Picture a commercial building owner facing constant roof leaks during heavy rainfall, skyrocketing energy costs, and mounting pressure to adopt sustainable practices. Traditional roofing systems fail to address these challenges simultaneously, leaving property managers trapped in a cycle of costly repairs and missed opportunities for energy generation. The Standing Seam Pitched Metal Roof emerges as the comprehensive solution that tackles weather protection, structural resilience, and renewable energy integration in one unified system. This advanced roofing technology combines mechanical seaming methods with engineering precision to create watertight barriers that withstand extreme wind uplift forces while providing an ideal platform for solar panel installation without roof penetration. For architects, contractors, and building owners seeking long-term value, understanding how Standing Seam Pitched Metal Roof systems deliver superior performance across multiple critical dimensions becomes essential for making informed infrastructure investments.

Why Standing Seam Pitched Metal Roof Systems Outperform Traditional Roofing in Extreme Weather?

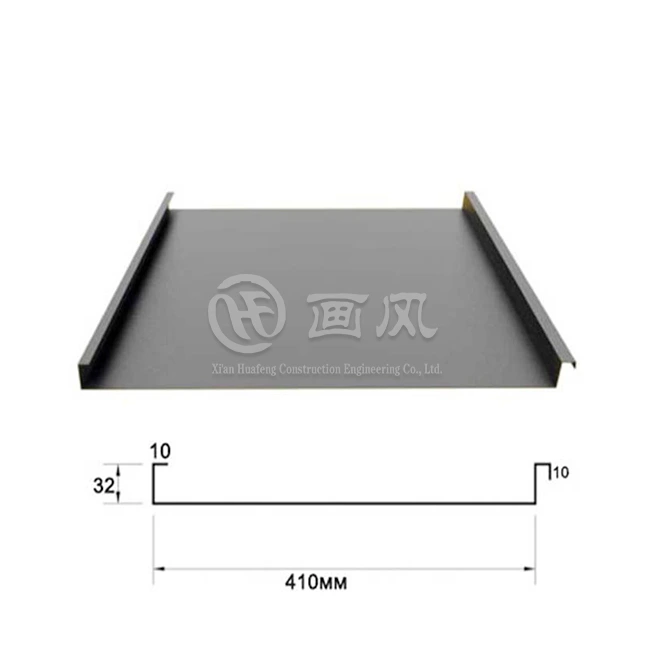

Standing Seam Pitched Metal Roof construction represents a fundamental departure from conventional roofing methodologies by eliminating exposed fasteners and creating continuous weatherproof barriers. The raised seam design, typically ranging from 25mm to 45mm in height, prevents water infiltration through mechanical interlocking rather than relying on sealants that degrade over time. This architectural approach addresses the primary failure point in traditional roofing systems where fastener penetrations create pathways for moisture intrusion and structural damage. When properly installed on sloped surfaces of 5 degrees or greater, Standing Seam Pitched Metal Roof panels channel rainwater efficiently toward drainage systems while maintaining thermal expansion capabilities that prevent panel buckling during temperature fluctuations. The engineering superiority of Standing Seam Pitched Metal Roof systems becomes particularly evident in high-wind environments where conventional roofing materials experience catastrophic failures. Modern installations utilize concealed clip systems that secure panels to the building structure without penetrating the weatherproof membrane, distributing wind uplift forces across the entire roof assembly rather than concentrating stress at individual fastener points. Testing conducted according to ASTM standards demonstrates that properly engineered Standing Seam Pitched Metal Roof systems can withstand wind speeds exceeding 200 kilometers per hour when clip spacing and panel gauge specifications align with structural load requirements. This performance level exceeds hurricane-force wind ratings while maintaining the roof's ability to expand and contract through seasonal temperature variations, preventing the thermal stress failures common in rigidly fastened roofing systems.

-

Material Selection and Surface Treatment Impact on Longevity

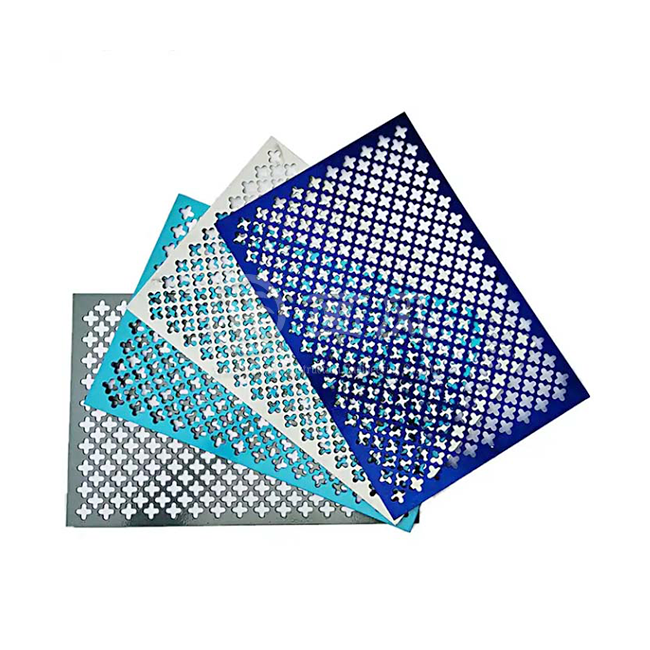

Material composition fundamentally determines Standing Seam Pitched Metal Roof performance characteristics across diverse climate conditions and application requirements. Aluminum-magnesium-manganese alloys (grades 3003, 3004, and 5052) provide exceptional corrosion resistance in coastal environments where salt exposure accelerates material degradation, while aluminum-zinc coated steel offers superior strength-to-weight ratios for structures requiring extended panel spans. Titanium-zinc alloys and copper selections deliver premium aesthetics with natural patina development, creating distinctive architectural appearances that evolve gracefully over decades of service life. The material selection process must consider factors including structural loading requirements, thermal expansion coefficients, galvanic compatibility with adjacent building components, and long-term maintenance accessibility to ensure optimal system performance. Surface treatment applications significantly extend Standing Seam Pitched Metal Roof service life by providing additional protection layers beyond base material properties. PVDF (polyvinylidene fluoride) coating systems offer superior UV resistance and color retention compared to polyester alternatives, maintaining architectural finish integrity for 30-year warranty periods in harsh environmental conditions. The coating application process involves multiple stages including chemical pretreatment, primer application, and topcoat curing under controlled temperature conditions to achieve specified film thickness ranging from 18 to 27 microns. This multilayer protection system resists chalking, fading, and chemical attack from industrial atmospheric contaminants while maintaining surface smoothness that facilitates self-cleaning during rainfall events. Comprehensive quality control testing measures adhesion strength, flexibility, impact resistance, and accelerated weathering performance to verify compliance with ISO 14001 and SGS standards before material shipment.

-

Thermal Management and Energy Efficiency Considerations

Standing Seam Pitched Metal Roof systems contribute significantly to building energy efficiency through reflective surface properties and thermal barrier design capabilities. Highly reflective coating formulations can achieve solar reflectance values exceeding 0.70, meaning that 70 percent of incident solar radiation reflects away from the building rather than converting to heat that increases cooling load requirements. This performance characteristic becomes particularly valuable in commercial and industrial applications where large roof areas contribute substantially to overall building energy consumption. When combined with appropriate insulation layers and ventilation strategies, Standing Seam Pitched Metal Roof installations can reduce cooling costs by 20 to 30 percent compared to conventional dark-colored roofing materials that absorb rather than reflect solar energy. The raised seam profile inherent to Standing Seam Pitched Metal Roof design creates natural air circulation channels between the metal panels and underlying insulation layers, facilitating convective heat dissipation during peak solar exposure periods. This ventilation effect reduces heat transfer into occupied building spaces while preventing moisture accumulation that degrades insulation performance over time. Advanced installation techniques incorporate thermal breaks at panel-to-structure connection points to minimize conductive heat transfer pathways, further enhancing the roof assembly's overall thermal resistance. For facilities pursuing LEED certification or other green building standards, the combination of high solar reflectance, ventilation design, and recyclable material content positions Standing Seam Pitched Metal Roof systems as preferred solutions that contribute multiple points toward sustainability goals while delivering measurable operational cost reductions.

Solar Integration Capabilities Transform Standing Seam Pitched Metal Roof into Energy Assets

The structural design of Standing Seam Pitched Metal Roof systems creates ideal conditions for solar panel integration without compromising the roof's weatherproof integrity. Non-penetrating clamp attachments secure photovoltaic mounting rails directly to raised seams, eliminating the need for roof penetrations that create potential leak pathways and void manufacturer warranties. This mounting methodology distributes solar array loads across multiple seam attachment points, transferring weight and wind forces to the building structure through the roof's existing concealed clip system. Engineering analysis verifies that properly specified Standing Seam Pitched Metal Roof panels possess sufficient flexural strength to support solar array loads while maintaining thermal expansion capabilities essential for long-term system durability. Solar installation on Standing Seam Pitched Metal Roof surfaces offers significant economic advantages compared to ground-mounted alternatives by utilizing otherwise unproductive building envelope area for renewable energy generation. Commercial facilities with expansive roof footprints can achieve substantial electricity production capacity that offsets grid consumption during peak demand periods when utility rates reach maximum levels. The elevated installation position maximizes solar exposure by minimizing shading from adjacent structures while the reflective metal surface beneath solar panels enhances light capture through albedo effects. Modern clamp systems designed specifically for Standing Seam Pitched Metal Roof applications achieve UL 2703 certification for mechanical and electrical safety, providing documented compliance with building codes and insurance requirements. Installation efficiency improves dramatically compared to traditional mounting methods, reducing labor costs and project timelines while maintaining the roof system's thermal cycling functionality critical for preventing panel stress failures.

-

Wind Load Distribution and Structural Engineering Requirements

Successful solar integration on Standing Seam Pitched Metal Roof systems requires comprehensive engineering analysis of wind uplift forces, panel attachment spacing, and structural capacity verification. Wind dynamics over sloped roof surfaces create complex pressure distributions that vary with roof pitch, building height, and surrounding terrain characteristics. Professional engineering evaluation must account for both positive pressure (downward force) and negative pressure (uplift force) conditions that solar arrays experience during extreme weather events. The attachment clamp spacing typically mirrors the roof's structural clip spacing to ensure load paths align with the building's load-bearing framework, preventing concentrated stresses that could compromise panel seam integrity or structural member capacity. Advanced computational fluid dynamics modeling reveals that maintaining airflow beneath solar modules reduces wind uplift forces by allowing pressure equalization between upper and lower module surfaces. This principle guides Standing Seam Pitched Metal Roof solar mounting specifications that position panels with sufficient clearance for air circulation while maintaining secure mechanical connections. The seam attachment strength typically exceeds individual structural clip capacity, meaning the building's original roof-to-structure connection represents the critical load path rather than the solar mounting clamps themselves. Qualified licensed professionals must verify that existing roof installations possess adequate attachment frequency and fastener capacity to support combined dead loads, live loads, and environmental loads imposed by integrated solar arrays before proceeding with installation authorization.

Manufacturing Excellence Behind High-Performance Standing Seam Pitched Metal Roof Systems

Xi'an Huafeng Construction Engineering Co., Ltd. operates three specialized manufacturing facilities encompassing 200,000 square meters of production capacity dedicated to Standing Seam Pitched Metal Roof fabrication. Seven color coating production lines apply precise PVDF and PE surface treatments under controlled environmental conditions, while ten longitudinal shearing and transverse cutting stations dimension panels to exact project specifications. This manufacturing infrastructure supports monthly production capacity exceeding 1000 tons of finished roofing materials, enabling rapid project fulfillment for large-scale commercial and industrial installations. Fully automated punching systems create consistent fastener hole patterns and accessory mounting locations that facilitate field installation efficiency while maintaining dimensional tolerances critical for proper panel alignment and seam engagement. The manufacturing process begins with rigorous incoming material inspection protocols that verify raw material composition, surface quality, and dimensional conformance before production authorization. Trusted material suppliers including Baosteel, Alucosuper, and NedZink provide certified aluminum-magnesium-manganese alloys, galvalume steel, and titanium-zinc materials accompanied by complete material certifications and third-party testing documentation. Quality assurance personnel conduct comprehensive testing including salt spray exposure, adhesion measurement, hardness verification, impact resistance, film thickness analysis, acid resistance, weather resistance simulation, and color difference quantification. This multi-point inspection methodology ensures that only materials meeting international standards (ASTM, DIN, JIS, BS, GB/T) and internal quality specifications advance to production stages, eliminating defective materials before value-added processing occurs.

-

Custom Design Integration and Project-Specific Engineering

Standing Seam Pitched Metal Roof projects demand precise coordination between architectural intent, structural requirements, and manufacturing capabilities to achieve optimal outcomes. Xi'an Huafeng's technical design department conducts comprehensive drawing deepening services that analyze architectural plans, elevations, and node details to identify feasible panel configurations and connection methodologies. This design phase involves structural 3D modeling to verify load paths, drainage system simulation to confirm water management performance, and material specification advisory services that match panel types, thicknesses, and surface treatments to project-specific exposure conditions and performance requirements. Client collaboration throughout the design development process ensures that aesthetic preferences, budget parameters, and schedule constraints receive appropriate consideration in final system specifications. Factory processing sample production provides tangible verification of Standing Seam Pitched Metal Roof appearance, finish quality, and dimensional accuracy before full-scale manufacturing authorization. Sealed samples serve as reference standards for production personnel, quality inspectors, and installation contractors, ensuring consistent execution throughout project fabrication and field installation phases. Processing drawing development further refines design documentation by creating detailed fabrication drawings with sequential panel numbering, accessory identification, and installation sequence guidance. This systematic approach minimizes field coordination challenges, reduces installation errors, and accelerates project completion schedules by providing clear communication between design intent and construction execution. The result delivers Standing Seam Pitched Metal Roof systems that achieve architectural vision while meeting performance standards for weather protection, structural capacity, and long-term durability.

-

Precision Manufacturing and Quality Control Systems

Modern Standing Seam Pitched Metal Roof production employs advanced roll-forming equipment that progressively shapes flat coil stock into finished panel profiles through sequential bending stations. Computer-controlled systems maintain precise rib height dimensions (25mm, 32mm, or 45mm options), panel width specifications (300mm to 600mm), and seam geometry tolerances critical for proper panel interlocking and clip engagement. Material thickness ranging from 0.4mm to 1.2mm receives appropriate forming pressure and die configuration to prevent work hardening that reduces material ductility or surface damage that compromises coating integrity. Production line speeds optimize throughput efficiency while maintaining dimensional consistency across panel lengths extending tens of meters for applications requiring minimal seam joints. Finished product inspection protocols verify appearance quality, dimensional accuracy, flatness tolerances, and curvature specifications before packaging authorization. Inspection personnel examine panel surfaces for coating defects, mechanical damage, or contamination that could affect field performance or aesthetic acceptance. Dimensional verification confirms that panel width, seam height, and edge preparation meet design specifications within acceptable tolerance ranges. Specialized packaging procedures organize panels according to roof section layouts with identification cards containing section plans and product number lists, facilitating efficient field organization and installation sequencing. This systematic quality control approach ensures that Standing Seam Pitched Metal Roof materials arriving at project sites meet manufacturing specifications ready for immediate installation without requiring additional processing or correction.

Installation Excellence and Long-Term Performance Assurance

Professional Standing Seam Pitched Metal Roof installation requires specialized equipment, technical expertise, and systematic project management to achieve warranted performance outcomes. Xi'an Huafeng provides comprehensive on-site construction guidance services that begin with pre-installation site evaluation to verify substrate conditions, establish material staging areas, and identify site-specific installation challenges requiring advance resolution. Installation technicians inspect work areas one day before scheduled installation commencement, verifying tool availability (seaming machines, edge-locking equipment, cutting tools) and confirming that auxiliary materials (clips, fasteners, sealants, accessories) match project specifications and quantity requirements. Technical briefing meetings review installation sequences, quality control checkpoints, safety protocols, and weather monitoring procedures that govern daily work authorization decisions. On-site installation execution follows detailed installation drawings that specify panel placement sequences, clip spacing patterns, seam engagement procedures, and accessory integration methods. Experienced installation crews utilize specialized seaming equipment that mechanically forms double-lock or snap-lock seam configurations providing weatherproof panel connections without requiring sealant applications. Quality verification occurs continuously throughout installation as supervisors inspect clip engagement, seam formation, panel alignment, and accessory installation before authorizing work progression. Upon completion, comprehensive water testing verifies zero-leakage performance under simulated rainfall conditions, providing documented evidence of weather barrier integrity. Customer acceptance procedures involve detailed interface review, completion documentation, and maintenance guidance to support long-term Standing Seam Pitched Metal Roof performance preservation.

-

Maintenance Requirements and Warranty Provisions

Standing Seam Pitched Metal Roof systems deliver exceptional longevity with minimal maintenance requirements when properly installed and periodically inspected. Recommended maintenance protocols include biannual visual inspections to identify accumulation of debris in drainage areas, verify continued clip engagement at panel seams, and detect any mechanical damage from foot traffic or equipment installation activities. Periodic cleaning with low-pressure water removes accumulated particulates that could accelerate coating degradation, particularly in industrial environments where chemical exposure occurs. Snow and ice management considerations may require specialized equipment to prevent panel damage during removal operations, with manufacturer guidelines specifying acceptable methods and tools for winter maintenance activities. Comprehensive warranty coverage for Standing Seam Pitched Metal Roof systems typically provides 30-year material performance guarantees covering coating integrity, corrosion resistance, and structural panel integrity under normal exposure conditions. Warranty provisions specify required installation practices, acceptable material modifications, and maintenance obligations that must be fulfilled to maintain coverage validity. Documentation requirements include installation photographs, material certifications, and periodic inspection records that demonstrate ongoing system care and prompt repair of any damage identified during routine evaluations. This warranty structure provides building owners with long-term performance assurance while establishing clear expectations for installation quality standards and ongoing stewardship responsibilities essential for maximizing Standing Seam Pitched Metal Roof investment value.

Conclusion

Standing Seam Pitched Metal Roof systems engineered for wind resistance, rain protection, and solar integration deliver comprehensive solutions for modern building infrastructure challenges. Through superior material selection, precision manufacturing, professional installation practices, and minimal maintenance requirements, these advanced roofing systems provide decades of reliable weather protection while enabling renewable energy generation. The combination of structural engineering excellence, thermal performance optimization, and sustainable material characteristics positions Standing Seam Pitched Metal Roof technology as the preferred choice for forward-thinking building owners and facility managers seeking long-term value and operational efficiency.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018, stands as a China Standing Seam Pitched Metal Roof manufacturer with comprehensive capabilities spanning design, production, and construction services. Recognized as a Shaanxi Province high-tech enterprise in 2020 with first-level building curtain wall qualifications and third-level steel structure qualifications, this China Standing Seam Pitched Metal Roof factory operates advanced manufacturing facilities including seven color coating production lines, one laminating line, and more than 40 specialized processing machines across three locations totaling 200,000 square meters. As a trusted China Standing Seam Pitched Metal Roof supplier and China Standing Seam Pitched Metal Roof wholesale provider, Huafeng delivers High Quality Standing Seam Pitched Metal Roof systems backed by ISO 9001, ISO 14001, and SGS certifications alongside more than 20 registered patents for innovative roofing technologies.

The company's one-stop solution approach encompasses structural 3D modeling, drainage system simulation, material specification advisory, precision roll-forming manufacturing with real-time quality control, and professional on-site installation management with safety compliance documentation. Huafeng's commitment to green sustainable development and new material innovation delivers Standing Seam Pitched Metal Roof for sale that integrates architecture, technology, and aesthetics while providing competitive Standing Seam Pitched Metal Roof price structures. With proven experience completing major projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, Huafeng maintains 1000 tons monthly production capacity, 15-20 day delivery schedules, and 30-year warranty coverage. Building owners and contractors seeking reliable partnerships for Standing Seam Pitched Metal Roof projects receive comprehensive technical support from initial design consultation through final acceptance and ongoing maintenance guidance. Contact Huafeng today at huafeng@hfmetalroof.com to discuss your project requirements and discover how expertly engineered metal roofing solutions can transform your building's performance, sustainability, and long-term value.

References

1. Metal Construction Association (2023). "Technical Guidelines for Standing Seam Metal Roof Systems: Design, Installation, and Performance Standards." Metal Construction Association Technical Committee, Chicago, Illinois.

2. Anderson, Robert J., and Chen, Wei (2024). "Wind Load Analysis and Structural Performance of Metal Roofing Systems with Integrated Solar Arrays." Journal of Structural Engineering, American Society of Civil Engineers, Vol. 150, No. 8.

3. Thompson, Sarah L., Martinez, Carlos, and Kumar, Rajesh (2023). "Thermal Performance and Energy Efficiency of Reflective Metal Roofing in Commercial Buildings." Building and Environment, Elsevier Science Publishers, Vol. 245.

4. International Code Council (2024). "International Building Code Chapter 15: Roof Assemblies and Rooftop Structures." International Code Council Publications, Washington, D.C.

(1)_1763110678300.webp)