Are you tired of replacing your roof every decade due to weather damage, leaks, or deterioration? Traditional roofing materials often fail when you need them most, leaving property owners frustrated with constant repairs and skyrocketing maintenance costs. Ribbed Standing Seam Metal Roofing offers a revolutionary solution that combines exceptional durability, superior weather resistance, and contemporary aesthetics to protect your investment for decades to come.

Understanding Ribbed Standing Seam Metal Roofing Technology

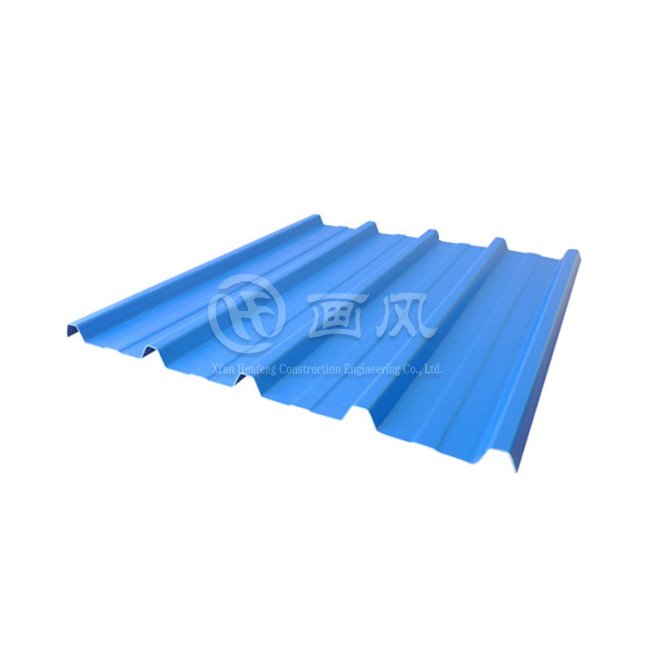

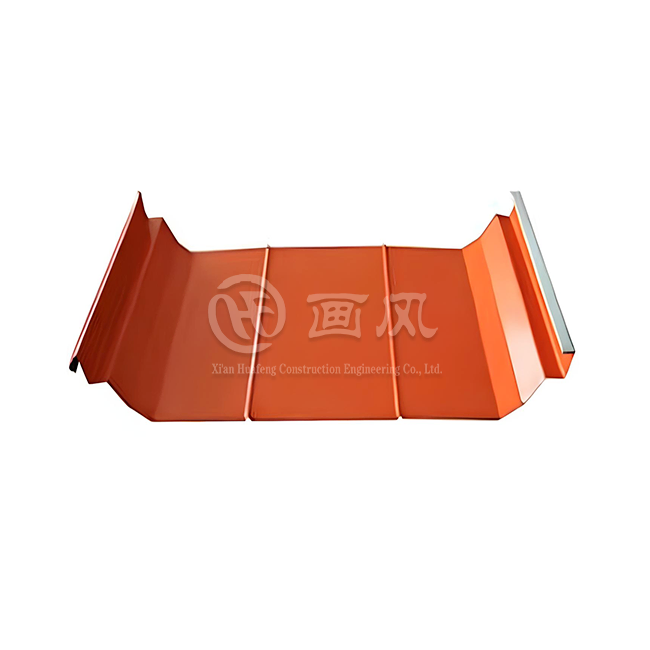

Ribbed Standing Seam Metal Roofing represents an advanced roofing system that merges the best features of traditional standing seam panels with enhanced structural ribbing for superior performance. This innovative design features vertical raised seams that interlock along the roof surface, creating a watertight barrier that effectively protects against the elements. Unlike conventional roofing materials that deteriorate over time, Ribbed Standing Seam Metal Roofing maintains its integrity through decades of exposure to harsh weather conditions including heavy rain, snow, hail, and intense UV radiation. The ribbed profile distinguishes this roofing system from standard flat panels by incorporating vertical ridges that run the length of each panel. These ribs serve multiple critical functions: they add structural rigidity to prevent warping, facilitate thermal expansion and contraction without compromising the roof's integrity, and enhance water drainage to prevent pooling. The standing seam design employs concealed fasteners that remain hidden beneath interlocking seams, eliminating the vulnerability associated with exposed screws that can loosen over time or become entry points for moisture infiltration.

The Engineering Behind Superior Performance

The engineering excellence of Ribbed Standing Seam Metal Roofing lies in its multi-layered approach to protection and longevity. Each panel is manufactured from premium materials including aluminum alloy, galvanized steel, galvalume steel, stainless steel, copper, or titanium zinc, with thickness options ranging from 0.5mm to 1.2mm to accommodate various structural requirements and climate conditions. The 25mm height of the standing seams provides optimal water shedding capability while the ribbed contour adds dimensional strength that resists impact damage from falling debris or hail. Manufacturing precision is paramount in producing Ribbed Standing Seam Metal Roofing that meets international standards including ASTM, DIN, JIS, BS, and GB/T specifications. Advanced roll-forming technology shapes each panel with exact tolerances ensuring perfect alignment during installation. The panels can be customized to project-specific dimensions, eliminating unnecessary seams that could compromise weather-tightness. Premium finishes including PVDF and PE coatings provide superior color retention and protection against fading, chalking, and corrosion, with color options spanning the entire RAL spectrum plus custom formulations to match architectural requirements.

Weather-Proof Protection That Stands the Test of Time

When severe weather strikes, your roof serves as the first line of defense protecting your property, occupants, and valuable assets. Ribbed Standing Seam Metal Roofing excels in extreme conditions where traditional roofing materials frequently fail. The raised seam design creates a continuous weathertight barrier that prevents water penetration even during horizontal rain driven by strong winds. The concealed fastener system eliminates the primary weakness found in exposed fastener roofs where screws create potential leak points that worsen as rubber washers deteriorate over time. The smooth metal surface combined with the panel's ideal slope facilitates rapid shedding of rain and snow, preventing the accumulation that can lead to ice damming or structural stress. In regions experiencing heavy snowfall, the metal surface prevents snow from adhering while the ribbed profile provides channels for meltwater to drain efficiently. Hail resistance is particularly impressive, with properly installed Ribbed Standing Seam Metal Roofing achieving Class 4 impact ratings, the highest designation awarded by insurance industry testing standards. This means the roofing can withstand impacts from hail up to 2.5 inches in diameter without sustaining damage that compromises its protective function.

Thermal Performance and Energy Efficiency

Beyond protection from precipitation and impact, Ribbed Standing Seam Metal Roofing delivers significant energy efficiency advantages that reduce operational costs throughout its service life. Reflective coatings applied to the metal surface deflect solar radiation rather than absorbing it, substantially reducing heat transfer into building interiors. This solar reflectance can reduce cooling costs by up to twenty-five percent during summer months, with the effect most pronounced in hot climates where air conditioning represents a major energy expense. The air space created by the raised seam design provides an additional thermal break that enhances insulation performance. During winter months, properly installed Ribbed Standing Seam Metal Roofing works in concert with underlayment and insulation systems to prevent heat loss while allowing the roof system to breathe, preventing condensation issues that plague many conventional roofing installations. The low thermal mass of metal means the roof responds quickly to changing temperatures rather than storing and slowly releasing heat, contributing to more stable interior conditions with less HVAC cycling.

Architectural Beauty Meets Functional Excellence

Contemporary architecture increasingly embraces clean lines, minimalist aesthetics, and materials that make bold visual statements while delivering practical performance. Ribbed Standing Seam Metal Roofing perfectly aligns with these design priorities, offering a sleek modern appearance that enhances property value and curb appeal. The vertical lines created by the raised seams add visual interest and dimension while emphasizing the building's architectural features. The shadow lines cast by the ribs change throughout the day as the sun angle shifts, creating dynamic visual effects that bring the roof to life. Color selection represents a critical component of architectural expression, and Ribbed Standing Seam Metal Roofing provides virtually unlimited options through standard RAL colors and custom color matching services. From traditional earth tones that complement natural surroundings to bold contemporary hues that make architectural statements, the coating options ensure perfect integration with any design vision. The color coatings employ advanced resin technologies that maintain their appearance for decades, with fade and chalk resistance that far exceeds conventional painted surfaces. This means the roof will look virtually as good in twenty years as it did on installation day.

Versatility Across Building Types and Applications

The adaptability of Ribbed Standing Seam Metal Roofing makes it suitable for an extraordinarily diverse range of applications spanning residential, commercial, industrial, and institutional buildings. Modern residential architecture increasingly specifies metal roofing for new construction homes where homeowners seek materials that combine beauty with practical advantages including fire resistance, wind uplift protection, and minimal maintenance requirements. The roofing performs equally well on traditional residential forms as on contemporary designs with complex roof geometries including curves, angles, and multi-plane configurations. Commercial and industrial facilities benefit from the large-scale efficiency of Ribbed Standing Seam Metal Roofing installations that can cover expansive roof areas with minimal seams while accommodating rooftop equipment, solar arrays, and other accessories. The structural strength of the ribbed profile allows for wider panel widths that reduce installation time and cost while maintaining superior weather protection. Institutional buildings including schools, hospitals, government facilities, and cultural centers often specify this roofing system for its combination of longevity, safety characteristics including fire resistance and non-combustible classification, and lifecycle cost advantages that align with responsible stewardship of public resources.

Xi'an Huafeng's Manufacturing Excellence

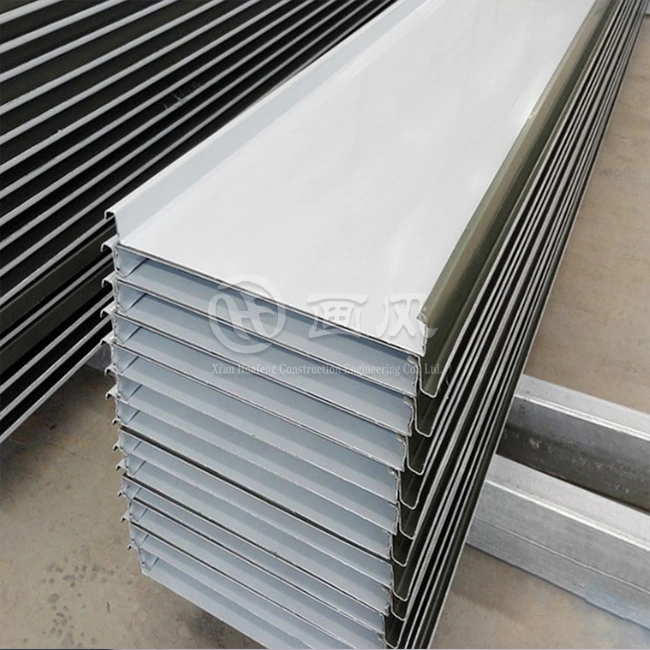

Producing superior Ribbed Standing Seam Metal Roofing requires substantial manufacturing capability, technical expertise, and unwavering commitment to quality standards. Xi'an Huafeng Construction Engineering Co., Ltd. operates three dedicated production facilities featuring seven specialized production lines and more than forty advanced manufacturing machines that enable production capacity exceeding one thousand tons monthly. This industrial infrastructure ensures consistent material quality, precise dimensional tolerances, and reliable delivery schedules that keep construction projects on track regardless of order volume. The manufacturing process begins with careful material selection from Xi'an Huafeng's approved supplier network including premium brands such as Alucosuper, YATAI, and LIDAO for aluminum alloys in 3003, 3004, and 5052 grades; BAOSTEEL, GUANZHOU, and XINYU for steel products including cold rolled, galvanized, galvalume, and color coated sheets; Baosteel and Tsingshan stainless steel in 316 and 304 grades; NedZink titanium zinc; and Chinalco copper in T2 and TP2 specifications. Every incoming material shipment undergoes rigorous inspection including verification of manufacturer certifications and third-party testing reports before acceptance into inventory.

Quality Control Throughout Production

Quality assurance at Xi'an Huafeng encompasses every stage of the manufacturing process, not just final product inspection. Incoming raw materials face comprehensive testing including more than a dozen inspection procedures covering appearance, dimensions, salt spray resistance, adhesion, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency. This multi-point verification ensures that only materials meeting the highest standards enter production, preventing defects that could compromise finished product performance. During production, real-time quality monitoring tracks critical parameters including panel dimensions, seam heights, coating thickness, and finish quality. Advanced roll-forming equipment maintains precise tolerances that ensure panels fit together perfectly during installation without gaps or misalignment that could affect weather-tightness. Finished product inspection verifies appearance quality, dimensional accuracy, flatness, and curvature before packaging. Products are organized and labeled according to project-specific requirements with identification cards showing section plans and product numbers, facilitating efficient installation and minimizing the potential for errors on the construction site.

Professional Installation and Project Support Services

Even the highest quality Ribbed Standing Seam Metal Roofing will underperform if installation is not executed to exacting standards. Xi'an Huafeng provides comprehensive support services that begin during the design phase and continue through project completion and beyond. The technical design team works directly with clients to analyze architectural drawings, identify optimal panel configurations, and develop detailed installation drawings that address every aspect of the roof system including penetrations, transitions, drainage, and accessory integration. Before manufacturing begins, sample panels are produced incorporating all specified parameters including material selection, thickness, finish coating, and color. Client approval of these physical samples establishes the standard for full production, ensuring that expectations align perfectly with delivered products. The design team then develops detailed fabrication drawings that break down complex roof geometries into manageable installation sequences with each component numbered sequentially to prevent confusion during construction.

On-Site Technical Guidance and Quality Verification

Xi'an Huafeng's commitment to project success extends to the construction site through experienced technical personnel who provide installation guidance, verify proper techniques, and ensure adherence to manufacturer specifications that protect warranty coverage. Installation technicians conduct pre-construction site visits to verify that substrate conditions meet requirements, confirm that necessary tools and accessories are available, and review the installation sequence with the construction team. Technical briefings cover critical details including weather limitations, fastener specifications, seam engagement methods, and safety protocols. Upon installation completion, Xi'an Huafeng performs comprehensive testing to verify weather-tight performance including water testing of completed roof sections to ensure zero leakage. Final acceptance procedures involve client walkthrough, documentation of completed work, and formal sign-off confirming that the installation meets all specified requirements. Post-installation support includes maintenance guidance and periodic inspection services that help building owners protect their investment and maximize the roof system's operational lifespan.

Proven Performance in Landmark Projects

The credibility of any roofing system ultimately rests on real-world performance across diverse applications and challenging conditions. Xi'an Huafeng's Ribbed Standing Seam Metal Roofing has been successfully installed on numerous high-profile projects that demonstrate its versatility and reliability. The Xiongan Station Commercial Body features extensive aluminum-magnesium-manganese metal roofing that protects this important transportation hub while contributing to its modern architectural identity. The Xi'an International Convention and Exhibition Center metal roof project showcases the system's ability to cover large spans while maintaining visual appeal appropriate for a facility hosting international events. Transportation infrastructure projects including the metal roof installation at Xi'an Station East Auxiliary Building and the Liyuanping Highway Station demonstrate the roofing system's suitability for high-traffic public facilities where durability, safety, and minimal maintenance are paramount concerns. Cultural and educational facilities including South Hall 2-2 of Jinghe New City International Culture and Art Center, the Archaeological Museum design deepening project, Inner Mongolia Tongliao Art Museum, and Weihua Cadre College Teaching Building showcase how Ribbed Standing Seam Metal Roofing contributes to buildings of civic importance while meeting rigorous performance standards. The Hangzhou Sanpu Drainage Pump Station aluminum-magnesium-manganese metal roof installation illustrates the system's performance in challenging industrial environments where corrosion resistance and long-term reliability are critical to operational continuity. These diverse project references provide prospective clients with confidence that Xi'an Huafeng possesses the technical capability and execution experience to successfully complete projects regardless of scale, complexity, or functional requirements.

Conclusion

Ribbed Standing Seam Metal Roofing delivers unmatched combination of weather protection, durability, energy efficiency, and architectural beauty that makes it the optimal choice for discerning property owners and design professionals seeking roofing solutions that perform exceptionally for decades with minimal maintenance requirements.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Ribbed Standing Seam Metal Roofing manufacturer, China Ribbed Standing Seam Metal Roofing supplier, and China Ribbed Standing Seam Metal Roofing factory established in Shaanxi Province in 2018, Xi'an Huafeng Construction Engineering Co., Ltd. specializes in comprehensive metal roofing system solutions. Recognized as a high-tech enterprise in Shaanxi Province in 2020 with first-level building curtain wall qualifications and third-level building steel structure qualifications, the company operates a 200,000 square meter raw material production plant in Anhui plus processing facilities in Hangzhou and Xi'an equipped with seven color coating production lines, one laminating line, ten shearing production lines, and fully automatic punching systems.

Xi'an Huafeng integrates green sustainable development principles throughout operations while advancing new materials in metal roof applications. The company mission focuses on developing solutions that add production capacity benefits, optimize idle building roof utilization, and enhance architectural beauty. With more than twenty registered patents, ISO9001 and ISO14000:14001 certifications, and SGS quality verification, Xi'an Huafeng maintains strict quality control systems ensuring every Ribbed Standing Seam Metal Roofing panel meets the highest international standards.

The company provides complete one-stop services from initial design consultation through final installation and maintenance. Engineering capabilities include structural 3D modeling, load analysis, drainage system simulation, and material specification advisory. The comprehensive approach encompasses project drawing deepening with 1:1 node detailing, factory sample production, sequential numbering systems preventing installation confusion, rigorous material procurement from certified suppliers, multi-point incoming inspection, precision manufacturing with real-time quality control, finished product verification, and intelligent packaging facilitating efficient site operations.

Whether you need High Quality Ribbed Standing Seam Metal Roofing, competitive Ribbed Standing Seam Metal Roofing price, or Ribbed Standing Seam Metal Roofing for sale with China Ribbed Standing Seam Metal Roofing wholesale options, Xi'an Huafeng delivers exceptional value backed by engineering excellence, manufacturing precision, and dedicated customer support. The company offers customized solutions meeting specific project requirements with delivery times of fifteen to twenty days, minimum order quantities of 500 square meters or one ton, and 30-year product warranties demonstrating confidence in long-term performance. Ready to experience superior roofing solutions? Contact Xi'an Huafeng Construction Engineering Co., Ltd. today at huafeng@hfmetalroof.com to discuss your project requirements, request samples, or obtain detailed quotations. Save this page for easy reference whenever roofing questions arise during your planning process.

References

1. Metal Roofing Alliance. "Durability and Performance Standards for Standing Seam Metal Roofing Systems." Metal Roofing Technical Bulletin Series.

2. American Society for Testing and Materials. "ASTM E1592 - Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems." ASTM International Standards.

3. National Roofing Contractors Association. "Metal Panel Roofing Systems: Design and Installation Best Practices." NRCA Roofing Manual.

4. Cool Roof Rating Council. "Rated Product Directory: Reflective Properties and Thermal Performance of Metal Roofing Materials." CRRC Technical Documentation.

5. International Code Council. "International Building Code Requirements for Metal Roof System Installation and Weather Resistance." ICC Building Safety Standards.