Every winter season brings the hidden danger of snow avalanches cascading from metal roofs without warning, creating life-threatening situations for pedestrians below and causing thousands of dollars in property damage to vehicles, landscaping, and building structures. Metal Roofing Snowguards have emerged as the critical safety solution that prevents these disasters while protecting your substantial roofing investment. Selecting the right OEM manufacturer for your metal roofing snowguards directly impacts system performance, long-term durability, and ultimately the safety of everyone who works or walks near your building throughout the winter months.

Understanding Metal Roofing Snowguards and Their Critical Role

Metal Roofing Snowguards serve as engineered retention devices specifically designed to control the movement of accumulated snow and ice on sloped metal roofing systems. Unlike traditional roofing materials with textured surfaces that naturally create friction, metal roofs feature smooth surfaces that allow snow to slide rapidly and unpredictably once temperatures rise even slightly. This phenomenon, known as roof avalanche, presents serious risks to building occupants, visitors, and adjacent property. Professional-grade snow guards on standing seam metal roof systems work by strategically distributing snow loads across the roof surface, allowing frozen precipitation to melt gradually or release in manageable quantities rather than dangerous avalanches. The engineering principles behind effective Metal Roofing Snowguards involve understanding snow density variations, regional climate patterns, roof pitch angles, and structural load capacities. Snow that accumulates on roofs can vary dramatically in weight depending on moisture content and compaction levels. Fresh powder snow typically weighs fifteen to twenty pounds per cubic foot, while wet, compacted snow can exceed fifty pounds per cubic foot. When this substantial weight begins sliding simultaneously across large roof sections, the kinetic energy generated creates devastating impact forces. Quality snowguard systems interrupt this sliding motion through strategically positioned barriers that segment the snow mass into smaller sections, dramatically reducing both the volume and velocity of any snow release.

Material Selection and Manufacturing Standards

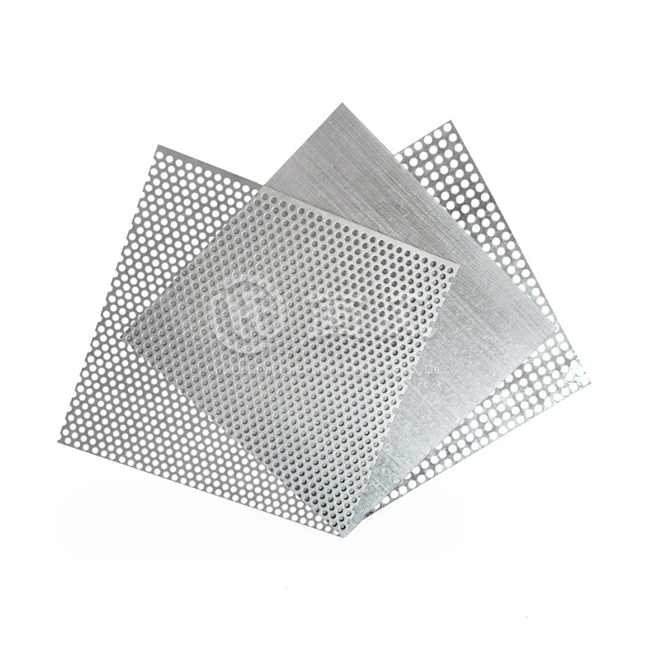

Premium OEM Metal Roofing Snowguards manufacturers utilize aerospace-grade materials specifically selected for exceptional strength-to-weight ratios and superior corrosion resistance across decades of exposure to harsh environmental conditions. High-grade aluminum alloys including 3003, 3004, and 5052 specifications provide excellent durability while maintaining lightweight characteristics that minimize additional structural loads. Stainless steel options in 304 and 316 grades deliver unmatched corrosion resistance particularly valuable in coastal environments where salt exposure accelerates material degradation. Advanced manufacturers also offer specialized materials including magnesium-aluminum-zinc alloys that combine the corrosion protection of zinc coating with enhanced mechanical properties from magnesium additions. The manufacturing processes employed by leading OEM producers incorporate precision roll-forming systems that create consistent profiles with exact dimensional tolerances essential for proper installation and optimal performance. Modern color coating production lines apply PVDF and PE finishes through sophisticated multi-layer processes that bond protective coatings at molecular levels, ensuring color stability and surface protection throughout the product's service life. Quality manufacturers operate facilities with comprehensive quality control systems including real-time monitoring of coating thickness, adhesion strength, color consistency, and dimensional accuracy. These rigorous manufacturing standards ensure every component meets international specifications including ASTM, DIN, JIS, BS, and GB/T requirements that govern material properties and performance characteristics.

Key Factors When Selecting an OEM Manufacturer

Production Capacity and Technical Capabilities

Evaluating an OEM manufacturer's production infrastructure provides essential insights into their ability to deliver consistent quality at scale while meeting demanding project timelines. Leading manufacturers operate multiple specialized production lines dedicated to different aspects of snowguard fabrication, from raw material processing through final finishing operations. A comprehensive facility should include color coating lines capable of applying uniform finishes across various substrate materials, laminating equipment for creating composite structures when required, and longitudinal and transverse shearing systems for precision cutting operations. Advanced punching and forming equipment enables creation of complex geometries necessary for specialized mounting configurations and aesthetic requirements. Manufacturing capacity directly correlates with supply reliability particularly critical for large commercial projects requiring thousands of units delivered according to strict construction schedules. Manufacturers offering monthly production capacities exceeding ten thousand tons demonstrate operational scale sufficient for major institutional and infrastructure projects. This substantial capacity ensures manufacturers maintain adequate inventory buffers and can accommodate expedited orders without compromising quality standards. Additionally, facilities with multiple processing plants strategically located across geographic regions provide logistical advantages including reduced shipping costs and faster delivery times through proximity to project sites.

Engineering Design Support and Customization Services

Distinguished OEM manufacturers differentiate themselves through comprehensive engineering support services that extend far beyond simple product sales. Professional design teams should offer structural 3D modeling capabilities that accurately represent proposed snowguard installations within complete building information models, enabling architects and engineers to visualize installations and identify potential conflicts before fabrication begins. Load analysis services using sophisticated finite element modeling determine optimal snowguard spacing patterns based on specific roof geometries, local snow load requirements, and structural capacity limitations. Drainage system simulation ensures snowguard placement does not create unintended water pooling or ice dam formation that could compromise waterproofing systems. Advanced manufacturers provide detailed project drawing deepening services where engineering teams analyze architectural plans and develop comprehensive installation drawings showing exact placement locations, mounting details, and material specifications for every snowguard unit. This meticulous planning process includes analyzing floor plans, elevations, and node diagrams to identify optimal mounting locations that maximize effectiveness while maintaining aesthetic appeal. Following initial concept development, manufacturers should facilitate extensive customer communication to refine designs based on practical considerations and budget parameters. The ability to customize products across multiple dimensions including specifications ranging from 1.2 to 2.4 meters, various material options, diverse color selections, and specialized mounting configurations demonstrates manufacturing flexibility essential for addressing unique project requirements.

Quality Assurance Throughout the Manufacturing Process

Raw Material Procurement and Verification

Exceptional OEM manufacturers implement stringent material sourcing protocols that begin with carefully curated supplier relationships and comprehensive verification procedures. Leading producers maintain approved supplier registries featuring only premium material brands with proven performance histories spanning decades. For aluminum applications, specifications should reference established manufacturers producing certified alloys meeting international standards. Steel components should originate from premier steel mills with documented quality management systems and consistent metallurgical properties. Stainless steel procurement should specify exact grade requirements ensuring appropriate corrosion resistance for anticipated environmental exposure. Upon material arrival, rigorous incoming inspection procedures verify that delivered materials precisely match ordered specifications before entering production streams. Inspection protocols should include comprehensive documentation review where material certifications and third-party testing reports undergo detailed examination confirming chemical composition, mechanical properties, and surface quality characteristics. Physical sampling programs extract representative specimens for independent verification testing covering appearance standards, dimensional accuracy, salt spray corrosion resistance, coating adhesion strength, surface hardness, impact resistance, film thickness uniformity, acid resistance, weathering performance, and color consistency. These exhaustive inspection procedures, encompassing more than a dozen distinct verification steps, prevent any substandard materials from compromising final product quality.

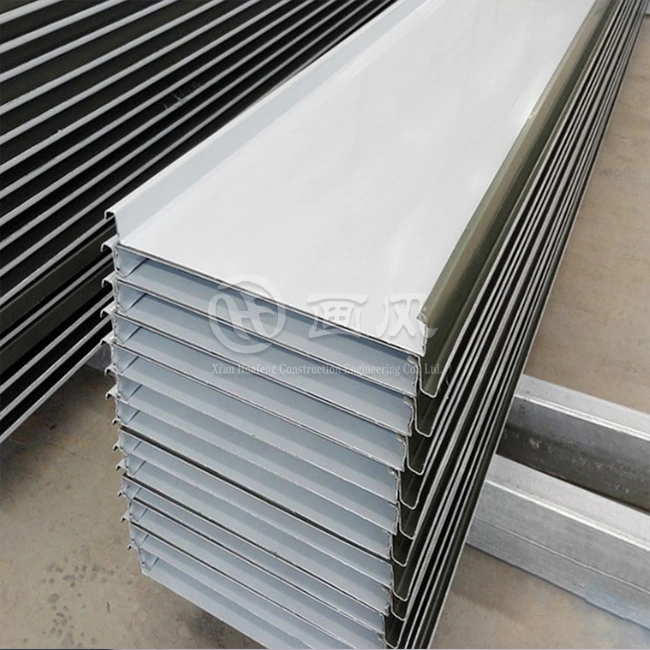

Production Control and Finished Product Inspection

Throughout manufacturing operations, sophisticated quality control systems monitor critical process parameters ensuring consistent output meeting exacting specifications. Real-time monitoring equipment tracks coating application thickness, curing temperatures, forming pressures, and dimensional tolerances, automatically alerting operators to any deviations from established parameters. This continuous oversight prevents defect propagation and enables immediate corrective actions maintaining production quality. Upon completion of manufacturing operations, comprehensive finished product inspections verify every unit meets established acceptance criteria before packaging and shipment. Finished product examination protocols evaluate appearance characteristics including surface finish uniformity, color matching, and absence of visual defects such as scratches, dents, or coating irregularities. Dimensional verification confirms that fabricated components match design specifications within acceptable tolerances ensuring proper fit during installation operations. Flatness and curvature measurements verify geometric accuracy essential for aesthetic appearance and functional performance. To facilitate efficient installation processes, packaging operations organize components according to installation sequences with clearly labeled identification cards containing sectional floor plans and detailed product number listings. This systematic organization enables installation crews to quickly locate required components and follow predetermined installation patterns minimizing field confusion and installation errors.

Installation Support and Project Management Services

On-Site Technical Guidance and Safety Compliance

Distinguished manufacturers recognize that even superior products require proper installation to achieve intended performance, therefore providing comprehensive on-site technical support throughout construction phases. Experienced installation technicians conduct pre-construction site evaluations examining actual field conditions and confirming that site logistics adequately accommodate material storage, staging areas, and equipment requirements. Upon material delivery, technical representatives verify that components arrive in proper condition and guide warehousing procedures ensuring products remain protected until installation commences. Installation guidance services include detailed tooling inspections confirming that crews possess appropriate specialized equipment including seam-locking machines, edge-forming tools, and precision fastening equipment. Technical briefings review installation procedures, quality standards, and critical safety protocols ensuring all personnel understand their responsibilities and potential hazards. Throughout installation operations, manufacturer representatives remain available to address questions, resolve unexpected conditions, and verify that installation techniques follow established best practices. Following installation completion, comprehensive testing procedures verify system integrity including water testing to confirm zero leakage at all penetrations and connections, and load verification ensuring proper attachment strength throughout the installation.

Acceptance Procedures and Maintenance Planning

Professional project closeout procedures include formal acceptance inspections where customers review completed installations verifying that finished work meets contract requirements and quality expectations. Detailed documentation including as-built drawings, material certifications, testing reports, and warranty information provide comprehensive project records supporting future maintenance and potential modifications. Manufacturers offering extended warranty coverage demonstrate confidence in product durability and manufacturing quality while providing customers financial protection against potential defects. Forward-thinking manufacturers establish ongoing maintenance programs educating building owners regarding proper inspection procedures, cleaning protocols, and potential repair requirements that extend system service life. Regular maintenance guidance should address seasonal inspection timing, visual assessment criteria for identifying potential issues, procedures for clearing debris accumulation, and methods for addressing minor damage before problems escalate. Some manufacturers provide direct maintenance services or coordinate with qualified contractors ensuring that building owners have reliable resources for addressing maintenance needs throughout the system's operational lifetime spanning decades.

Conclusion

Selecting the appropriate OEM manufacturer for Metal Roofing Snowguards requires comprehensive evaluation of production capabilities, engineering support services, quality assurance systems, and installation expertise. Organizations that prioritize these critical factors secure superior products backed by manufacturers committed to customer success and long-term system performance.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

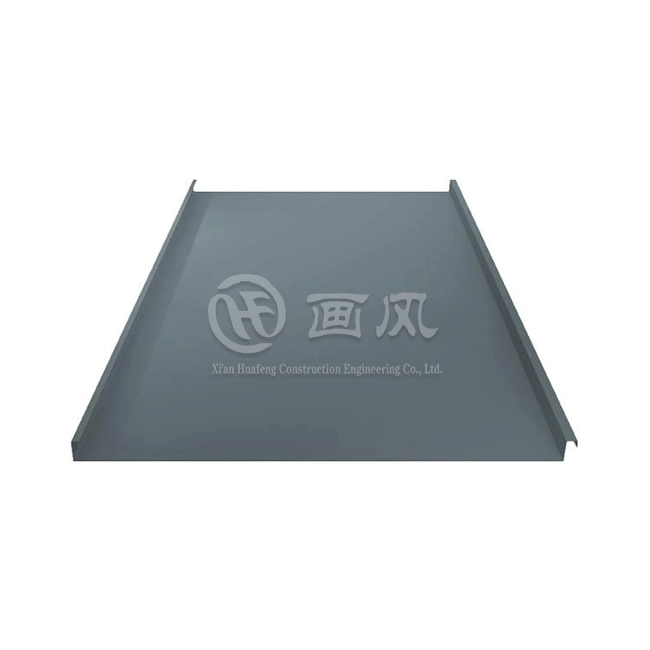

As a China Metal Roofing Snowguards factory, China Metal Roofing Snowguards supplier, and China Metal Roofing Snowguards manufacturer offering Metal Roofing Snowguards for sale at competitive Metal Roofing Snowguards price points, Xi'an Huafeng Construction Engineering Co., Ltd. delivers High Quality Metal Roofing Snowguards backed by extensive engineering experience and proven manufacturing excellence. Since establishment in 2018, we've specialized in comprehensive metal roofing system solutions including standing seam panels, aluminum-magnesium-manganese products, and advanced building envelope systems. Our manufacturing infrastructure spans three strategically located facilities including a 200,000-square-meter raw material production plant in Anhui and specialized processing facilities in Hangzhou and Xi'an equipped with seven color coating production lines, ten shearing systems, and over forty precision machines ensuring monthly production capacity exceeding 10,000 tons with delivery timelines of 15-20 days.

Operating as a recognized high-tech enterprise holding first-level building curtain wall qualifications and third-level steel structure certifications, we provide integrated services encompassing custom engineering design with structural 3D modeling, precision manufacturing using premium materials from Baosteel, Alucosuper, and NedZink, comprehensive quality control meeting ISO9001 and ISO14000:14001 standards, and seamless installation support. Our China Metal Roofing Snowguards wholesale programs deliver exceptional value through customized solutions addressing diverse roof configurations and snow load requirements. With over twenty registered patents and successful project implementations including Xiongan Station Commercial Complex, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum, we demonstrate proven expertise delivering Metal Roofing Snowguards that enhance safety while maintaining architectural aesthetics. Partner with us to access one-stop procurement from raw materials through finished accessories, expert technical consultation, and reliable Fortune 500-level quality standards. Contact our team at huafeng@hfmetalroof.com to discuss your project requirements and receive customized solutions backed by comprehensive engineering support and manufacturing excellence.

References

1. Metal Construction Association. "Snow Retention Systems for Metal Roofs: Design and Installation Guidelines." Technical Bulletin Series, 2023.

2. American Society of Civil Engineers. "Minimum Design Loads and Associated Criteria for Buildings and Other Structures." ASCE/SEI 7-22 Standard, Structural Engineering Institute, 2022.

3. Tobiasson, Wayne and Greatorex, Alan. "Database and Methodology for Conducting Site-Specific Snow Load Case Studies for the United States." U.S. Army Corps of Engineers Cold Regions Research and Engineering Laboratory, 2021.

4. National Roofing Contractors Association. "Metal Panel Roof Systems Design Manual." NRCA Technical Operations Division, 2023.

5. International Code Council. "International Building Code: Chapter 15 Roof Assemblies and Rooftop Structures." ICC Publications, 2024 Edition.

(1)_1763110678300.webp)