Finding a reliable supplier for large-scale corrugated galvanized metal panel projects can be a nightmare. Delays in production, inconsistent quality standards, and hidden costs often plague construction managers and procurement specialists seeking bulk orders. The challenge becomes even more critical when you need custom specifications, strict delivery timelines, and comprehensive technical support. The answer lies in partnering with manufacturers who combine production capacity, quality certifications, and proven engineering expertise to deliver Corrugated Galvanized Metal Panel solutions that meet international standards while maintaining competitive pricing structures for high-volume orders.

Understanding OEM Corrugated Galvanized Metal Panel Production Requirements

When sourcing corrugated galvanized metal panels at scale, understanding the fundamental production requirements separates successful projects from costly failures. OEM manufacturing of Corrugated Galvanized Metal Panel products requires sophisticated infrastructure that goes far beyond basic metal fabrication capabilities. The corrugated galvanized metal manufacturing process involves multiple critical stages, starting with raw material selection and extending through galvanization, roll-forming, quality inspection, and precise packaging systems. Modern production facilities utilize advanced roll-forming systems that transform flat galvanized steel sheets into corrugated profiles with exceptional precision. These systems must maintain consistent wave heights ranging from 8mm to 80mm and wave distances between 60mm and 300mm, depending on structural requirements and architectural specifications. The galvanization process itself involves hot-dip coating techniques that apply zinc layers ranging from Z80 to Z275 grams per square meter, providing the corrosion resistance essential for long-term performance in demanding environmental conditions. Production capacity represents another crucial consideration when evaluating OEM suppliers for large-scale projects. Manufacturers must demonstrate the ability to process substantial monthly volumes while maintaining strict quality standards throughout every production run. The integration of multiple production lines, automated punching systems, and comprehensive quality control protocols ensures that each Corrugated Galvanized Metal Panel meets specified dimensional tolerances, mechanical properties, and surface finish requirements. Raw material traceability systems allow manufacturers to track every batch from steel mill delivery through final panel production, providing complete documentation for quality assurance purposes.

Critical Specifications for Large-Scale Orders

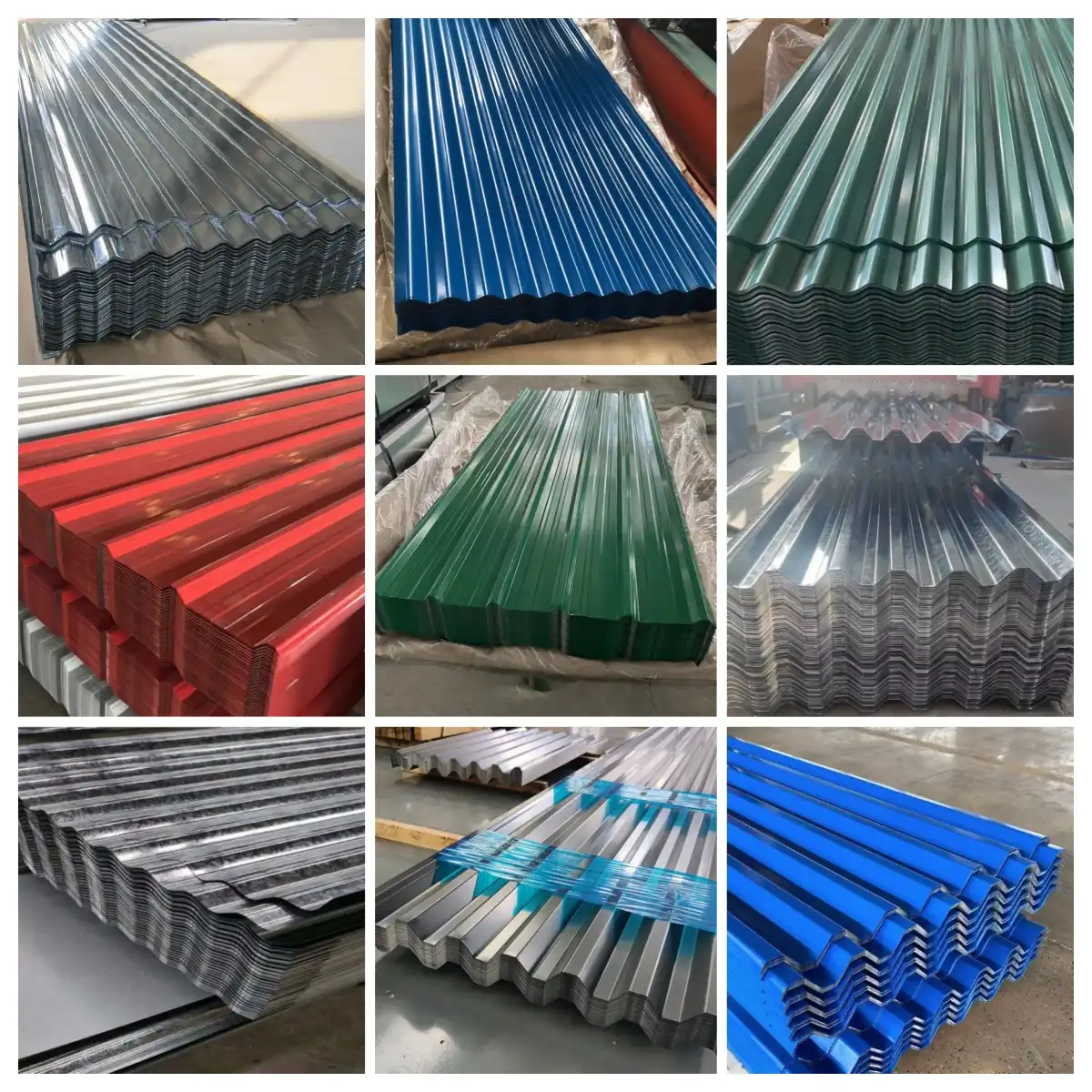

Material specifications for corrugated galvanized metal panels at scale must address multiple technical parameters that directly impact structural performance and longevity. Base material selection typically involves low carbon steel grades such as Q235 or SGCC, offering optimal combinations of formability, strength, and welding characteristics. Thickness ranges commonly span from 0.12mm to 1.5mm, with most structural applications utilizing panels between 0.3mm and 0.6mm thickness to balance weight considerations with load-bearing requirements. The galvanization coating represents the primary defense against corrosion, making coating weight specifications critically important for long-term performance. Standard coating weights include Z80, Z120, Z180, and Z275 designations, with heavier coatings providing enhanced protection in coastal environments or industrial settings with high atmospheric contamination. Additional protective coatings such as PE, HDP, or PVDF can be applied over the galvanized substrate to enhance aesthetic appeal while providing supplementary weather resistance and UV protection.

Dimensional specifications must account for the specific corrugation profile required for each application. Trapezoidal, sine wave, and U-shaped profiles each offer distinct structural characteristics and aesthetic appearances. Panel width customization typically ranges from 600mm to 1200mm, with coverage widths varying based on the degree of overlap required for weather-tight installation. Length customization capabilities extending from 1 meter to 12 meters allow manufacturers to minimize on-site cutting requirements and reduce installation waste. Mechanical properties including tensile strength, yield strength, and elongation percentages must meet or exceed international standards such as ASTM, DIN, JIS, BS, or GB/T specifications. Typical performance parameters include tensile strength values of at least 300 MPa, yield strength exceeding 240 MPa, and elongation percentages of 15% or greater, ensuring panels maintain structural integrity under applied loads while accommodating thermal expansion and contraction cycles.

Evaluating Manufacturing Capabilities for Scale Production

The manufacturing capabilities of potential OEM suppliers directly determine their ability to deliver consistent quality at scale while meeting aggressive project timelines. Comprehensive evaluation requires examining production infrastructure, quality management systems, customization capabilities, and supply chain resilience. Manufacturers specializing in Corrugated Galvanized Metal Panel production must demonstrate substantial investment in modern equipment, trained technical personnel, and systematic quality control protocols. Production line quantity and configuration provide immediate insights into manufacturing capacity and operational flexibility. Leading manufacturers typically operate seven or more color coating production lines, multiple laminating systems, and extensive longitudinal and transverse shearing capabilities. This infrastructure enables simultaneous processing of multiple orders with varying specifications, reducing lead times and improving delivery reliability. Roll-forming equipment must demonstrate precision tolerances capable of maintaining consistent corrugation profiles across thousands of linear meters of production without significant tool wear or dimensional drift. Quality control systems represent the backbone of reliable OEM manufacturing operations. Comprehensive incoming material inspection procedures verify that raw steel substrates, galvanization coatings, and paint systems meet specified chemical and physical properties before entering production streams. In-process monitoring includes dimensional verification, surface quality assessment, and coating thickness measurement at multiple production stages. Final product inspection protocols encompass appearance evaluation, flatness and curvature measurements, salt spray testing, adhesion verification, hardness assessment, and impact resistance confirmation.

Certification Standards and Quality Assurance

International certification standards provide objective validation of manufacturing quality and management system effectiveness. ISO 9001 certification demonstrates implementation of comprehensive quality management systems covering all aspects of production operations, from design and development through manufacturing execution and customer service delivery. ISO 14001 environmental management certification indicates commitment to sustainable manufacturing practices, waste reduction initiatives, and environmental impact minimization. Product-specific certifications such as CE marking confirm compliance with European safety, health, and environmental protection standards, facilitating market access across international markets. SGS certification provides third-party verification of product specifications, quality standards, and performance characteristics, offering customers additional confidence in material properties and manufacturing consistency. These certifications require regular audits, continuous improvement documentation, and systematic corrective action programs to maintain active status. Patent portfolios and intellectual property holdings demonstrate innovation capabilities and technical expertise. Manufacturers holding twenty or more registered patents related to roofing system design, installation methods, or product configurations typically possess deeper engineering knowledge and superior problem-solving capabilities. This innovation focus translates into better technical support, more effective customization solutions, and enhanced product performance characteristics.

Key Advantages of Partnering with Established OEM Manufacturers

Established OEM manufacturers of corrugated galvanized metal panels bring substantial competitive advantages that directly benefit large-scale construction projects and industrial applications. Their accumulated expertise, refined production processes, and comprehensive service offerings create value throughout the project lifecycle, from initial design consultation through final installation and ongoing maintenance support. Production efficiency represents a primary advantage of working with experienced manufacturers. Established facilities have optimized material flow patterns, minimized changeover times between different product specifications, and implemented lean manufacturing principles that reduce waste while maximizing output quality. This operational excellence translates into shorter lead times, more competitive pricing structures, and greater scheduling flexibility for customers managing complex project timelines with multiple delivery windows. Technical expertise accumulated over years of production experience enables established manufacturers to provide valuable design optimization guidance. Engineering teams familiar with diverse application requirements can recommend optimal corrugation profiles, material thicknesses, and coating specifications for specific project conditions. This consultative approach helps customers avoid over-specification that unnecessarily increases costs while ensuring that selected products deliver required performance characteristics across anticipated service life spans.

Customization Capabilities and Engineering Support

Customization capabilities distinguish professional OEM manufacturers from commodity suppliers focused solely on standard product offerings. Comprehensive customization services address color selection, pattern development, corrugation profile modification, and dimensional adaptation to meet precise project requirements. Advanced manufacturers maintain extensive material selection libraries encompassing multiple aluminum alloys, various steel grades, stainless steel options, and specialized materials such as titanium-zinc composites. Engineering support services extend beyond basic product selection to include structural analysis, load calculation assistance, drainage system design, and installation method optimization. Three-dimensional modeling capabilities allow technical teams to visualize complex roof configurations, identify potential installation challenges, and develop detailed fabrication drawings before production begins. This proactive approach minimizes costly field modifications and reduces installation time requirements. Project-specific sample production enables customers to verify material specifications, surface finishes, and color accuracy before committing to full production runs. Sample panels undergo the same manufacturing processes as final products, providing authentic representation of appearance characteristics and physical properties. This verification step proves particularly valuable for architectural applications where aesthetic considerations carry significant importance alongside structural performance requirements.

Supply Chain Considerations for Large-Scale Projects

Effective supply chain management becomes increasingly critical as project scale expands and delivery coordination complexity increases. Successful OEM partnerships require careful evaluation of raw material sourcing strategies, production scheduling flexibility, packaging methodologies, logistics capabilities, and inventory management approaches. Manufacturers with robust supply chains deliver superior reliability, reduced procurement risk, and enhanced project outcomes. Raw material sourcing strategies directly impact product consistency and cost stability throughout multi-phase projects. Leading manufacturers maintain qualified supplier networks encompassing premium material providers with established quality reputations. For Corrugated Galvanized Metal Panel production, this includes relationships with major steel mills, galvanizing facilities, and coating material suppliers. Multiple sourcing options for critical materials provide supply continuity insurance against disruptions while creating competitive pricing leverage. Production scheduling flexibility allows manufacturers to accommodate varying delivery requirements across complex construction timelines. Facilities operating multiple shifts with adequate equipment capacity can respond to expedited delivery requests, manage staggered shipment schedules, and adjust production priorities as project conditions evolve. This operational agility proves particularly valuable when managing large-scale developments with sequential building phases or weather-dependent installation windows.

Packaging and Logistics Excellence

Packaging methodology significantly influences material handling efficiency and on-site installation productivity. Professional OEM manufacturers develop packaging systems specifically designed to facilitate construction site material management. Corrugated galvanized metal panels require protection from scratches, dents, and moisture contamination during transportation and storage. Advanced packaging includes protective film application, strategic bundling configurations, and weather-resistant wrapping materials. Section-based packaging organization aligns material delivery with installation sequences, reducing sorting requirements and minimizing handling time at construction sites. Each package includes detailed identification cards displaying section reference numbers, panel quantity lists, and installation sequence information. This systematic approach enables installation crews to quickly locate required materials without extensive searching or unnecessary package opening. Transportation logistics for large-scale panel orders require careful coordination to optimize freight costs while maintaining delivery schedule integrity. Manufacturers with established relationships across multiple transportation providers can leverage competitive shipping rates while ensuring adequate equipment availability during peak construction seasons. Geographic distribution of manufacturing and processing facilities reduces transportation distances and associated costs for regional projects.

One-Stop Solution Integration

Comprehensive service integration differentiates premium OEM manufacturers from simple product suppliers. One-stop solution providers manage the entire project lifecycle, offering design consultation, engineering analysis, custom manufacturing, quality verification, installation support, and maintenance guidance under unified management. This integrated approach streamlines procurement processes, reduces coordination complexity, and improves overall project outcomes through enhanced accountability and communication efficiency. Design phase services include detailed architectural drawing review, feasibility analysis for alternative panel configurations, and development of optimized roofing system specifications. Technical teams evaluate structural requirements, drainage patterns, thermal performance expectations, and aesthetic objectives to recommend optimal product selections. Computer-aided design tools enable visualization of proposed solutions, facilitating informed decision-making and stakeholder alignment before production commitments. Manufacturing phase management encompasses complete production oversight from raw material procurement through final panel fabrication and packaging. Dedicated project managers coordinate production scheduling, quality control verification, and delivery logistics to ensure seamless execution. Regular progress updates and photographic documentation provide customers with real-time visibility into manufacturing status, enabling proactive management of downstream construction activities.

Installation Support and Technical Training

Installation support services prove invaluable for large-scale projects where proper installation techniques directly determine long-term system performance and warranty compliance. Experienced manufacturers provide on-site technical guidance, ensuring installation crews understand panel handling requirements, fastening specifications, overlap configurations, and weather sealing procedures. Pre-installation consultations address site-specific challenges, tool requirements, and safety protocols before work begins. Technical training programs equip installation teams with knowledge and skills necessary for efficient, high-quality panel installation. Training covers proper material handling to prevent damage, correct fastener selection and placement, effective overlap seaming techniques, and appropriate flashing integration methods. Hands-on demonstrations reinforce theoretical instruction, building confidence and competence among installation personnel. Post-installation inspection services verify that completed installations meet design specifications and performance expectations. Comprehensive testing protocols include water penetration verification under simulated rain conditions, visual appearance assessment, dimensional accuracy confirmation, and fastener installation validation. Documentation packages include photographic records, test results, and maintenance recommendations that support warranty activation and long-term facility management.

Cost Optimization Strategies for Bulk Orders

Cost optimization for large-scale Corrugated Galvanized Metal Panel procurement requires strategic approaches that extend beyond simple per-unit pricing comparisons. Comprehensive value analysis considers total project costs including material prices, transportation expenses, handling labor, installation time requirements, and long-term maintenance implications. Manufacturers offering integrated solutions frequently deliver superior overall value despite potentially higher initial material costs. Volume-based pricing structures provide immediate cost advantages for large orders while incentivizing consolidated purchasing across multiple project phases. Manufacturers operating at scale achieve raw material cost advantages, production efficiency improvements, and logistics optimization that enable competitive pricing for substantial orders. Minimum order quantities of 500 square meters or greater trigger preferential pricing tiers, creating meaningful cost reductions for major construction projects. Customization efficiency impacts total project costs through reduced field labor requirements and minimized material waste. Factory-fabricated panels precisely matching installation requirements eliminate on-site cutting, reduce scrap generation, and accelerate installation progress. Pre-engineered accessories, matching trim components, and coordinated fastening systems further streamline installation processes while ensuring compatibility and aesthetic consistency.

Value-Added Services and Long-Term Partnership Benefits

Value-added services extend cost optimization benefits beyond initial procurement transactions to encompass multi-year relationship advantages. Technical support availability reduces engineering consulting expenses while improving design quality and implementation effectiveness. Warranty programs providing 30-year coverage against material defects and premature coating failure protect long-term facility investment values while transferring performance risk to manufacturers. Maintenance guidance programs help facility managers implement appropriate cleaning schedules, conduct periodic inspections, and identify potential issues before they develop into costly repairs. Manufacturers familiar with specific panel installations can provide targeted recommendations addressing site-specific environmental conditions and usage patterns. This proactive maintenance support extends service life, preserves aesthetic appearance, and maximizes return on initial capital investment. Ongoing partnership relationships create opportunities for future project cost optimization through established communication channels, documented performance history, and refined specification understanding. Repeat customers benefit from streamlined quoting processes, priority production scheduling, and preferential pricing considerations. Accumulated project experience enables manufacturers to anticipate requirements, suggest improvements, and deliver enhanced value across successive engagements.

Conclusion

Sourcing OEM corrugated galvanized metal panels at scale demands careful evaluation of manufacturing capabilities, quality certifications, customization options, and comprehensive service offerings. Success requires partnering with established manufacturers who combine substantial production capacity with proven engineering expertise and systematic quality management. The optimal supplier delivers consistent product quality, competitive pricing, reliable delivery performance, and valuable technical support throughout project lifecycles.

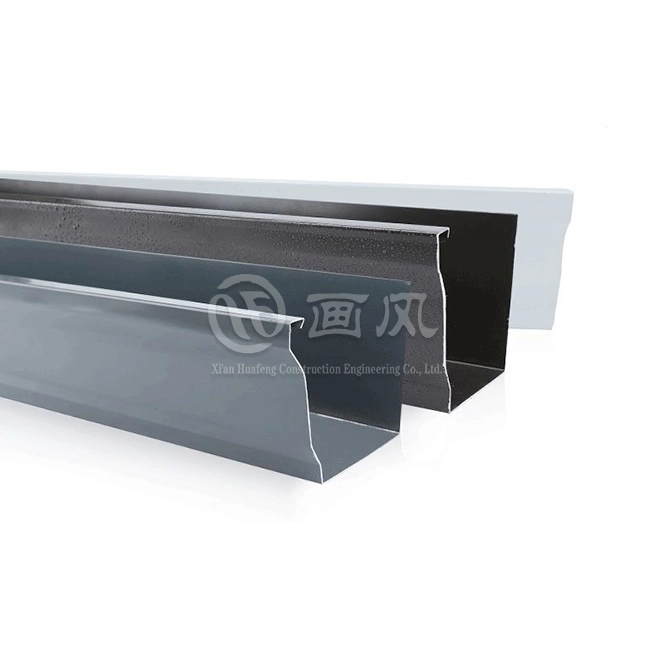

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Corrugated Galvanized Metal Panel factory established in 2018, Xi'an Huafeng Construction Engineering Co., Ltd. represents a premier choice for large-scale OEM panel sourcing. Our designation as a Shaanxi Province high-tech enterprise reflects our commitment to innovation and quality excellence. With first-level building curtain wall qualifications and third-level steel structure credentials, we deliver professional solutions backed by comprehensive engineering expertise.

Our China Corrugated Galvanized Metal Panel supplier infrastructure includes a 200,000-square-meter raw material production facility in Anhui plus two specialized processing plants in Hangzhou and Xi'an. This geographic distribution enables efficient service across China and international markets. Our seven color coating lines, one laminating line, ten shearing production systems, and more than forty processing machines ensure production capacity exceeding 1,000 tons monthly. As a trusted China Corrugated Galvanized Metal Panel manufacturer, we maintain 15-20 day delivery timelines even for substantial custom orders.

Product offerings span standing seam metal roofing, aluminum-magnesium-manganese plates, titanium-zinc systems, corrugated roofing, flat lock panels, and comprehensive accessory selections. All High Quality Corrugated Galvanized Metal Panel products comply with ASTM, DIN, JIS, BS, and GB/T standards, verified through ISO9001, ISO14001, and SGS certifications. Our China Corrugated Galvanized Metal Panel wholesale capabilities include complete customization for color, pattern, and design specifications with a 500-square-meter minimum order quantity.

Our development philosophy integrates green sustainable practices with continuous material innovation. We provide complete one-stop solutions encompassing design optimization, precision manufacturing with real-time quality control, and seamless installation support. Twenty-plus registered patents demonstrate our innovation leadership, while successful projects including Xiongan Station Commercial Body, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum showcase our execution capabilities. For Corrugated Galvanized Metal Panel for sale inquiries and competitive Corrugated Galvanized Metal Panel price quotations, contact our team at huafeng@hfmetalroof.com to discuss your project requirements.

References

1. "Metal Building Systems: Design and Specifications" by Alexander Newman, American Institute of Steel Construction, 2023

2. "Corrosion Protection of Steel Structures: Coating and Cathodic Protection" by Dr. Michael Richardson, International Corrosion Council, 2022

3. "Modern Metal Roofing Manufacturing: Processes and Quality Control" by Industrial Metal Association Technical Committee, 2024

4. "Sustainable Building Envelope Systems" by Prof. Jennifer Martinez, Green Building Research Institute, 2023

5. "Structural Performance of Corrugated Metal Panels" by Dr. Robert Chen and Dr. Sarah Thompson, Journal of Construction Steel Research, Volume 198, 2024

(1)_1763110678300.webp)