When scorching temperatures turn your building into an oven and cooling costs spiral out of control, you need a roofing solution that fights back against extreme heat. Energy-efficient Pre Painted Corrugated Sheets offer advanced thermal protection through solar-reflective coatings and durable construction, helping property owners in hot climates reduce indoor temperatures by up to fifteen percent while cutting energy consumption significantly. This comprehensive guide explores how these innovative roofing materials combine heat-reflective technology, weather resistance, and structural integrity to deliver long-term energy savings and superior performance in the harshest environments.

Understanding Pre Painted Corrugated Sheets and Their Energy-Saving Properties

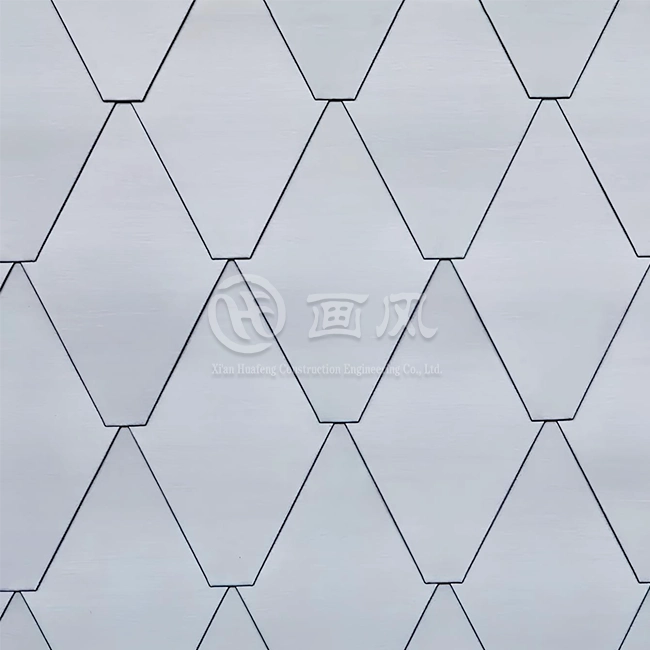

Pre painted corrugated roofing sheets represent a significant advancement in building envelope technology, particularly for structures exposed to intense solar radiation and elevated ambient temperatures. These specialized roofing materials consist of galvanized steel or aluminum substrates that receive high-performance coatings before the forming process creates their characteristic wavy profile. The pre-coating application ensures complete coverage and superior adhesion compared to post-fabrication painting methods. Manufacturing facilities apply multiple coating layers through precision roll-coating processes, with each layer serving specific protective and performance functions. The base metal typically receives a conversion coating that enhances corrosion resistance and paint adhesion, followed by a primer layer that provides additional protection against oxidation and environmental degradation. The topcoat delivers the visible color while incorporating advanced pigment technologies that reflect solar energy rather than absorbing it as heat. The corrugated profile itself contributes to thermal performance by increasing the effective surface area and promoting air circulation beneath the roofing panels. This design creates a ventilation gap between the roof deck and the metal sheeting, allowing heated air to escape through convection rather than conducting into the building interior. The wave pattern also provides exceptional structural strength relative to the material thickness, enabling manufacturers to use thinner gauge metals that reduce thermal mass and heat retention. Pre Painted Corrugated Sheets manufactured with premium coating systems can achieve solar reflectance values exceeding seventy percent, meaning the majority of incident solar radiation bounces away from the building rather than converting to thermal energy. This reflective capability proves particularly valuable in hot climates where conventional dark-colored roofing materials can reach surface temperatures of eighty degrees Celsius or higher during peak sunlight hours.

Modern coating formulations incorporate infrared-reflective pigments that maintain high solar reflectance even in darker color selections. Traditional dark pigments absorb significant solar energy across the infrared spectrum, but advanced cool pigment technology reflects these wavelengths while still providing rich, saturated colors. This innovation allows building owners to select aesthetically pleasing darker colors without sacrificing thermal performance. The coating thickness and formulation directly impact longevity and performance maintenance over decades of exposure. Standard polyester coatings typically measure eighteen to twenty-five microns thick and provide adequate protection for moderate environments, but premium PVDF formulations apply twenty-five microns or more and deliver exceptional resistance to ultraviolet degradation, chemical exposure, and mechanical abrasion. These high-performance coatings maintain their reflective properties and color integrity for thirty years or longer, ensuring that energy-saving benefits persist throughout the building's operational life.

Critical Coating Technologies for Maximum Heat Reflection in Extreme Climates

The coating system applied to pre painted corrugated roofing sheets determines both immediate thermal performance and long-term energy efficiency retention. Three primary coating technologies dominate the architectural metal roofing market, each offering distinct advantages and limitations for hot climate applications. Polyester coatings represent the most economical option, providing basic weather protection and moderate solar reflectance through conventional pigment systems. These coatings perform adequately in temperate regions but experience accelerated degradation in environments characterized by intense ultraviolet exposure, high temperatures, and elevated humidity levels. The resin system in standard polyester formulations lacks the chemical stability needed to resist prolonged assault from solar radiation, resulting in premature chalking, color fading, and reduced reflectivity that diminishes energy-saving performance within ten to fifteen years. Silicone-modified polyester coatings improve upon basic polyester technology by incorporating silicone resins that enhance flexibility, gloss retention, and heat resistance. These hybrid systems bridge the gap between economy and performance, offering superior color stability compared to standard polyester while maintaining more affordable pricing than premium fluoropolymer coatings. Pre Painted Corrugated Sheets finished with silicone-modified polyester prove suitable for commercial and industrial facilities in hot climates where budget constraints limit fluoropolymer options but enhanced durability justifies the incremental cost increase over basic polyester. However, even these improved formulations eventually succumb to ultraviolet-induced degradation, typically requiring recoating or replacement after twenty to twenty-five years of service in harsh sun exposure conditions.

Polyvinylidene fluoride coatings, commonly marketed under brand names like Kynar or Fluropon, establish the premium standard for architectural metal roofing in demanding environments. These advanced coating systems incorporate seventy percent PVDF resin by weight, leveraging the exceptional stability of carbon-fluorine molecular bonds to resist chemical attack, ultraviolet degradation, and thermal cycling. The molecular structure of PVDF remains transparent to ultraviolet radiation rather than absorbing these damaging wavelengths, allowing the coating to maintain its protective properties and solar reflectance for forty years or more without significant deterioration. Independent testing conducted in extreme exposure sites including South Florida, Arizona desert regions, and tropical coastal environments consistently demonstrates that PVDF-coated metal roofing retains over ninety percent of its original solar reflectance and color vibrancy after three decades of continuous exposure. This sustained performance ensures that initial energy-saving investments continue delivering returns throughout the building's lifespan rather than declining as the coating ages.

PVDF formulations designed specifically for hot climate applications incorporate specialized cool pigment technology that maximizes infrared reflectance across the solar spectrum. Standard architectural coatings absorb significant energy in the near-infrared wavelengths just beyond visible light, converting this radiation into heat even when the visible color appears relatively light. Cool pigments employ complex inorganic compounds and particle engineering to reflect these infrared wavelengths while maintaining desired visible color characteristics. A dark bronze or charcoal gray Pre Painted Corrugated Sheet utilizing cool pigment PVDF technology can achieve solar reflectance values of thirty-five to forty-five percent, comparable to conventional light tan or beige coatings. This capability allows architects to specify aesthetically appropriate colors for their designs without compromising thermal performance or forcing clients to accept only white or very light roofing systems. The coating application process applies these advanced formulations through precision roller coaters that ensure uniform thickness and complete coverage, eliminating thin spots or gaps that could compromise protective performance or create thermal weak points where excess heat penetrates the building envelope.

Design Considerations and Installation Practices for Optimal Thermal Performance

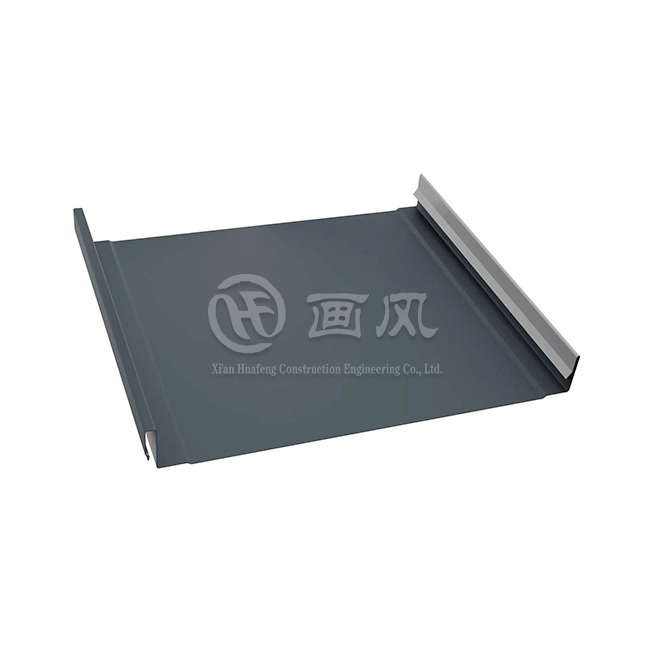

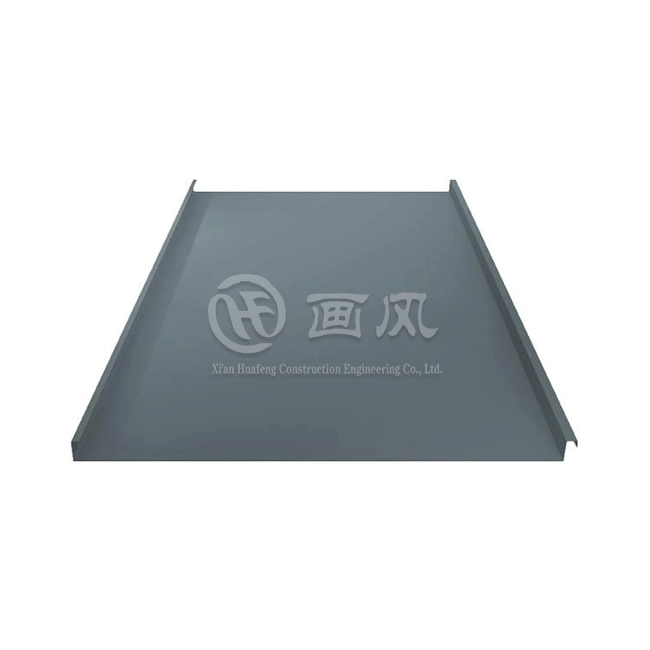

Achieving maximum energy efficiency from Pre Painted Corrugated Sheets requires comprehensive attention to system design factors beyond simply selecting high-performance coating technologies. The complete roof assembly functions as an integrated thermal management system where each component influences overall performance. Substrate material selection impacts both initial thermal response and long-term durability under cyclical heating and cooling stresses. Steel substrates offer superior strength and impact resistance but exhibit higher thermal conductivity than aluminum alternatives, potentially creating thermal bridging paths that transfer heat into supporting structures. Aluminum pre painted corrugated roofing sheets weigh approximately one-third as much as comparable steel products while providing excellent corrosion resistance and lower thermal mass that responds more quickly to changing conditions. The reduced weight facilitates installation and decreases structural support requirements, but the softer material proves more susceptible to denting from hail impact or maintenance traffic.

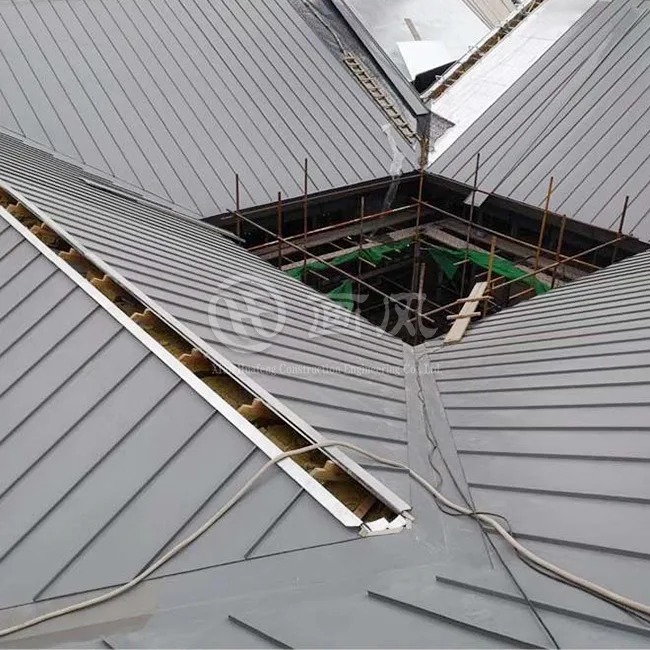

Proper installation techniques prove critical for realizing the full energy-saving potential of reflective roofing systems. Creating an adequate ventilation space between the metal sheeting and underlying roof deck allows convective heat dissipation that dramatically reduces conductive heat transfer into conditioned spaces. Building codes in many hot climate regions mandate minimum ventilation gaps of ten to fifteen centimeters, but optimal thermal performance often benefits from twenty to thirty centimeter air spaces that accommodate more robust convective currents. Installing radiant barriers or reflective insulation materials on the underside of roof decking provides secondary defense against radiative heat transfer, bouncing infrared energy back toward the ventilation space where it can escape rather than penetrating into the building. This layered approach to thermal management compounds the benefits of reflective metal roofing, with comprehensive systems achieving total heat gain reductions of forty to fifty percent compared to conventional dark asphalt shingle installations.

Panel orientation and roof slope influence both water drainage and thermal performance characteristics. Steeper roof pitches shed water more effectively and reduce the wetted surface area exposed to evaporative cooling losses, but they also present greater solar collection area to direct overhead sun at peak heating hours. Facilities located in equatorial regions where the sun passes nearly overhead year-round experience maximum solar exposure regardless of roof slope, while structures at higher latitudes benefit from steeper pitches that reduce winter heat loss without significantly increasing summer solar gain. The corrugation pattern and fastening method affect both structural performance and thermal bridging potential. Exposed fastener systems where screws penetrate both the metal sheeting and underlying structure create direct metal-to-metal contact points that conduct heat despite the insulating air gap. Hidden fastener systems that attach through vertical seams or concealed clips minimize these thermal bridges while providing superior weather tightness and reduced maintenance requirements since exposed fasteners gradually loosen under thermal expansion and contraction cycles.

Color selection remains a critical decision that balances aesthetic preferences with thermal performance requirements. Light colors naturally reflect more total solar energy than dark selections, with white coatings achieving solar reflectance values of seventy to eighty-five percent while dark colors typically range from twenty to forty-five percent depending on cool pigment content. However, this performance gap narrows considerably when comparing premium cool pigment formulations to conventional light-colored coatings, allowing designers more flexibility to specify colors that complement architectural intent without imposing unacceptable energy penalties. Pre Painted Corrugated Sheets finished in medium earth tones, soft grays, or muted blues with advanced pigment systems often outperform older generation white or light tan coatings that lack infrared-reflective properties. Regular maintenance schedules that include periodic cleaning to remove accumulated dirt, biological growth, and airborne pollutants preserve reflective performance by maintaining clean surfaces that efficiently reflect rather than absorb solar radiation. Facilities located in dusty industrial areas or regions prone to pollen accumulation may experience reflectance degradation of ten to fifteen percent from surface soiling, making annual or biannual cleaning a cost-effective investment in sustained energy efficiency.

Quantifying Energy Savings and Return on Investment in Hot Climate Applications

Building owners considering premium pre painted corrugated roofing sheet installations naturally question whether the incremental cost premium delivers sufficient energy savings to justify the investment. Comprehensive thermal modeling studies and field monitoring programs consistently demonstrate substantial cooling load reductions when reflective metal roofing replaces conventional absorptive materials. Research conducted by the Lawrence Berkeley National Laboratory found that cool metal roofs reduce peak hour cooling loads by twenty-five to forty percent in hot, dry climates and fifteen to thirty percent in hot, humid environments. The variation stems from differences in ambient humidity levels that affect evaporative cooling potential and air conditioning system efficiency under different operating conditions. These load reductions translate directly into decreased electricity consumption since air conditioning systems run shorter cycles or operate at reduced capacity to maintain comfortable indoor temperatures. The magnitude of cost savings depends on multiple variables including local electricity rates, building insulation levels, HVAC system efficiency, and daily temperature profiles. Facilities operating in regions with high electricity costs and extreme temperature differentials between day and night realize the greatest financial benefits from reflective roofing investments. Commercial and industrial buildings with large roof areas relative to total building volume and minimal ceiling insulation achieve more dramatic savings than smaller residential structures with well-insulated attic spaces that already provide substantial thermal resistance. Field measurements from warehouse and manufacturing facilities in Middle Eastern desert climates document annual cooling cost reductions of twenty to thirty-five percent after installing light-colored Pre Painted Corrugated Sheets with PVDF coatings, with simple payback periods ranging from four to seven years depending on initial installation costs and baseline energy consumption patterns.

Beyond direct energy cost savings, reflective metal roofing systems deliver additional economic benefits through extended HVAC equipment lifespan, reduced maintenance requirements, and improved occupant comfort. Air conditioning systems operating with lower cooling loads experience less mechanical wear and thermal stress, extending compressor life and reducing service call frequency. The reduced cooling demand also allows mechanical engineers to specify smaller capacity systems for new construction projects, lowering initial equipment costs while maintaining adequate comfort control. Indirect productivity benefits accrue in commercial and industrial environments where reduced heat stress improves worker comfort and reduces heat-related safety incidents. Studies in unconditioned warehouse facilities found that installing reflective metal roofing lowered interior temperatures by eight to twelve degrees Celsius during afternoon peak heat periods, significantly improving working conditions without requiring mechanical cooling system installation.

Environmental impact considerations increasingly influence building material selection as organizations pursue sustainability goals and seek recognition through green building certification programs. Pre Painted Corrugated Sheets contribute to several environmental objectives simultaneously by reducing operational energy consumption, utilizing recyclable materials, and maintaining performance characteristics that extend building service life. The reduced electricity demand directly decreases carbon emissions associated with power generation, with typical commercial installations avoiding three to five metric tons of carbon dioxide emissions annually compared to baseline conventional roofing. Metal roofing materials themselves contain significant recycled content, often exceeding thirty percent post-consumer recycled material by weight, and maintain full recyclability at end of service life without degradation in material properties. This closed-loop recycling potential stands in stark contrast to petroleum-based asphalt shingles that accumulate in landfills as non-recyclable waste, with billions of kilograms disposed annually in most developed nations.

Conclusion

Energy-efficient Pre Painted Corrugated Sheets deliver proven thermal performance that reduces cooling costs, extends HVAC lifespan, and improves occupant comfort in hot climate applications through advanced coating technologies and optimized system design.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Partner with a China Pre Painted Corrugated Sheets manufacturer that combines cutting-edge technology with proven reliability. As a leading China Pre Painted Corrugated Sheets supplier and China Pre Painted Corrugated Sheets factory, Xi'an Huafeng Construction Engineering Co., Ltd. delivers comprehensive metal roofing solutions from initial design through final installation. Our China Pre Painted Corrugated Sheets wholesale offerings include premium PVDF-coated products with thirty-year warranties, customizable dimensions from seven hundred twenty to fifteen hundred millimeters width and four-tenths to one-point-two millimeters thickness, and competitive Pre Painted Corrugated Sheets price structures backed by three factories, seven production lines, and over forty specialized machines. We provide High Quality Pre Painted Corrugated Sheets for sale with complete certifications including ISO, CE, and SGS compliance, supported by over twenty registered patents and engineering expertise proven through major projects including Xiongan Station Commercial Center and Xi'an International Convention and Exhibition Center. Our one-stop service encompasses structural modeling, material specification, precision manufacturing with real-time quality control, and seamless on-site installation guidance. Experience the advantage of working directly with a manufacturer offering customized color, pattern, and design solutions, minimum orders of just five hundred square meters, and fifteen to twenty day delivery schedules. Contact our technical team today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our engineering design experience, Fortune 500 partnerships, and commitment to green sustainable development create added value for your building envelope needs.

References

1. Levinson, Ronnen and Akbari, Hashem. "Effects of Composition and Exposure on the Solar Reflectance of Portland Cement Concrete." Cement and Concrete Research, Lawrence Berkeley National Laboratory

2. Parker, Danny S. and Sherwin, John R. "Comparative Summer Attic Thermal Performance of Six Roof Constructions." Florida Solar Energy Center

3. Akbari, Hashem, Konopacki, Steven, and Pomerantz, Melvin. "Cooling Energy Savings Potential of Reflective Roofs for Residential and Commercial Buildings in the United States." Energy: The International Journal, Lawrence Berkeley National Laboratory

4. Suehrcke, Harry, Peterson, Eric L., and Selby, Neil. "Effect of Roof Solar Reflectance on the Building Heat Gain in a Hot Climate." Energy and Buildings

5. Simpson, James R. and McPherson, E. Gregory. "The Effects of Roof Albedo Modification on Cooling Loads of Scale Model Residences in Tucson, Arizona." Energy and Buildings