate new alloy formulations, surface treatments, and connection systems that enhance weather resistance, thermal performance, and installation efficiency. When evaluating potential suppliers for your Aluminum Standing Seam Metal Roof Panels, examine their factory infrastructure, production line capacity, equipment sophistication, material traceability systems, and track record on major commercial and institutional projects where performance failures would have significant consequences.

Manufacturing Capabilities and Production Infrastructure

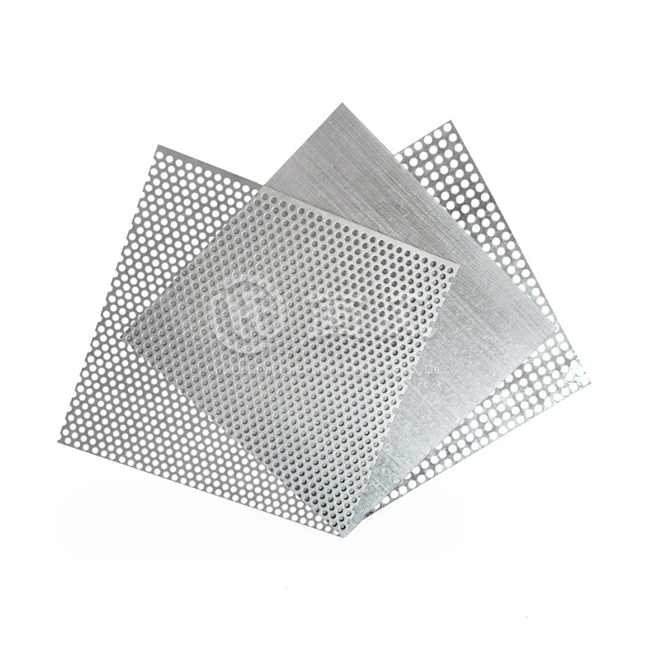

Elite OEM suppliers of Aluminum Standing Seam Metal Roof Panels operate multiple manufacturing facilities strategically located to serve diverse geographic markets while maintaining consistent quality standards across all production sites. The most capable manufacturers possess raw material production plants spanning hundreds of thousands of square meters, equipped with multiple color coating production lines, laminating systems, longitudinal and transverse shearing equipment, fully automated punching machines, and dozens of specialized forming, pressing, and bending machines. This extensive infrastructure enables these suppliers to handle projects of virtually any scale, from small residential installations requiring 500 square meters to massive commercial developments demanding tens of thousands of square meters of roofing panels with precise specifications and tight delivery timelines. Advanced roll-forming systems represent the cornerstone of quality aluminum panel production, transforming flat coil stock into precisely dimensioned standing seam profiles with consistent leg heights, seam configurations, and panel widths. Leading manufacturers utilize computer-controlled forming equipment that maintains tolerances within fractions of a millimeter across continuous panel lengths ranging from four to sixty-four feet, eliminating the dimensional variations that can compromise installation quality and system performance. Real-time quality monitoring throughout the production process tracks critical parameters including material thickness, coating uniformity, dimensional accuracy, and surface finish, allowing immediate corrective action when deviations occur. This commitment to precision manufacturing directly translates into Aluminum Standing Seam Metal Roof Panels that install more easily, seal more effectively, and perform more reliably over their multi-decade service life.

Raw material traceability systems employed by premium suppliers document the complete provenance of every aluminum coil, recording alloy composition, mill certifications, coating specifications, and test results that verify compliance with project requirements and industry standards. This comprehensive documentation proves essential for projects requiring LEED certification, building code compliance, or warranty validation. Additionally, top-tier manufacturers maintain preferred supplier relationships with globally recognized aluminum producers, ensuring access to premium-grade AA3003, AA3004, and AA5052 alloys that deliver optimal combinations of strength, formability, corrosion resistance, and weldability for standing seam roofing applications.

Key Technical Specifications for Aluminum Standing Seam Metal Roof Panels

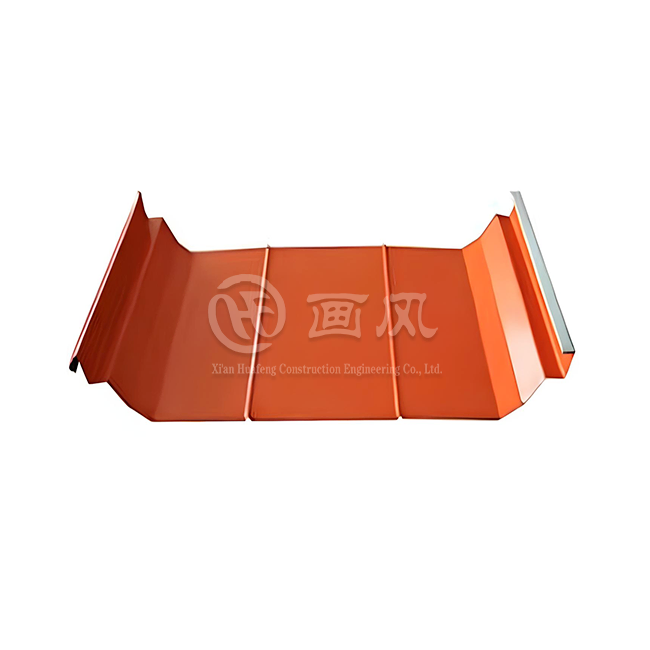

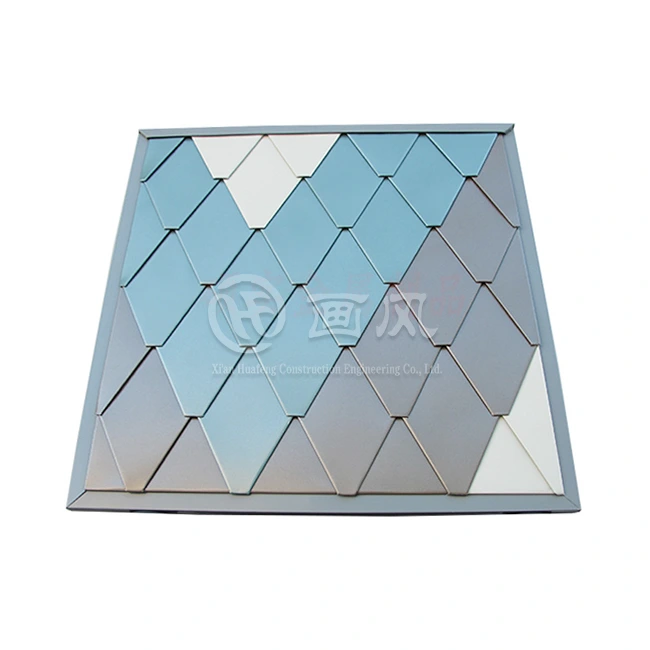

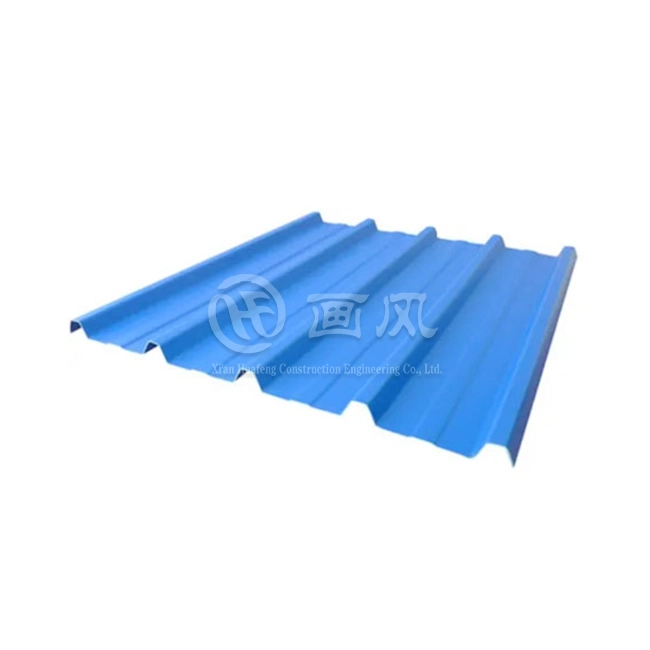

Understanding the technical specifications that define high-performance Aluminum Standing Seam Metal Roof Panels enables architects, engineers, and contractors to make informed supplier selections based on project-specific requirements rather than marketing claims alone. Critical specifications include base material alloy composition, panel thickness range, rib height options, effective coverage width, connection method, surface treatment system, color range, and compliance with applicable industry standards. Premium manufacturers offer panels fabricated from corrosion-resistant aluminum alloys in thicknesses ranging from 0.7mm to 1.2mm, providing the structural strength needed for spanning requirements while maintaining the lightweight characteristics that reduce building load and simplify installation logistics. Rib height selection significantly impacts both the aesthetic appearance and structural performance of standing seam systems, with heights typically ranging from 25mm to 65mm depending on roof pitch, panel span, wind load requirements, and architectural design preferences. Taller ribs provide greater structural stiffness and more pronounced shadow lines that create dramatic visual effects, particularly on commercial and institutional buildings where architectural distinction is paramount. Connection methods vary between snap-lock systems that enable rapid installation without specialized equipment and mechanically seamed systems that offer superior wind uplift resistance and enhanced weather-tightness for low-slope applications or extreme climate zones.

Surface Treatment and Coating Systems

The surface treatment applied to Aluminum Standing Seam Metal Roof Panels fundamentally determines their long-term color retention, corrosion resistance, and overall durability in service. PVDF fluorocarbon coatings represent the premium standard for architectural metal roofing applications, delivering exceptional ultraviolet stability, chemical resistance, and dirt retention properties that maintain vibrant color and pristine appearance for twenty years or more under normal environmental exposure. These advanced coating systems utilize fluoropolymer resins formulated to flex with thermal expansion and contraction cycles without cracking, chalking, or delaminating, ensuring the protective barrier remains intact throughout the panel's service life. Alternative surface treatments including anodizing and mill-finish bare aluminum serve specialized applications where natural metallic appearance, electrical conductivity, or unique weathering characteristics are desired. Anodized finishes create an integral oxide layer that enhances corrosion resistance while offering distinctive bronze, champagne, or pewter tones that develop subtle patina over time. Leading Aluminum Standing Seam Metal Roof Panel suppliers maintain extensive color libraries encompassing standard RAL and Pantone palettes plus custom-matched colors developed to coordinate with specific architectural visions or corporate branding requirements. This color customization capability, combined with multiple finish options including high-gloss, low-gloss, and matte surfaces, empowers designers to achieve precisely the aesthetic effect their projects demand. Quality surface preparation before coating application proves equally critical to long-term performance as the coating formulation itself. Premium manufacturers employ multi-stage chemical treatment processes that thoroughly clean aluminum surfaces, promote coating adhesion, and establish corrosion-resistant conversion layers before applying primer and topcoat systems. Rigorous quality control testing verifies coating thickness, adhesion strength, flexibility, impact resistance, salt spray endurance, and accelerated weathering performance, ensuring every panel leaving the factory meets or exceeds the stringent requirements specified in ISO9001 quality management systems and SGS certification protocols.

Comprehensive Project Support from Design Through Installation

The distinction between adequate aluminum panel suppliers and truly exceptional OEM partners becomes most apparent in the breadth and depth of project support services they provide throughout the entire building lifecycle. Elite manufacturers recognize that Aluminum Standing Seam Metal Roof Panels represent only one component of a complex building envelope system, and successful outcomes depend on thoughtful design integration, precise fabrication coordination, and skilled installation execution. Consequently, top-tier suppliers maintain in-house technical departments staffed by experienced engineers and architects who collaborate with project teams from initial concept development through final acceptance testing and long-term maintenance planning. Custom engineering services begin with comprehensive project drawing deepening, where supplier design teams analyze architectural plans, structural calculations, and site conditions to develop optimized roofing solutions that balance performance requirements, budget constraints, and aesthetic objectives. This analysis identifies potential constructability issues, suggests value-engineering alternatives, and ensures that specified Aluminum Standing Seam Metal Roof Panels integrate seamlessly with adjacent building systems including insulation, vapor barriers, flashing components, and drainage infrastructure. Through iterative communication and collaborative refinement, design teams produce detailed shop drawings, installation sequences, and quality control protocols that guide fabrication and construction activities.

Sample Production and Quality Verification

Before committing to full-scale production, leading suppliers produce physical samples based on confirmed specifications including panel profile, material alloy, thickness, surface treatment method, and color selection. These samples enable stakeholders to verify dimensional accuracy, assess finish quality, evaluate color matching, and validate mechanical properties under actual handling and installation conditions. After client approval, sealed samples become the reference standard against which all subsequent production is measured, ensuring consistency across the entire order quantity regardless of production timing or facility location. This sample-based quality assurance process prevents costly misunderstandings and establishes clear performance expectations that protect both supplier and client interests. Processing drawing deepening represents another critical phase where overall project designs are decomposed into detailed fabrication drawings that specify exact dimensions, hole locations, bend angles, and assembly sequences for every individual panel and accessory component. Sequential numbering systems track each unit from fabrication through quality inspection, packaging, shipping, and field installation, eliminating confusion and minimizing installation errors on complex projects involving thousands of individual components. This meticulous attention to documentation and traceability demonstrates the operational sophistication that separates professional OEM manufacturers from commodity panel suppliers.

Material Procurement and Quality Control Excellence

Premium Aluminum Standing Seam Metal Roof Panel suppliers maintain rigorous material procurement protocols that source raw materials exclusively from certified manufacturers with proven track records for consistency, reliability, and technical support. These preferred supplier relationships encompass globally recognized aluminum producers, coating system manufacturers, and specialty component suppliers who provide comprehensive material certifications and third-party testing documentation for every shipment. Incoming inspection procedures verify that received materials meet specified requirements through systematic sampling and testing protocols that examine product appearance, dimensional accuracy, coating thickness, adhesion strength, hardness, impact resistance, salt spray endurance, weatherability, and color conformance. Full inspection protocols apply to small-quantity, high-value materials where every piece undergoes individual examination before acceptance into inventory. Random sampling approaches govern large-volume, frequently ordered materials, with statistically valid sample sizes subjected to the same comprehensive testing regimen applied during full inspection. Materials failing to meet acceptance criteria are rejected and returned to suppliers, preventing defective raw materials from contaminating production processes and compromising finished product quality. This uncompromising approach to incoming quality control establishes the foundation for manufacturing excellence that produces Aluminum Standing Seam Metal Roof Panels capable of delivering decades of trouble-free performance.

Production Processing and Finished Product Inspection

Throughout the fabrication sequence, skilled operators and automated systems work in concert to transform raw materials into precision-engineered roofing components. Computer-controlled forming equipment, guided by processing drawings and quality specifications, shapes aluminum coil into standing seam panels with exact dimensional tolerances. Automated punching systems create fastener holes, drainage slots, and clip engagement features at precisely specified locations. Specialized bending equipment forms end closures, ridge caps, valley pans, and transition flashing components that complete the roofing system. At each production stage, in-process inspections verify conformance to specifications before materials advance to subsequent operations, preventing defective components from progressing through the manufacturing sequence. Finished product inspection represents the final quality gate before Aluminum Standing Seam Metal Roof Panels are released for packaging and shipment. Comprehensive inspection protocols examine product appearance for surface defects, dents, scratches, or coating irregularities that could compromise aesthetics or durability. Dimensional verification confirms that panel width, length, rib height, and seam configuration match specified tolerances. Flatness and curvature measurements ensure panels will install smoothly without oil-canning or buckling. Functional testing validates that mechanical seam connections engage properly and clip systems operate as designed. Only panels passing all inspection criteria receive approval for packaging and shipment to project sites. Strategic packaging approaches employed by leading suppliers facilitate efficient site handling and installation by organizing panels according to roof section plans and installation sequences. Product identification cards attached to each package display section-specific floor plans and numbered component lists that enable installation crews to quickly locate required materials and maintain proper installation sequence. This attention to packaging logistics and documentation reflects the operational maturity and customer-focused orientation that characterize elite OEM suppliers.

On-Site Installation Support and Technical Guidance

Recognizing that even the highest-quality Aluminum Standing Seam Metal Roof Panels can fail to deliver intended performance if improperly installed, leading manufacturers provide comprehensive on-site installation support ranging from pre-installation consultation through final acceptance testing and ongoing maintenance guidance. Installation technicians from supplier organizations visit job sites before construction begins to assess site conditions, verify that supporting structure meets design requirements, confirm that necessary tools and accessories are available, and review installation sequences with contractor personnel. This proactive engagement identifies potential issues before they impact construction schedules or compromise installation quality. Pre-installation technical briefings bring together project stakeholders to review detailed installation drawings, discuss critical work details, establish quality control checkpoints, and emphasize safety protocols that protect workers and ensure code compliance. During active construction, supplier representatives monitor installation progress, answer technical questions, troubleshoot unexpected conditions, and verify that work proceeds according to specifications. This hands-on support proves particularly valuable on complex projects involving challenging geometries, transitions between building systems, or coordination with multiple trades working in compressed schedules.

Acceptance Testing and Long-Term Maintenance

Upon installation completion, comprehensive testing procedures verify that the completed roofing system meets performance expectations and warranty requirements. Water testing protocols, often involving flood testing of representative roof sections or spray testing of critical details, confirm that the system is completely watertight before building occupancy. Visual inspections document that surface appearance meets aesthetic standards and that all components are properly installed and secured. Performance testing may include measurement of thermal performance, verification of drainage capacity, or confirmation of wind uplift resistance depending on project specifications and local code requirements. Post-installation support extends beyond construction completion to encompass ongoing maintenance guidance and long-term performance monitoring. Supplier representatives provide training to building maintenance personnel on proper cleaning techniques, inspection protocols, and repair procedures that preserve roofing system integrity and appearance throughout its service life. Scheduled inspection programs identify minor maintenance needs before they develop into significant performance issues, maximizing system longevity and ensuring that Aluminum Standing Seam Metal Roof Panels deliver the full economic value their premium cost commands.

Conclusion

Selecting the right OEM supplier for Aluminum Standing Seam Metal Roof Panels requires careful evaluation of manufacturing capabilities, technical expertise, quality control systems, project support services, and long-term commitment to customer success beyond initial product delivery.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Aluminum Standing Seam Metal Roof Panels manufacturer established in 2018, Xi'an Huafeng Construction Engineering Co., Ltd. delivers comprehensive metal roofing solutions backed by Shaanxi Province high-tech enterprise recognition and first-level building curtain wall qualifications. Our manufacturing infrastructure includes a 200,000-square-meter raw material production plant in Anhui plus two specialized processing facilities in Hangzhou and Xi'an, equipped with seven color coating production lines, ten shearing systems, and over forty precision fabrication machines. This extensive capacity enables us to serve as your trusted China Aluminum Standing Seam Metal Roof Panels supplier and China Aluminum Standing Seam Metal Roof Panels factory, offering customized High Quality Aluminum Standing Seam Metal Roof Panels with 0.7-1.2mm thickness, 25-65mm rib heights, PVDF finishes in RAL and custom colors, ASTM/DIN/JIS/BS/GB/T compliance, competitive Aluminum Standing Seam Metal Roof Panels price, and Aluminum Standing Seam Metal Roof Panels for sale with 15-20 day delivery, 500㎡ MOQ, and 30-year warranties. Our one-stop service encompasses project drawing deepening, 3D structural modeling, sample production, precision manufacturing with material traceability, on-site installation guidance, and acceptance testing. With 20+ registered patents, ISO9001/ISO14000/SGS certifications, and proven performance on major projects including Xiongan Station, Xi'an International Convention Center, and Jinghe New City International Culture and Art Center, we integrate green sustainable development principles with advanced engineering to create China Aluminum Standing Seam Metal Roof Panels wholesale solutions that add production capacity benefits while solving idle roof space challenges. Contact our team at huafeng@hfmetalroof.com to discuss how our design optimization services, raw material quality testing, customized production capabilities, and comprehensive technical support can enhance your next architectural project.

References

1. Metal Construction Association, "Standing Seam Metal Roofing Systems Design Manual," authored by Technical Committee on Metal Roofing Systems

2. American Society for Testing and Materials, "Standard Specification for Aluminum-Alloy Sheet and Plate for Building and Construction," ASTM B209 Committee

3. National Roofing Contractors Association, "The NRCA Roofing Manual: Metal Panel and SPF Roof Systems," NRCA Technical Operations Department

4. Cool Roof Rating Council, "Product Rating Program Manual for Metal Roofing Products," CRRC Technical Committee

5. Aluminum Association, "Aluminum Design Manual: Specification for Aluminum Structures," Aluminum Association Engineering Design Task Force