Picture this scenario: your architectural project demands a sophisticated exterior that can withstand decades of harsh weather while maintaining its visual appeal, yet traditional cladding systems either compromise on aesthetics or fail to deliver long-term performance. Flat Lock Wall Panels offer the perfect solution by combining timeless elegance with engineered durability through precision-crafted materials, expertly designed interlocking seams, and concealed clip systems that ensure structural integrity without visible fasteners.

Understanding Flat Lock Wall Panels Construction and Applications

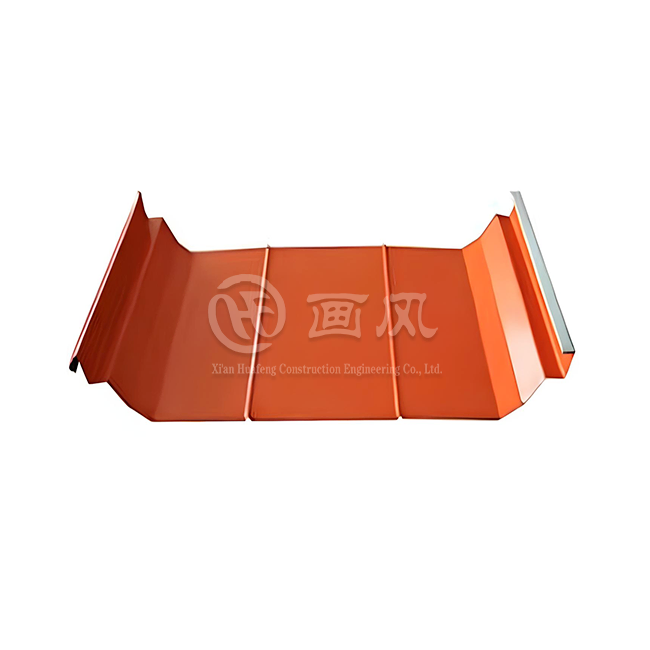

Flat lock metal panel systems represent a sophisticated approach to modern building cladding that has evolved from traditional roofing techniques into versatile architectural solutions. These panels consist of precisely fabricated metal sheets featuring interlocking seams on all four edges, creating a continuous and weather-resistant surface that delivers both functional protection and striking visual impact. The fundamental design principle revolves around rectangular or custom-shaped panels typically ranging from eighteen by twenty-four inches to twenty-four by thirty-six inches, though custom dimensions are readily available to meet specific project requirements. Each panel incorporates three-quarter inch folds on all sides, with two edges folded over and two folded under, allowing them to nest seamlessly with adjacent panels through single or double lock seam configurations. The installation methodology relies on concealed clips mechanically fastened to the building substrate, which engage with the folded edges of each panel to create a secure attachment while maintaining a clean, uninterrupted exterior appearance. This clip-based mounting system accommodates thermal expansion and contraction of the metal panels, preventing buckling or distortion over the building's lifespan while ensuring water cannot penetrate through fastener holes. Flat Lock Wall Panels excel in applications requiring monolithic finished surfaces where the seams themselves become subtle design elements rather than prominent visual interruptions. Modern flat lock metal panel installations have proven particularly effective for commercial facades, institutional buildings, residential accent walls, and architectural features including curved surfaces, domes, and complex geometries that traditional panel systems cannot easily accommodate.

Material Selection for Optimal Performance

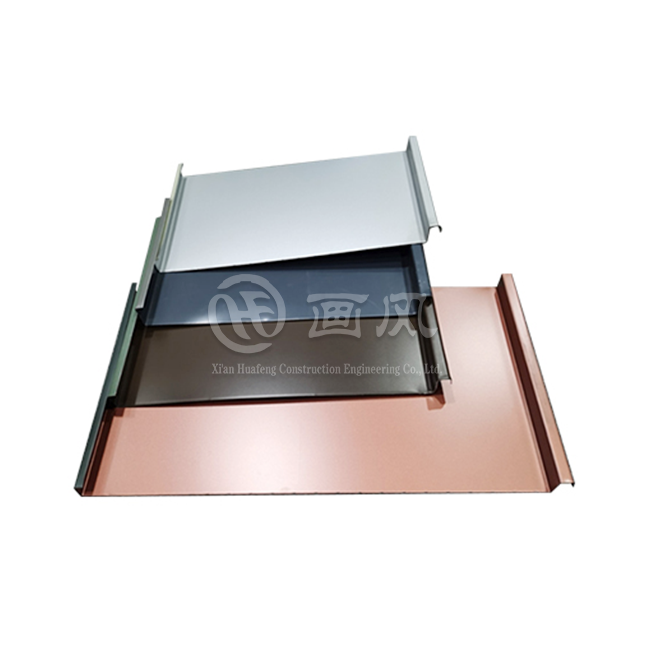

The material composition of Flat Lock Wall Panels directly impacts their longevity, maintenance requirements, aesthetic characteristics, and overall project cost, making informed material selection critical to achieving desired outcomes. Aluminum-magnesium-manganese alloy panels have emerged as highly popular choices due to their exceptional corrosion resistance, lightweight properties, and natural formation of protective oxide layers that enhance weather resistance without requiring additional coating systems. These alloys typically utilize grade 3003, 3004, or 5052 aluminum specifications, each offering distinct mechanical properties suited to different structural requirements and environmental exposures. The material's inherent malleability facilitates fabrication of complex shapes while maintaining structural integrity, and its recyclability aligns with sustainable construction practices increasingly demanded by modern building codes and environmental certifications. Stainless steel flat lock metal panel options, particularly grades 304 and 316, provide superior strength and resistance to corrosive environments, making them ideal for coastal installations or industrial settings where atmospheric pollutants could compromise lesser materials. The chromium content in stainless steel creates a passive protective film that regenerates when scratched, offering self-healing properties that maintain appearance throughout the panel's service life. Titanium-zinc panels represent premium material choices that develop attractive patina finishes over time, transforming from bright metallic surfaces to distinctive matte gray tones that many architects specify for their unique aesthetic character. Copper panels, including both natural copper and lead-coated copper variants, offer traditional appeal with the added benefit that their seams can be soldered for enhanced water-tightness in critical applications, though their characteristic green patina development may not suit all design intentions.

Steel-based Flat Lock Wall Panels, including cold-rolled, galvanized, and galvalume options, provide cost-effective solutions with robust structural properties suitable for large-scale commercial installations. These panels typically receive color coating treatments using polyvinylidene fluoride (PVDF) or polyester finishes that protect the base metal while offering extensive color customization options aligned with RAL and other international color standards. The thickness range from 0.4 millimeters to 0.8 millimeters allows designers to balance panel rigidity against weight considerations, with thicker gauges recommended for larger panel dimensions or applications subject to higher wind loads. Material traceability has become increasingly important, with reputable manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. sourcing from certified suppliers including Baosteel, Alucosuper, YATAI, NedZink, and other recognized brands that provide comprehensive material certifications and third-party testing documentation verifying compliance with international standards.

Engineering Excellence in Seam Design and Clip Systems

The seam configuration represents the defining characteristic of flat lock metal panel systems, distinguishing them from other architectural cladding approaches through their distinctive horizontal or vertical joint patterns. Single lock seams involve folding the edges of adjacent panels together once, creating a clean linear joint that gets hammered flat to form a smooth transition between panels. This seaming method proves adequate for vertical wall applications where water drainage occurs naturally through gravity, eliminating the need for additional sealants or soldering in most installations. Double lock seams provide enhanced security by folding the panel edges together twice, creating a more robust mechanical connection that has demonstrated century-long performance in demanding environments. The double lock configuration offers superior wind resistance and structural integrity, making it the preferred choice for large-format panels or installations in high-wind zones where panel detachment could pose safety risks. Flat Lock Wall Panels incorporate carefully engineered seam widths and profiles that balance aesthetic considerations against functional requirements. The typical three-quarter inch lock dimension provides sufficient material overlap to ensure reliable mechanical engagement while maintaining proportional visual harmony with overall panel dimensions. Corners receive particular attention during fabrication, with each corner trimmed at precise forty-five degree angles to facilitate proper nesting and prevent material bunching that could create visible irregularities or compromise weather resistance. The seam treatment process involves specialized hand tools or power equipment that progressively fold and compress the interlocking edges, achieving consistent joint tightness across entire facade installations. Quality control during seam formation proves critical, as improperly formed seams may allow water infiltration, create thermal bridges, or fail prematurely under thermal cycling stresses that buildings routinely experience throughout seasonal temperature variations.

Concealed Clip Technology for Structural Integrity

The clip system supporting Flat Lock Wall Panels represents sophisticated engineering that balances multiple functional requirements including structural support, thermal movement accommodation, installation efficiency, and long-term reliability. Concealed clips attach directly to the building substrate using corrosion-resistant stainless steel screws or other approved fasteners, with spacing determined by structural calculations considering panel dimensions, material gauge, wind loading, and seismic requirements. For typical residential applications, clip spacing centers around three hundred millimeters, though commercial projects subject to higher design loads may require closer spacing verified through project-specific engineering analysis. Each clip engages with the folded upper edge of installed panels while providing support for the next course of panels, creating a progressive interlocking assembly that distributes loads evenly across the building structure.

Modern clip designs incorporate features addressing thermal expansion, with some configurations allowing controlled panel movement while others maintain fixed positioning depending on panel length and anticipated temperature differentials. Expansion clips permit limited sliding motion parallel to the panel surface, preventing stress accumulation that could distort panels or compromise seam integrity during thermal cycling. Fixed clips provide rigid positioning appropriate for smaller panels or strategic locations requiring absolute dimensional stability. The clip material selection typically favors stainless steel alloys offering compatible thermal expansion coefficients with the panel material, preventing differential movement that could create squeaking, clicking, or premature wear at contact interfaces. Proper clip installation requires precise alignment and appropriate torque application to fasteners, as overtightening can restrict necessary thermal movement while undertightening may permit excessive panel motion that accelerates wear or creates noise during wind events. Quality manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. provide comprehensive clip systems developed through extensive testing and field experience, ensuring compatibility with various substrate types including wood sheathing, concrete, steel framing, and specialized mounting rails. Their manufacturing facilities employ roll-forming systems and precision fabrication equipment producing clips with consistent dimensions and mechanical properties essential for reliable long-term performance. The company's real-time quality control processes verify clip dimensions, material properties, and surface treatments before packaging and shipment, while raw material traceability systems document the supply chain from steel coils through finished components, facilitating warranty administration and quality assurance verification.

Customization Options and Design Versatility

Flat Lock Wall Panels offer remarkable design flexibility through customizable dimensions, shapes, colors, and surface treatments that enable architects to realize virtually any aesthetic vision while maintaining the system's functional advantages. Standard rectangular panels provide classic elegance suitable for traditional or contemporary designs, while custom shapes including rhombus, trapezoid, and hexagon configurations create distinctive patterns that transform building facades into architectural statements. The width range from one hundred to four hundred millimeters accommodates various visual scales from fine-grained textures resembling traditional shingle patterns to bold contemporary expressions using larger format panels that emphasize horizontal or vertical lines. Panel length customization up to three meters or more enables designers to minimize seams on tall wall sections, though longer panels require careful handling during installation and may necessitate additional intermediate clip support to prevent sagging or oil-canning. Color selection represents another powerful customization dimension, with factory-applied PVDF and polyester coatings available in any RAL specification plus unlimited custom color formulations matching specific branding requirements or complementing surrounding architectural elements. These high-performance coatings resist fading, chalking, and environmental degradation far better than field-applied paints, with PVDF systems offering exceptional ultraviolet resistance that maintains color integrity for decades even under intense solar exposure. Natural metal finishes provide alternative aesthetic directions, with mill finish aluminum offering bright metallic luster, brushed or polished stainless steel creating refined contemporary appearances, and weathering metals like copper, zinc, and weathering steel developing organic patinas that evolve beautifully over time. Surface texture options extend beyond smooth finishes to include embossed patterns, perforations for visual lightness or acoustic control, and specialty treatments creating unique tactile and visual characteristics.

The installation orientation offers additional design variables, with Flat Lock Wall Panels adaptable to horizontal, vertical, or diagonal diamond pattern layouts that dramatically alter visual perception of building proportions and scale. Horizontal installations emphasize building length and create calming, grounded aesthetics, while vertical orientations draw the eye upward and can make structures appear taller and more dynamic. Diamond patterns introduce geometric complexity and visual movement particularly effective for accent walls or feature elements requiring maximum visual impact. Xi'an Huafeng Construction Engineering Co., Ltd. supports these design explorations through comprehensive 3D modeling services, structural load analysis, and drainage system simulation that verify proposed configurations will perform reliably while achieving intended aesthetic effects. Their design department conducts one-to-one drawing deepening of project nodes, developing detailed installation drawings that address unique conditions and ensure field crews can execute complex designs accurately without costly field modifications.

Quality Assurance and Manufacturing Excellence

The production quality of flat lock metal panel systems fundamentally determines their long-term performance, making manufacturer capabilities and quality control processes critical evaluation criteria during supplier selection. Xi'an Huafeng Construction Engineering Co., Ltd. operates three manufacturing facilities including a two-hundred-thousand-square-meter raw material production plant in Anhui and two plate and accessories processing plants located in Hangzhou and Xi'an respectively. These facilities house seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, and fully automatic punching production lines complemented by more than forty shearing machines, presses, bending machines, and specialized equipment enabling comprehensive in-house manufacturing control from raw materials through finished panels. This vertical integration ensures consistent quality while providing flexibility to accommodate custom specifications without dependence on external suppliers whose quality or delivery reliability may prove variable. The manufacturing process begins with rigorous incoming material inspection verifying that raw aluminum, steel, copper, and other metals meet specified chemical composition, mechanical properties, and surface quality standards. Suppliers must provide material certifications and third-party testing reports documenting compliance with international standards including ASTM, DIN, JIS, BS, and GB/T specifications. Inspection methods combine full inspection for small quantities and high-value materials with statistical sampling for large volumes, preventing defective materials from entering production while maintaining cost efficiency. The inspection protocol encompasses more than a dozen verification steps including product appearance inspection, dimensional verification, salt spray testing, adhesion evaluation, hardness measurement, impact resistance, coating thickness verification, acid resistance, weather resistance testing, and color difference assessment using calibrated spectrophotometric equipment.

Production operations leverage precision roll-forming technology that shapes flat metal coils into profiled panels with consistent cross-sectional geometry and minimal material stress that could compromise long-term dimensional stability. Real-time quality control monitoring tracks critical process parameters including forming pressure, material feed rate, and die alignment, with automated inspection systems detecting dimensional deviations or surface defects before defective panels proceed to subsequent operations. Finished product inspection verifies appearance quality, dimensional accuracy, flatness, curvature, and seam formation quality against stringent acceptance criteria developed through decades of field performance observation and continuous improvement initiatives. Panels failing any inspection criterion undergo remediation or rejection, with root cause analysis procedures identifying and correcting systemic issues preventing recurrence. The packaging methodology facilitates efficient site logistics and installation sequencing, with products organized by building section and clearly labeled with identification cards containing sectional floor plans and product number lists. This systematic approach enables installation crews to locate required panels quickly without sorting through randomly packaged materials, reducing installation time while preventing damage from excessive handling. Xi'an Huafeng's quality management system holds ISO9001 and ISO14001 certifications demonstrating compliance with internationally recognized quality management and environmental management standards, while their more than twenty registered patents for roofing and wall systems document ongoing innovation addressing evolving market needs and performance requirements.

Installation Best Practices and Project Support

Successful flat lock metal panel installation requires careful planning, skilled craftspeople, appropriate tooling, and comprehensive project support from manufacturers experienced in translating design intent into built reality. Xi'an Huafeng Construction Engineering Co., Ltd. provides end-to-end installation guidance beginning with site-specific construction planning that considers product storage requirements, staging areas for panel preparation, and construction sequencing coordinated with other trades. Their field technicians conduct pre-installation site inspections verifying substrate conditions, dimensional accuracy of structural framing, and readiness to receive panels according to approved installation drawings. This proactive approach identifies potential issues before installation commences, preventing costly delays or remediation when problems become apparent only after work begins. The installation process demands specialized tools including panel-bending equipment, seam-closing tools, edge-locking machines, and various hand tools enabling precise manipulation of metal panels without damaging protective coatings or inducing permanent deformation. Installation crews must verify substrate flatness meets specified tolerances, as irregularities telegraph through thin metal panels creating visible waviness that compromises aesthetic quality even when panels themselves maintain perfect geometry. Clip installation requires accurate alignment and consistent spacing, with each clip secured using specified fastener types and installation torques documented in project specifications. The progressive panel installation methodology builds from bottom to top or side to side depending on orientation, with each panel engaging previously installed panels while receiving support from clips positioned during prior installation steps.

Technical briefings conducted before installation commencement review critical details including seam formation procedures, flashing integration methods, penetration treatments, and safety protocols protecting workers from fall hazards, sharp edges, and other construction site risks. Installation quality verification includes water testing upon completion, with low-pressure spray or controlled flooding confirming zero leakage through properly formed seams and correctly detailed transitions. Xi'an Huafeng supports these quality verification activities through on-site technical guidance ensuring installation teams understand and correctly implement specified procedures while adapting to site-specific conditions that inevitably differ from idealized drawing representations. Post-installation support includes formal acceptance procedures where customers review completed work against contract requirements before signing acceptance documentation. The company provides maintenance guidance ensuring building owners understand proper cleaning methods, inspection intervals, and minor repair procedures that preserve panel appearance and performance throughout the warranty period. Their thirty-year warranty coverage demonstrates confidence in product quality and manufacturing excellence while providing owners assurance that their investment delivers long-term value. The maintenance requirements remain minimal compared to alternative cladding systems, typically limited to periodic washing removing accumulated dirt or pollutants and occasional inspection verifying seam integrity and clip condition.

Conclusion

Flat Lock Wall Panels deliver unmatched architectural versatility through precision-engineered materials, robust seam systems, and concealed clip technology providing weather-tight, visually striking building envelopes suited to diverse applications from commercial facades to residential accent walls.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, specializes in metal roofing and wall cladding systems with first-level curtain wall qualifications and third-level steel structure qualifications. Our three factories operating seven production lines and more than forty advanced machines produce premium Flat Lock Wall Panels meeting ASTM, DIN, JIS, BS, and GB/T standards through ISO9001, ISO14001, and SGS certified processes. As a China Flat Lock Wall Panels factory, China Flat Lock Wall Panels supplier, and China Flat Lock Wall Panels manufacturer offering China Flat Lock Wall Panels wholesale with competitive Flat Lock Wall Panels price, we provide High Quality Flat Lock Wall Panels for sale with extensive customization, one-stop service from design through installation, and successful collaboration with Fortune 500 companies. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and receive free samples demonstrating our manufacturing excellence and commitment to creating added value for global customers.

References

1. Copper Development Association Inc., "Architectural Details: Wall Cladding Systems," Copper in Architecture Design Handbook.

2. Metal Construction Association, "Metal Wall Panel Systems: Design Guide for Architects and Engineers," Technical Standards and Guidelines.

3. American Society of Civil Engineers, "Minimum Design Loads and Associated Criteria for Buildings and Other Structures," ASCE/SEI 7 Standards.

4. Sheet Metal and Air Conditioning Contractors' National Association, "Architectural Sheet Metal Manual," Installation and Fabrication Practices.

5. National Roofing Contractors Association, "Metal Panel Roof and Wall Systems Manual," Performance Standards and Installation Guidelines.