Imagine investing thousands in a new metal roof, only to face persistent leaks during the first heavy rainstorm. For architects, contractors, and building owners selecting standing seam systems, the choice between Double Lok Roof Panel and snap-lock technology directly impacts long-term performance, maintenance costs, and structural integrity. Double Lok Roof Panel systems feature mechanically seamed connections with double-folded joints (180-degree seams), delivering superior weatherproofing and durability compared to snap-lock alternatives, particularly for low-slope applications and extreme climate zones.

Understanding Double Lok Roof Panel Systems

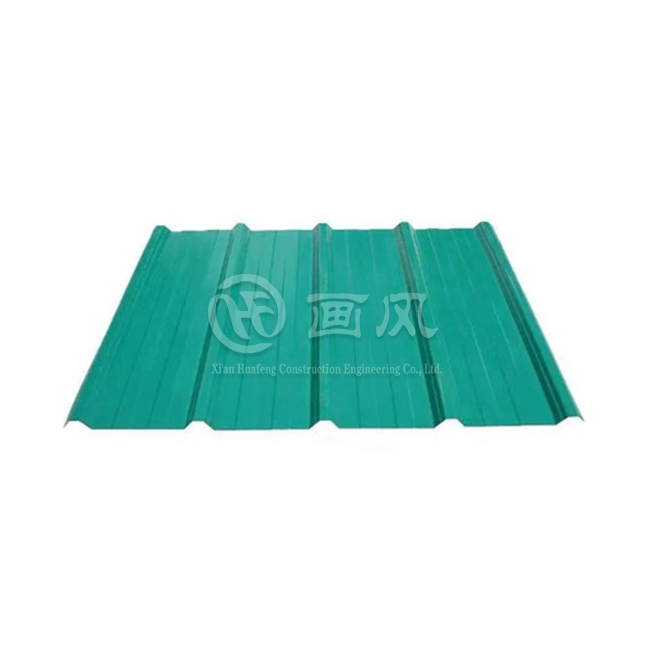

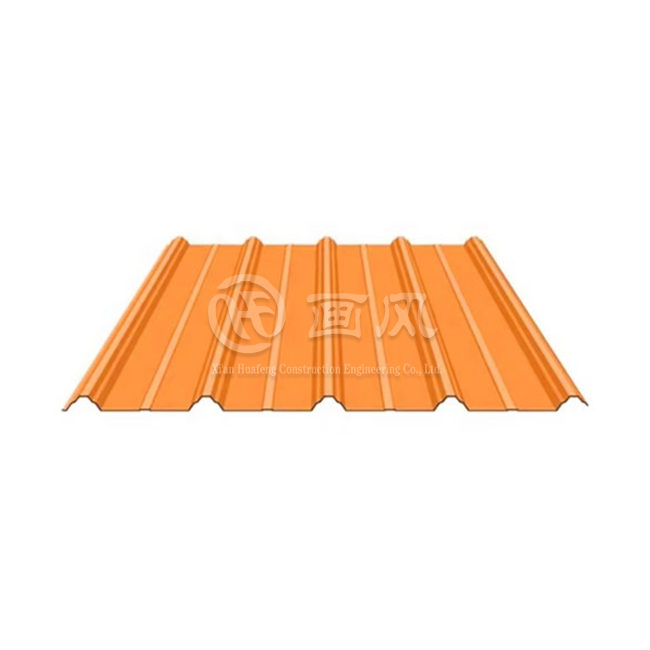

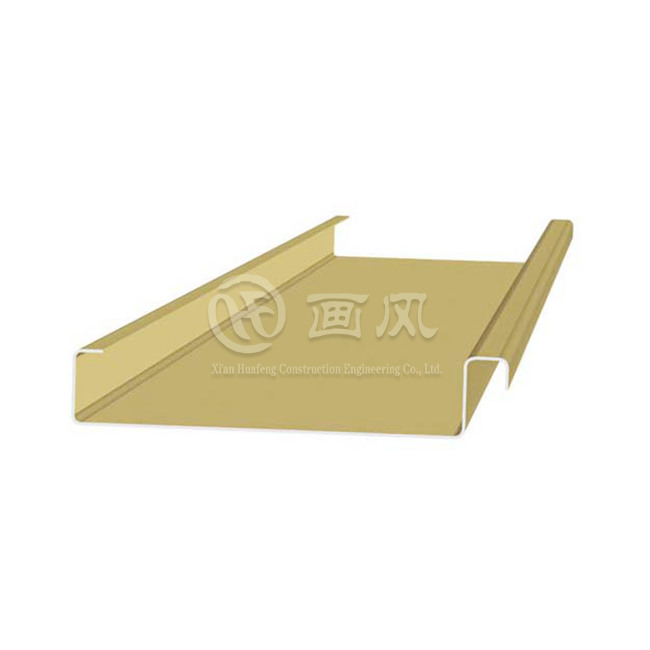

The Double Lok Roof Panel represents an advanced mechanically seamed standing seam metal roofing solution specifically engineered for demanding applications. Unlike conventional roofing systems, this technology employs a double-lock seaming mechanism where vertical panel legs are folded twice at 180 degrees, creating an exceptionally tight seal that eliminates water infiltration pathways. This engineering approach addresses critical vulnerabilities found in alternative systems, particularly regarding weathertightness and structural performance under extreme conditions. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Double Lok Roof Panel systems using premium materials including aluminum alloy (AA3003/AA3004), galvanized steel (AZ150), and stainless steel. The panels feature customizable specifications ranging from 0.6mm to 1.2mm thickness, with panel widths between 400mm and 600mm. Standard lock edge height measures 25mm, ensuring adequate seam depth for mechanical seaming operations. These panels comply with international standards including ASTM, DIN, JIS, BS, and GB/T certifications, demonstrating commitment to quality manufacturing processes across three production facilities with seven dedicated production lines and over 40 specialized machines. The manufacturing process incorporates rigorous quality control protocols beginning with incoming material inspection. Raw material manufacturers must provide material certification and third-party testing reports before acceptance. Inspection procedures encompass more than a dozen verification steps including salt spray testing, adhesion analysis, hardness measurement, impact resistance evaluation, film thickness verification, acid resistance testing, weather resistance assessment, and color difference analysis. This comprehensive approach ensures every Double Lok Roof Panel meets exacting performance standards before reaching construction sites.

Key Technical Specifications and Performance Standards

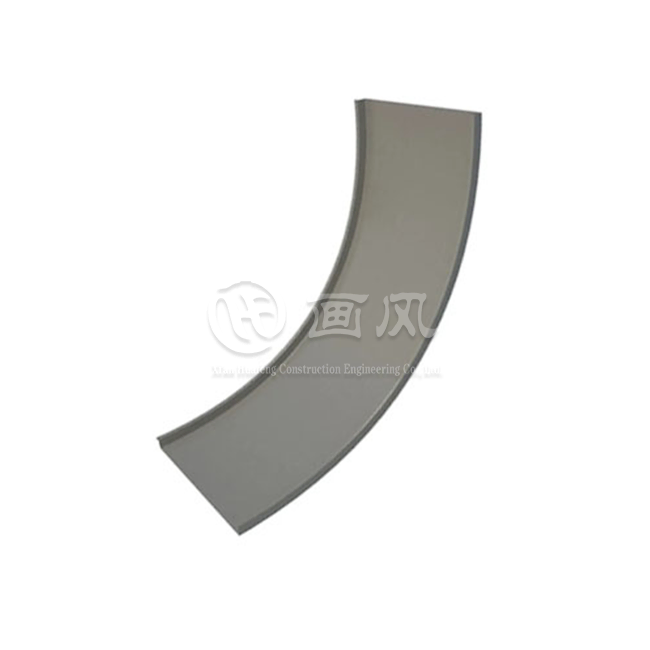

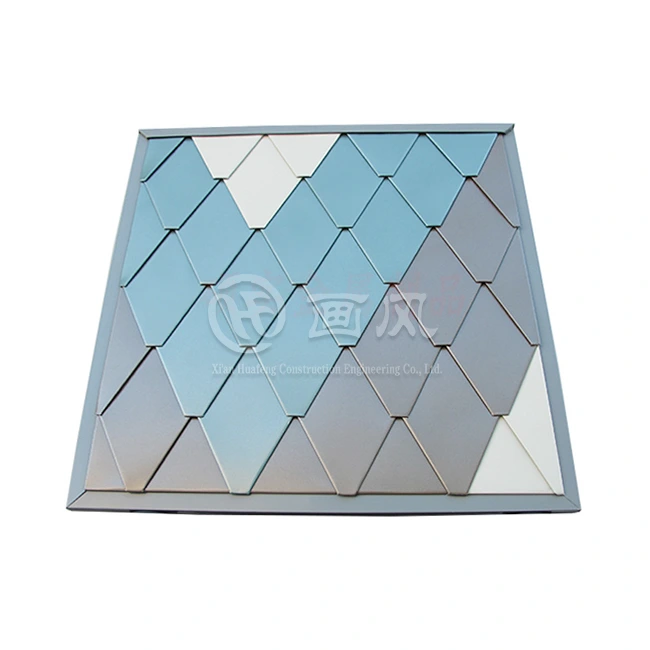

Double Lok Roof Panel systems offer impressive technical specifications designed for long-term performance. Surface treatments include PVDF (Polyvinylidene Fluoride) and PE (Polyester) coatings, providing exceptional resistance to UV degradation, chemical exposure, and atmospheric corrosion. The PVDF coating option delivers superior color retention and weathering performance, maintaining aesthetic appeal for decades even in harsh industrial or coastal environments. Panels are available in extensive RAL and Pantone color ranges, allowing architectural customization while maintaining structural performance. Installation requirements demand careful attention to substrate preparation. The steel structure or wooden base must achieve perfect flatness with minimum roof slope of 3 degrees to ensure proper drainage. The edge locking process utilizes specialized seaming machines for on-site rolling operations, guaranteeing hermetic sealing between adjacent panels. Critical to long-term performance, installation teams must incorporate expansion joints throughout the roof assembly to accommodate thermal expansion and contraction cycles, preventing stress accumulation that could compromise seam integrity over time. Application scenarios for Double Lok Roof Panel systems span diverse building types including large public facilities such as airports, gymnasiums, and convention centers. Commercial structures like shopping centers, office buildings, and hotels benefit from the clean aesthetic lines and proven weatherproofing. Industrial plants including logistics warehouses and manufacturing facilities appreciate the durability and low maintenance requirements. Transportation hubs such as high-speed rail stations and subway terminals rely on the system's reliability and longevity. Increasingly, green building applications incorporate Double Lok Roof Panel technology for photovoltaic integrated roofs (BIPV), supporting sustainable energy generation while maintaining superior weather protection.

Snap-Lock Standing Seam Systems Explained

Snap-lock standing seam panels represent an alternative approach to metal roofing, featuring male and female legs that simply snap together without mechanical seaming. This connection method relies on concealed clips fastened directly to the roof substrate, with panels interlocking through designed geometries rather than mechanical folding operations. The simplified installation process eliminates the need for specialized seaming equipment, reducing labor requirements and accelerating project timelines significantly compared to mechanically seamed alternatives like Double Lok Roof Panel systems. The primary advantage of snap-lock technology lies in installation efficiency. Roofing contractors can complete snap-lock installations considerably faster because panels simply click into place without hand-seaming or power-seaming operations. This efficiency translates directly into reduced labor costs, making snap-lock systems financially attractive for budget-conscious projects. The concealed fastener design maintains clean aesthetic lines similar to mechanically seamed profiles, delivering contemporary architectural appearance while simplifying the construction process. For steep-slope residential applications and projects in moderate climate zones, snap-lock panels often provide adequate performance at competitive pricing. However, snap-lock systems present notable limitations regarding weather resistance and structural performance. The connection mechanism, while effective under normal conditions, creates potential pathways for water infiltration that mechanically seamed systems like Double Lok Roof Panel inherently prevent. Industry analysis consistently demonstrates that mechanically seamed panels, especially double-locked configurations, achieve superior weathertightness by eliminating gaps where moisture could penetrate. This differential becomes critically important for low-slope applications where water accumulation risks are substantially higher.

Critical Performance Limitations of Snap-Lock Systems

Slope restrictions represent a significant constraint for snap-lock applications. These panels cannot be reliably installed on roofs with pitch below 3:12 due to increased leakage risks associated with water pooling. In contrast, Double Lok Roof Panel systems with proper double-lock seaming can safely accommodate slopes as low as 1:12 or even 0.25:12 with appropriate installation protocols and in-seam sealant application. This versatility makes mechanically seamed systems essential for modern commercial architecture where low-slope and nearly flat roof designs are increasingly common. Thermal movement management presents another critical distinction. While snap-lock systems do allow panel expansion and contraction through clip design, the connection points experience different stress distributions compared to mechanically seamed assemblies. For panels exceeding 25 feet in length, or in climates with dramatic temperature fluctuations, expansion clip configurations become essential. Double Lok Roof Panel installations typically incorporate specialized expansion clips designed specifically for mechanical seam applications, providing engineered solutions for thermal stress management that maintain seam integrity throughout seasonal temperature cycles. Wind uplift performance also differentiates these systems. Mechanically seamed profiles, particularly double-lock configurations, achieve superior wind resistance ratings due to the physical crimping that bonds adjacent panels together. Independent testing consistently shows that Double Lok Roof Panel assemblies withstand higher wind loads compared to snap-lock alternatives, making them preferred choices for buildings in hurricane-prone regions or exposed hilltop locations where wind forces are substantial.

Comprehensive Comparison: Double Lok Roof Panel vs Snap-Lock

When evaluating Double Lok Roof Panel against snap-lock alternatives, weatherproofing performance emerges as the most critical differentiator. The double-lock seaming process creates an essentially watertight barrier by folding panel edges twice at 180 degrees, physically eliminating potential water entry points. This mechanical bond represents fundamental engineering superiority over snap-together connections that rely on precise manufacturing tolerances and clip tension to prevent moisture infiltration. Field performance data from installations worldwide demonstrates that properly installed Double Lok Roof Panel systems virtually eliminate leak-related service calls, even in regions experiencing extreme rainfall or heavy snow accumulation. Installation complexity and cost considerations reveal contrasting value propositions. Snap-lock systems undeniably offer faster installation with lower initial labor costs, making them attractive for residential projects or buildings with steep slopes in moderate climates. However, this short-term cost advantage must be weighed against long-term performance factors. Double Lok Roof Panel installations require specialized seaming equipment and trained technicians, increasing upfront investment. Yet this initial premium purchases decades of superior performance, eliminating costly leak repairs, water damage remediation, and premature roof replacement expenses that can plague inferior systems.

Durability and service life expectations further distinguish these technologies. Xi'an Huafeng Construction Engineering Co., Ltd. provides a 30-year warranty on Double Lok Roof Panel systems, reflecting confidence in material quality and seam integrity. Independent assessments suggest properly maintained mechanically seamed roofs can achieve 40-60 years of service life or more. Snap-lock systems, while durable under ideal conditions, may experience seam degradation over time, particularly where thermal cycling stresses connection points or where installation quality varies. The physical crimping of Double Lok Roof Panel seams creates permanent bonds that resist deterioration, maintaining weatherproofing performance throughout the building's service life.

Application-Specific Recommendations

Project requirements should drive system selection decisions. For large public buildings, commercial facilities, industrial plants, and transportation infrastructure, Double Lok Roof Panel technology delivers proven performance that justifies the investment. These applications demand absolute reliability, minimal maintenance, and extended service life—attributes that mechanically seamed systems consistently provide. The ability to accommodate low-slope designs expands architectural possibilities, supporting modern building aesthetics while maintaining functional requirements. Residential applications with steep slopes in temperate climates may find snap-lock systems adequate if budget constraints are primary concerns. However, even in residential contexts, regions experiencing severe weather—heavy snow loads, ice damming, hurricane-force winds, or torrential rainfall—benefit substantially from Double Lok Roof Panel superior weatherproofing. Homeowners prioritizing long-term value and minimal maintenance should seriously consider mechanically seamed options despite higher initial costs. Climate conditions play decisive roles in system selection. Regions with temperature extremes, dramatic day-night temperature swings, or freeze-thaw cycles place extraordinary stress on roofing connections. Double Lok Roof Panel systems engineered with proper expansion clips and thermal management features handle these conditions reliably. Coastal environments with salt spray exposure, industrial zones with atmospheric contaminants, or areas with intense UV radiation benefit from PVDF-coated Double Lok Roof Panel that maintain appearance and performance under harsh exposure conditions. Snap-lock systems may experience accelerated degradation in these demanding environments.

Technical Advantages of Double Lok Roof Panel Manufacturing

Xi'an Huafeng Construction Engineering Co., Ltd.'s manufacturing capabilities directly support Double Lok Roof Panel quality and performance. The company operates three production facilities equipped with seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing production lines. Fully automatic punching production lines work alongside more than 40 shearing machines, presses, and bending machines, enabling precise panel fabrication to exact specifications. This manufacturing infrastructure ensures consistent dimensional accuracy and surface quality critical for proper seam formation during installation. Material procurement procedures emphasize quality assurance. The company maintains a rigorous supplier registration system, requiring test reports and conducting multiple inspections before approving materials for production. The material selection brand library includes premium aluminum from Alucosuper, YATAI, and LIDAO (grades 3003, 3004, 5052), steel from BAOSTEEL, GUANZHOU, and XINYU (including cold rolled sheet, galvanized sheet, galvalume sheet, and color coated sheet), stainless steel from Baosteel and Tsingshan (grades 316 and 304), titanium zinc plate from NedZink, and copper from Chinalco (grades T2/TP2). This emphasis on premium raw materials establishes the foundation for Double Lok Roof Panel long-term performance. Quality control extends throughout the production process. Finished product inspection includes appearance examination, dimensional verification, flatness assessment, and curvature measurement. Products are packaged systematically according to roof section plans, with identification cards containing sectioned floor plans and product number lists facilitating organized installation. This attention to detail reflects Huafeng's commitment to delivering complete roofing solutions rather than simply manufacturing components.

Design and Engineering Support Services

Beyond manufacturing excellence, Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive design and engineering support differentiating their Double Lok Roof Panel offerings. The project drawing deepening process begins with analyzing floor plans, elevations, and node diagrams from architectural engineering drawings. Engineers identify feasible alternatives and communicate with customers to determine optimal panel types for specific roof structures. The design department then conducts 1:1 drawing deepening of nodes throughout different project areas, ensuring constructability and performance. Factory processing samples allow customers to verify parameters before full production. Samples are manufactured according to confirmed board type, material, thickness, surface treatment method, and color specifications. After customer approval, samples are sealed as standards for subsequent processing, production, and acceptance procedures. This validation process eliminates costly errors and ensures delivered products match project requirements exactly. Processing drawing deepening breaks down detailed drawings into specific production instructions. Each unit receives sequential numbering according to project specifications and quantities, enabling systematic processing, quality assurance inspection, packaging, and on-site installation according to numbered components. This organizational discipline prevents confusion during complex installations and ensures every panel reaches its designated position.

Installation Excellence and Project Management

On-site construction services distinguish Xi'an Huafeng Construction Engineering Co., Ltd.'s Double Lok Roof Panel solutions. Based on actual construction site conditions, the company consults with customers to confirm specific construction layouts, including product and accessory storage space and on-site processing areas. Upon product arrival, data verification and proper positioning occur according to packaging identification cards, sectioned floor plans, and product number lists. This systematic approach ensures installation efficiency and accuracy. Installation technicians visit construction sites one day in advance to inspect work areas and verify tool completeness—including pliers, edge-locking machines, and hammers—along with auxiliary materials such as rivets, structural adhesive, screws, and other accessories. Technical briefing meetings thoroughly review work details and safety precautions before installation commences. This preparation minimizes delays and ensures safety compliance throughout the construction process. Upon installation completion, comprehensive on-site testing ensures zero leakage. The acceptance process invites customers to review installation interfaces, with formal sign-off completing acceptance procedures. Post-installation, Huafeng provides guidance for regular maintenance or arranges for personnel to perform maintenance services, supporting long-term Double Lok Roof Panel performance throughout the building's service life.

Project Portfolio Demonstrating Proven Performance

Xi'an Huafeng Construction Engineering Co., Ltd.'s project portfolio validates Double Lok Roof Panel capabilities across diverse applications. Notable installations include Xiongan Station Commercial Body with aluminum-magnesium-manganese metal roof, Xi'an International Convention and Exhibition Center metal roof project, and the metal roof project at Xi'an Station East Auxiliary Building. Additional significant projects encompass South Hall 2-2 of Jinghe New City International Culture and Art Center, Liyuanping Highway Station metal roof project, and Weihua Cadre College Teaching Building and Office Building with aluminum-magnesium-manganese metal roof and wall systems. Other successful implementations include Hangzhou Sanpu Drainage Pump Station with aluminum-magnesium-manganese metal roof and wall, design deepening for the Archaeological Museum, and Inner Mongolia Tongliao Art Museum metal roof and wall systems. These diverse projects demonstrate versatility and reliability across public, commercial, transportation, and cultural building types. Each installation showcases proper Double Lok Roof Panel application, from design through construction and acceptance.

Conclusion

The comparison reveals Double Lok Roof Panel systems deliver measurably superior weatherproofing, durability, and long-term value compared to snap-lock alternatives. While snap-lock technology offers installation efficiency and lower initial costs, the double-lock mechanical seaming of Double Lok Roof Panel creates permanent, watertight connections essential for demanding applications. Project requirements, climate conditions, and long-term cost considerations should drive selection decisions, with mechanically seamed systems representing the professional standard for commercial, industrial, and institutional buildings requiring proven performance and minimal maintenance throughout extended service lives.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 in Shaanxi Province, China, specializes in metal roofing systems, building curtain wall systems, and building steel structure enclosure systems. Recognized as a high-tech enterprise in Shaanxi Province in 2020, the company holds first-level qualification for building curtain walls and third-level qualification for building steel structures. With a raw material production plant covering 200,000 square meters in Anhui and two plate and accessories processing plants in Hangzhou and Xi'an, Huafeng integrates green sustainable development concepts throughout operations.

The company's comprehensive product range includes standing seam metal roofing panels, aluminum-magnesium-manganese plates, titanium-zinc plates, standing seam metal wall sheets, corrugated roofing and wall sheets, flat lock panels, roofing system accessories, and color aluminum/steel coil. With over 20 registered patents for roofing systems, various trademarks, and computer software certificates, all products comply with ISO9001, ISO14000:14001 SGS guidelines and strict quality control systems.

As a China Double Lok Roof Panel factory, China Double Lok Roof Panel supplier, and China Double Lok Roof Panel manufacturer, Xi'an Huafeng provides China Double Lok Roof Panel wholesale solutions with High Quality Double Lok Roof Panel for sale at competitive Double Lok Roof Panel price points. The company delivers one-stop services from design through production to construction, providing structural 3D modeling, load analysis, drainage system simulation, and material specification advisory. With customizable solutions, state-of-the-art production facilities, experienced engineering teams, competitive pricing, bulk order discounts, on-time delivery, and excellent after-sales service, Huafeng creates added value for global customers. Contact huafeng@hfmetalroof.com to discuss your project requirements.

References

1. Western States Metal Roofing. "Snap Lock Standing Seam v. Mechanical Seamed Panels: The Pros And Cons." Metal Roofing Technical Guide.

2. Sheffield Metals International. "Snap-lock vs. Mechanical Seam vs. Nail Strip Standing Seam Roof Profiles." SMI Metal Roofing Learning Center.

3. New Tech Machinery. "Mechanical Lock vs. Snap-lock Metal Roof Profiles: What Are the Differences?" Industrial Roofing Equipment Technical Documentation.

4. SFS USA. "Standing Seam Comparisons: Snap-Lock vs. Mechanically Seamed." Commercial Roofing Systems Analysis.

5. One Oak Exteriors. "Double Lock vs Snap Lock Standing Seam Roof: A Comprehensive Comparison." Professional Roofing Contractor Resources.