When faced with the challenge of balancing aesthetic appeal, long-term durability, and budget constraints in modern building design, architects increasingly turn to Corrugated Galvanized Metal Panel as their facade solution of choice. This material transforms what was once considered purely utilitarian into a sophisticated architectural element that addresses critical pain points in contemporary construction while delivering exceptional value across commercial, industrial, and public building projects.

Superior Durability and Weather Resistance of Corrugated Galvanized Metal

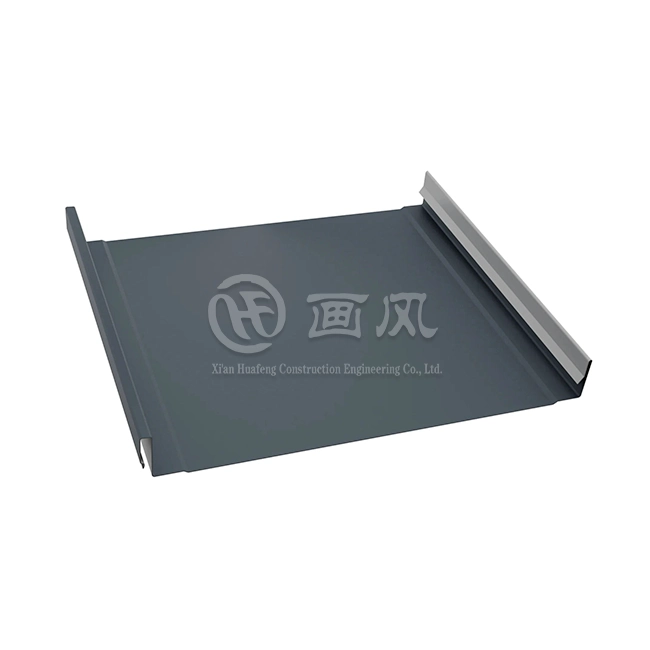

The fundamental reason architects specify corrugated galvanized metal for building facades lies in its exceptional ability to withstand harsh environmental conditions over extended periods. The hot-dip galvanization process creates a protective zinc coating that forms a metallurgical bond with the base steel, providing multi-layered defense against corrosion. This galvanized coating typically ranges from Z80 to Z275 grams per square meter, with thicker coatings specified for coastal environments or industrial areas where corrosive elements are more prevalent. The corrugated profile itself adds significant structural strength perpendicular to the corrugations, allowing the Corrugated Galvanized Metal Panel to resist wind loads, impact damage, and thermal expansion without compromising the building envelope integrity. Unlike flat sheet materials that may buckle or deform under stress, the wave pattern inherent in corrugated galvanized metal distributes loads across the entire panel surface, effectively creating a self-reinforcing structure. This three-dimensional geometry provides exceptional rigidity despite the relatively thin material thickness, typically ranging from 0.12mm to 1.5mm for facade applications. The material maintains its structural integrity across temperature ranges from extreme cold to intense heat, making it suitable for diverse climate zones from arctic regions to tropical environments. When properly installed with appropriate fasteners and flashing details, Corrugated Galvanized Metal Panel systems have demonstrated service lives exceeding thirty years with minimal maintenance requirements, representing a significant lifecycle cost advantage over materials requiring frequent repair or replacement.

Zinc Coating Protection Mechanism

The zinc coating on corrugated galvanized metal functions through both barrier protection and sacrificial corrosion. The zinc layer acts as a physical barrier preventing moisture and oxygen from reaching the underlying steel substrate. More importantly, zinc is anodic to steel in the galvanic series, meaning that if the coating is scratched or damaged, the zinc preferentially corrodes to protect the exposed steel. This galvanic protection extends several millimeters beyond any cut edge or scratch, effectively self-healing minor damage and preventing rust propagation. The zinc patina that develops over time actually enhances this protective function, creating a stable zinc carbonate layer that further slows the corrosion rate. For enhanced protection in aggressive environments, architects may specify additional organic coatings such as PVDF or HDP over the galvanized substrate, combining the galvanic protection of zinc with the barrier properties of high-performance polymer coatings.

Structural Performance in Extreme Conditions

Corrugated Galvanized Metal Panel excels in challenging environmental scenarios where many alternative facade materials fail prematurely. In coastal locations, the salt-laden atmosphere that rapidly degrades unprotected materials has minimal impact on properly galvanized corrugated panels, particularly when specified with heavier zinc coatings or supplementary organic finishes. Hurricane-prone regions benefit from the exceptional wind resistance provided by the corrugated profile's inherent stiffness, with properly engineered installations withstanding wind speeds exceeding 150 miles per hour when attached according to manufacturer specifications. Seismic zones appreciate the lightweight nature of corrugated galvanized metal, which reduces lateral loads on building structures during earthquakes while maintaining facade integrity through flexible connection details that accommodate structural movement without panel damage. The material's proven performance in these extreme conditions makes it a preferred specification for critical infrastructure projects, educational facilities, healthcare buildings, and other structures where long-term reliability is paramount.

Cost-Effectiveness and Economic Advantages

Financial considerations significantly influence material selection in architectural projects, and Corrugated Galvanized Metal Panel delivers compelling economic advantages throughout the building lifecycle. Initial material costs for corrugated galvanized metal typically range substantially lower than alternatives like aluminum composite panels, fiber cement boards, or natural stone cladding systems. The manufacturing process for corrugated panels involves efficient roll-forming operations that produce consistent products with minimal waste, translating into competitive pricing even for custom profiles or specific dimensions. Installation labor costs remain moderate because the lightweight panels are easily handled by two-person crews using standard tools, eliminating the need for specialized equipment or extensive structural support systems. The overlapping installation method common with Corrugated Galvanized Metal Panel creates inherent waterproofing redundancy, reducing the complexity and cost of weatherproofing details compared to systems requiring extensive sealant applications or complex flashing configurations.

Long-term economic benefits further enhance the value proposition of corrugated galvanized metal facades. Maintenance requirements remain minimal throughout the panel's service life, typically limited to periodic washing to remove accumulated dirt or pollutants, with no need for repainting, resealing, or component replacement in properly specified installations. Energy performance contributes to operational cost savings, as the reflective surface of galvanized steel can reduce cooling loads in sunny climates by reflecting solar radiation rather than absorbing heat. When buildings eventually reach end-of-life or undergo renovation, the high scrap value of steel ensures that Corrugated Galvanized Metal Panel can be recycled economically, with steel maintaining its properties through infinite recycling cycles. This recyclability provides both environmental benefits and potential cost recovery at building decommissioning, completing a favorable economic cycle that few alternative facade materials can match. Projects manufactured by Xi'an Huafeng Construction Engineering Co., Ltd. benefit from their three strategically located processing facilities and seven production lines, ensuring consistent quality and competitive pricing through efficient logistics and economies of scale.

Project Budget Optimization Strategies

Architects working with constrained budgets find numerous strategies to optimize value when specifying Corrugated Galvanized Metal Panel systems. Standard profile selection from manufacturer catalogs avoids custom tooling charges while still providing diverse aesthetic options through various corrugation patterns, panel widths, and mounting orientations. Thickness selection balanced against structural requirements prevents over-specification, with thinner gauges adequate for wall applications while thicker materials reserved for roof surfaces or areas subject to potential impact. Finish selection ranging from mill galvanized through various organic coatings allows precise matching of performance requirements with budget allocations, avoiding unnecessary premium finishes in protected locations while specifying enhanced coatings only where environmental exposure demands additional protection. Strategic panel layout minimizes cutting waste and reduces installation time, particularly important given that Xi'an Huafeng Construction Engineering Co., Ltd. offers customized panel lengths from one to twelve meters, allowing designers to optimize panel runs for specific building dimensions.

Design Versatility and Aesthetic Flexibility

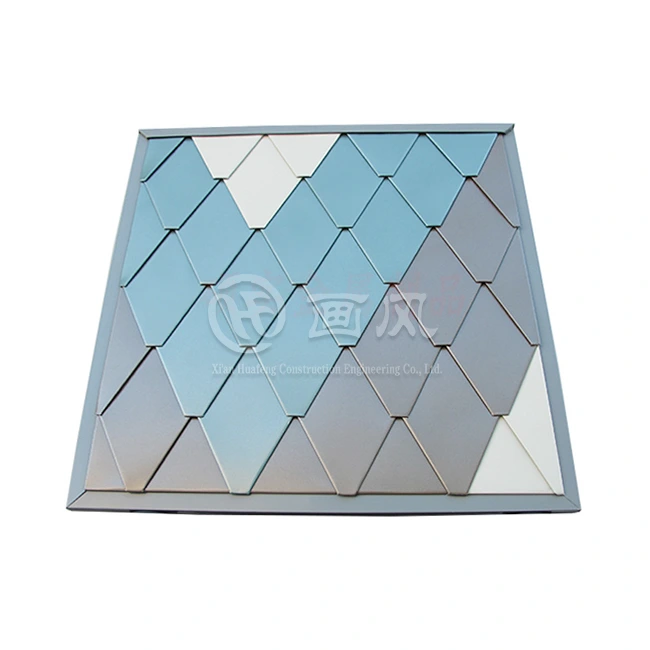

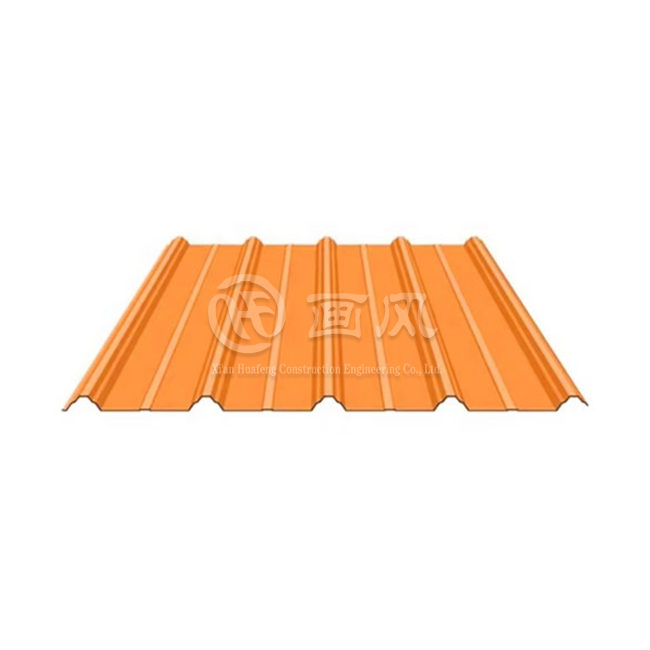

Contemporary architectural practice increasingly recognizes corrugated galvanized metal not merely as a functional material but as a sophisticated design element capable of creating distinctive visual identities for diverse building types. The characteristic linear pattern created by corrugations generates dynamic shadow lines that change throughout the day as solar angles shift, activating building facades with subtle movement and visual interest without any mechanical intervention. Architects manipulate this inherent texture through strategic panel orientation, mixing horizontal and vertical installation patterns to create visual zones, emphasize building proportions, or guide the eye toward significant architectural features. The industrial aesthetic associated with Corrugated Galvanized Metal Panel resonates particularly well with contemporary design philosophies emphasizing material honesty and functional expression, making it a natural choice for projects ranging from urban loft conversions to cutting-edge institutional buildings seeking to project innovation and forward-thinking values.

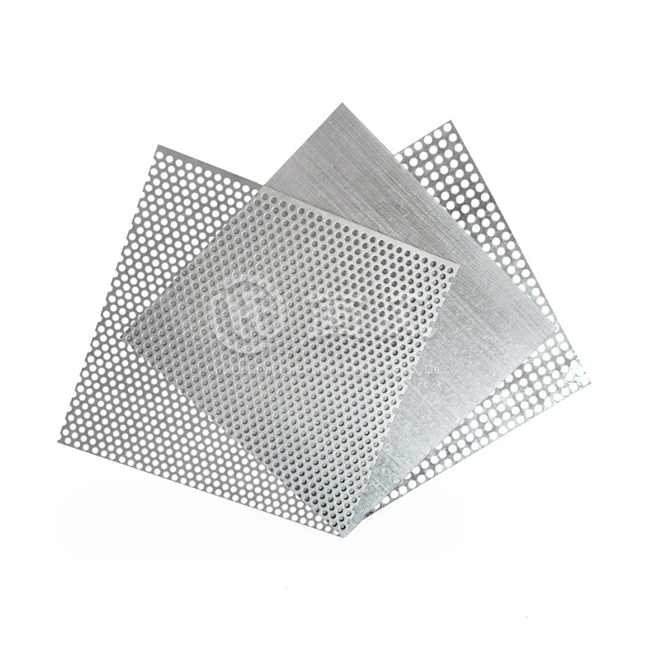

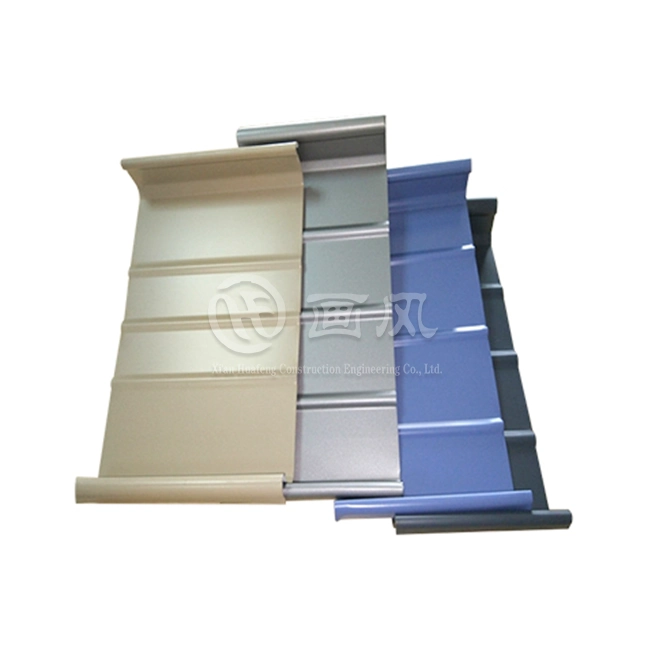

Color customization expands design possibilities beyond the traditional metallic silver appearance of mill-finish galvanized steel. Pre-painted corrugated panels with polyester, plastisol, or PVDF organic coatings are available in virtually unlimited color palettes, allowing architects to integrate corrugated galvanized metal into complex design schemes requiring specific hue matching or brand color coordination. Metallic finishes including copper, bronze, or champagne tones provide upscale aesthetic options while maintaining the durability benefits of the galvanized substrate. Surface textures ranging from smooth mill finish through embossed patterns or matte treatments further diversify visual possibilities, with some manufacturers offering perforated corrugated panels that combine the structural profile with controlled transparency for applications like screening mechanical equipment or creating semi-private outdoor spaces. The width customization capability of modern roll-forming equipment allows panel dimensions from 600mm to 1200mm, providing designers with precise control over facade rhythm and proportions. Xi'an Huafeng Construction Engineering Co., Ltd. specializes in customized solutions including specific colors, patterns, and design details, supported by their 3D modeling capabilities and extensive material library featuring premium brands like Baosteel, NedZink, and Chinalco for specialized applications.

Integration with Contemporary Architecture

Modern architectural movements embrace corrugated galvanized metal for its ability to bridge industrial heritage with contemporary design sensibilities. Minimalist design schemes appreciate the clean lines and material honesty of exposed Corrugated Galvanized Metal Panel, where the functional structure becomes the finished surface without applied decoration. Mixed-material compositions frequently juxtapose the metallic coolness of corrugated panels against warm wood cladding, smooth concrete, or expansive glazing, creating dynamic contrasts that enhance the unique properties of each material. Urban infill projects leverage the cost-effectiveness and rapid installation of corrugated metal to deliver affordable housing or community facilities within tight budgets and accelerated schedules, proving that economical materials need not compromise design ambition. Heritage renovation projects increasingly incorporate corrugated galvanized metal as a respectful contemporary intervention that distinguishes new construction from historic fabric while maintaining visual compatibility through careful detailing and material selection. The lightweight nature of Corrugated Galvanized Metal Panel makes it particularly valuable for rooftop additions or structural modifications where minimizing additional loads is critical.

Sustainable Building Credentials

Environmental performance has become a fundamental consideration in architectural specification, and Corrugated Galvanized Metal Panel offers substantial sustainability advantages throughout its lifecycle. Steel ranks among the most recycled materials globally, with steel production incorporating significant recycled content and the material maintaining full structural properties through unlimited recycling cycles. The galvanization process, while energy-intensive, produces a durable coating that dramatically extends product lifespan, effectively amortizing the embodied energy over multiple decades of service life. Manufacturing efficiency in modern roll-forming facilities minimizes production waste, with offcuts and rejected panels immediately recyclable back into the steel production stream. Transportation impacts remain moderate due to the material's high strength-to-weight ratio, allowing significant surface coverage with relatively low shipping weights, particularly important for projects distant from manufacturing facilities.

Operational environmental benefits complement the material production sustainability profile. The reflective surface of mill-finish Corrugated Galvanized Metal Panel reduces solar heat gain, decreasing cooling energy requirements in warm climates and contributing to overall building energy efficiency. When combined with proper insulation and ventilation strategies, corrugated metal facades contribute to comfortable interior environments with minimal mechanical conditioning. The material's impermeability and resistance to moisture infiltration prevents mold growth and maintains healthy indoor air quality by excluding biological contaminants. End-of-life recyclability ensures that building demolition generates valuable material streams rather than landfill waste, with steel processors readily accepting Corrugated Galvanized Metal Panel for reprocessing. The thirty-year warranty offered by manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. demonstrates confidence in long-term durability, discouraging premature replacement and the associated environmental impacts of material production and construction waste. Green building certification systems including LEED and BREEAM recognize these attributes through various credit pathways related to recycled content, local material sourcing, and lifecycle environmental impacts.

Circular Economy Integration

The circular economy model finds an ideal exemplar in Corrugated Galvanized Metal Panel systems, where materials flow through multiple use cycles without degradation. Salvaged corrugated panels from demolished structures retain significant value and functionality, finding secondary applications in agricultural buildings, temporary structures, or artistic installations. Manufacturers increasingly design panel systems for disassembly rather than permanent installation, using mechanical fasteners rather than adhesives or welds, facilitating future material recovery. The standardized dimensions and profiles common in corrugated panel production enable compatibility across different manufacturers and projects, expanding opportunities for material reuse. Xi'an Huafeng Construction Engineering Co., Ltd. demonstrates commitment to sustainable practices through ISO14001 environmental management certification and green building integration philosophy, aligning product development with evolving sustainability standards while maintaining the practical performance characteristics that make corrugated galvanized metal a preferred architectural material.

Proven Technical Performance and Standards Compliance

Architectural specifications demand rigorous technical documentation demonstrating that specified materials meet applicable building codes and performance standards. Corrugated Galvanized Metal Panel systems benefit from extensive testing protocols and industry standards that verify structural capacity, fire resistance, wind uplift resistance, and other critical performance parameters. Compliance with international standards including ASTM, DIN, JIS, BS, and GB/T specifications ensures that panels meet recognized quality benchmarks regardless of manufacturing location or project jurisdiction. Third-party certifications from organizations like SGS, ISO, and CE provide independent verification of manufacturing quality control and product consistency, giving architects confidence that specified materials will perform as designed throughout their service life.

Load capacity testing determines the structural performance of specific corrugated profiles under various stress conditions, establishing safe span lengths and fastener spacing requirements for different building heights and wind exposure categories. Coating thickness measurements verify adequate galvanization levels to ensure corrosion protection meets design assumptions for the specific environmental exposure classification. Accelerated weathering tests simulate years of outdoor exposure in compressed timeframes, validating color retention, coating adhesion, and overall appearance durability for pre-finished panels. Salt spray testing specifically addresses coastal environment performance, quantifying resistance to chloride-induced corrosion that rapidly degrades many building materials in marine locations. Manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. maintain rigorous quality control throughout their production process, implementing more than a dozen inspection steps including appearance verification, dimensional accuracy, salt spray testing, adhesion evaluation, hardness testing, impact resistance, film thickness measurement, acid resistance, weather resistance, and color consistency checks, ensuring that every panel meets stringent performance standards before shipping to project sites.

Manufacturing Quality Assurance

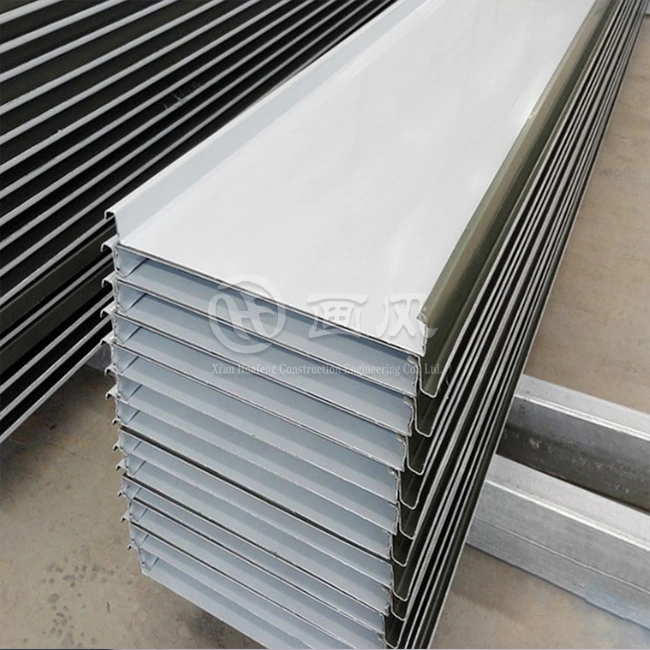

The reliability of Corrugated Galvanized Metal Panel depends fundamentally on consistent manufacturing quality, requiring sophisticated production management and quality control systems. Raw material verification processes confirm that incoming steel coils meet specified chemical composition, mechanical properties, and coating weight requirements, with material certifications and third-party test reports documented for traceability. Roll-forming equipment calibration ensures accurate profile dimensions and consistent corrugation geometry across production runs, preventing fit-up issues during installation. Surface preparation and coating application receive particular attention, as inadequate cleaning or contamination during processing can compromise coating adhesion and long-term performance. Finished product inspection examines each panel for appearance defects, dimensional accuracy, flatness, and curvature before packaging, with defective panels rejected and documented for continuous improvement feedback. The manufacturing infrastructure at Xi'an Huafeng Construction Engineering Co., Ltd. includes seven color coating production lines, one laminating line, ten longitudinal and transverse shearing lines, fully automatic punching equipment, and more than forty shearing machines, presses, and bending machines, enabling high-volume production while maintaining quality standards through real-time monitoring and statistical process control methodologies. This production capacity, coupled with strategic factory locations in Anhui, Hangzhou, and Xi'an, ensures reliable supply chains and responsive technical support throughout project execution.

Conclusion

Architects specify Corrugated Galvanized Metal Panel for facades because this material uniquely combines exceptional durability, cost-effectiveness, design versatility, sustainability, and proven performance backed by rigorous testing and quality standards, addressing the multifaceted demands of contemporary building design while delivering reliable long-term value.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, specializes in comprehensive metal roofing and facade solutions with first-level building curtain wall qualifications and third-level steel structure qualifications. Our integrated service approach encompasses every project phase from initial design through final installation, supported by three manufacturing facilities covering 200,000 square meters in Anhui with processing plants in Hangzhou and Xi'an, ensuring quality control and efficient logistics throughout China and internationally. Our design team provides detailed 3D structural modeling, load analysis, drainage system simulation, and material specification advisory services, transforming architectural concepts into precise manufacturing drawings through collaborative client engagement and 1:1 node drawing development. As a China Corrugated Galvanized Metal Panel factory, China Corrugated Galvanized Metal Panel supplier, and China Corrugated Galvanized Metal Panel manufacturer offering China Corrugated Galvanized Metal Panel wholesale solutions, we maintain extensive inventory of Corrugated Galvanized Metal Panel for sale at competitive Corrugated Galvanized Metal Panel price points, all meeting High Quality Corrugated Galvanized Metal Panel standards certified through ISO9001, ISO14001, and SGS verification. Our production capabilities include customization services for color, pattern, and design specifications with widths from 600-1200mm, thickness from 0.12-1.5mm, PE/HDP/PVDF coating finishes, monthly supply capacity of 1,000 tons, 500 square meter minimum order quantity, fifteen to twenty day delivery schedules, and comprehensive thirty-year warranties backed by more than twenty registered patents and successful completion of landmark projects including Xiongan Station Commercial Complex, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum. Partner with us to transform your architectural vision into reality through superior materials, expert engineering, and dedicated project support. Contact our team at huafeng@hfmetalroof.com to discuss your specific requirements and receive detailed technical proposals tailored to your project parameters.

References

1. "Corrugated Galvanised Iron: Historical Development and Contemporary Applications" - Building Research & Information Journal - Authors: Thompson, R.J. and Mitchell, P.D.

2. "Sustainable Metal Facade Systems: Performance Evaluation and Lifecycle Assessment" - Journal of Architectural Engineering - Authors: Zhang, Wei; Chen, Lin; and Rodriguez, Maria

3. "Durability of Galvanized Steel in Building Envelopes: Long-term Performance Studies" - Construction and Building Materials - Authors: Anderson, K.M.; Park, J.H.; and Wilson, S.T.

4. "Design Guidelines for Corrugated Metal Cladding Systems" - American Institute of Architects Technical Report - Authors: Professional Practice Committee

5. "Zinc Coatings for Corrosion Protection: Mechanisms and Performance Standards" - International Journal of Corrosion - Authors: Mueller, Hans; Nakamura, Hiroshi; and Levesque, Claire