When your construction project demands sustainability without compromising performance, the environmental credentials of your roofing material become critical. Are Pre Painted Corrugated Sheets truly eco-friendly, or is it just marketing hype? This comprehensive material review examines the sustainability profile of Pre Painted Corrugated Sheets, analyzing their recyclability, energy efficiency, lifecycle impact, and environmental benefits to help you make informed decisions for your next building project.

Understanding the Environmental Profile of Pre Painted Corrugated Sheets

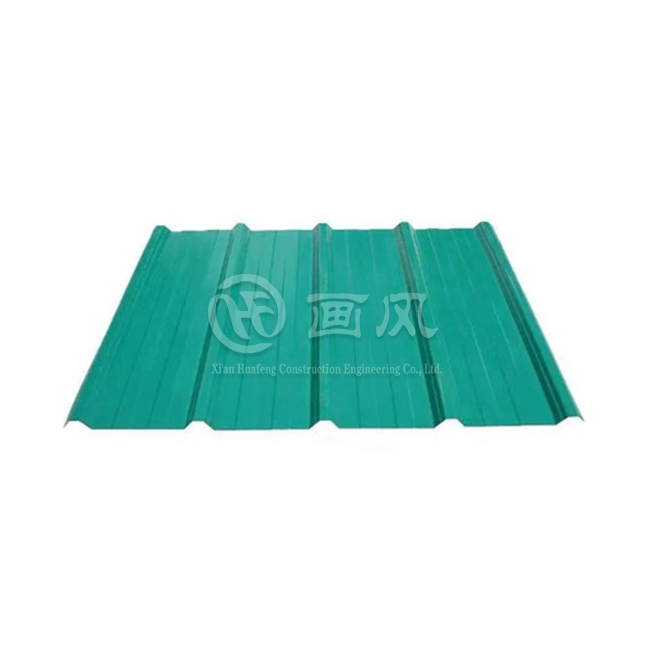

Pre Painted Corrugated Sheets represent a significant advancement in sustainable construction materials, combining functional performance with environmental responsibility. These pre painted corrugated roofing sheets consist of galvanized or galvanized steel substrates that receive high-performance coatings before forming into their characteristic wavy profiles. The environmental assessment of these materials requires examining multiple dimensions, from raw material sourcing through end-of-life disposal. The manufacturing process for Pre Painted Corrugated Sheets inherently supports sustainability through material efficiency. Unlike traditional painting methods that generate substantial waste and volatile organic compound emissions, the coil-coating process applies finishes with precision at speeds reaching 700 feet per minute. This factory-controlled application minimizes overspray, reduces solvent emissions, and ensures consistent coating thickness that maximizes material longevity. The corrugation process itself adds structural strength without requiring additional material, allowing thinner gauge metals to achieve performance characteristics that would otherwise demand heavier alternatives. Modern Pre Painted Corrugated Sheets incorporate advanced coating technologies including polyester, high-durability polyester, and polyvinylidene fluoride systems. These coatings provide exceptional weather resistance, UV protection, and color retention that extend the functional lifespan of the roofing system to 30 years or more. The extended service life represents a crucial environmental benefit, as it reduces the frequency of replacement cycles and the associated environmental impacts of manufacturing, transportation, and installation of new materials. When properly maintained, these pre painted corrugated roofing sheets maintain their protective and aesthetic properties throughout their extended lifespan, eliminating the need for repainting or recoating that would introduce additional environmental burdens.

Material Composition and Recyclability

The recyclability of Pre Painted Corrugated Sheets stands as one of their most compelling environmental advantages. Steel-based corrugated sheets can contain up to 95 percent recycled content sourced from various post-consumer and post-industrial streams, including discarded automobiles, appliances, construction debris, and manufacturing scrap. This high recycled content significantly reduces the environmental impact associated with mining virgin ores, processing raw materials, and the energy-intensive production of primary steel. The ability to incorporate such high levels of recycled content without compromising structural performance or durability demonstrates the circular economy potential of these materials. Equally important is the fact that Pre Painted Corrugated Sheets remain 100 percent recyclable at the end of their service life. Unlike composite materials that present separation challenges or roofing products that inevitably end up in landfills, metal roofing systems can be completely recovered and reprocessed into new products. The recycling process for steel maintains the material's fundamental properties, allowing it to be recycled repeatedly without degradation. This perpetual recyclability creates a closed-loop system that conserves natural resources, reduces energy consumption compared to primary production, and diverts substantial waste streams from landfills. Research indicates that steel recycling uses approximately 75 percent less energy than producing steel from virgin materials, resulting in significant greenhouse gas emission reductions.

The paint coatings on Pre Painted Corrugated Sheets do not impede recyclability. During the steel recycling process, organic coatings burn off in the initial heating stages, allowing the base metal to be recovered and reprocessed without contamination. This seamless integration into existing recycling infrastructure ensures that pre painted corrugated roofing sheets contribute positively to waste reduction goals and circular economy principles. Manufacturers increasingly track and report the recycled content percentages and end-of-life recyclability rates through environmental product declarations and life cycle assessments, providing transparency that supports informed material selection for green building projects.

Energy Efficiency and Cool Roof Technology in Pre Painted Corrugated Sheets

Energy efficiency represents another critical dimension of the environmental performance of Pre Painted Corrugated Sheets. Metal roofing systems naturally possess high solar reflectance and thermal emissivity properties that reduce heat transfer into building interiors. These characteristics become even more pronounced with the application of cool roof coatings that incorporate specialized reflective pigments. Research conducted by Oak Ridge National Laboratory demonstrated that cool metal roofing can reduce cooling energy consumption by up to 40 percent compared to conventional dark-colored roofing materials, translating into substantial energy savings and reduced greenhouse gas emissions from power generation. The physics behind this energy efficiency involve both reflection and emission. High solar reflectance means that Pre Painted Corrugated Sheets bounce back a significant portion of incoming solar radiation rather than absorbing it as heat. Thermal emissivity refers to the material's ability to release absorbed heat through infrared radiation rather than conducting it into the building. Together, these properties keep roof surface temperatures significantly lower than alternative materials. Studies have documented that light-colored metal roofs can operate up to 50 degrees Fahrenheit cooler than dark asphalt shingles under the same sunlight exposure, dramatically reducing the thermal load on building cooling systems. Modern coating technologies have advanced cool roof performance even for darker colors. Traditional dark-colored roofing materials absorb substantial solar energy, but innovative infrared-reflective pigments now allow Pre Painted Corrugated Sheets to achieve cool roof performance across a broader color palette. These specially engineered pigments reflect near-infrared wavelengths while still absorbing visible light to achieve the desired color appearance. This development means that architectural preferences for darker colors no longer necessitate sacrificing energy efficiency, expanding the applicability of cool roof technology to projects with specific aesthetic requirements.

Longevity and Durability Impact on Sustainability

The exceptional longevity of Pre Painted Corrugated Sheets fundamentally enhances their environmental profile by reducing lifecycle impacts. While asphalt shingles typically require replacement every 12 to 23 years, and other conventional roofing materials demonstrate similar limited lifespans, properly installed Pre Painted Corrugated Sheets commonly provide 30 to 60 years of reliable performance. This extended service life means that a building might require only one or two metal roof replacements over a century-long lifespan, compared to four to eight replacement cycles for alternative materials. Each avoided replacement eliminates the environmental impacts of manufacturing new materials, transporting them to the construction site, installing them, and disposing of the removed materials. The durability characteristics that enable this longevity include inherent corrosion resistance from galvanized coatings, superior wind resistance from interlocking seam designs, impact resistance that withstands hail and falling debris, and fire resistance that provides safety without requiring chemical treatments. Pre painted corrugated roofing sheets resist common failure modes that plague other roofing systems, including rot, insect damage, mold growth, and moisture infiltration. This comprehensive durability portfolio means that maintenance requirements remain minimal throughout the service life, avoiding the environmental impacts and resource consumption associated with repairs, recoating, or partial replacements.

The lightweight nature of Pre Painted Corrugated Sheets, typically weighing 50 to 150 pounds per square compared to 750 to 900 pounds for concrete tile roofing, generates additional environmental benefits. Reduced weight simplifies transportation, lowering fuel consumption and emissions during delivery to construction sites. The lighter structural loads also allow for more efficient building designs with reduced structural support requirements, conserving materials in framing systems. Installation proceeds more quickly and safely with lighter materials, reducing labor hours and the associated environmental impacts of construction activities. These combined factors contribute to a comprehensive sustainability profile that extends beyond the material itself to encompass the entire building system.

Manufacturing Process and Environmental Standards

The manufacturing process for Pre Painted Corrugated Sheets reflects significant environmental advantages compared to field-applied finishing systems. Factory coating operations occur in controlled environments with sophisticated pollution control equipment, emission capture systems, and waste minimization protocols that would be impractical or impossible to implement for on-site painting operations. The continuous coil-coating process applies precise coating thicknesses with minimal waste, achieving transfer efficiencies approaching 95 percent compared to 40 to 60 percent for conventional spray painting methods. This efficiency dramatically reduces volatile organic compound emissions, hazardous waste generation, and material consumption per unit of finished product. Quality control in factory settings ensures consistent coating application that maximizes performance and durability. Automated systems monitor and adjust coating thickness, cure temperatures, and line speeds to optimize material properties and minimize defects. This precision prevents the coating failures that can occur with field-applied finishes due to environmental conditions, application technique variations, or inadequate surface preparation. By ensuring optimal coating performance from the outset, factory finishing extends product lifespans and reduces the likelihood of premature failures that would necessitate replacement or remediation.

Leading manufacturers of Pre Painted Corrugated Sheets increasingly adopt comprehensive environmental management systems certified to ISO 14001 standards, demonstrating systematic approaches to identifying, managing, and reducing environmental impacts. These systems encompass energy efficiency improvements, water conservation measures, waste reduction initiatives, and emission control programs that continuously enhance environmental performance. Many facilities now derive portions of their energy requirements from renewable sources, implement closed-loop water systems that minimize freshwater consumption, and achieve zero-waste-to-landfill status through comprehensive recycling and waste valorization programs. Xi'an Huafeng Construction Engineering Co., Ltd. operates with strict quality control systems compliant with ISO9001 and ISO14001 standards, ensuring that Pre Painted Corrugated Sheets meet the highest environmental and quality benchmarks.

Lifecycle Assessment and Carbon Footprint

Comprehensive lifecycle assessment provides the most rigorous framework for evaluating the environmental performance of Pre Painted Corrugated Sheets across their entire existence, from raw material extraction through end-of-life disposition. These assessments quantify environmental impacts including greenhouse gas emissions, primary energy consumption, water usage, air pollutants, water effluents, and solid waste generation at each lifecycle stage. Research consistently demonstrates that metal roofing systems, including pre painted corrugated roofing sheets, achieve favorable environmental profiles when evaluated holistically across multiple impact categories and extended time horizons. The high recycled content of Pre Painted Corrugated Sheets significantly reduces embodied carbon compared to materials requiring virgin resource extraction and primary processing. Steel production from recycled scrap generates approximately 1.5 tons of carbon dioxide equivalent per ton of product, compared to 2.5 to 3.0 tons for primary steel production from iron ore. When Pre Painted Corrugated Sheets incorporate 40 to 95 percent recycled content, this translates into substantial reductions in embodied carbon that improve their overall carbon footprint. The extended service life further amortizes this embodied impact over decades of functional performance, yielding low annualized environmental burdens.

Operational phase impacts, particularly energy consumption for building heating and cooling, represent a significant component of lifecycle environmental performance. The energy efficiency benefits of Pre Painted Corrugated Sheets generate ongoing carbon emission reductions throughout their service lives. In cooling-dominated climates, the combination of high solar reflectance and thermal emissivity can reduce annual cooling energy consumption by 15 to 40 percent, depending on building characteristics, climate zone, and HVAC system efficiency. These operational savings accumulate over decades, often exceeding any differential in embodied impacts compared to alternative materials. Lifecycle studies consistently show that operational energy consumption dominates total environmental impacts for long-lived building components, making the energy efficiency of Pre Painted Corrugated Sheets a critical sustainability attribute.

Comparative Environmental Performance Against Alternative Roofing Materials

When evaluated against alternative roofing materials, Pre Painted Corrugated Sheets demonstrate competitive or superior environmental performance across most sustainability metrics. Asphalt shingles, the most common roofing material in residential construction, present significant environmental challenges including limited recycled content, short service lives requiring frequent replacement, and disposal burdens that generate approximately 11 million tons of landfill waste annually in the United States alone. The production of asphalt shingles consumes petroleum-derived bitumen, contributing to fossil fuel dependence and associated environmental impacts. While asphalt shingle recycling infrastructure exists in some regions, actual recycling rates remain low, and recycled shingles typically face quality limitations that restrict their applications. Concrete and clay tile roofing offer greater longevity than asphalt shingles, potentially matching or exceeding the service life of Pre Painted Corrugated Sheets. However, tile roofing systems carry substantial weight that increases structural requirements, transportation energy, and installation complexity. The production of concrete and clay tiles requires high-temperature firing processes that consume significant energy and generate greenhouse gas emissions. While natural materials like clay possess some inherent environmental advantages, the complete lifecycle assessment must account for transportation impacts, which increase substantially with heavier materials, and the energy penalties associated with supporting greater structural loads. The solar reflectance characteristics of tile roofing vary considerably with color and surface treatments, with many common tile products exhibiting lower reflectance than comparably colored metal roofing.

Wood shake and shingle roofing present different environmental considerations involving renewable material sourcing, embodied carbon sequestration, and biodegradability at end-of-life. However, wood roofing demonstrates significant environmental disadvantages including chemical treatments required for fire and decay resistance, limited service lives in many climates, higher maintenance requirements, and potential contributions to wildfire hazards in fire-prone regions. The fire resistance of Pre Painted Corrugated Sheets provides safety benefits without requiring chemical treatments that may leach into the environment. When considering the full spectrum of environmental impacts, durability requirements, and safety considerations, pre painted corrugated roofing sheets offer compelling advantages for most applications.

Green Building Certification Contributions

Pre Painted Corrugated Sheets contribute meaningfully to green building certification under major rating systems including Leadership in Energy and Environmental Design, Living Building Challenge, BREEAM, and Green Star. These comprehensive sustainability frameworks evaluate buildings across multiple environmental, health, and resource efficiency categories, rewarding materials and systems that demonstrate superior performance. The recyclability, recycled content, energy efficiency, durability, and low-emission characteristics of Pre Painted Corrugated Sheets align with numerous credit opportunities within these rating systems. LEED certification, the most widely recognized green building standard globally, offers specific credits that Pre Painted Corrugated Sheets can help projects achieve. The Materials and Resources credits for recycled content reward products containing post-consumer and post-industrial recycled materials, with metal roofing commonly qualifying due to its high recycled content percentages. Regional materials credits recognize products sourced and manufactured within specified distances of project sites, encouraging the selection of locally produced Pre Painted Corrugated Sheets that minimize transportation impacts. The cool roof provisions within Energy and Atmosphere credits reward roofing products that meet minimum solar reflectance and thermal emissivity thresholds, criteria that properly selected metal roofing systems readily satisfy.

The Heat Island Reduction credit specifically addresses the environmental impacts of dark, heat-absorbing surfaces in urban environments. Pre Painted Corrugated Sheets with appropriate color selections and coating formulations help mitigate urban heat island effects by maintaining lower surface temperatures and reducing the thermal load on surrounding areas. This credit recognizes the broader environmental benefits that extend beyond individual building performance to encompass neighborhood and community-scale impacts. The long service life and compatibility with solar panel installations provide additional opportunities for credits related to material optimization and renewable energy generation. Xi'an Huafeng Construction Engineering Co., Ltd. supplies Pre Painted Corrugated Sheets that comply with international standards including ASTM, DIN, JIS, BS, and GB/T, ensuring compatibility with green building requirements across different regional frameworks and certification systems.

Conclusion

Pre Painted Corrugated Sheets demonstrate substantial eco-friendly credentials through recyclability, energy efficiency, longevity, and reduced lifecycle impacts. Their manufacturing process, material composition, and performance characteristics align with sustainability principles and contribute meaningfully to green building goals. When properly selected and installed, these pre painted corrugated roofing sheets deliver environmental benefits that extend throughout their extended service lives.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Partner with Xi'an Huafeng Construction Engineering Co., Ltd., your trusted China Pre Painted Corrugated Sheets manufacturer and China Pre Painted Corrugated Sheets supplier offering comprehensive solutions. Since 2018, we've provided superior China Pre Painted Corrugated Sheets wholesale and Pre Painted Corrugated Sheets for sale with competitive Pre Painted Corrugated Sheets price. Our High Quality Pre Painted Corrugated Sheets feature PE, HDP, PVDF coating with 30-year warranties. We maintain 3 factories, 7 color coating production lines, and over 40 advanced machines, ensuring 1000 tons monthly capacity. As China Pre Painted Corrugated Sheets factory with ISO9001, ISO14001, and SGS certifications, we provide one-stop services from custom design through installation. Our engineering expertise includes structural 3D modeling, quality control with comprehensive material testing, and on-site construction guidance. Contact huafeng@hfmetalroof.com to discuss your sustainable roofing project requirements today.

References

1. Oak Ridge National Laboratory Buildings Technology Center. "Energy Efficiency and Service Life Assessment of Metal Roofing Systems." Department of Energy Research Study. Conducted by researchers at ORNL.

2. Florida Department of Environmental Protection. "Recyclability and Waste Reduction Analysis of Roofing Materials." Environmental Research Division. Published by Florida DEP.

3. American Metal Roofing Manufacturers Association. "Sustainability and Lifecycle Assessment of Metal Roofing Products." Industry Technical Report. AMRMA Research Committee.

4. Cool Roof Rating Council. "Radiative Properties and Energy Performance of Pre-Painted Metal Roofing." Technical Bulletin Series. CRRC Standards Development.

5. National Association of Home Builders Research Center. "Comparative Environmental Performance of Residential Roofing Materials." Building Science Research Report. NAHB Research Division.