Are you tired of constantly repairing your roof after every storm season? Standing Seam Metal Roof Sheets are a premium roofing solution that features vertical panels with raised, interlocking seams and concealed fasteners, offering exceptional weather resistance, durability lasting up to 50 years, and a sleek modern appearance that eliminates the common headaches of traditional roofing materials.

Understanding Standing Seam Metal Roof Sheets: The Modern Roofing Solution

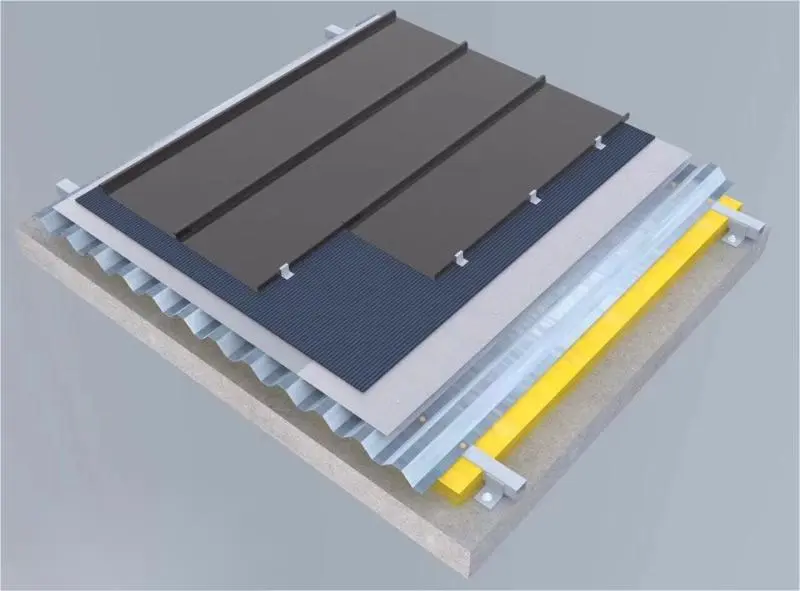

Standing Seam Metal Roof Sheets represent a revolutionary approach to building protection that has transformed both commercial and residential construction. These specialized panels feature a distinctive design where vertical metal sheets connect through raised seams that stand elevated above the flat surface of the roof, typically ranging from 25mm to 65mm in height. This innovative configuration creates a concealed fastener system where screws and attachments remain hidden beneath the panels, protecting them from direct exposure to ultraviolet radiation, moisture penetration, and thermal cycling that can cause premature failure in conventional roofing systems. The engineering behind Standing Seam Metal Roof Sheets focuses on creating a continuous barrier against water infiltration while accommodating the natural expansion and contraction that occurs with temperature fluctuations. Unlike traditional roofing materials that rely on overlapping shingles or exposed fasteners, these metal panels utilize mechanical seaming or snap-lock technology to form weathertight connections that run continuously from ridge to eave. This seamless integration eliminates horizontal joints where water might pool or penetrate, making them particularly effective in regions experiencing heavy rainfall, snow accumulation, or extreme weather events that would compromise less robust roofing systems.

The Structural Design and Material Composition

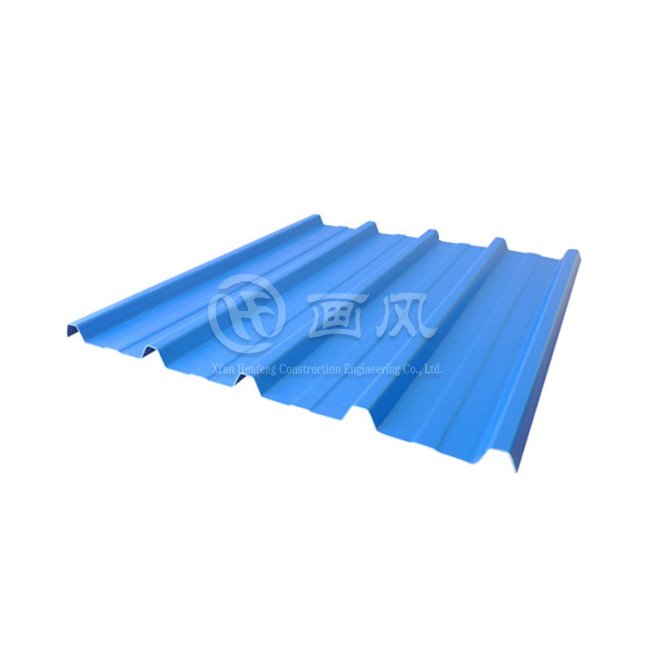

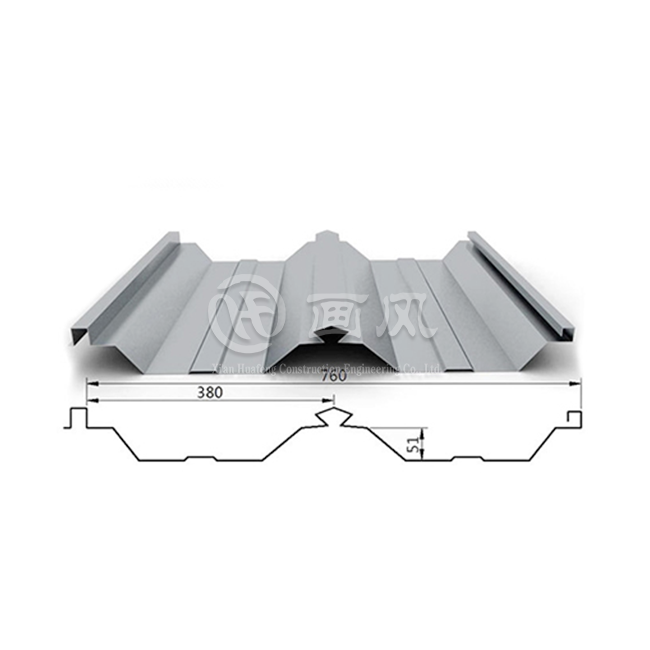

Standing Seam Metal Roof Sheets are manufactured from high-grade materials including galvanized steel, aluminum-magnesium-manganese alloys, stainless steel, titanium-zinc, and copper, each offering distinct performance characteristics suited to different environmental conditions and architectural requirements. The thickness typically ranges from 0.5mm to 1.2mm, with common gauges including 24-gauge and 26-gauge steel that provide optimal balance between structural strength and workability during installation. Surface treatments such as PVDF (Polyvinylidene Fluoride) and PE (Polyester) coatings add additional layers of protection against corrosion, fading, and chalking, while enabling a wide spectrum of color options from the RAL and Pantone systems to match any architectural vision. The panel specifications vary to accommodate different span requirements and aesthetic preferences, with common profiles including 25-330, 25-400, 25-430, 32-410, 45-400, and 65-400 configurations where the first number indicates seam height and the second represents coverage width in millimeters. These dimensional variations allow architects and contractors to optimize material usage while ensuring adequate structural performance for specific roof pitches, wind load requirements, and thermal insulation needs. The roll-forming manufacturing process creates panels in custom lengths up to 12 meters, eliminating horizontal seams that would otherwise create potential leak points and visual discontinuities across large roof expanses.

How Standing Seam Systems Outperform Traditional Roofing?

The concealed fastener system that defines Standing Seam Metal Roof Sheets provides fundamental advantages over exposed fastener alternatives commonly found on agricultural buildings and budget-conscious projects. When fasteners penetrate directly through roofing material, they create thousands of potential failure points where water can enter once sealant washers degrade from constant exposure to solar radiation and thermal cycling. Standing Seam Metal Roof Sheets eliminate this vulnerability by positioning all attachment hardware beneath the panels or within the raised seams themselves, where they remain protected from weather elements throughout the roof's service life, which typically exceeds 30 to 50 years depending on material selection and environmental conditions. The thermal movement accommodation built into Standing Seam Metal Roof Sheets represents another critical engineering advantage that prevents the buckling, oil-canning, and fastener distress that plagues fixed metal roofing systems. Special clips allow panels to expand and contract freely in response to temperature changes that can cause dimensional variations of several centimeters across long panel runs. This floating attachment method maintains weathertight integrity while preventing stress accumulation that would otherwise lead to fastener pull-through, panel distortion, or seam separation over time. The result is a roofing system that maintains its structural integrity and aesthetic appearance throughout decades of service despite exposure to extreme temperature swings, intense solar radiation, and moisture cycling.

Key Benefits of Choosing Standing Seam Metal Roof Sheets

Superior Weather Resistance and Waterproofing Performance

Standing Seam Metal Roof Sheets excel in environments where water infiltration poses a constant threat to building integrity and interior conditions. The raised seam configuration elevates the critical connection points 25mm to 65mm above the flat panel surface, creating a substantial vertical barrier that water must overcome to potentially penetrate the roofing system. This geometric advantage becomes particularly important during heavy rain events, wind-driven precipitation, or ice dam conditions where water might otherwise work its way through horizontal overlaps or capillary action gaps present in conventional roofing materials. The continuous panel runs that characterize Standing Seam Metal Roof Sheets eliminate the horizontal lap joints found in shorter roofing materials where water infiltration most commonly occurs. By extending panels from ridge to eave without interruption, these systems reduce potential leak points to the deliberately engineered and properly sealed vertical seams rather than distributing vulnerability across hundreds of overlapping connections. When combined with high-quality underlayment systems and properly executed flashing details at roof penetrations and transitions, Standing Seam Metal Roof Sheets create a virtually impenetrable barrier against moisture intrusion that protects building structures, insulation systems, and interior finishes throughout the roof's extended service life.

Exceptional Durability and Long Service Life

The material composition and protective coatings applied to Standing Seam Metal Roof Sheets enable them to resist the degradation mechanisms that limit the lifespan of alternative roofing materials. Unlike asphalt shingles that become brittle and crack from ultraviolet exposure, or wood shakes that rot from moisture retention, metal panels maintain their structural integrity throughout decades of exposure to solar radiation, precipitation, and thermal cycling. The PVDF and SMP coatings commonly applied to Standing Seam Metal Roof Sheets provide excellent resistance to chalking, fading, and chemical attack from atmospheric pollutants, maintaining their color and finish quality for 30 years or more in typical environments. The mechanical properties of metals used in Standing Seam Metal Roof Sheets contribute to their ability to withstand physical impacts from hail, falling branches, and maintenance traffic that would damage or penetrate less robust roofing materials. Aluminum-magnesium-manganese alloys offer excellent strength-to-weight ratios while resisting corrosion in coastal environments where salt spray accelerates degradation of ordinary steel. Galvanized and Galvalume steel provide cost-effective durability for inland applications, while stainless steel and titanium-zinc options deliver premium performance in the most demanding conditions. This material versatility allows Standing Seam Metal Roof Sheets to be optimized for specific environmental challenges while maintaining the fundamental durability advantages inherent to metal roofing systems.

Energy Efficiency and Thermal Performance

Standing Seam Metal Roof Sheets contribute to building energy efficiency through their inherent solar reflectance properties that reduce heat absorption compared to darker, more absorptive roofing materials like asphalt shingles or dark membrane systems. The smooth, metallic surface reflects a significant portion of incident solar radiation back into the atmosphere rather than converting it to thermal energy that would otherwise conduct into the building envelope, potentially reducing cooling loads by up to 25 percent in warm climates. Special cool roof coatings with enhanced reflectivity and emissivity characteristics can further improve this performance, often qualifying buildings for energy efficiency incentives and reduced insurance premiums. The air space created between Standing Seam Metal Roof Sheets and the structural deck provides an opportunity for ventilation that promotes passive cooling during warm weather while the low thermal mass of metal panels allows them to cool quickly after sunset, unlike massive roofing materials that store heat and continue radiating it into buildings throughout evening hours. When combined with proper insulation systems positioned below the metal panels, Standing Seam Metal Roof Sheets create highly efficient thermal barriers that minimize heat transfer in both directions, reducing heating costs during cold months while maintaining the summer cooling benefits. This year-round energy performance contributes to operational cost savings that help offset the higher initial investment required for Standing Seam Metal Roof Sheets compared to conventional roofing alternatives.

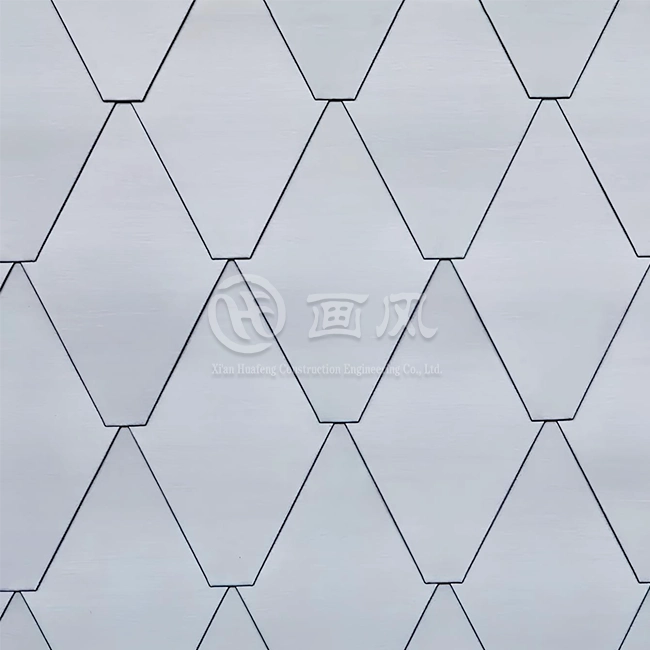

Aesthetic Appeal and Architectural Versatility

The clean, linear appearance of Standing Seam Metal Roof Sheets has made them increasingly popular for contemporary architectural designs where bold geometric forms and uncluttered surfaces create visual impact and modern sophistication. The concealed fastener system eliminates the visual distraction of exposed screw heads that characterize corrugated and ribbed metal roofing, creating smooth expanses of color and texture that emphasize building form rather than roofing mechanics. The vertical seam lines create strong visual rhythms that complement both modernist designs and more traditional architectural styles when specified with appropriate colors and finishes. Standing Seam Metal Roof Sheets are available in an extensive range of colors spanning the complete RAL and Pantone systems, enabling precise color matching to corporate branding requirements, regional aesthetic preferences, or specific design concepts. Finish options include high-gloss, matte, and textured surfaces that create different visual effects while maintaining the protective properties of the underlying coating systems. The ability to specify custom panel widths, seam heights, and panel lengths allows architects to optimize the visual proportions of Standing Seam Metal Roof Sheets for specific building scales and roof geometries, creating cohesive designs that integrate roofing as a considered architectural element rather than merely a protective covering.

Manufacturing Excellence and Quality Control at Xi'an Huafeng

Xi'an Huafeng Construction Engineering Co., Ltd. has established comprehensive manufacturing capabilities that ensure consistent quality and reliable performance across all Standing Seam Metal Roof Sheets production. Our raw material production plant in Anhui spans 200,000 square meters and houses seven dedicated color coating production lines that apply PVDF and PE finishes with precise thickness control and uniform coverage. These facilities work in coordination with our two plate and accessories processing plants located in Hangzhou and Xi'an, where more than 40 specialized machines including longitudinal shearing lines, transverse cutting systems, fully automatic punching equipment, and precision roll-forming machinery transform coated coils into finished Standing Seam Metal Roof Sheets that meet the exact specifications of each project.

Rigorous Material Selection and Incoming Quality Verification

Our material procurement process begins with careful supplier qualification based on established brand recognition and documented quality performance. For Standing Seam Metal Roof Sheets production, we source aluminum from certified manufacturers including Alucosuper, YATAI, and LIDAO, specifying alloys such as 3003, 3004, and 5052 that provide optimal combinations of formability, strength, and corrosion resistance. Steel materials come from premium suppliers including BAOSTEEL, GUANZHOU, and XINYU, encompassing cold rolled sheet, galvanized sheet, Galvalume sheet, and color coated sheet in various grades optimized for different performance requirements and environmental exposures. Every incoming material shipment undergoes comprehensive inspection procedures that verify conformance to specified properties before release for production. Our quality assurance team conducts more than a dozen distinct tests including appearance inspection for surface defects, dimensional verification of thickness and width tolerances, salt spray exposure to evaluate corrosion resistance, adhesion testing to confirm coating bond strength, hardness measurement to verify material properties, impact resistance assessment, film thickness confirmation, acid resistance evaluation, accelerated weathering simulation, and color difference analysis against approved standards. This rigorous incoming material inspection ensures that only materials meeting our stringent quality criteria enter production, establishing the foundation for Standing Seam Metal Roof Sheets that deliver reliable long-term performance.

Precision Manufacturing and Finished Product Verification

The production of Standing Seam Metal Roof Sheets at Xi'an Huafeng follows detailed processing drawings that break down each project into numbered components corresponding to specific roof sections and installation sequences. This systematic approach ensures that every panel receives proper identification linking it to its intended location, facilitating efficient quality assurance inspection, organized packaging, and streamlined installation without confusion or rework. Our roll-forming equipment produces Standing Seam Metal Roof Sheets with consistent profile dimensions, smooth surfaces free from oil-canning distortions, and precise edge conditions that enable proper seam engagement during installation. Finished product inspection procedures verify that completed Standing Seam Metal Roof Sheets meet all specification requirements before packaging and shipment. Inspection steps include comprehensive appearance evaluation to identify any surface defects, scratches, or coating imperfections that would compromise aesthetic quality or protective performance. Dimensional verification confirms that panel widths, lengths, and seam heights match specified tolerances, while flatness and curvature measurements ensure that panels will install properly without excessive waviness or distortion. Panels that fail to meet our quality standards are rejected and reprocessed rather than shipped to customers, maintaining our commitment to delivering Standing Seam Metal Roof Sheets that perform as intended throughout their entire service life.

Comprehensive Installation Support and Project Implementation

Xi'an Huafeng provides complete installation support that begins with detailed project drawing development and extends through final acceptance testing and maintenance guidance. Our engineering team conducts thorough analysis of architectural plans, elevations, and structural details to develop optimized Standing Seam Metal Roof Sheets specifications that address the unique requirements of each project while maximizing material efficiency and installation productivity. This front-end engineering work includes structural load analysis to verify adequate support capacity, drainage system simulation to confirm proper water management, and material specification advisory services that recommend optimal material grades, thicknesses, and coating systems for specific environmental conditions and performance expectations.

Technical Documentation and Sample Production

The project implementation process includes multiple stages of drawing refinement where our design department creates detailed node drawings showing precise connections, transitions, and flashing details for every unique condition on the project. These 1:1 scale drawings undergo review and revision through collaborative communication with customers until all parties agree on the technical approach, after which both parties sign and confirm the deepening drawings that will guide subsequent fabrication and installation. This thorough documentation process minimizes field uncertainties and ensures that Standing Seam Metal Roof Sheets arrive at the project site ready for efficient installation without requiring significant field modifications or problem-solving. Sample production precedes full-scale manufacturing, allowing customers to physically verify that material specifications, colors, surface finishes, and dimensional characteristics match their expectations before committing to complete panel fabrication. These samples undergo the same production processes and quality inspections as full production panels, providing accurate representation of the finished Standing Seam Metal Roof Sheets that will cover the building. Upon customer approval, samples are sealed and retained as reference standards for subsequent production quality assurance, ensuring consistency throughout panel fabrication even on large projects requiring multiple production runs or extended manufacturing schedules.

On-Site Construction Management and Quality Assurance

Our installation support extends to comprehensive on-site guidance that ensures Standing Seam Metal Roof Sheets achieve their full performance potential through proper installation practices. Installation technicians visit project sites before panel delivery to assess working conditions, verify that substrates meet requirements for panel attachment, and confirm that necessary tools and accessories are available to support efficient installation without delays or improvisation. This preparation includes organizing storage areas that protect panels from damage during the construction period, establishing processing zones where final trim cuts can be made safely and accurately, and reviewing safety protocols that protect both workers and building occupants during installation activities. Throughout installation, our technical representatives provide hands-on guidance demonstrating proper panel handling techniques, correct seaming procedures, appropriate fastener installation practices, and quality verification methods that ensure weathertight connections. Upon completion, comprehensive testing verifies zero leakage under simulated rainfall conditions, confirming that Standing Seam Metal Roof Sheets perform as designed before project acceptance. This thorough installation support, combined with clear maintenance guidance for ongoing performance optimization, ensures that our Standing Seam Metal Roof Sheets deliver the full durability, weather resistance, and aesthetic benefits that motivated their selection.

Proven Performance Across Diverse Applications

Xi'an Huafeng's Standing Seam Metal Roof Sheets have been successfully installed on numerous high-profile projects across China, demonstrating their versatility and reliability across different building types, scales, and environmental conditions. Our project portfolio includes the Xiongan Station Commercial Body where aluminum-magnesium-manganese Standing Seam Metal Roof Sheets cover extensive roof areas with complex geometries and demanding aesthetic requirements. The Xi'an International Convention and Exhibition Center showcases the architectural impact achievable with properly specified and expertly installed standing seam systems that integrate with sophisticated building designs while meeting stringent performance criteria for public assembly facilities. Transportation infrastructure projects including the Xi'an Station East Auxiliary Building and the Liyuanping Highway Station demonstrate the durability and low maintenance characteristics that make Standing Seam Metal Roof Sheets particularly suitable for facilities requiring long service life with minimal operational disruption. Cultural and institutional buildings including the Jinghe New City International Culture and Art Center South Hall, the Archaeological Museum design deepening project, and the Inner Mongolia Tongliao Art Museum illustrate how Standing Seam Metal Roof Sheets can be adapted to meet the unique aesthetic and technical requirements of architecturally significant structures. Educational facilities such as the Weihua Cadre College Teaching Building and Office Building, along with infrastructure projects like the Hangzhou Sanpu Drainage Pump Station, demonstrate the breadth of applications where Standing Seam Metal Roof Sheets deliver superior value through their combination of performance, appearance, and lifecycle cost advantages.

Conclusion

Standing Seam Metal Roof Sheets deliver unmatched durability, superior weather protection, and modern aesthetics through their innovative concealed fastener design and premium material construction. With service lives exceeding 30 to 50 years, minimal maintenance requirements, excellent energy efficiency, and comprehensive manufacturer support, they represent a smart long-term investment for commercial, industrial, and residential buildings demanding the highest roofing performance standards.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 as a high-tech enterprise in Shaanxi Province, specializes in the design, production, sales, and construction of metal roofing systems, building curtain wall systems, and steel structure enclosure systems. Holding first-level qualifications for building curtain walls and third-level qualifications for building steel structures, we integrate green sustainable development principles into every aspect of our operations. Our mission focuses on developing innovative metal roof solutions that add production capacity benefits, optimize idle building roofs, and enhance architectural beauty while meeting the highest quality standards stipulated by ISO9001, ISO14000:14001, and SGS guidelines supported by more than 20 registered patents.

As a China Standing Seam Metal Roof Sheets factory, China Standing Seam Metal Roof Sheets supplier, and China Standing Seam Metal Roof Sheets manufacturer offering comprehensive China Standing Seam Metal Roof Sheets wholesale services, we provide Standing Seam Metal Roof Sheets for sale at competitive Standing Seam Metal Roof Sheets price points without compromising on High Quality Standing Seam Metal Roof Sheets specifications. Our advanced manufacturing infrastructure featuring seven raw material production lines, more than 40 specialized processing machines, and ISO-certified quality management systems ensures consistent delivery of premium products backed by 30-year warranties. We offer one-stop solutions from custom engineering design and raw material quality testing through precision manufacturing, secure packaging, and comprehensive installation guidance, all supported by multiple certifications and proven performance on projects ranging from transportation hubs to cultural institutions. Contact us today at huafeng@hfmetalroof.com to discuss how our engineering expertise, manufacturing excellence, and customized solutions can bring superior roofing performance to your next project.

References

1. Sheffield Metals. "Standing Seam Metal Roofing: Types, Benefits, and Installation Guide." Metal Roofing Learning Center.

2. Western States Metal Roofing. "Ten Benefits of Standing Seam Metal Roofing Systems." Roofing Technical Publications.

3. American Iron and Steel Institute. "Standing Seam Metal Roofing Performance Standards and Applications." AISI Construction Guidelines.

4. Green Building Council. "Energy Efficiency and Sustainability of Metal Roofing Systems." LEED Reference Materials.

5. Metal Construction Association. "Concealed Fastener Metal Panel Systems: Design and Installation Best Practices." MCA Technical Publications.