Are you tired of dealing with visible fasteners, water infiltration, and frequent maintenance costs on your building's exterior walls? Inside Lock Metal Wall Panels offer a revolutionary solution that combines seamless aesthetics with superior weather protection. These innovative concealed fastening systems are transforming modern construction by delivering exceptional durability, energy efficiency, and design flexibility that traditional wall cladding simply cannot match.

What Makes Inside Lock Metal Wall Panels a Superior Choice for Modern Construction?

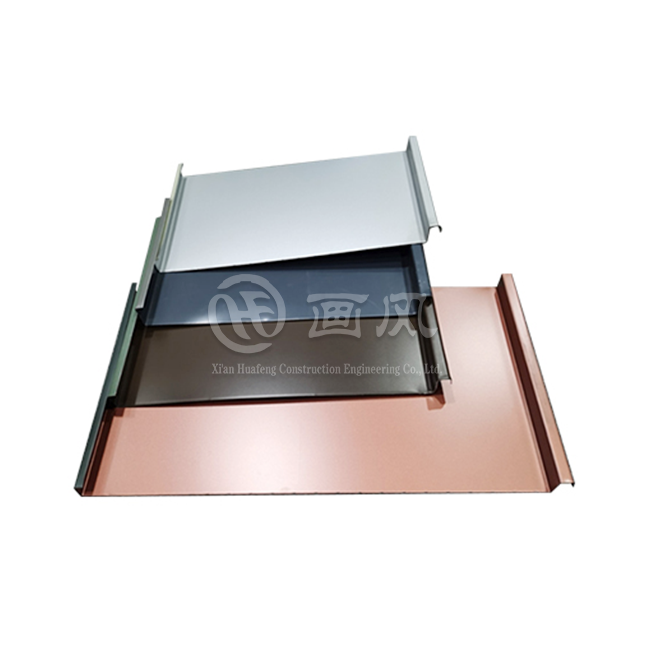

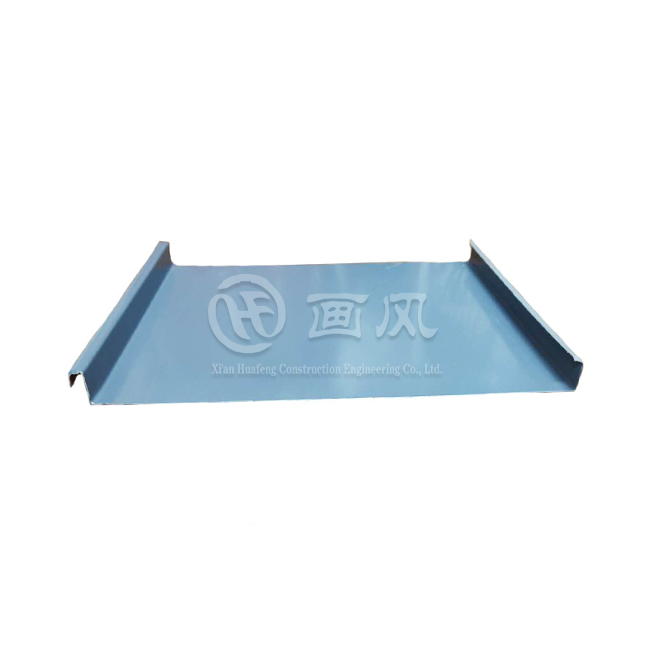

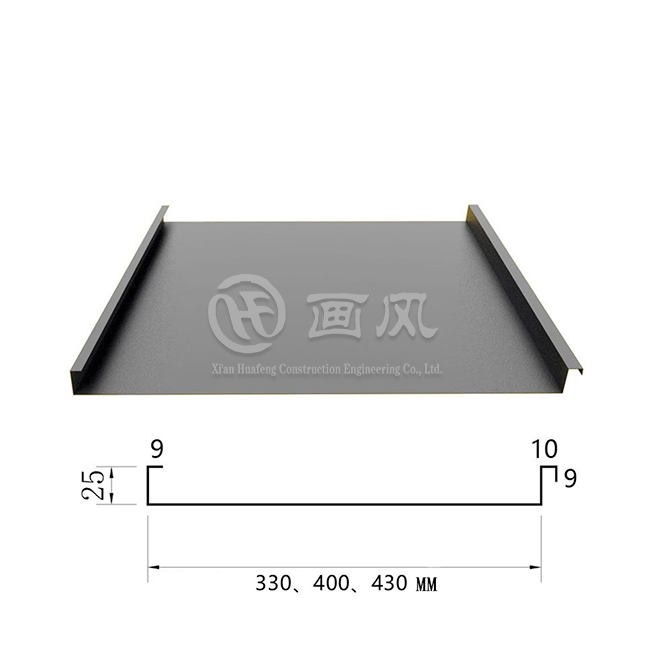

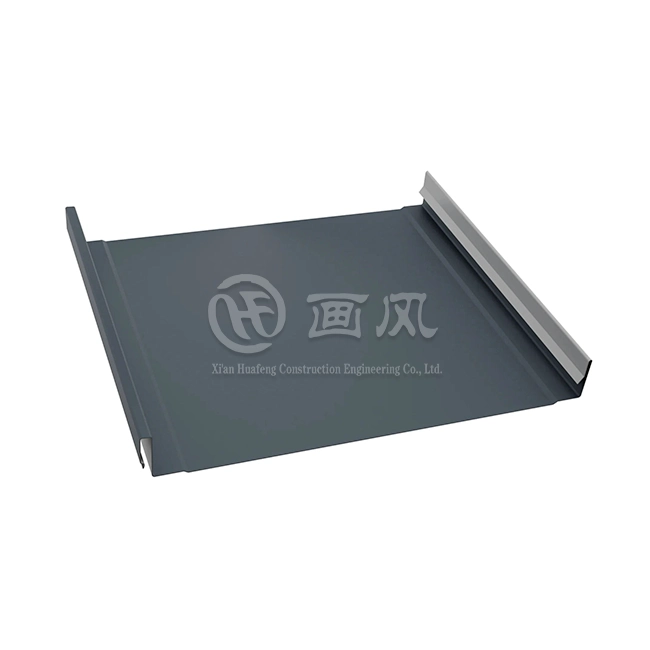

Inside Lock Metal Wall Panels represent a significant advancement in building envelope technology, offering architects and contractors a sophisticated alternative to conventional wall cladding systems. Unlike exposed fastener panels that compromise both aesthetics and weather resistance, Inside Lock Metal Wall Panels utilize a concealed clip system where fasteners are completely hidden within the panel joints. This innovative design approach creates a clean, uninterrupted facade while simultaneously providing enhanced protection against water infiltration and thermal bridging. The system works by mechanically interlocking adjacent panels through a specialized edge profile, with concealed clips secured to the building substrate. This method eliminates the unsightly appearance of exposed screws and prevents the common problems associated with fastener degradation, including rust staining and panel loosening over time. The manufacturing process for Inside Lock Metal Wall Panels involves precision roll-forming of high-grade aluminum alloy or galvanized steel substrates, with thickness typically ranging from 0.6mm to 1.5mm depending on project specifications and structural requirements. The panels can be customized in widths between 300mm and 600mm, with lengths extending up to 12 meters for uninterrupted vertical or horizontal installations. Surface treatments include PE polyester coatings for standard applications, HDP high-durability polyester for enhanced weather resistance, and PVDF fluoropolymer coatings that deliver exceptional UV resistance and color retention for up to 30 years. This manufacturing versatility allows Inside Lock Metal Wall Panels to meet diverse architectural visions while maintaining structural integrity across various climate conditions.

-

Understanding the Inside Lock Installation System

The Inside Lock system distinguishes itself through its engineered approach to panel attachment and weather sealing. Each panel features specially designed male and female edges that interlock during installation, creating a continuous weather barrier without relying on sealants or gaskets that can deteriorate over time. Installation begins with fixing concealed clips to the substrate at predetermined intervals, typically 400-600mm on center depending on wind load calculations. The first panel's male edge engages with the clip system, and subsequent panels lock into place by sliding their female edge over the previous panel's male edge, effectively concealing all fastening hardware. This method not only accelerates installation compared to traditional systems but also allows for thermal expansion and contraction without compromising the panel integrity or creating visible distortion. Professional installation of Inside Lock Metal Wall Panels requires specialized tools including edge-locking machines and calibrated hand seamers to ensure proper engagement between panel edges. The concealed nature of the fastening system means that installers must work with precision from the outset, as corrections after multiple panels have been installed become increasingly difficult. However, this same characteristic provides significant advantages in terms of maintenance and replacement. Should a panel become damaged, skilled technicians can remove and replace individual panels without disturbing adjacent sections, something virtually impossible with many conventional wall cladding systems where panels overlap or share visible fasteners.

Five Critical Advantages That Set Inside Lock Metal Wall Panels Apart

-

Enhanced Weather Protection and Water Management

Inside Lock Metal Wall Panels deliver unparalleled protection against moisture infiltration, a critical factor in building envelope performance and longevity. The concealed fastener design eliminates hundreds or even thousands of potential water entry points that plague exposed fastener systems, where each screw penetration creates a vulnerability for water intrusion. Over time, thermal cycling causes fastener holes to elongate, washer seals to compress and degrade, and metal panels to develop stress cracks around fastener locations. Inside Lock Metal Wall Panels eliminate these concerns entirely by positioning all fasteners behind the weatherproof panel surface, where they remain protected from UV exposure, temperature extremes, and moisture contact. The interlocking edge design functions as a drainage plane, channeling any water that penetrates the primary weather barrier downward and outward through designed weep paths at the system's base. This capillary break prevents water from being drawn into the wall assembly through surface tension, a common problem with systems that feature tight overlapping joints without proper drainage consideration. Field testing demonstrates that properly installed Inside Lock Metal Wall Panels can withstand sustained water exposure equivalent to driving rain conditions exceeding 100mm per hour without any moisture penetration to the substrate. This performance level proves particularly valuable in coastal environments, areas with frequent severe weather, and buildings where interior moisture control is critical, such as cold storage facilities, data centers, and healthcare institutions.

-

Superior Thermal Performance and Energy Efficiency

The thermal efficiency of Inside Lock Metal Wall Panels significantly exceeds that of traditional exposed fastener systems due to the elimination of thermal bridging at fastener locations. Each exposed fastener in a conventional system creates a thermal bypass where the metal screw shaft conducts heat or cold directly through the insulation layer and into the interior environment. In a typical commercial building facade with exposed fasteners on 12-inch centers, there may be over 10,000 individual thermal bridges, collectively reducing the effective R-value of the wall assembly by 15-25 percent compared to calculated values. Inside Lock Metal Wall Panels prevent this performance degradation by keeping all metal fasteners isolated from the exterior panel surface. When combined with continuous insulation strategies, Inside Lock Metal Wall Panels enable building envelope assemblies that achieve true thermal performance matching or exceeding design specifications. The concealed clip system allows for installation over various insulation types, including rigid foam boards, mineral wool, and spray-applied polyurethane, without compression or penetration of the insulation layer. This capability proves especially valuable for projects pursuing high-performance building certifications or seeking to minimize operational energy consumption. Buildings utilizing Inside Lock Metal Wall Panels with appropriate insulation strategies consistently demonstrate 20-30 percent reductions in heating and cooling loads compared to similar structures with conventional metal panel systems. These energy savings translate directly to reduced operational costs, improved occupant comfort, and substantially lower carbon emissions over the building's operational lifetime.

-

Exceptional Durability and Minimal Maintenance Requirements

Inside Lock Metal Wall Panels are engineered for decades of maintenance-free performance, with properly specified and installed systems routinely delivering service lives exceeding 30 years without requiring panel replacement or significant maintenance intervention. The concealed fastener design plays a central role in this longevity by protecting both the fasteners and the panel perforation points from environmental exposure. Exposed fastener systems commonly experience problems within 10-15 years as weather-resistant coatings on fasteners break down, allowing rust formation that stains panels and compromises structural connections. Inside Lock Metal Wall Panels avoid this degradation pathway entirely, as fasteners remain in a protected environment where they maintain their integrity indefinitely. The base materials used in Inside Lock Metal Wall Panels contribute significantly to their exceptional durability. High-grade aluminum alloys including AA3003, AA3004, and AA5005 offer excellent corrosion resistance without requiring additional protective coatings, making them ideal for aggressive environments including coastal locations with salt spray exposure and industrial settings with chemical fume presence. Galvanized steel substrates with G-90 coating or aluminum-zinc alloy coatings provide robust corrosion protection at lower material costs, while premium stainless steel grades 304 and 316 deliver ultimate longevity in the most demanding applications. Surface finish systems including PVDF fluoropolymer coatings resist fading, chalking, and chemical attack while maintaining their aesthetic appearance with only periodic washing to remove accumulated dirt and atmospheric deposits.

Maintenance requirements for Inside Lock Metal Wall Panels typically consist solely of annual visual inspections and gentle washing with clean water or mild detergent solutions. The absence of exposed fasteners eliminates the need for periodic re-tightening and seal replacement that burden conventional systems. Panels remain securely attached through their concealed clip connections, which experience no loosening or degradation over time. The interlocking panel edges maintain their weather seal without relying on sealant beads or gasket materials that require inspection and periodic replacement. This minimal maintenance profile translates to substantially reduced lifecycle costs and eliminates the recurring expenses and operational disruptions associated with maintaining traditional wall cladding systems.

-

Design Flexibility and Architectural Expression

Inside Lock Metal Wall Panels provide architects with exceptional design freedom to create distinctive building envelopes that express their creative vision while meeting performance requirements. The concealed fastener system enables completely smooth facade surfaces without the visual clutter of exposed screw heads that disrupt clean lines and modern aesthetics. This capability proves particularly valuable for contemporary architectural designs that emphasize minimalism, precision, and refined details. The uninterrupted panel surfaces can be specified in virtually unlimited color options through custom paint matching, allowing projects to achieve specific branding requirements or contextual design responses. Beyond color selection, Inside Lock Metal Wall Panels accommodate diverse finish options including metallic effects, matte surfaces, textured patterns, and even wood-grain embossing that replicates natural materials while maintaining metal's performance advantages. Panel widths can be varied across a single facade to create visual rhythm and proportion, with narrower panels emphasizing verticality and wider panels providing horizontal emphasis. The system adapts equally well to both vertical and horizontal installation orientations, and panels can transition between orientations on the same building to define architectural features or distinguish functional zones. Curved building forms present no obstacle, as panels can be gently curved through specialized roll-forming equipment to follow convex or concave building geometry with consistent appearance and weather performance.

The malleable nature of aluminum and steel substrates enables Inside Lock Metal Wall Panels to be formed into complex profiles beyond simple flat surfaces. Panels can incorporate subtle ribbing for added visual interest and structural rigidity, or feature deeper corrugations that create dramatic shadow lines and three-dimensional facade character. Perforated panel options introduce controlled transparency for applications requiring visual screening with maintained air flow, such as parking structure facades, mechanical equipment enclosures, and architectural sunshades. This comprehensive design flexibility empowers architects to specify Inside Lock Metal Wall Panels for projects ranging from simple industrial buildings to complex cultural institutions, knowing the system can deliver both their aesthetic aspirations and performance requirements.

-

Cost-Effectiveness Through Lifecycle Value

While Inside Lock Metal Wall Panels may present higher initial material costs compared to basic exposed fastener systems, they deliver superior cost-effectiveness when evaluated through comprehensive lifecycle analysis. The elimination of ongoing maintenance requirements immediately differentiates Inside Lock Metal Wall Panels from alternatives that demand periodic fastener inspection, seal replacement, and eventually complete panel replacement due to fastener-related degradation. A typical commercial building with exposed fastener wall panels might require maintenance intervention every 3-5 years, with major refurbishment or replacement necessary within 20 years. Inside Lock Metal Wall Panels eliminate these recurring costs while extending the facade service life to 30 years or beyond. Installation efficiency contributes additional economic value, as the concealed clip system typically installs faster than exposed fastener methods once crews develop familiarity with the technique. The absence of visible fasteners eliminates the time-consuming process of aligning screw patterns to create visually acceptable layouts, and installers work without constantly managing washer orientation and fastener tightness to prevent panel distortion or seal compromise. Labor productivity gains of 15-20 percent are commonly achieved compared to exposed fastener installations, offsetting the higher material costs and delivering competitive total installed pricing. Projects with significant staging or access challenges realize even greater value, as the durable, maintenance-free nature of Inside Lock Metal Wall Panels prevents costly future access requirements for facade maintenance.

The energy performance advantages of Inside Lock Metal Wall Panels generate ongoing operational savings that accumulate substantially over the building's lifetime. Reducing heating and cooling energy consumption by 20-30 percent translates to significant annual utility cost reductions, with the energy savings often recovering any premium material costs within 5-10 years depending on local utility rates and climate conditions. Beyond direct energy costs, improved thermal performance enhances occupant comfort, reduces HVAC equipment sizing and initial costs, and decreases the building's carbon footprint in alignment with increasingly stringent environmental regulations and corporate sustainability commitments. When all these factors combine, Inside Lock Metal Wall Panels consistently demonstrate superior return on investment compared to conventional alternatives.

Technical Specifications and Quality Assurance

Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Inside Lock Metal Wall Panels to exacting standards, ensuring consistent quality and reliable performance across every project. Our panels are produced using premium base materials sourced from industry-leading suppliers including Alucosuper, YATAI, and LIDAO for aluminum alloys in 3003, 3004, and 5052 grades. Steel substrates come from BAOSTEEL, GUANZHOU, and XINYU, providing cold rolled sheet, galvanized sheet, galvalume sheet, and color coated sheet options. For ultimate corrosion resistance, we offer stainless steel from Baosteel and Tsingshan in 304 and 316 grades, titanium zinc plate from NedZink, and copper materials from Chinalco in T2 and TP2 specifications. Our comprehensive quality control process begins with incoming material inspection, where every delivery undergoes rigorous verification including material certifications and third-party testing reports. Our quality assurance team performs more than a dozen inspection steps covering product appearance, dimensional accuracy, salt spray resistance, coating adhesion, hardness testing, impact resistance, film thickness measurement, acid resistance, weatherability testing, and color consistency verification. During production, our seven color coating lines, one laminating line, and ten longitudinal and transverse shearing lines operate under continuous monitoring, with real-time adjustments ensuring dimensional precision and surface quality perfection. Finished panels undergo additional inspection for appearance, size accuracy, flatness, and curvature before being carefully packaged in sectioned arrangements that facilitate efficient site installation.

Conclusion

Inside Lock Metal Wall Panels deliver exceptional weather protection, thermal performance, durability, design flexibility, and lifecycle value that conventional systems cannot match, making them the intelligent choice for modern construction projects demanding both aesthetic excellence and long-term performance reliability.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Inside Lock Metal Wall Panels manufacturer and China Inside Lock Metal Wall Panels supplier, Xi'an Huafeng Construction Engineering Co., Ltd. leads the industry with comprehensive capabilities spanning design, production, and installation. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province in 2020, we hold first-level qualification for building curtain walls and third-level qualification for building steel structures. Our 200,000-square-meter raw material production facility in Anhui, combined with plate and accessories processing plants in Hangzhou and Xi'an, ensures efficient production and timely delivery. With 3 factories, 7 production lines, and more than 40 advanced machines, we maintain a supply ability of 1000 tons per month, meeting projects of any scale.

Our China Inside Lock Metal Wall Panels factory produces High Quality Inside Lock Metal Wall Panels with customized services for color, pattern, and design, backed by more than 20 registered patents and certifications including ISO9001, ISO14000:14001, and SGS. We offer Inside Lock Metal Wall Panels for sale with competitive Inside Lock Metal Wall Panels price through our China Inside Lock Metal Wall Panels wholesale programs. From structural 3D modeling and load analysis to precision manufacturing and seamless installation, we provide one-stop solutions that ensure your project succeeds. Our experienced team has completed prestigious projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, delivering excellence consistently.

Ready to elevate your building's performance and aesthetics? Contact our team today at huafeng@hfmetalroof.com to discuss your Inside Lock Metal Wall Panels requirements and receive a detailed quotation. Let us transform your architectural vision into reality with our proven expertise and commitment to quality.

References

1. Metal Construction Association, "Life Cycle Assessment and Environmental Product Declarations for Metal Building and Roofing Products," MCA Technical Standards, 2023.

2. Johnson, R.M. and Peterson, L.K., "Concealed Fastener Systems in Commercial Building Envelopes: Performance Analysis and Design Considerations," Journal of Architectural Engineering, Volume 28, Issue 4, 2024.

3. American Society for Testing and Materials, "ASTM E1592 Standard Test Method for Structural Performance of Exterior Dimension Stone Cladding Systems by Uniform Static Air Pressure Difference," ASTM International Standards, 2022.

4. National Institute of Building Sciences, "Whole Building Design Guide: Metal Wall Panel Systems - Design and Construction Best Practices," NIBS Building Enclosure Technology and Environment Council, 2024.