Living in a coastal paradise comes with breathtaking ocean views and refreshing sea breezes, but it also presents unique challenges for your home's roofing system. Salt-laden air, hurricane-force winds, intense UV exposure, and persistent moisture create a harsh environment that destroys ordinary roofing materials within years. Many homeowners discover too late that their metal roof warranty is void within 1,500 feet of saltwater, leaving them with corroded panels and expensive replacements. The solution lies in selecting the right Aluminum Standing Seam Metal Roof Panels specifically engineered to withstand coastal conditions while providing decades of reliable protection. These specialized roofing systems combine corrosion-resistant aluminum cores with advanced PVDF coatings and concealed fastener designs to deliver unmatched performance where traditional materials fail.

Why Aluminum Standing Seam Metal Roof Panels Are Essential for Coastal Environments?

Coastal regions demand roofing solutions that can resist the relentless assault of environmental factors that would quickly destroy conventional materials. Aluminum Standing Seam Metal Roof Panels have emerged as the premier choice for oceanfront properties because aluminum naturally resists corrosion unlike steel-based alternatives. When aluminum oxidizes, it forms a protective aluminum oxide layer on its surface that shields the underlying metal from further deterioration, ensuring long-term structural integrity even in saltwater environments. This inherent corrosion resistance means your roof maintains its protective qualities for 40 to 60 years without the rust stains, degradation, and premature failure common with steel roofing systems. The standing seam design provides superior weather-tightness through its concealed fastener system, where clips attach panels to the roof deck without penetrating the visible surface. This eliminates thousands of potential leak points created by exposed screws with rubber grommets that deteriorate rapidly under coastal sun and salt exposure. The raised vertical seams mechanically interlock to create watertight barriers that prevent wind-driven rain infiltration even during hurricane conditions. For properties within 3,000 feet of the coast, where salt spray continuously attacks roofing materials, Aluminum Standing Seam Metal Roof Panels offer warranty coverage that steel manufacturers refuse to provide, giving homeowners genuine protection for their investment.

Superior Wind Resistance and Hurricane Protection

Hurricane-prone coastal areas require roofing systems engineered to withstand extreme wind events that regularly exceed 120 miles per hour. Aluminum Standing Seam Metal Roof Panels deliver exceptional wind uplift resistance through their interlocking panel design and secure clip attachment system. The clips allow controlled thermal expansion and contraction while maintaining structural integrity during high-wind events. Unlike exposed fastener systems where screws can back out over time due to metal movement, standing seam systems keep fasteners concealed and protected, ensuring they maintain their holding power throughout decades of service. The lightweight nature of aluminum compared to steel provides an additional advantage during hurricane conditions. At only one-third the density of steel, aluminum panels reduce the structural load on your home while maintaining superior strength-to-weight ratios. This means less stress on your roof structure during high winds and reduced risk of structural failure. When properly installed by experienced professionals, these roofing systems meet or exceed the stringent wind uplift codes required in coastal building zones, with many systems rated for winds up to 140 miles per hour or higher.

Advanced PVDF Coating Technology for Long-Term Performance

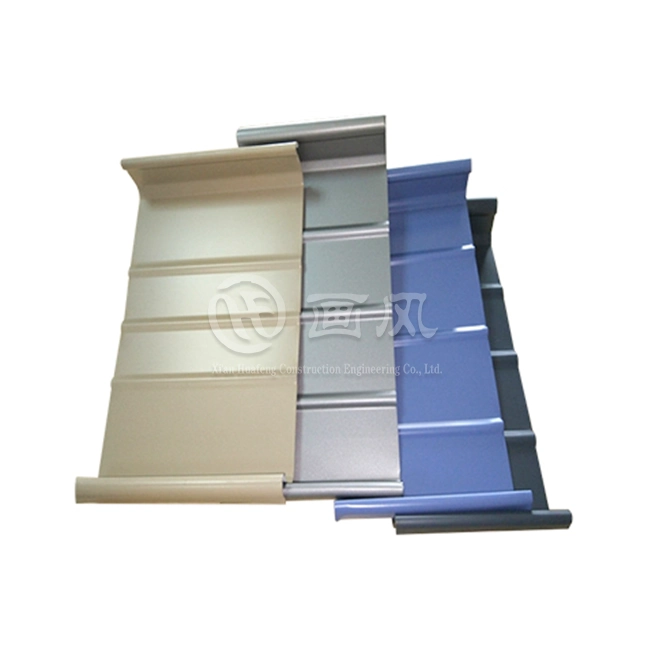

The harsh coastal environment accelerates color fading and chalking on painted metal surfaces due to intense UV exposure amplified by water reflection. Aluminum Standing Seam Metal Roof Panels utilize premium PVDF fluorocarbon coating systems to combat these destructive forces. PVDF coatings provide superior resistance to UV degradation, chemical exposure, and weathering compared to standard paint finishes. These thermally set coatings bond molecularly to the aluminum substrate, creating a protective barrier that maintains color vibrancy and prevents chalking for 20 to 30 years or more. High-quality PVDF finishes also contribute to energy efficiency through their high solar reflectance values. Cool roof coatings reflect significant portions of solar radiation, reducing heat absorption and lowering cooling costs in hot coastal climates. The combination of reflective coatings and aluminum's natural thermal properties creates roofing systems that enhance building comfort while reducing energy consumption. For coastal homeowners concerned about both aesthetics and operating costs, Aluminum Standing Seam Metal Roof Panels with PVDF coatings deliver lasting beauty and measurable energy savings throughout their service life.

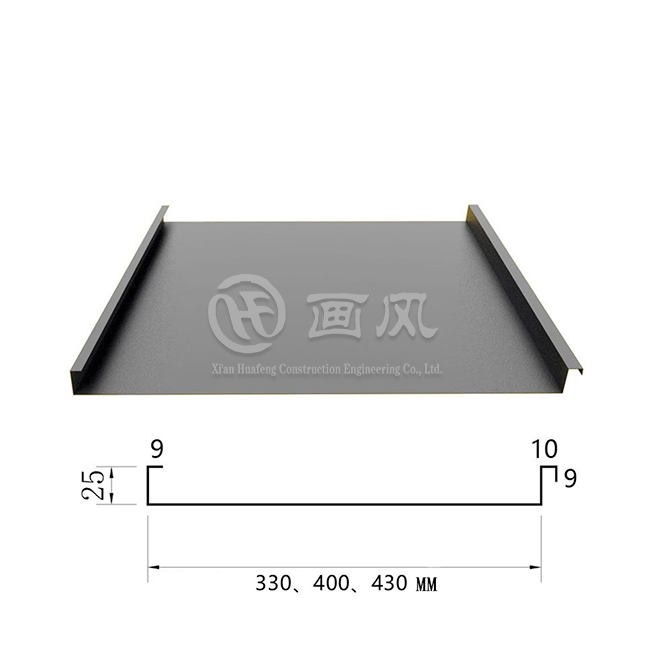

Key Technical Specifications for Coastal Aluminum Standing Seam Systems

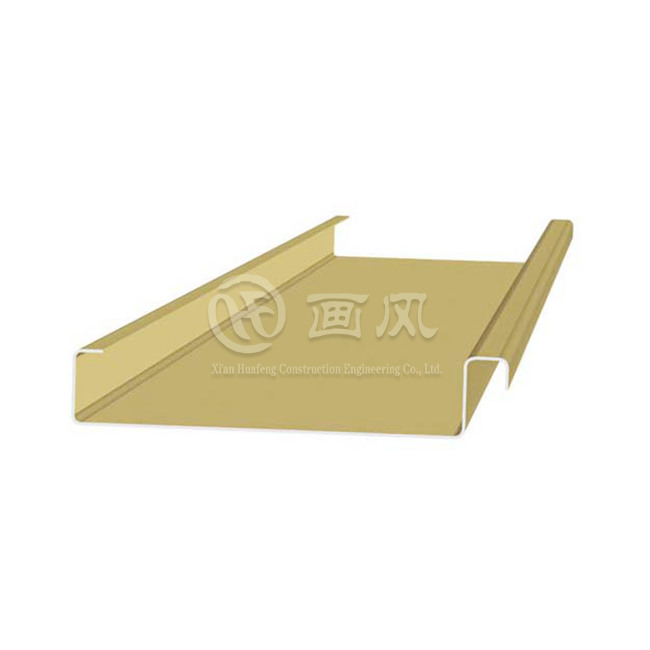

Understanding the technical specifications of Aluminum Standing Seam Metal Roof Panels helps homeowners and builders make informed decisions for coastal applications. Material composition represents the foundation of performance, with aluminum alloys AA3003, AA3004, and AA5052 offering optimal combinations of corrosion resistance and structural strength. These alloys contain manganese and magnesium additions that enhance their mechanical properties while maintaining excellent formability for standing seam profiles. The aluminum core ensures zero rust potential regardless of saltwater exposure, eliminating the catastrophic corrosion failures common with galvanized or galvalume steel panels in marine environments. Panel thickness typically ranges from 0.7mm to 1.2mm, with thicker gauges providing enhanced dent resistance and structural performance. For coastal regions subject to high winds and occasional hail, specifications of 0.9mm to 1.2mm thickness deliver superior impact resistance while maintaining the lightweight advantages of aluminum construction. Rib heights between 25mm and 65mm create the characteristic standing seam profile, with taller ribs offering greater water-shedding capacity and enhanced visual depth. The effective coverage width of panels ranges from 300mm to 600mm depending on the specific profile, allowing efficient installation while maintaining the clean linear aesthetics that define modern standing seam roofing.

Connection Methods and Installation Considerations

Aluminum Standing Seam Metal Roof Panels utilize two primary connection methods to achieve their weather-tight performance. Double standing seam systems employ mechanical seaming where adjacent panel edges are folded together and crimped with specialized equipment, creating a robust waterproof joint with exceptional wind uplift resistance. This mechanically seamed approach represents the gold standard for commercial applications and high-performance residential installations, particularly in extreme coastal environments. The mechanical seaming process ensures consistent joint quality and maximum structural integrity across the entire roof surface. Snap-lock or single-lock systems provide a more economical alternative while maintaining concealed fastener benefits. These panels feature interlocking edges that snap together over clips fastened to the roof deck, allowing for thermal movement without compromising weather-tightness. While snap-lock systems may have slightly lower wind ratings than mechanically seamed alternatives, quality snap-lock Aluminum Standing Seam Metal Roof Panels still provide excellent performance for most coastal residential applications. The choice between mechanical seaming and snap-lock depends on specific project requirements including wind zone classifications, budget considerations, and aesthetic preferences.

Material Sourcing and Quality Control Standards

Reputable manufacturers of Aluminum Standing Seam Metal Roof Panels maintain rigorous quality control protocols and source materials from established aluminum producers. Leading brands utilize aluminum coils from suppliers meeting international standards including ASTM, DIN, JIS, and BS specifications. These standards ensure consistent alloy composition, mechanical properties, and surface quality essential for long-term performance. Third-party material testing and certification documentation provide verification of material compliance, giving specifiers and homeowners confidence in product quality. Manufacturing facilities employ multiple inspection points throughout the production process to maintain consistent panel quality. Incoming material inspection verifies aluminum coil specifications including alloy composition, thickness tolerances, and coating integrity. Production monitoring ensures precise panel forming, accurate dimensions, and proper coating application. Finished product inspection examines appearance, flatness, straightness, and dimensional accuracy before packaging. This comprehensive quality assurance approach minimizes defects and ensures that every panel leaving the factory meets or exceeds performance specifications. For coastal applications where material failure can have severe consequences, selecting manufacturers with documented quality management systems and international certifications provides essential risk mitigation.

Comparing Aluminum to Alternative Coastal Roofing Materials

When evaluating roofing options for coastal properties, understanding how Aluminum Standing Seam Metal Roof Panels compare to alternatives helps homeowners make cost-effective long-term decisions. Galvalume steel consists of a steel core coated with a zinc-aluminum alloy designed to resist corrosion. While galvalume performs adequately in many environments, manufacturers typically void warranties for installations within 1,500 feet of saltwater due to corrosion concerns at cut edges and fastener penetrations. The steel core remains vulnerable to rust if the protective coating becomes compromised through scratches, cuts, or weathering, creating potential failure points in harsh marine atmospheres. Copper roofing offers exceptional longevity and develops an attractive patina finish when exposed to saltwater environments, as demonstrated by structures like the Statue of Liberty that have endured for over a century. However, copper represents the most expensive metal roofing option, with material costs significantly exceeding aluminum by factors of three to four. While copper's century-plus lifespan may justify the investment for high-end applications, most residential coastal projects find better value in Aluminum Standing Seam Metal Roof Panels that deliver 40 to 60 years of reliable service at substantially lower initial cost. The price differential between copper and aluminum typically ranges from three to five dollars per square foot for materials alone.

Advantages Over Traditional Asphalt Shingles

Asphalt shingles represent the most common residential roofing material but face severe limitations in coastal environments. Salt-laden air accelerates shingle deterioration, high winds lift and damage individual shingles, and UV exposure causes rapid aging and brittleness. Most asphalt shingle installations in harsh coastal zones require replacement every 12 to 18 years, creating recurring expenses and disruption. In contrast, Aluminum Standing Seam Metal Roof Panels installed once can protect coastal homes for four to five decades with minimal maintenance, eliminating multiple shingle replacement cycles. The total lifecycle cost comparison strongly favors aluminum standing seam systems despite higher initial investment. While asphalt shingles might cost four to six dollars per square foot installed, homeowners face three to four complete re-roofing projects over a 50-year period, multiplying costs and creating disposal waste. Aluminum Standing Seam Metal Roof Panels installed at twelve to seventeen dollars per square foot require only one installation with minimal ongoing maintenance, resulting in lower total ownership costs. Additionally, aluminum roofing provides superior wind resistance, eliminates granule loss and shingle blow-offs, and offers better energy efficiency through reflective coatings that reduce cooling costs in hot coastal climates.

Zinc Roofing as a Premium Alternative

Zinc roofing shares aluminum's natural corrosion resistance and develops a protective patina finish that enhances its weathering characteristics. Zinc performs exceptionally well in coastal environments with expected service lives of 60 to 80 years or more. The material possesses self-healing properties where minor scratches and imperfections blend into the developing patina over time. However, zinc roofing carries a premium price point approaching copper costs, making it less accessible for most residential projects. The material also requires specialized installation expertise due to its unique expansion characteristics and chemical reactivity with certain materials. For homeowners seeking maximum longevity and distinctive aesthetics willing to invest in premium materials, zinc presents a viable option alongside Aluminum Standing Seam Metal Roof Panels. The choice between zinc and aluminum often comes down to budget considerations and aesthetic preferences regarding the patina appearance versus consistent color finishes. Aluminum's lower cost, wider color availability through PVDF coatings, and more straightforward installation make it the practical choice for most coastal residential applications where performance, value, and appearance must balance effectively.

Installation Best Practices for Coastal Applications

Proper installation represents the critical factor determining whether Aluminum Standing Seam Metal Roof Panels achieve their full performance potential in coastal environments. Working with experienced roofing contractors who understand the unique requirements of coastal installations ensures that material benefits translate into real-world protection. Installation begins with thorough substrate preparation, verifying that roof decking is structurally sound, properly dried, and adequately ventilated. Solid sheathing provides the stable foundation necessary for clip attachment and panel performance, with moisture barriers installed according to manufacturer specifications and local building codes. Clip placement and fastening require precise attention to spacing, alignment, and torque specifications. Clips must attach securely to roof structure while allowing controlled thermal movement of aluminum panels. Over-tightening clips restricts necessary expansion and contraction, potentially causing panel distortion or fastener failure. Under-tightening compromises wind uplift resistance and weather-tightness. Experienced installers understand these nuances and use calibrated tools to achieve proper fastener tension consistently across the entire roof surface. Panel alignment and seam quality directly impact both aesthetics and performance, requiring careful measurement and adjustment throughout the installation process.

Flashing Details and Penetration Management

Coastal roofing installations demand exceptional attention to flashing details around penetrations, transitions, and roof edges where water infiltration risks concentrate. Aluminum Standing Seam Metal Roof Panels require compatible flashing materials to prevent galvanic corrosion that can occur when dissimilar metals contact in the presence of moisture. Using aluminum or coated steel flashings ensures electrochemical compatibility and long-term durability. All penetrations including vents, chimneys, and equipment mounts must integrate with standing seam panels through properly designed flashing assemblies that maintain weather-tightness while accommodating thermal movement. Eave and gable trims require secure attachment and proper sealant application to resist wind-driven rain that characterizes coastal storm events. Installers must follow manufacturer specifications for trim attachment, overlap dimensions, and sealant types to maintain warranty coverage and performance standards. Ridge caps and hip treatments need particular attention to ensure adequate ventilation where required while preventing water and wind infiltration. Quality coastal installations often incorporate additional underlayment protection and ice-and-water shield membranes in vulnerable areas to provide secondary protection against extreme weather events.

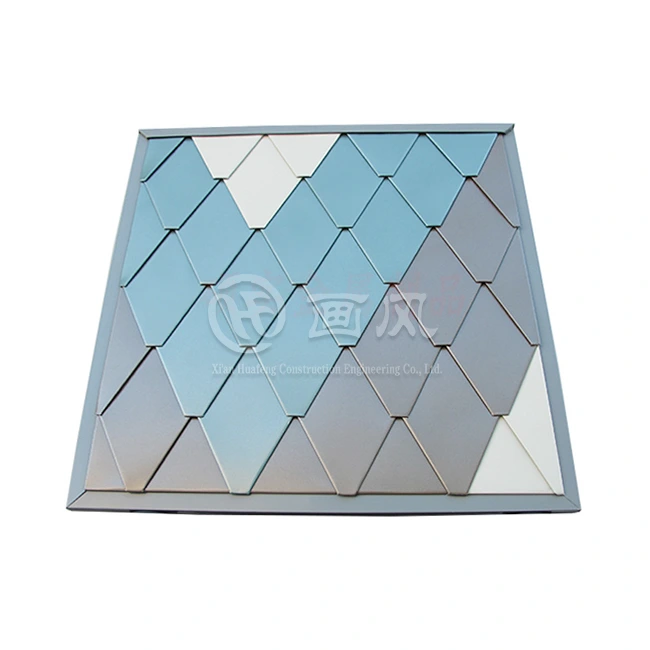

Site-Specific Customization and Project Planning

Professional manufacturers of Aluminum Standing Seam Metal Roof Panels offer comprehensive design support services including structural analysis, load calculations, and drainage system optimization. These engineering services ensure that roofing systems meet specific coastal site requirements including high wind zones, heavy rainfall patterns, and local building code requirements. Computer-aided design tools enable precise panel layout planning that minimizes waste, coordinates with architectural features, and maintains aesthetic consistency across complex roof geometries. Manufacturing facilities can provide pre-cut panels with precise dimensions and pre-notched penetration locations based on detailed shop drawings, significantly reducing field labor and improving installation quality. This factory customization ensures dimensional accuracy, proper panel sequencing, and efficient on-site assembly. Packaging systems organize panels by roof sections with clear identification labeling that simplifies material handling and installation sequencing. For large coastal projects, coordinating panel delivery schedules with construction progress prevents material exposure to weather and site conditions that could compromise quality before installation.

Maintenance Requirements and Long-Term Care

One of the compelling advantages of Aluminum Standing Seam Metal Roof Panels for coastal applications is their minimal maintenance requirements compared to alternative roofing systems. However, some basic care practices help maximize service life and maintain warranty coverage. Annual or bi-annual inspections allow homeowners to identify and address minor issues before they develop into significant problems. Inspections should examine panel condition, fastener security, flashing integrity, and drainage system function. Coastal environments may accelerate accumulation of organic debris, salt deposits, and atmospheric pollutants that benefit from periodic cleaning to maintain optimal appearance and performance. Cleaning procedures for Aluminum Standing Seam Metal Roof Panels typically involve gentle washing with mild detergent solutions and low-pressure water rinses. Avoiding abrasive cleaners, high-pressure washing, and aggressive scrubbing prevents damage to PVDF coatings that could compromise appearance and corrosion resistance. Some manufacturers specify cleaning frequency requirements for coastal installations to maintain warranty validity, typically ranging from annual to bi-annual intervals depending on proximity to saltwater and local environmental conditions. Documenting maintenance activities and retaining service records provides important warranty protection and demonstrates responsible ownership practices.

Addressing Minor Damage and Touch-Ups

Despite aluminum's excellent durability, occasional minor damage from falling branches, hail, or installation activities may occur requiring attention. Small scratches or coating damage can be addressed through manufacturer-supplied touch-up paint systems specifically formulated for PVDF coatings. Proper surface preparation including cleaning and light abrading ensures good adhesion of touch-up materials. For more significant panel damage such as dents or punctures, panel replacement represents the most reliable repair approach. The standing seam system design facilitates selective panel replacement without disturbing adjacent undamaged sections, making localized repairs practical and cost-effective. Fastener maintenance primarily involves verification that clip attachments remain secure and properly aligned. Loose or displaced clips should be reattached or replaced promptly to maintain panel stability and weather resistance. Sealant joints at penetrations and transitions require periodic inspection for deterioration, with degraded sealants requiring removal and replacement using compatible materials. Maintaining proper drainage system function includes clearing gutters, downspouts, and roof drains of accumulated debris that could cause water backup and potential infiltration. These straightforward maintenance tasks, when performed regularly, ensure that Aluminum Standing Seam Metal Roof Panels deliver their full expected service life with minimal intervention.

Warranty Coverage and Performance Guarantees

Quality manufacturers of Aluminum Standing Seam Metal Roof Panels for coastal applications provide comprehensive warranty programs covering both material and finish performance. Material warranties typically guarantee structural integrity and corrosion resistance for periods extending 30 to 50 years, reflecting confidence in aluminum's inherent durability. Finish warranties cover color retention and chalk resistance for 20 to 30 years when PVDF coating systems are specified, ensuring that roofs maintain their aesthetic appeal throughout decades of service. These warranty programs distinguish premium products from commodity alternatives and provide important financial protection for homeowners' roofing investments. Understanding warranty terms and conditions helps homeowners maintain coverage and avoid inadvertent violations. Common warranty requirements include professional installation by qualified contractors, use of compatible accessories and fasteners, and adherence to specified maintenance schedules including periodic cleaning. Some warranties require registration within specific timeframes after installation to activate coverage. Coastal installations may have modified warranty terms reflecting the increased environmental challenges, but reputable manufacturers continue to offer substantial protection recognizing that properly specified aluminum systems perform reliably in marine environments where steel alternatives cannot.

Conclusion

Coastal homeowners seeking reliable, long-lasting roofing solutions find optimal performance in Aluminum Standing Seam Metal Roof Panels specifically engineered for marine environments. These advanced roofing systems combine aluminum's inherent corrosion resistance with standing seam weather-tightness and premium PVDF coatings to deliver 40 to 60 years of maintenance-free protection where traditional materials fail within years.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China Aluminum Standing Seam Metal Roof Panels manufacturer and China Aluminum Standing Seam Metal Roof Panels supplier, offering comprehensive solutions from design through installation. As a recognized high-tech enterprise with over 20 patented roofing technologies, Huafeng operates three state-of-the-art manufacturing facilities spanning 200,000 square meters equipped with seven color coating production lines and more than 40 specialized processing machines. Our High Quality Aluminum Standing Seam Metal Roof Panels meet international standards including ISO9001, ISO14001, and SGS certifications, ensuring consistent performance for coastal applications worldwide.

Our engineering team provides complete one-stop services including structural 3D modeling, load analysis, drainage system optimization, and custom material specifications tailored to your coastal project requirements. From initial design consultation through final installation guidance and maintenance planning, Huafeng delivers turnkey solutions that eliminate the complexity of multi-vendor coordination. As a leading China Aluminum Standing Seam Metal Roof Panels wholesale provider, we offer competitive Aluminum Standing Seam Metal Roof Panels price structures without compromising quality, with Aluminum Standing Seam Metal Roof Panels for sale directly from our factory to your project site. Contact our experienced technical team at huafeng@hfmetalroof.com to discuss your coastal roofing needs and receive customized solutions backed by decades of engineering expertise and proven project success.

References

1. Metal Construction Association. "Guidelines for Specification and Installation of Metal Roofing Systems in Coastal Environments." Technical Bulletin Series, 2023.

2. Johnson, Robert and Martinez, Elena. "Corrosion Performance of Aluminum Alloys in Marine Atmospheres: A Comprehensive Field Study." Journal of Materials Engineering and Performance, Volume 32, 2024.

3. American Society for Testing and Materials. "Standard Specification for Aluminum Sheet and Plate for Roofing and Siding Applications." ASTM B209-14, 2023 Edition.

4. Thompson, David. "Standing Seam Metal Roofing Systems: Design, Installation and Performance in Hurricane-Prone Regions." Professional Roofing Magazine, National Roofing Contractors Association, 2024.

5. International Code Council. "Metal Roof System Design and Installation Requirements for High Wind Coastal Zones." International Building Code Commentary, Chapter 15, 2024 Edition.

(1)_1763110678300.webp)