Modern building exteriors face a critical challenge: achieving aesthetic appeal without compromising weather resistance and long-term durability. Many traditional cladding systems either lack visual sophistication or fail to withstand harsh environmental conditions, leaving building owners frustrated with premature deterioration and costly replacements. Flat Lock Wall Panels emerge as an elegant solution that combines refined aesthetics with exceptional performance, offering architects and developers a proven system that transforms building facades while ensuring decades of reliable protection against the elements.

Understanding Flat Lock Wall Panels and Their Design Versatility

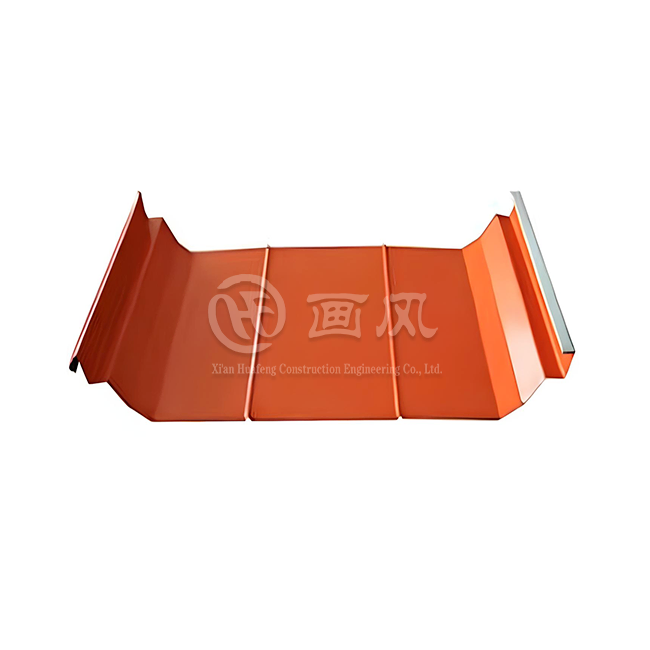

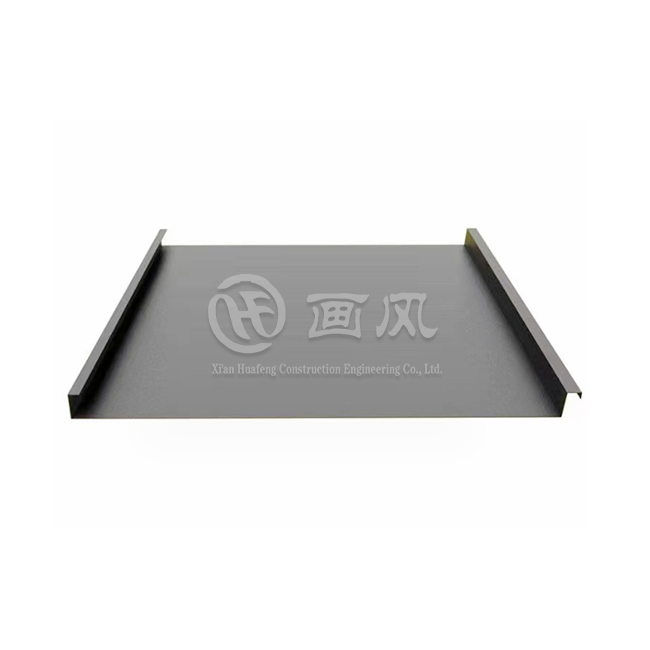

Flat Lock Wall Panels represent an advanced architectural cladding system that utilizes interlocking metal sheets to create visually stunning building exteriors. These flat lock metal panel systems consist of individual panels that hook together through a specialized concealed fastening mechanism, producing a nearly seamless appearance with subtle shadow lines that add dimensional depth to facades. The interlocking design allows each panel to overlap on all four sides, creating a sophisticated shingle-like pattern that can be customized to match virtually any architectural vision. The manufacturing process for Flat Lock Wall Panels involves precision roll-forming and break-forming techniques that shape premium metal materials into uniform panels with exact dimensional tolerances. Materials commonly used include titanium-zinc alloys, copper, aluminum-magnesium-manganese alloys, and stainless steel, each offering distinct aesthetic qualities and performance characteristics. With thicknesses ranging from 0.4mm to 0.8mm and customizable widths between 100mm to 400mm, these panels provide architects with tremendous flexibility in design execution. The panels can be fabricated in various geometric shapes including rectangles, rhombuses, trapezoids, and hexagons, enabling creative facade compositions that distinguish buildings from conventional structures.

Material Selection and Performance Characteristics

The choice of material for flat lock metal panel installations significantly impacts both the visual outcome and long-term performance of building facades. Titanium-zinc panels offer exceptional corrosion resistance and develop a natural protective patina over time, creating a distinctive weathered appearance that many architects favor for contemporary projects. Copper panels provide unmatched longevity with service lives exceeding 70 years, evolving through various color stages from metallic brown to verdigris green, adding living character to building exteriors. Aluminum-magnesium-manganese alloys deliver excellent strength-to-weight ratios while maintaining superior formability, making them ideal for complex geometric applications where panels must conform to curved or irregular surfaces. Stainless steel options, particularly 304 and 316 grades, provide remarkable durability in coastal or industrial environments where salt exposure and atmospheric pollutants would rapidly degrade lesser materials. Surface coatings such as PVDF (polyvinylidene fluoride) and PE (polyester) finishes enhance weather resistance while offering virtually unlimited color possibilities through RAL and custom color matching systems. These coating systems protect underlying metal substrates from UV degradation, acid rain, and industrial fallout, ensuring facades maintain their intended appearance for decades. Advanced coating technologies also provide self-cleaning properties through hydrophobic surface treatments that cause water to bead and roll off panels, carrying away dirt and contaminants without manual intervention.

Installation Flexibility and Architectural Applications

Flat Lock Wall Panels offer unparalleled installation flexibility, accommodating horizontal, vertical, and diagonal orientations to achieve diverse aesthetic effects. Horizontal installations create linear visual rhythms that emphasize building width and complement contemporary minimalist designs. Vertical arrangements accentuate building height while facilitating efficient water drainage, making them particularly suitable for regions experiencing heavy rainfall. Diagonal diamond pattern installations produce dynamic visual interest that breaks conventional facade monotony, creating striking architectural statements that capture attention and distinguish projects within competitive urban landscapes. The concealed clip attachment system used in flat lock metal panel installations provides several critical advantages beyond aesthetic considerations. Clips allow panels to expand and contract with temperature fluctuations without creating stress points that could lead to warping or oil-canning effects. This floating installation method prevents the buckling and distortion problems common in rigidly fastened systems, maintaining the intended flat appearance throughout seasonal temperature cycles. Installation over solid substrates such as plywood sheathing or compatible wooden frameworks creates ventilated rain-screen assemblies that manage moisture effectively, preventing condensation accumulation and protecting underlying building structures from water damage.

Key Benefits of Flat Lock Wall Panels for Modern Building Projects

Superior Weather Protection and Building Envelope Performance

Flat Lock Wall Panels function as high-performance rain-screen cladding systems that provide exceptional protection against water infiltration, wind-driven precipitation, and atmospheric moisture. The overlapping panel configuration creates multiple defense layers where water cannot penetrate into wall cavities, while the ventilated airspace behind panels allows any incidental moisture to evaporate naturally. This ventilation principle proves critical in preventing mold growth and structural deterioration that plague non-ventilated wall assemblies. Testing conducted according to ETAG 006 standards confirms that properly installed Flat Lock Wall Panels withstand extreme wind suction forces without panel displacement or fastener failure, ensuring structural integrity during severe weather events. The interlocking seam design eliminates the need for exposed fasteners that create potential water entry points and visual interruptions on facade surfaces. Unlike conventional panel systems requiring visible screws or rivets that eventually corrode and compromise watertightness, the concealed fastening approach maintains consistent weather protection throughout the system's service life. Panel materials themselves contribute to weather resistance through inherent corrosion resistance properties, with metals like titanium-zinc and copper developing stable protective oxide layers that actually improve over time. Aluminum-magnesium-manganese alloys incorporate alloying elements that enhance atmospheric corrosion resistance compared to standard aluminum products, particularly in marine environments where salt spray accelerates material degradation.

Aesthetic Excellence and Design Customization

The refined appearance of Flat Lock Wall Panels elevates building facades beyond standard cladding solutions, offering architects opportunities to create distinctive visual identities for commercial, institutional, and high-end residential projects. The subtle shadow lines created by overlapping panels add three-dimensional depth that changes throughout the day as sunlight angles shift, producing dynamic facades that interact with their environment rather than presenting static surfaces. This dimensional quality proves particularly effective on large building elevations where monotonous flat cladding can appear lifeless and uninspiring. The ability to specify custom panel sizes, shapes, and arrangements enables designers to develop unique facade patterns that reflect project-specific aesthetic goals and brand identities. Color selection possibilities extend far beyond standard architectural finishes, with RAL color systems providing access to thousands of precisely matched hues that can be applied through durable PVDF coating processes. Custom color development allows exact matching to corporate branding requirements or coordination with surrounding architectural contexts in historically sensitive areas. Natural metal finishes offer alternative aesthetic directions, with pre-weathered zinc products providing immediate aged appearances, bright mill finish options delivering contemporary metallic aesthetics, and patinated copper selections offering rich brown and green tones that evoke traditional craftsmanship. The combination of material choice, finish selection, panel geometry, and installation pattern creates nearly infinite design possibilities that distinguish each project while meeting specific performance requirements.

Long-Term Durability and Minimal Maintenance Requirements

The exceptional durability of Flat Lock Wall Panels translates into significant lifecycle cost advantages compared to maintenance-intensive cladding alternatives. High-quality installations using premium materials like titanium-zinc or copper routinely achieve service lives exceeding 70 years with minimal maintenance interventions, dramatically reducing total ownership costs when evaluated over building lifespans. The non-combustible nature of metal panels contributes to fire safety while eliminating deterioration issues that affect organic cladding materials exposed to moisture, biological growth, and UV radiation. Unlike painted wood, fiber-cement, or polymer-based products requiring periodic refinishing or replacement, metal flat lock systems maintain structural integrity and appearance with only occasional cleaning to remove accumulated surface deposits. The self-supporting nature of individual panels allows selective replacement of damaged units without disturbing adjacent areas, facilitating economical repairs following impact damage or vandalism incidents. This modular repairability proves particularly valuable in commercial applications where maintaining building appearance directly impacts property values and tenant satisfaction. Factory-applied PVDF coatings carry warranties up to 30 years against excessive fading and chalking, providing building owners with long-term performance assurance and reducing uncertainty in maintenance budget planning. The dimensional stability of properly installed systems prevents the warping, sagging, and joint opening problems that plague inferior cladding products, maintaining crisp facade appearance throughout the building's service life.

Sustainability and Environmental Advantages of Flat Lock Wall Panels

Modern construction increasingly prioritizes environmental responsibility, making material sustainability critical in product specification decisions. Flat Lock Wall Panels excel in sustainability metrics through multiple pathways. All metal materials used in panel fabrication remain fully recyclable at end of service life, with recycling rates for aluminum, copper, and steel exceeding 90% in most developed markets. This recyclability prevents cladding materials from entering waste streams while conserving embodied energy and virgin material resources. The longevity of metal panel systems reduces replacement frequency compared to shorter-lived alternatives, minimizing the environmental impacts associated with manufacturing, transportation, and installation of replacement materials. The ventilated rain-screen configuration created by Flat Lock Wall Panel installations contributes to building energy efficiency through several mechanisms. The airspace behind panels provides additional thermal resistance that supplements primary insulation layers, reducing heat transfer through building envelopes during both heating and cooling seasons. Solar heat absorbed by panel surfaces dissipates through ventilation airflow rather than conducting into building interiors, reducing cooling loads and associated energy consumption. In winter conditions, the ventilation cavity allows moisture vapor to escape before condensing on cold surfaces, preventing the insulation degradation that occurs when moisture accumulates within wall assemblies. These thermal performance benefits combine with the inherent durability and longevity of metal systems to create building envelopes that minimize environmental impacts throughout extended service lives.

Many flat lock metal panel products qualify for credits within green building certification programs such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method). Credits may be earned for recycled content in materials, regional material sourcing when manufacturers operate within specified distances from project sites, and contributions to building energy performance through improved envelope thermal properties. Manufacturers increasingly provide Environmental Product Declarations (EPDs) that document lifecycle environmental impacts according to standardized assessment methodologies, giving designers transparent information for comparing product alternatives and substantiating sustainability claims in certification documentation.

Professional Installation and Quality Assurance with Xi'an Huafeng

Successful Flat Lock Wall Panel installations require experienced craftsmen who understand the nuances of metal panel behavior, proper fastening techniques, and building science principles governing moisture management in ventilated facades. Xi'an Huafeng Construction Engineering Co., Ltd. brings comprehensive expertise spanning design development, precision manufacturing, and field installation to deliver turnkey facade solutions. The company's technical design department conducts detailed 1:1 drawing development that identifies potential installation challenges before fabrication begins, preventing costly field modifications and ensuring efficient construction sequences. This upfront design investment produces detailed shop drawings that guide manufacturing processes and provide field installers with clear, unambiguous construction documentation. The manufacturing capabilities at Xi'an Huafeng include multiple quality control checkpoints that verify dimensional accuracy, material specifications, and finish quality before products ship to project sites. Incoming material inspection procedures confirm that raw materials from approved suppliers including Baosteel, Alucosuper, and NedZink meet specified composition and physical property requirements. Factory processing sample development allows clients to verify colors, finishes, and panel details before committing to full production runs, eliminating surprises and ensuring final products match design intent. Sequential numbering systems applied during fabrication correlate panels with specific installation locations according to shop drawings, streamlining field logistics and preventing installation errors that could compromise weather protection or visual continuity.

On-site construction management by experienced Xi'an Huafeng technicians ensures proper substrate preparation, accurate panel layout, and correct installation techniques throughout the construction process. Pre-installation site inspections verify that substrates meet flatness tolerances and moisture conditions appropriate for panel installation, preventing future performance problems attributable to inadequate preparation. Installation technicians provide hands-on guidance to ensure clips position correctly, panels interlock properly, and flashing details integrate seamlessly with adjacent building elements. Upon completion, thorough testing protocols verify system watertightness before final acceptance, providing building owners confidence that facades will perform as intended throughout their service lives.

Conclusion

Flat Lock Wall Panels deliver comprehensive benefits for modern building facades, combining sophisticated aesthetics with proven weather protection, exceptional durability, and environmental responsibility. Their versatility accommodates diverse architectural visions while providing practical performance advantages that reduce lifecycle costs.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Partner with Xi'an Huafeng Construction Engineering Co., Ltd., a recognized high-tech enterprise offering complete metal facade solutions from design through construction. As a leading China Flat Lock Wall Panels manufacturer, China Flat Lock Wall Panels supplier, and China Flat Lock Wall Panels factory, we provide China Flat Lock Wall Panels wholesale services with High Quality Flat Lock Wall Panels at competitive Flat Lock Wall Panels price points. Our Flat Lock Wall Panels for sale include 30-year warranties backed by ISO, CE, and SGS certifications. With three factories operating seven production lines and over 40 specialized machines producing 1000 tons monthly, we deliver customizable solutions from raw materials through accessories. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and receive technical specifications, and save this resource for future reference.

References

1. Metal Architecture Design Guidelines for Architectural Metal Panel Systems. American Institute of Architects and Metal Construction Association, 2019.

2. Thompson, Richard. Sustainable Building Envelopes: Design Principles for Energy-Efficient Facades. Architectural Press, 2021.

3. International Code Council. International Building Code Requirements for Exterior Wall Coverings and Weather-Resistant Barriers. ICC Publications, 2021.

4. Chen, Wei and Martinez, Sofia. Performance Testing of Metal Cladding Systems: Wind Resistance and Water Penetration Studies. Journal of Building Engineering, Vol. 45, 2022.

5. European Organization for Technical Assessment. ETAG 006: Guideline for European Technical Approval of Systems of Metal Sheet for Roof and Wall Cladding. EOTA Publications, 2020.