Industrial facility managers face a common challenge: aging roofs that leak during storms, drive up energy costs, and require constant maintenance. The Double Lok Roof Panel solves these pain points by delivering a mechanically seamed standing seam system that withstands extreme weather, minimizes thermal loss, and lasts decades with minimal upkeep. This guide reveals how Double Lok Roof Panel technology transforms industrial roofing performance across manufacturing plants, warehouses, distribution centers, and heavy industrial facilities.

Why Double Lok Roof Panel Dominates Industrial Applications?

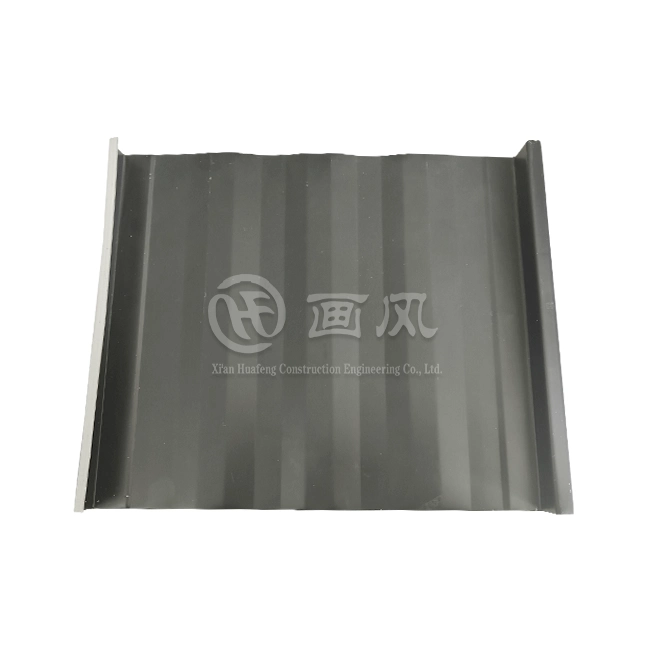

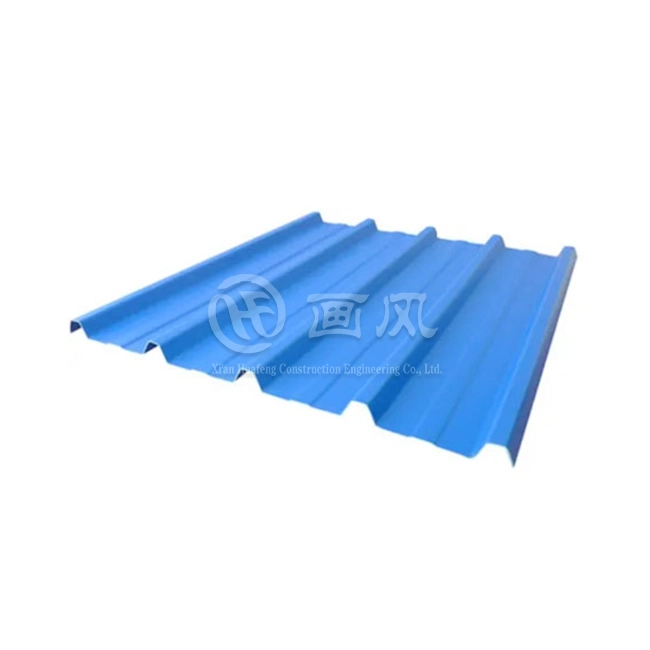

The Double Lok Roof Panel stands as the preferred choice for industrial facilities due to its mechanically field-seamed trapezoidal standing seam design. Unlike conventional roofing systems that compromise under heavy loads or severe weather, the Double Lok Roof Panel employs a double-lock seaming mechanism where panels fold twice at 180-degree angles. This engineering creates an exceptionally weathertight seal that prevents water infiltration even under hurricane-force winds and driving rain. Industrial buildings operating around the clock cannot afford production disruptions from roof failures, making the reliability of Double Lok Roof Panel systems essential for maintaining operational continuity. The concealed fastening system inherent to Double Lok Roof Panel construction eliminates up to eighty percent of exposed fasteners compared to traditional side-lap panels. This reduction directly translates to fewer potential leak points across vast industrial roof expanses. The panels attach to subframing through interlocking clips that accommodate thermal expansion and contraction without compromising structural integrity. Manufacturing facilities with processes generating significant heat benefit enormously from this thermal movement capability, as the Double Lok Roof Panel expands and contracts naturally without creating stress fractures or separating at seams. Industrial environments subject roofing systems to chemical exposure, corrosive atmospheres, and physical impacts that would degrade lesser materials. The Double Lok Roof Panel addresses these challenges through premium material selections including aluminum alloy grades AA3003 and AA3004, galvanized steel with AZ150 coating, and stainless steel variants for the most demanding applications. Surface treatments using PVDF or PE coatings provide additional protection against industrial pollutants while maintaining aesthetic appearance over decades. With thickness options ranging from 0.6mm to 1.2mm, specifiers can match Double Lok Roof Panel strength precisely to structural load requirements and environmental exposure levels.

Manufacturing Plants and Processing Facilities

Manufacturing operations generate unique roofing demands that the Double Lok Roof Panel meets through superior performance characteristics. Production facilities housing heavy machinery create vibrations that can loosen conventional roofing fasteners over time, but the Double Lok Roof Panel's mechanically seamed standing seam construction maintains structural integrity regardless of operational conditions. The system accommodates roof-mounted equipment such as HVAC units, exhaust systems, and material handling apparatus without compromising weathertightness. Chemical processing plants particularly benefit from the corrosion-resistant properties of Double Lok Roof Panel systems specified with stainless steel or specially coated aluminum materials. Temperature fluctuations within manufacturing environments pose significant challenges for roofing systems. Processes involving furnaces, ovens, or refrigeration create substantial thermal differentials between interior and exterior roof surfaces. The Double Lok Roof Panel's floating clip attachment system allows each panel to move independently in response to thermal stress, preventing the buckling and oil-canning that plague rigidly fastened roofing. This thermal performance extends to energy efficiency, where reflective coatings on Double Lok Roof Panel surfaces reduce solar heat gain by up to forty percent. Lower interior temperatures translate directly to reduced HVAC operating costs, a critical consideration for energy-intensive manufacturing operations.

Large-span manufacturing buildings present particular engineering challenges due to roof dimensions that can exceed 300 feet in width. The Double Lok Roof Panel accommodates these expanses through its ability to be installed in lengths up to 12 meters, minimizing end-lap joints that represent potential weak points. For buildings requiring even longer spans, the system's compression joint design at end laps maintains weathertightness while allowing proper fastener spacing. The 16-gauge backup plates with pre-punched holes at end laps ensure solid connections that meet rigorous structural requirements. Manufacturing facilities can specify Double Lok Roof Panel systems with confidence that performance will remain consistent across entire roof areas regardless of building dimensions.

Warehouse and Distribution Centers

Modern warehousing operations demand roofing systems that protect inventory while supporting sustainable operational practices, requirements that the Double Lok Roof Panel fulfills comprehensively. Distribution centers storing temperature-sensitive goods require stable interior environments, and the thermal performance of Double Lok Roof Panel systems contributes significantly to climate control efficiency. The standing seam profile creates an airspace between the roof deck and the metal panel that serves as an additional insulation layer, particularly when enhanced with fiber insulation products. This multi-layer approach reduces heat transfer and minimizes condensation risk, protecting stored goods from moisture damage. The rapid construction schedules typical of warehouse development align perfectly with Double Lok Roof Panel installation efficiency. Field crews can install panels from either end of the building or work simultaneously on both sides, dramatically reducing roof closure time compared to systems requiring sequential installation. Pre-punched holes in Double Lok Roof Panel components improve installation accuracy while assuring proper panel placement, factors that become critical when coordinating trades on fast-track construction schedules. The reduced labor time for Double Lok Roof Panel installation partially offsets the premium material cost, making total project economics favorable for warehouse developers.

Distribution facilities increasingly integrate photovoltaic systems for on-site power generation, and the Double Lok Roof Panel provides an ideal substrate for solar installations. The standing seam design accommodates clamp-on solar mounting systems that attach without penetrating the roof membrane, preserving weathertightness while supporting renewable energy infrastructure. The structural strength of Double Lok Roof Panel systems rated for wind uplift and snow loads ensures adequate capacity for additional solar array weight. Warehouse operators pursuing LEED certification or other sustainability credentials find that combining Double Lok Roof Panel systems with solar installations accelerates achievement of green building goals while reducing long-term operating expenses.

Double Lok Roof Panel Performance in Extreme Industrial Environments

Heavy industrial facilities operating in challenging climates require roofing systems that maintain performance under extreme conditions, a domain where the Double Lok Roof Panel demonstrates exceptional capabilities. Coastal industrial plants face salt-laden atmospheres that corrode conventional metal roofing within years, but Double Lok Roof Panel systems specified with marine-grade coatings and stainless steel materials resist corrosion for decades. The mechanically seamed joints create barriers against moisture intrusion that remain effective even when individual coating layers experience minor degradation. Industrial facilities in hurricane-prone regions rely on Double Lok Roof Panel systems rated for wind uplift pressures exceeding requirements for the most severe exposure categories. Arctic and subarctic industrial operations encounter roof loading from snow accumulation that would collapse lesser systems, yet the Double Lok Roof Panel accommodates these loads through engineered panel profiles and appropriate gauge specifications. The smooth metal surface facilitates snow shedding, reducing accumulation and associated structural loads. Cold climate installations benefit from the Double Lok Roof Panel's thermal break capabilities, which minimize ice dam formation at eaves where melting snow can refreeze and back up under conventional roofing. Industrial operations maintaining heated interiors in extremely cold environments appreciate how Double Lok Roof Panel systems reduce heat loss and associated energy waste.

Retrofit Applications Over Existing Industrial Roofs

Industrial facility managers facing failing roof systems traditionally confronted disruptive complete roof replacements that halted production and generated substantial waste. The Double Lok Roof Panel revolutionizes this scenario through retrofit capabilities that allow installation directly over existing metal panel roofs without removing the original roofing. This approach preserves the structural diaphragm provided by the existing roof while creating a new, high-performance weatherproof envelope. The retrofit application of Double Lok Roof Panel systems continues facility operations without interruption while delivering contemporary performance standards. The retrofit process begins with high clips that provide clearance between the Double Lok Roof Panel and the major ribs of the existing corrugated or through-fastened panel roof. This standoff creates an insulating airspace that dramatically improves thermal performance even before adding dedicated insulation materials. Facility managers can further enhance energy efficiency by installing unfaced fiberglass insulation between the old and new roof systems or by incorporating ventilation through eave intake vents and ridge exhaust configurations. These thermal upgrade options transform energy-inefficient industrial buildings into contemporary high-performance structures while avoiding the cost and disruption of complete roof replacement. The structural advantages of Double Lok Roof Panel retrofit installations extend beyond immediate weatherproofing benefits. The existing roof continues to contribute to the building's lateral bracing system, maintaining the structural stability established in the original design while the new Double Lok Roof Panel adds a redundant weather barrier. This dual-layer approach provides exceptional reliability for mission-critical industrial operations that cannot tolerate weather-related shutdowns. The retrofit application proves particularly valuable for facilities housing sensitive equipment or processes where interior environmental control must remain uninterrupted throughout roofing work.

Technical Specifications That Define Double Lok Roof Panel Excellence

Understanding the technical parameters that enable Double Lok Roof Panel superior performance helps industrial facility planners make informed specifications. The system accommodates minimum roof slopes of 1/4:12, making it appropriate for the low-slope configurations common in industrial architecture. This shallow pitch capability expands design flexibility while maintaining complete weathertightness through the mechanically seamed joint system. Panel widths of 400mm to 600mm provide effective coverage that balances material efficiency with structural performance. The 25mm lock edge height creates the standing seam profile that defines the system's appearance while providing the structure necessary for mechanical seaming. Material selection represents a critical decision point where Double Lok Roof Panel systems offer comprehensive options matched to specific application requirements. Aluminum alloy panels in grades AA3003 and AA3004 deliver exceptional corrosion resistance combined with favorable strength-to-weight ratios, making them ideal for structures where roof loading limitations exist. Galvanized steel panels with AZ150 coating provide robust performance for general industrial applications at economical pricing. Stainless steel variants serve the most demanding environments where chemical exposure or extreme corrosion potential justifies premium material investment. All material options accept PVDF or PE surface treatments that enhance weather resistance while offering extensive color selection for architectural integration.

The manufacturing capabilities supporting Double Lok Roof Panel production ensure consistent quality across all delivered components. Xi'an Huafeng Construction Engineering Co., Ltd. operates three factories equipped with seven production lines and over forty specialized machines dedicated to metal roofing fabrication. This industrial capacity produces Double Lok Roof Panel components with precise dimensional tolerances essential for field installation efficiency. Quality control protocols incorporating appearance inspection, dimensional verification, salt spray testing, adhesion evaluation, hardness measurement, impact resistance assessment, film thickness confirmation, acid resistance validation, weather resistance testing, and color difference analysis ensure every panel meets specification requirements. The rigorous inspection regimen guarantees that Double Lok Roof Panel systems perform as engineered throughout their service life.

Installation Excellence and Quality Assurance

The performance advantages inherent to Double Lok Roof Panel design only realize full potential through proper installation executed by trained technicians. The mechanically seamed standing seam connection requires specialized equipment and technique to achieve the double-lock joint that defines system weathertightness. Installation crews utilize portable seaming machines that progressively fold the panel edges together while moving along the joint length, creating uniform seam profiles across the entire roof area. This field-seaming process accommodates jobsite conditions and allows panel length customization impossible with pre-formed systems. Base preparation establishes the foundation for successful Double Lok Roof Panel installation. Steel structure or wooden substrate systems require verification of flatness within specified tolerances and confirmation of adequate slope for drainage. The substrate must provide secure fastening points for the concealed clip system that supports the panels. Thermal expansion and contraction considerations mandate the inclusion of expansion joints at prescribed intervals, preventing temperature-induced stress from compromising system integrity. These technical installation requirements underscore the importance of experienced contractors familiar with Double Lok Roof Panel best practices. Quality verification following Double Lok Roof Panel installation provides the assurance that the system will deliver expected performance. On-site testing protocols include water testing to confirm zero leakage across the entire roof assembly. Visual inspection verifies proper seam formation and validates that all penetrations receive appropriate flashing and sealing. The thorough acceptance process protects the facility owner's investment while establishing baseline documentation for future maintenance planning. Properly installed and verified Double Lok Roof Panel systems routinely deliver thirty years or more of trouble-free service, making them among the most reliable industrial roofing solutions available.

Cost-Effectiveness and Long-Term Value of Double Lok Roof Panel Systems

Industrial facility decision-makers evaluating roofing options must consider total lifecycle costs rather than initial installation expense alone. The Double Lok Roof Panel presents a compelling value proposition when analyzed through this comprehensive lens. While material costs for Double Lok Roof Panel systems exceed those of conventional through-fastened metal roofing, the elimination of exposed fasteners that require periodic replacement and resealing generates substantial maintenance savings. The mechanically seamed joints maintain their integrity across decades without the degradation that affects sealant-dependent systems, avoiding costly repairs and associated production disruptions. Energy efficiency contributions from Double Lok Roof Panel installations provide quantifiable operational savings throughout building life. Reflective coatings that reduce solar heat gain lower cooling loads during warm months, while the thermal break characteristics minimize heat loss during cold periods. Industrial facilities with significant interior climate control requirements realize substantial utility cost reductions that accumulate year after year. The energy savings often justify Double Lok Roof Panel specification purely on economic grounds before considering the additional benefits of extended service life and reduced maintenance requirements.

The longevity characteristics of Double Lok Roof Panel systems fundamentally alter facility lifecycle planning. Conventional industrial roofing typically requires replacement every fifteen to twenty years, creating recurring capital expenses and operational disruptions. The Double Lok Roof Panel, backed by thirty-year warranties and actual service lives extending beyond forty years, essentially eliminates roof replacement from facility planning horizons. This extended performance transforms the roof from a recurring expense item into a permanent building element, simplifying long-term capital budgeting while reducing total occupancy costs. For industrial operations planning multi-decade facility utilization, the Double Lok Roof Panel represents the economically rational choice despite higher initial investment requirements.

Conclusion

Industrial facilities demand roofing systems that combine exceptional weather resistance, structural integrity, thermal performance, and longevity. The Double Lok Roof Panel delivers on all these requirements through mechanically seamed standing seam construction that withstands extreme conditions while minimizing maintenance. From manufacturing plants to distribution centers, from coastal environments to arctic installations, Double Lok Roof Panel systems provide reliable protection that supports uninterrupted operations across decades of service.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018, stands as a high-tech enterprise specializing in metal roofing systems, building curtain wall systems, and steel structure enclosure systems. Recognized as a Shaanxi Province high-tech enterprise in 2020, the company holds first-level qualifications for building curtain walls and third-level qualifications for building steel structures. With a 200,000 square meter raw material production plant in Anhui and processing facilities in Hangzhou and Xi'an, Huafeng operates seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, and over forty specialized machines ensuring consistent quality and timely delivery.

The company integrates green sustainable development principles throughout operations while advancing new materials in metal roof products. With more than twenty registered patents and certifications including ISO9001, ISO14000:14001, CE, and SGS, Xi'an Huafeng delivers comprehensive one-stop solutions from design through construction. Successful project implementations include Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, and Inner Mongolia Tongliao Art Museum, demonstrating proven expertise across large-scale industrial and commercial applications.

Partner with a leading China Double Lok Roof Panel manufacturer, supplier, and factory for High Quality Double Lok Roof Panel at competitive Double Lok Roof Panel prices. Xi'an Huafeng offers China Double Lok Roof Panel wholesale opportunities with customized solutions backed by engineering design experience, construction expertise, and multiple quality certifications. Contact us today at huafeng@hfmetalroof.com for Double Lok Roof Panel for sale inquiries and discover how our one-stop service transforms your industrial roofing project.

References

1. American Society for Testing and Materials. "ASTM E283: Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors." ASTM International Committee E06 on Performance of Buildings.

2. Factory Mutual Research Corporation. "FM Approvals: Roof Assembly and Roof Deck Securement Classification." FM Global Property Loss Prevention Data Sheets.

3. International Code Council. "International Building Code Chapter 15: Roof Assemblies and Rooftop Structures." ICC Standards Development.

4. Metal Construction Association. "Technical Guidelines for Metal Roof System Design and Installation." MCA Engineering Committee Publications.

5. Underwriters Laboratories. "UL 580: Standard for Tests for Uplift Resistance of Roof Assemblies." UL Fire and Building Materials Division.