Picture this: a beautiful winter morning turns dangerous when a massive sheet of snow suddenly crashes from your roof, damaging vehicles, injuring pedestrians, or destroying landscaping below. In heavy snow zones, this nightmare scenario is all too real without proper protection. Metal Roofing Snowguards are essential safety devices that prevent catastrophic snow avalanches by controlling how snow releases from sloped metal roofs, protecting both property and lives while ensuring your roofing investment remains intact throughout harsh winter conditions.

Understanding Metal Roofing Snowguards and Their Critical Role in Heavy Snow Regions

Metal roofs present unique challenges in regions that experience substantial winter precipitation. Unlike traditional asphalt shingles or other textured roofing materials, metal surfaces are exceptionally smooth and offer minimal friction. This characteristic, while beneficial for water drainage and longevity, creates a hazardous condition when snow accumulates. As temperatures fluctuate, snow begins to melt at the roof's base, creating a slippery layer that allows the entire snowpack to slide off suddenly in dangerous sheets. Metal Roofing Snowguards address this critical safety concern by creating strategic barriers that hold accumulated snow in place, allowing it to melt gradually and release in controlled amounts rather than catastrophic avalanches. The physics behind snow movement on metal roofs is straightforward yet concerning. When snow accumulates on a sloped metal surface, gravity constantly pulls it downward. The combination of the roof's smoothness, slope angle, and warming temperatures creates perfect conditions for sudden releases. A typical residential roof measuring just 2,000 square feet can hold several tons of snow after a heavy storm. When this mass releases simultaneously, it generates tremendous force capable of demolishing gutters, bending handrails, crushing vehicles, and seriously injuring anyone unfortunate enough to be in its path. Snow guards on standing seam metal roof systems function as retention devices that interrupt this downward momentum, distributing weight evenly across the roof structure while preventing the formation of these dangerous avalanche conditions.

Types of Metal Roofing Snowguards for Different Applications

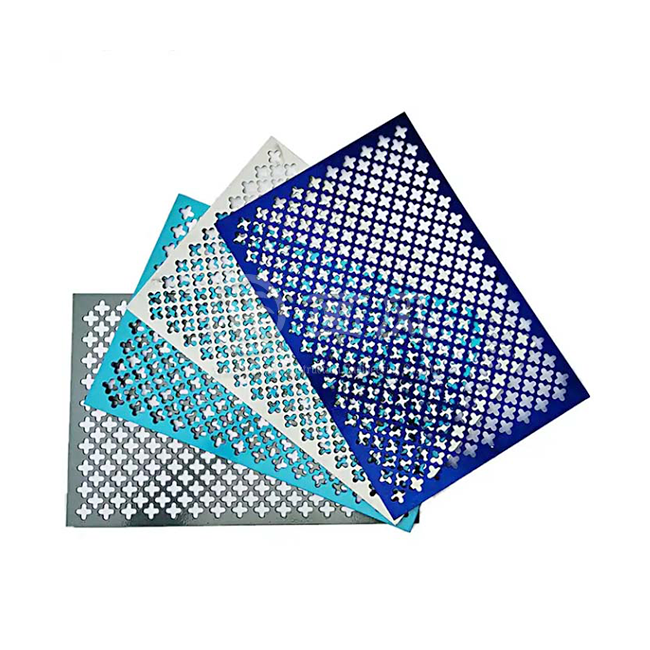

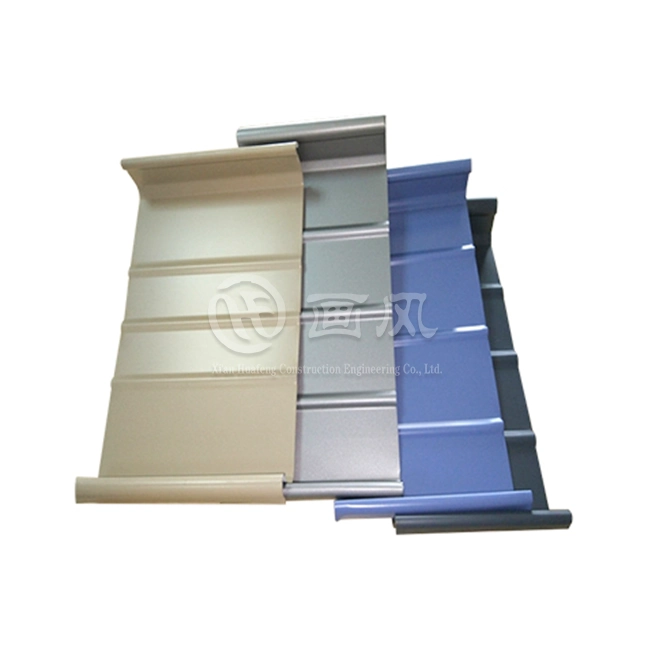

Understanding the various types of Metal Roofing Snowguards available helps property owners select the most appropriate system for their specific conditions and requirements. The primary categories include pad-style snow guards, continuous bar systems, and fence-style retention systems, each offering distinct advantages for different snow load scenarios and architectural considerations. Pad-style snow guards represent the most common and economical option for moderate snow regions. These individual units, typically constructed from aluminum alloy, stainless steel, or high-grade polycarbonate materials, are installed across the roof surface in strategic patterns. Each pad measures approximately two to three inches in height and features either mechanical fastening systems or specialized adhesive mounting options. For standing seam metal roofs, pad-style guards often utilize non-penetrating clamp attachments that secure to the raised seams without compromising the roof's weather-tight integrity. In heavy snow zones, pad-style guards must be installed in multiple staggered rows extending from the eave upward, with spacing calculated based on snow load data, roof pitch, and local building requirements.

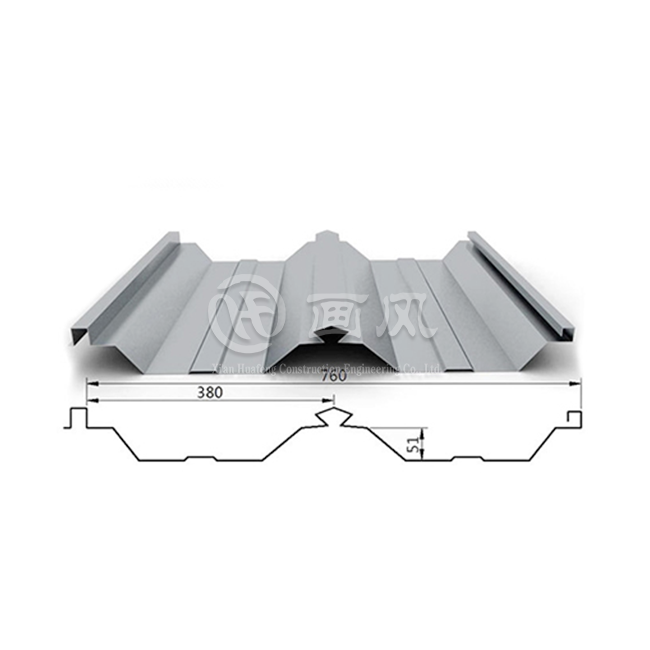

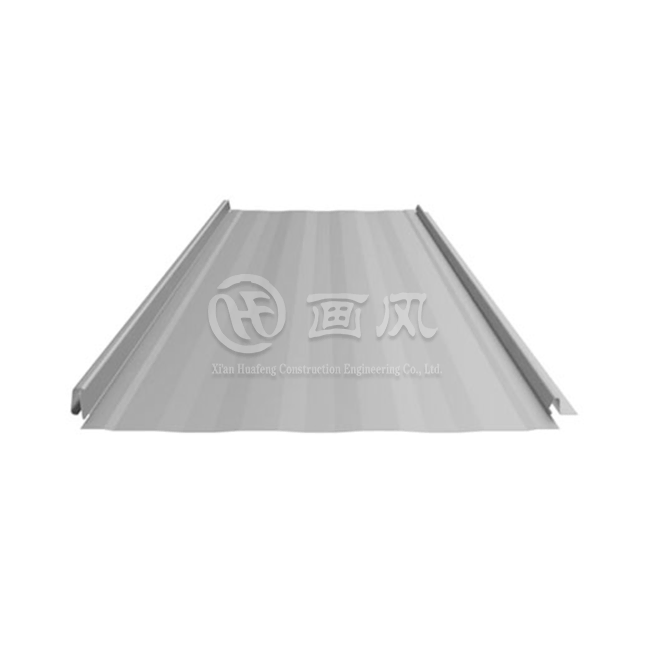

Continuous bar systems, frequently called snow rails or snow bars, provide superior retention capacity for regions experiencing extreme snowfall. These systems feature horizontal aluminum or stainless steel bars, typically two to three inches in diameter, that span across the entire roof width. The bars attach to the metal roof panels through specialized brackets or clamps positioned at regular intervals, creating a robust physical barrier against downward snow movement. Bar systems excel in commercial applications and residential properties with large roof surfaces where snow accumulation exceeds 45 pounds per square foot. Advanced bar systems like those manufactured with PVDF or PE finishes can be color-matched to the roof panels, maintaining aesthetic appeal while delivering exceptional performance. Installation specifications for our snow guards on standing seam metal roof products range from 1.2 to 2.4 meters in length, accommodating various roof configurations and span requirements.

Material Selection and Performance Characteristics

The material composition of Metal Roofing Snowguards directly impacts their longevity, strength, and effectiveness in challenging winter environments. Professional-grade snow retention systems utilize premium materials engineered to withstand extreme temperature fluctuations, heavy snow loads, and prolonged exposure to moisture and UV radiation without degrading or failing. Aluminum alloy snow guards offer an excellent balance of strength, weight, and corrosion resistance. High-grade aluminum alloys such as 3003, 3004, and 5052 provide exceptional durability while remaining lightweight enough to avoid adding significant structural load to the roofing system. Aluminum naturally forms a protective oxide layer that prevents rust and corrosion, making it ideal for coastal regions or areas with high precipitation. When finished with powder coating in colors like black, gray, or brick red, aluminum snow guards blend seamlessly with metal roof panels while gaining additional protection against weathering. The material maintains structural integrity across temperature extremes ranging from minus forty to plus one hundred degrees Fahrenheit, ensuring reliable performance throughout winter's harshest conditions.

Stainless steel represents the premium choice for Metal Roofing Snowguards requiring maximum strength and durability. Grades 304 and 316 stainless steel offer superior tensile strength compared to aluminum, making them essential for applications involving extreme snow loads or particularly steep roof pitches. Stainless steel's exceptional corrosion resistance ensures decades of maintenance-free service, even in environments with salt exposure or industrial pollutants. While heavier and more expensive than aluminum alternatives, stainless steel snow guards provide unmatched reliability for critical applications where failure could result in significant property damage or liability. The material's inherent strength allows for smaller profile designs that maintain effectiveness while presenting a more refined aesthetic appearance. Magnesium-aluminum-zinc alloy sheets represent an innovative material option that combines beneficial properties from multiple metals. This advanced alloy demonstrates superior corrosion resistance compared to standard galvanized steel while offering enhanced formability for complex guard designs. The material's protective coating forms through a sophisticated metallurgical process that creates a multi-layered barrier against oxidation and chemical degradation, extending service life well beyond traditional materials in aggressive environments.

Installation Considerations and Proper Placement Strategies

Effective Metal Roofing Snowguards installation requires careful planning based on multiple engineering factors including snow load calculations, roof geometry, panel type, and local building codes. Improper installation not only compromises the system's effectiveness but can also damage the roofing panels or create liability issues if snow retention proves inadequate during severe weather events. The fundamental principle governing snow guard placement involves distributing retention devices across the entire roof surface rather than concentrating them only near the eave. Many property owners mistakenly believe that a single row of guards along the bottom edge will suffice, but this approach fails to account for snow dynamics on smooth metal surfaces. Once accumulated snow begins sliding, it gains momentum and can easily overwhelm guards positioned only at the eave. Professional installation protocols call for multiple rows of Metal Roofing Snowguards extending from approximately six inches above the roof's lowest edge upward in staggered patterns, with row spacing calculated based on specific site conditions. For regions experiencing ground snow loads below 45 pounds per square foot, standard spacing patterns typically place guards twelve to twenty-four inches apart horizontally with rows positioned eight to ten feet apart vertically. Heavy snow zones exceeding 45 PSF require customized engineering calculations to determine appropriate guard density and placement.

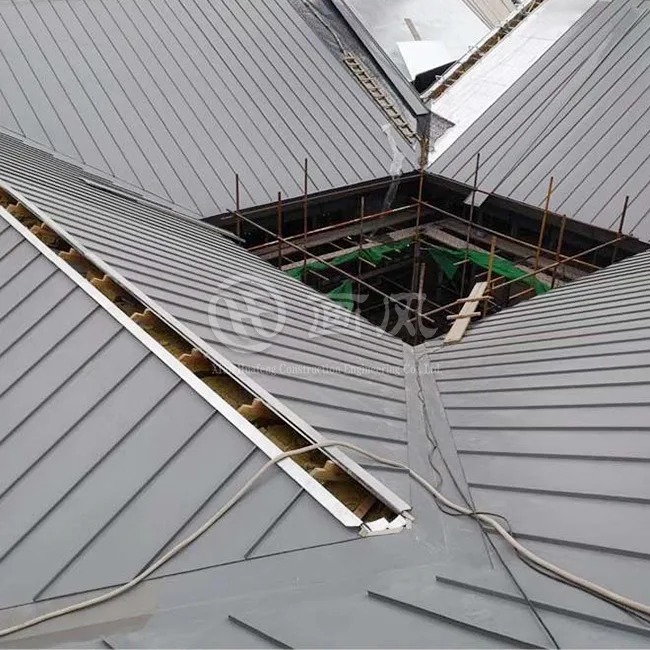

Standing seam metal roofs offer significant installation advantages because specialized clamps attach directly to the raised panel seams without penetrating the roof surface. This non-penetrating mounting method preserves the roof's waterproof integrity while creating extremely secure attachment points capable of withstanding substantial lateral and uplift forces. Each clamp undergoes rigorous load testing to verify its capacity to retain hundreds of pounds of snow without detaching or damaging the seam profile. For snow guards on standing seam metal roof applications, clamp selection must match the specific seam geometry since standing seam profiles vary significantly between manufacturers. Professional suppliers maintain comprehensive fitting guides identifying compatible clamps for every major standing seam system, ensuring proper mechanical engagement and optimal load transfer.

Calculating Snow Load Requirements and Guard Density

Accurate snow load assessment forms the foundation of effective Metal Roofing Snowguards system design. Snow loads vary dramatically based on geographic location, elevation, local microclimate patterns, and roof configuration. Building codes reference ground snow load data compiled from decades of meteorological measurements, providing baseline figures for design purposes. However, snow behavior on roofs differs from ground accumulation due to factors including wind redistribution, thermal effects, and geometric features that create drift zones. The International Building Code and related standards establish minimum design requirements for structural snow loads, but these provisions focus primarily on preventing roof collapse rather than controlling snow release. Metal Roofing Snowguards systems require separate engineering analysis that considers the vector load acting parallel to the roof surface. Vector load calculation multiplies the ground snow load by the sine of the roof angle, determining the actual force attempting to pull accumulated snow downslope. For example, a roof with a 30-degree pitch in a region with 50 PSF ground snow load experiences a vector load of approximately 25 PSF trying to slide the snowpack off the structure. The retention system must counteract this force while distributing the perpendicular load evenly across attachment points.

Heavy snow zones typically experience ground snow loads ranging from 50 to over 200 PSF in extreme mountainous regions. Properties located in these areas require robust retention systems with substantially higher guard density compared to moderate climate installations. Professional engineering services analyze site-specific conditions including roof pitch, panel type, eave-to-ridge distance, valley configurations, and local weather patterns to generate customized layout plans. These engineered designs specify exact guard locations, quantities, attachment specifications, and materials needed to achieve code compliance and reliable performance. Our manufacturing facility produces Metal Roofing Snowguards meeting international standards including ASTM, DIN, JIS, BS, and GB/T certifications, ensuring products meet rigorous quality and performance requirements for heavy snow applications.

Quality Manufacturing and Product Specifications

Professional-grade Metal Roofing Snowguards manufactured to exacting standards deliver reliable performance throughout decades of service in demanding winter environments. Manufacturing quality encompasses material selection, fabrication processes, finishing techniques, and quality control protocols that verify each component meets specified performance criteria before shipment. Our production facilities utilize advanced manufacturing equipment including seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, and fully automatic punching production lines supported by more than forty specialized machines. This extensive manufacturing capacity enables production of 10,000 tons monthly while maintaining strict quality standards throughout every production phase. Raw material procurement follows rigorous supplier qualification protocols, requiring material certifications and third-party testing reports from recognized brands including Alucosuper, YATAI, LIDAO for aluminum alloys, BAOSTEEL, GUANZHOU, and XINYU for steel products, and Baosteel and Tsingshan for stainless steel components. Each incoming material shipment undergoes comprehensive inspection including appearance evaluation, dimensional verification, salt spray testing, adhesion analysis, hardness measurement, impact resistance, film thickness assessment, acid resistance, weather resistance, and color consistency checks.

Surface finishing significantly impacts both aesthetic appearance and long-term durability of Metal Roofing Snowguards. PVDF (polyvinylidene fluoride) and PE (polyester) coating systems provide superior protection against UV degradation, chemical exposure, and weathering compared to standard paint finishes. PVDF coatings demonstrate exceptional color retention and chalk resistance, maintaining appearance for thirty years or more in harsh outdoor environments. PE coatings offer excellent durability at lower cost, making them appropriate for projects where budget constraints exist but quality performance remains essential. Both coating types are available in customizable colors including black, gray, brick red, and numerous architectural shades, allowing precise color matching to existing roof panels for seamless visual integration.

Testing, Certification, and Performance Validation

Comprehensive testing and certification demonstrate that Metal Roofing Snowguards meet or exceed industry performance standards for structural capacity, weathering resistance, and long-term reliability. Independent testing laboratories conduct load testing that subjects guard assemblies to forces exceeding anticipated service conditions, verifying that attachment systems, structural components, and material properties deliver adequate safety factors. Pull-out testing evaluates the force required to detach clamp-mounted guards from standing seam panels, confirming that mechanical attachments can resist expected snow loads without failure. Adhesive-mounted systems undergo shear and peel testing under various temperature conditions to validate bond strength throughout seasonal temperature extremes. Material testing verifies that component metals meet specified alloy compositions, mechanical properties, and corrosion resistance characteristics. Salt spray testing exposes finished components to accelerated corrosion conditions equivalent to years of marine or industrial atmosphere exposure, confirming that protective coatings and inherent material properties prevent degradation. Weathering tests simulate decades of UV exposure, thermal cycling, and moisture exposure to predict long-term appearance retention and structural integrity. Products achieving ISO9001 quality management certification, ISO14001 environmental management certification, and SGS compliance verification demonstrate commitment to systematic quality control and environmental responsibility throughout manufacturing operations.

Our company holds more than twenty registered patents for roofing system innovations along with various trademarks and computer software certificates protecting proprietary design features and engineering methodologies. These intellectual property assets reflect ongoing investment in research and development focused on advancing Metal Roofing Snowguards technology through material science, engineering analysis, and manufacturing process optimization. Continuous improvement initiatives leverage field performance data, customer feedback, and emerging industry best practices to refine product designs and enhance installation procedures.

Project Applications and Real-World Performance

Metal Roofing Snowguards deployed across diverse project types demonstrate their versatility and effectiveness in protecting properties ranging from commercial facilities to residential homes in heavy snow regions. Successful installations share common characteristics including proper system selection based on site-specific conditions, professional installation following engineered layouts, and appropriate maintenance practices that preserve system integrity throughout years of service. Large-scale commercial and institutional projects demand robust snow retention systems capable of managing substantial roof areas and heavy snow accumulations. Our Metal Roofing Snowguards have been successfully implemented in high-profile projects including the Xiongan Station Commercial Body featuring aluminum-magnesium-manganese metal roofing, Xi'an International Convention and Exhibition Center metal roof systems, and the Xi'an Station East Auxiliary Building installation. Public facilities such as the Jinghe New City International Culture and Art Center South Hall, Inner Mongolia Tongliao Art Museum, and various educational buildings including the Weihua Cadre College complex demonstrate the products' capability in demanding applications where public safety and architectural aesthetics both carry significant importance. Highway infrastructure projects like the Liyuanping Highway Station and utility facilities including the Hangzhou Sanpu Drainage Pump Station showcase Metal Roofing Snowguards performance across varied building types and exposure conditions.

Residential applications benefit equally from professional snow retention systems that protect families, vehicles, and landscaping from dangerous roof avalanches. Homeowners in heavy snow regions face particular challenges because residential properties often feature multiple roof planes, valleys, dormers, and other architectural elements that complicate snow management. Entry walkways, driveways, and outdoor living spaces situated below roof edges become hazardous zones during winter months without adequate protection. Well-designed Metal Roofing Snowguards installations transform these vulnerable areas into safe spaces by preventing sudden snow releases while maintaining the home's architectural character through color-matched components and thoughtful layout planning.

Maintenance, Inspection, and Long-Term Performance Optimization

While Metal Roofing Snowguards require minimal maintenance compared to many building components, periodic inspection and basic upkeep ensure optimal performance throughout their extended service life. Proactive maintenance identifies potential issues before they compromise system effectiveness or lead to costly failures during critical winter weather periods. Annual pre-winter inspections should examine all attachment points for signs of loosening, corrosion, or mechanical damage. Clamp-mounted systems may experience slight movement over time as metal roof panels expand and contract with temperature variations. While properly installed clamps accommodate this normal panel movement, inspection verifies that clamps remain fully engaged with seam profiles and that no separation has occurred. Mechanically fastened guards require inspection of mounting screws and fasteners to confirm they remain tight and that seal gaskets maintain waterproof integrity around penetrations. Any compromised fasteners should be replaced immediately using appropriate hardware specified by the manufacturer.

Guard surfaces and surrounding roof areas should be cleared of accumulated debris including leaves, branches, and other organic material that can trap moisture against metal components and accelerate corrosion. Debris accumulation also interferes with proper snow retention by creating uneven surfaces that allow snow to bridge over guards rather than being effectively retained. During winter months, property owners should monitor guard performance following significant snow events, observing whether guards successfully hold snow in place and allow gradual melting. Unusual snow release patterns or evidence that guards have detached or bent indicates problems requiring professional evaluation and correction. Professional roofing contractors experienced with snow retention systems can provide comprehensive inspection services that include load capacity assessment, attachment verification, and recommendations for system modifications if property usage or snow exposure conditions have changed since original installation. Our company provides expert technical support and installation guidance to ensure Metal Roofing Snowguards continue delivering optimal protection throughout their service life. We offer guidance to customers for performing regular maintenance and can arrange personnel to perform professional service when required.

Conclusion

Selecting appropriate Metal Roofing Snowguards for heavy snow zones requires understanding site-specific conditions, material options, and proper installation methodologies that ensure reliable protection against dangerous snow avalanches throughout harsh winter seasons.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Metal Roofing Snowguards factory, China Metal Roofing Snowguards supplier, and China Metal Roofing Snowguards manufacturer, Xi'an Huafeng Construction Engineering Co., Ltd. offers comprehensive solutions for metal roofing systems and snow retention applications. Established in 2018 in Shaanxi Province, our company specializes in design, production, sales, and construction of metal roofing systems, building curtain wall systems, and building steel structure enclosure systems. Recognized as a high-tech enterprise in Shaanxi Province in 2020, we hold first-level qualification for building curtain walls and third-level qualification for building steel structures, demonstrating our technical capabilities and industry standing.

Our manufacturing infrastructure includes a raw material production plant covering 200,000 square meters in Anhui Province, plus two plate and accessories processing plants located in Hangzhou and Xi'an respectively. With seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, fully automatic punching production lines, and more than forty specialized machines, we maintain production capacity exceeding 10,000 tons monthly. This extensive manufacturing capability ensures fast delivery times of 15-20 days for China Metal Roofing Snowguards wholesale orders while maintaining strict quality control throughout production.

Our High Quality Metal Roofing Snowguards meet international standards including ASTM, DIN, JIS, BS, and GB/T certifications, backed by more than twenty registered patents, multiple quality certifications including ISO9001 and ISO14001, and comprehensive SGS compliance verification. We provide one-stop service from initial design consultation through precision manufacturing to seamless installation, supported by experienced technical teams capable of structural 3D modeling, load analysis, and project-specific engineering. Our customized solutions accommodate various roof types, snow load requirements, and architectural specifications, with Metal Roofing Snowguards for sale in multiple materials including aluminum alloy, stainless steel, and magnesium-aluminum-zinc sheets, available in customizable colors and finishes. Contact us today to discuss your project requirements and receive competitive Metal Roofing Snowguards price quotations. Our expert team will help you select optimal solutions that protect your property while maintaining aesthetic excellence. For inquiries, reach us at huafeng@hfmetalroof.com. Bookmark this page for easy reference whenever questions arise about snow retention solutions for your metal roofing projects.

References

1. Smith, J. & Thompson, R. (2022). Snow Load Engineering for Metal Roof Systems. American Society of Civil Engineers Press.

2. Anderson, M. (2021). Metal Roofing Installation and Snow Retention Design. Building Science Corporation Technical Report.

3. International Code Council (2021). International Building Code: Chapter 16 - Structural Design Requirements Including Snow Loads.

4. National Roofing Contractors Association (2020). Metal Roofing Systems: Design and Installation Guidelines for Cold Climate Regions.

5. Williams, P. & Chen, L. (2023). Comparative Analysis of Snow Retention System Performance on Standing Seam Metal Roofs. Journal of Building Engineering and Technology, Volume 45, Pages 203-218.