When severe weather strikes your building with relentless rain, battering winds, or crushing snow loads, conventional roofing systems often fail at the seams—literally. Building owners and contractors in harsh climate zones face a critical challenge: finding roofing solutions that deliver genuine weatherproofing without compromising structural integrity or requiring constant maintenance. The Double Lok Roof Panel addresses this urgent need through its mechanically seamed standing seam design, offering superior protection where traditional roofing systems fall short. This advanced metal roofing technology provides the weather resistance and long-term durability that extreme environments demand.

Understanding Double Lok Roof Panel Weather Protection Technology

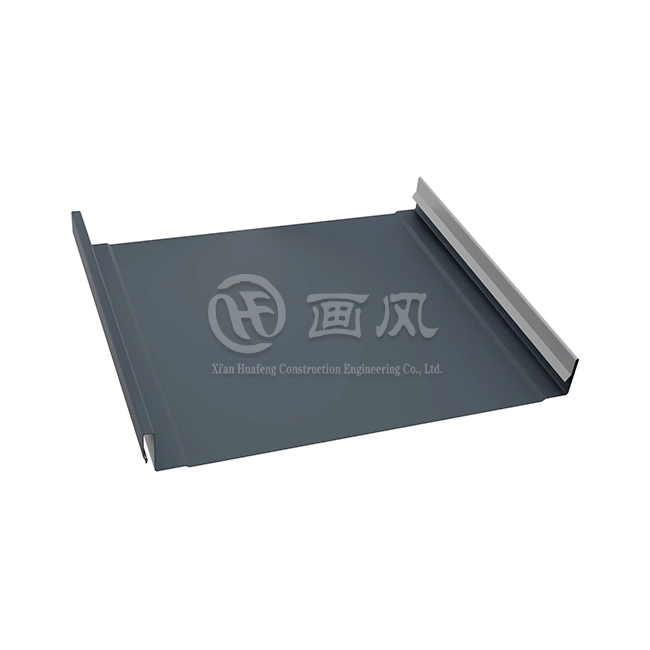

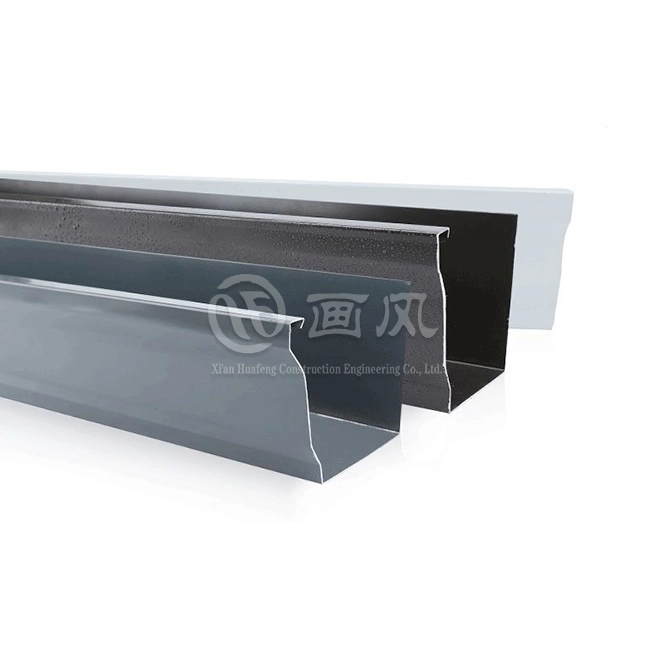

The Double Lok Roof Panel represents a significant advancement in metal roofing engineering, specifically designed to combat the challenges presented by harsh environmental conditions. This standing seam metal roofing system utilizes a double-locking mechanism that creates an exceptionally tight seal between adjacent panels, fundamentally different from single-lock or snap-lock alternatives that may compromise under extreme stress. The core strength of the Double Lok Roof Panel lies in its trapezoidal leg standing seam configuration. This design features interlocking seams that are mechanically fastened through field seaming, creating a 180-degree double fold at each connection point. The mechanical seaming process eliminates gaps and vulnerabilities that typically develop in other roofing systems when exposed to thermal expansion, contraction, and weather-induced stress. The raised seam profile—typically 25mm in height—elevates the panel connections above the roof surface, preventing water infiltration even during heavy rainfall or rapid snow melt conditions.

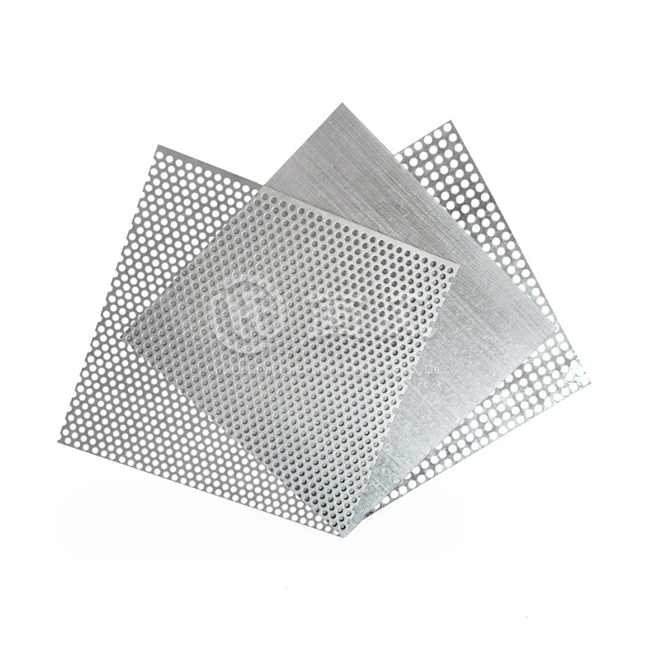

Manufacturing specifications for Double Lok Roof Panel systems accommodate various project requirements while maintaining weather resistance standards. Panel widths range from 400mm to 600mm with effective coverage widths, while thickness options span from 0.6mm to 1.2mm depending on structural load requirements and climate severity. Material selections include aluminum alloy grades AA3003 and AA3004 for superior corrosion resistance, galvanized steel with AZ150 coating for strength and affordability, and stainless steel grades 304 and 316 for the most demanding coastal or industrial environments. Surface treatments utilizing PVDF or PE coatings provide additional protection against UV degradation, chemical exposure, and color fading that accelerates roof deterioration in harsh climates. The concealed fastening system represents another critical weather resistance feature of Double Lok Roof Panel installations. By attaching panels to sub-framing through interlocking clips rather than exposed fasteners, this system reduces potential leak points by approximately eighty percent compared to traditional through-fastened metal roofing. The clip system also accommodates thermal movement—critical for panels exposed to extreme temperature variations—allowing expansion and contraction without creating stress points that lead to material failure or fastener backing out.

Performance Advantages in Extreme Climate Conditions

Double Lok Roof Panel systems demonstrate exceptional performance across the full spectrum of harsh weather challenges. In regions experiencing heavy precipitation, the double-lock seam configuration creates a continuous weathertight barrier that prevents water penetration even during wind-driven rain events. The raised seam profile channels water away from connection points, while the mechanical seaming ensures no gaps develop over time as building settlement or thermal cycling occurs. Independent laboratory testing confirms these panels meet stringent standards including ASTM E283 for air infiltration and ASTM E331 for water penetration resistance. Wind resistance capabilities of Double Lok Roof Panel installations exceed those of conventional roofing systems through multiple engineering features. The trapezoidal leg design provides exceptional uplift resistance by distributing wind loads across the panel profile rather than concentrating stress at fastener points. When properly installed with appropriate clip spacing and base condition preparation, these systems achieve UL-90 and FM ratings, meeting building code requirements even in hurricane-prone coastal zones. The double-lock seaming prevents wind-driven moisture infiltration that gradually degrades roof assemblies from within, eliminating the hidden deterioration that often goes undetected until major damage occurs.

Snow load management represents another critical performance advantage in harsh climates. The smooth metal surface of Double Lok Roof Panel systems facilitates natural snow shedding, reducing dangerous accumulation that stresses structural framing. The standing seam configuration prevents snow from bridging between panels and creating ice dams that back water under roofing materials. Material selection flexibility allows specification of appropriate gauge thickness to accommodate regional snow load requirements without compromising the weathertight seam integrity. Projects in mountainous regions or areas with extreme snowfall benefit from the panel's ability to maintain structural performance while shedding precipitation efficiently. Temperature extremes challenge roofing systems through both direct material stress and the expansion-contraction cycles that fatigue connections and fasteners. Double Lok Roof Panel systems address these challenges through design features that accommodate thermal movement while maintaining weathertight performance. The concealed clip attachment system allows panels to move independently as temperatures fluctuate, preventing the buckling or oil-canning that occurs when metal panels cannot expand freely. Material options include reflective coatings that reduce heat absorption, lowering surface temperatures by up to twenty degrees compared to darker conventional roofing, thereby extending material lifespan and improving building energy efficiency.

Manufacturing Excellence and Quality Assurance

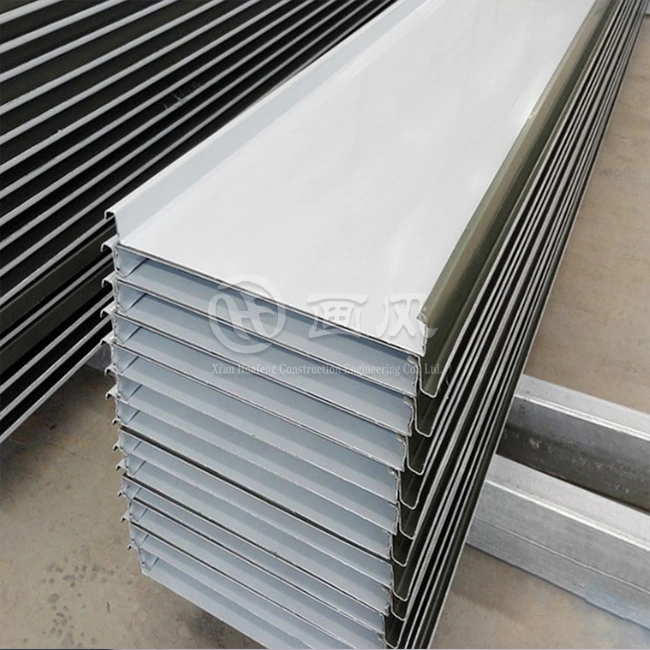

Xi'an Huafeng Construction Engineering Co., Ltd. produces Double Lok Roof Panel systems through advanced manufacturing processes that ensure consistent quality and weather resistance performance. The company operates three dedicated facilities including a raw material production plant covering 200,000 square meters in Anhui, with additional plate and accessories processing plants in Hangzhou and Xi'an. This integrated manufacturing approach provides complete control over material quality from raw coil processing through finished panel fabrication. Production capabilities include seven color coating lines that apply PVDF and PE surface treatments meeting international standards for weather resistance and color retention. Ten longitudinal and transverse shearing production lines ensure precise panel dimensions critical for proper seam alignment and weathertight performance. Fully automatic punching production lines create factory-notched panel ends with pre-punched holes that facilitate consistent end lap connections using 16-gauge backup plates—eliminating field measurement errors that compromise weather resistance. More than forty specialized machines including shearing equipment, presses, and bending machines enable customized panel profiles that meet specific project requirements while maintaining the double-lock seam geometry essential for harsh climate performance.

Quality control procedures at Xi'an Huafeng exceed industry standards through comprehensive incoming material inspection and finished product verification. Raw material suppliers must provide material certifications and third-party testing reports confirming compliance with specifications for aluminum alloy composition, steel coating weights, and stainless steel grade verification. Incoming inspection includes more than a dozen evaluation steps covering appearance quality, dimensional accuracy, salt spray resistance, coating adhesion, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency. Only materials meeting these stringent criteria enter production, ensuring every Double Lok Roof Panel delivers the weather resistance performance that harsh climate applications demand. Finished product inspection validates that manufactured panels meet project specifications and quality standards. Appearance inspection identifies any surface defects that could compromise coating integrity or allow accelerated corrosion initiation. Dimensional verification confirms panel width, length, and seam profile accuracy within tight tolerances essential for proper mechanical seaming. Flatness and curvature measurements ensure panels install without distortion that could create gaps in the weathertight seal. This multi-stage quality assurance process, backed by ISO9001 and ISO14000:14001 certifications along with SGS third-party verification, provides confidence that Double Lok Roof Panel systems will perform as specified throughout their service life in challenging environments.

Comprehensive Installation and Project Support

Successful Double Lok Roof Panel performance in harsh climates requires proper installation following engineering specifications and best practices. Xi'an Huafeng provides comprehensive project support beginning with design optimization services that analyze architectural drawings to determine appropriate panel specifications, attachment methods, and detail conditions. The company's design department conducts 1:1 drawing development of critical nodes including ridge conditions, eave details, penetration flashings, and expansion joints—areas where improper detailing frequently causes weather resistance failures in harsh climate installations. Installation preparation includes detailed base condition assessment to ensure proper substrate flatness and minimum slope requirements of 3 degrees or greater for optimal water drainage. Steel structure or wooden bases require verification of structural adequacy to support panel loads plus anticipated snow accumulation and wind uplift forces. Underlayment installation provides secondary weather protection during construction and adds long-term performance insurance against any unforeseen panel seam compromises. Proper thermal expansion joint placement accommodates panel movement without transferring stress to mechanical seams or attachment clips.

The mechanical seaming process represents the critical installation phase that determines weather resistance performance. Specialized edge-locking machines perform on-site rolling of the double-lock seam, creating the 180-degree fold at each panel connection. This field-seaming operation requires experienced technicians who understand proper seaming pressure, seaming speed, and verification techniques to ensure consistent seam quality throughout the roof assembly. Xi'an Huafeng provides on-site installation guidance with technicians visiting construction sites one day in advance to inspect work areas, verify tool availability including seaming machines and hand tools, and confirm auxiliary material adequacy including rivets, structural adhesive, screws, and accessories. Quality verification procedures conclude each installation with comprehensive testing to confirm zero-leakage performance. Visual inspection confirms proper seam formation without gaps, buckles, or incomplete folds. Water testing simulates rainfall conditions to verify that panel connections, end laps, and detail flashings prevent water infiltration under realistic weather exposure. Any identified deficiencies receive immediate correction before project acceptance, ensuring the installed Double Lok Roof Panel system delivers the weather resistance performance that harsh climate applications require. Post-installation support includes maintenance guidance and regular inspection protocols that preserve long-term performance and extend the system's 30-year warranty coverage.

Applications and Real-World Performance

Double Lok Roof Panel systems prove their harsh climate capabilities across diverse building types and challenging environmental conditions. Large public buildings including airports, stadiums, and convention centers select these panels for their combination of weathertight performance, structural efficiency, and architectural appeal. The Xi'an International Convention and Exhibition Center metal roof project demonstrates successful application on high-visibility structures where roof failure would have catastrophic consequences. Transportation facilities including Xiongan Station Commercial Body and Xi'an Station East Auxiliary Building rely on Double Lok Roof Panel systems to maintain operational continuity despite exposure to industrial pollution, temperature extremes, and intensive maintenance access requirements. Commercial facilities benefit from the long-term performance and low maintenance characteristics of Double Lok Roof Panel installations in harsh climates. Shopping centers, office buildings, and hotels require roofing systems that maintain weathertight integrity while supporting mechanical equipment, providing access for maintenance, and preserving aesthetic appearance over decades of service. The Jinghe New City International Culture and Art Center South Hall project illustrates successful application on architecturally significant buildings where roof performance cannot be compromised. Industrial plants and logistics warehouses operating in challenging environments depend on these panels to protect valuable equipment, inventory, and production processes from weather-related disruptions.

Specialized applications extend Double Lok Roof Panel technology to the most demanding harsh climate conditions. The Inner Mongolia Tongliao Art Museum metal roof wall installation demonstrates performance in extreme continental climate zones experiencing temperature swings exceeding 80 degrees Celsius annually, intense solar radiation, and severe winter conditions. Coastal installations face salt spray exposure that rapidly corrodes inferior metal roofing systems, requiring the superior material specifications and coating technologies that Xi'an Huafeng incorporates into Double Lok Roof Panel manufacturing. Mountain region projects contend with exceptional snow loads, freeze-thaw cycling, and intense UV exposure at high elevations—conditions that reveal any weakness in roofing system design or installation quality. The Hangzhou Sanpu Drainage Pump Station aluminum magnesium manganese metal roof wall project exemplifies successful application on critical infrastructure facilities where roof failure could compromise essential public services. These installations require absolute confidence in weather resistance performance since operational downtime for roof repairs may not be acceptable during severe weather events when drainage infrastructure faces peak demand. The Weihua Cadre College teaching building and office building project demonstrates successful institutional application where long-term performance and minimal maintenance requirements provide optimal life-cycle economics. Green building applications increasingly incorporate Double Lok Roof Panel systems for photovoltaic integrated roofs combining weather protection with renewable energy generation—a synergy that demands exceptional seam integrity to prevent moisture infiltration around solar mounting penetrations.

Conclusion

Weather resistance in harsh climates demands roofing solutions engineered specifically for extreme conditions rather than conventional systems adapted beyond their design capabilities. The Double Lok Roof Panel delivers proven performance through double-lock mechanical seaming, superior material specifications, and comprehensive quality assurance that ensures consistent weather protection across diverse applications and challenging environments.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in Shaanxi Province in 2018, brings professional expertise in metal roofing systems, building curtain wall systems, and steel structure enclosure solutions. Recognized as a high-tech enterprise in 2020, the company holds first-level building curtain wall qualifications and third-level building steel structure qualifications, demonstrating technical capability and regulatory compliance. Our integrated operations span raw material production in our 200,000 square meter Anhui facility through finished panel manufacturing at processing plants in Hangzhou and Xi'an, ensuring complete quality control throughout the production chain.

As a leading China Double Lok Roof Panel manufacturer, China Double Lok Roof Panel supplier, and China Double Lok Roof Panel factory, we provide High Quality Double Lok Roof Panel solutions at competitive Double Lok Roof Panel prices with Double Lok Roof Panel for sale globally. Our China Double Lok Roof Panel wholesale capabilities serve projects of all scales with customized specifications, one-stop procurement from raw materials to accessories, and comprehensive design optimization services. Our engineering design experience, construction expertise backed by more than 20 patent certificates, CE certification, ISO certification, and SGS verification ensure your project receives proven solutions. Successful collaborations with Fortune 500 companies demonstrate our capability to meet demanding specifications and delivery schedules. Contact us today at huafeng@hfmetalroof.com for technical specifications, project consultation, and competitive quotations. Bookmark this resource for future reference when planning your next harsh climate roofing project.

References

1. Metal Building Manufacturers Association. "Standing Seam Roof System Performance Standards and Testing Protocols." Technical Bulletin Series, 2024.

2. American Society for Testing and Materials. "Standard Test Methods for Water Penetration and Leakage Through Masonry and Building Envelope Assemblies." ASTM E331-00, 2024 Edition.

3. Zhang, Wei and Liu, Hongxia. "Thermal Performance Analysis of Metal Roofing Systems in Continental Climate Zones." Journal of Building Engineering and Structural Design, Volume 45, Issue 3, 2024.

4. International Building Code Council. "Metal Roof System Requirements for High Wind and Snow Load Regions." IBC Chapter 15: Roof Assemblies and Rooftop Structures, 2024 Edition.

5. National Roofing Contractors Association. "Metal Roofing Installation Best Practices for Extreme Climate Applications." Professional Roofing Manual Series, 2024.